Specification Section 08 71 00- Door Hardware - DeKalb County ...

Specification Section 08 71 00- Door Hardware - DeKalb County ...

Specification Section 08 71 00- Door Hardware - DeKalb County ...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

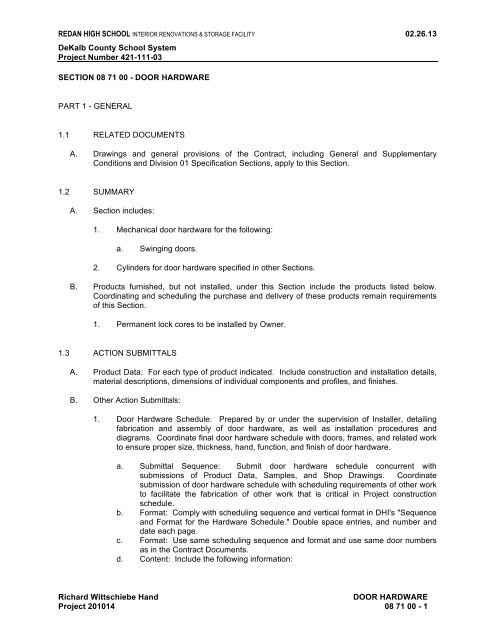

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-03SECTION <strong>08</strong> <strong>71</strong> <strong>00</strong> - DOOR HARDWAREPART 1 - GENERAL1.1 RELATED DOCUMENTSA. Drawings and general provisions of the Contract, including General and SupplementaryConditions and Division 01 <strong>Specification</strong> <strong>Section</strong>s, apply to this <strong>Section</strong>.1.2 SUMMARYA. <strong>Section</strong> includes:1. Mechanical door hardware for the following:a. Swinging doors.2. Cylinders for door hardware specified in other <strong>Section</strong>s.B. Products furnished, but not installed, under this <strong>Section</strong> include the products listed below.Coordinating and scheduling the purchase and delivery of these products remain requirementsof this <strong>Section</strong>.1. Permanent lock cores to be installed by Owner.1.3 ACTION SUBMITTALSA. Product Data: For each type of product indicated. Include construction and installation details,material descriptions, dimensions of individual components and profiles, and finishes.B. Other Action Submittals:1. <strong>Door</strong> <strong>Hardware</strong> Schedule: Prepared by or under the supervision of Installer, detailingfabrication and assembly of door hardware, as well as installation procedures anddiagrams. Coordinate final door hardware schedule with doors, frames, and related workto ensure proper size, thickness, hand, function, and finish of door hardware.a. Submittal Sequence: Submit door hardware schedule concurrent withsubmissions of Product Data, Samples, and Shop Drawings. Coordinatesubmission of door hardware schedule with scheduling requirements of other workto facilitate the fabrication of other work that is critical in Project constructionschedule.b. Format: Comply with scheduling sequence and vertical format in DHI's "Sequenceand Format for the <strong>Hardware</strong> Schedule." Double space entries, and number anddate each page.c. Format: Use same scheduling sequence and format and use same door numbersas in the Contract Documents.d. Content: Include the following information:Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 1

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-031) Identification number, location, hand, fire rating, size, and material of eachdoor and frame.2) Locations of each door hardware set, cross-referenced to Drawings on floorplans and to door and frame schedule.3) Complete designations, including name and manufacturer, type, style,function, size, quantity, function, and finish of each door hardware product.4) Fastenings and other pertinent information.5) Explanation of abbreviations, symbols, and codes contained in schedule.6) Mounting locations for door hardware.7) List of related door devices specified in other <strong>Section</strong>s for each door andframe.1.4 INFORMATIONAL SUBMITTALSA. Qualification Data: For Installer .1.5 CLOSEOUT SUBMITTALSA. Maintenance Data: For each type of door hardware to include in maintenance manuals.Include final hardware schedule.1.6 QUALITY ASSURANCEA. Installer Qualifications: Supplier of products and an employer of workers trained and approvedby product manufacturers and an Architectural <strong>Hardware</strong> Consultant who is available during thecourse of the Work to consult with Contractor, Architect, and Owner about door hardware andkeying.1. Warehousing Facilities: In Project's vicinity.2. Scheduling Responsibility: Preparation of door hardware and keying schedules.B. Source Limitations: Obtain each type of door hardware from a single manufacturer.C. Fire-Rated <strong>Door</strong> Assemblies: Where fire-rated door assemblies are indicated, provide doorhardware rated for use in assemblies complying with NFPA 80 that are listed and labeled by aqualified testing agency, for fire-protection ratings indicated, based on testing at positivepressure according to NFPA 252 or UL 10C, unless otherwise indicated.D. Smoke- and Draft-Control <strong>Door</strong> Assemblies: Where smoke- and draft-control door assembliesare required, provide door hardware that meet requirements of assemblies tested according toUL 1784 and installed in compliance with NFPA 105.1. Air Leakage Rate: Maximum air leakage of 0.3 cfm/sq. ft. (3 cu. m per minute/sq. m) atthe tested pressure differential of 0.3-inch wg (75 Pa) of water.E. Means of Egress <strong>Door</strong>s: Latches do not require more than 15 lbf (67 N) to release the latch.Locks do not require use of a key, tool, or special knowledge for operation.F. Accessibility Requirements: For door hardware on doors in an accessible route, comply withthe U.S. Architectural & Transportation Barriers Compliance Board's ADA-ABA AccessibilityGuidelines and ICC/ANSI A117.1.Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 2

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-03A. Provide door hardware for each door as scheduled in Part 3 "<strong>Door</strong> <strong>Hardware</strong> Schedule" Articleto comply with requirements in this <strong>Section</strong>.1. <strong>Door</strong> <strong>Hardware</strong> Sets: Provide quantity, item, size, finish or color indicated, and namedmanufacturers' products or products complying with BHMA designations referenced.2. Sequence of Operation: Provide electrified door hardware function, sequence ofoperation, and interface with other building control systems indicated.B. Designations: Requirements for design, grade, function, finish, size, and other distinctivequalities of each type of door hardware are indicated in Part 3 "<strong>Door</strong> <strong>Hardware</strong> Schedule"Article. Products are identified by using door hardware designations, as follows:1. Named Manufacturers' Products: Manufacturer and product designation are listed foreach door hardware type required for the purpose of establishing minimum requirements.Manufacturers' names are abbreviated in Part 3 "<strong>Door</strong> <strong>Hardware</strong> Schedule" Article.2. References to BHMA Designations: Provide products complying with these designationsand requirements for description, quality, and function.2.2 HINGESA. Hinges: BHMA A156.1.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Bommer Industries, Inc.b. Hager Companies.c. PBB, Inc.2.3 CONTINUOUS HINGESA. Continuous Hinges: BHMA A156.26; minimum 0.120-inch- (3.0-mm-) thick, hinge leaves withminimum overall width of 4 inches (102 mm); fabricated to full height of door and frame and totemplate screw locations; with components finished after milling and drilling are complete.B. Continuous, Gear-Type Hinges: Extruded-aluminum, pinless, geared hinge leaves joined by acontinuous extruded-aluminum channel cap; with concealed, self-lubricating thrust bearings.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. PBB, Inc.b. Select Products Limited.c. Zero International.2.4 MECHANICAL LOCKS AND LATCHESA. Lock Functions: As indicated in door hardware schedule.B. Lock Throw: Comply with testing requirements for length of bolts required for labeled fire doors,and as follows:1. Bored Locks: Minimum 1/2-inch (13-mm) latchbolt throw.2. Mortise Locks: Minimum 3/4-inch (19 mm) latchbolt throw.3. Deadbolts: Minimum 1-inch (25-mm) bolt throw.Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 4

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-03C. Lock Backset: 2-3/4 inches (70 mm), unless otherwise indicated.D. Lock Trim:1. Levers: Accessible design; cast or solid, as scheduled.2. Dummy Trim: Match lever lock trim and escutcheons.E. Strikes: Provide manufacturer's standard strike for each lock bolt or latchbolt complying withrequirements indicated for applicable lock or latch and with strike box and curved lip extendedto protect frame; finished to match lock or latch.1. Flat-Lip Strikes: For locks with three-piece antifriction latchbolts, as recommended bymanufacturer.2. Extra-Long-Lip Strikes: For locks used on frames with applied wood casing trim.3. Aluminum-Frame Strike Box: Manufacturer's special strike box fabricated for aluminumframing.4. Rabbet Front and Strike: Provide on locksets for rabbeted meeting stiles.F. Bored Locks: BHMA A156.2; Grade 1; Series 4<strong>00</strong>0.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Best Access Systems; Div. of Stanley Security Solutions, Inc.b. SARGENT Manufacturing Company; an ASSA ABLOY Group company.c. Schlage Commercial Lock Division; an Ingersoll-Rand company.G. Mortise Locks: BHMA A156.13; Grade 1; stamped steel case with steel or brass parts;Series 1<strong>00</strong>0.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Adams Rite Manufacturing Co.; an ASSA ABLOY Group company.b. Best Access Systems; Div. of Stanley Security Solutions, Inc.c. SARGENT Manufacturing Company; an ASSA ABLOY Group company.d. Schlage Commercial Lock Division; an Ingersoll-Rand company.2.5 SURFACE BOLTSA. Surface Bolts: BHMA A156.16.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Best Access Systems; Div. of Stanley Security Solutions, Inc.b. SARGENT Manufacturing Company; an ASSA ABLOY Group company.c. Schlage Commercial Lock Division; an Ingersoll-Rand company.2.6 AUTOMATIC AND SELF-LATCHING FLUSH BOLTSA. Automatic and Self-Latching Flush Bolts: BHMA A156.16; minimum 3/4-inch (19-mm) throw;designed for mortising into door edge.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Burns Manufacturing Incorporated.b. Hiawatha, Inc.c. Rockwood Manufacturing Company.Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 5

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-032.7 EXIT DEVICES AND AUXILIARY ITEMSA. Exit Devices and Auxiliary Items: BHMA A156.3.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Precision <strong>Hardware</strong>, Inc.; Division of Stanley Security Solutions, Inc.b. SARGENT Manufacturing Company; an ASSA ABLOY Group company.c. Von Duprin; an Ingersoll-Rand company.2.8 LOCK CYLINDERSA. Lock Cylinders: Tumbler type, constructed from brass or bronze, stainless steel, or nickel silver.1. Manufacturer: Best Access Systems.B. Standard Lock Cylinders: BHMA A156.5; Grade 1; permanent cores that are interchangeable;face finished to match lockset.C. Construction Cores: Provide construction keying for use during construction period. AfterSubstantial Completion, void construction keying with Owner’s permanent keying.2.9 KEYINGA. Keying System: Factory registered, complying with guidelines in BHMA A156.28, Appendix A.Incorporate decisions made in keying conference.1. Existing System:a. Master key or grand master key locks to Owner's existing system.b. Re-key Owner's existing master key system into new keying system.2. Keyed Alike: Key all cylinders to same change key.B. Keys: Nickel Silver.1. Stamping: Permanently inscribe each key with a visual key control number and includethe following notation:a. Notation: "DO NOT DUPLICATE."2. Key Quantity: Furnish 3 change keys for each lock, 5 master keys for each mastersystem, 5 grandmaster keys for each grandmaster system, and 1 control key forinterchangeable core series.a. Furnish one extra blank for each lock.b. Deliver keys to Owner.2.10 OPERATING TRIM (PUSH/PULL)A. Operating Trim: BHMA A156.6; stainless steel.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Burns Manufacturing Incorporated.b. Hiawatha, Inc.Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 6

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-03c. Rockwood Manufacturing Company.2.11 ACCESSORIES FOR PAIRS OF DOORSA. Coordinators: BHMA A156.3; consisting of active-leaf, hold-open lever and inactive-leaf releasetrigger; fabricated from steel with nylon-coated strike plates; with built-in, adjustable safetyrelease.B. Carry-Open Bars: BHMA A156.3; prevent the inactive leaf from opening before the active leaf;provide polished brass or bronze carry-open bars with strike plate for inactive leaves of pairs ofdoors unless automatic or self-latching bolts are used.C. Astragals: BHMA A156.22.2.12 SURFACE CLOSERSA. Surface Closers: BHMA A156.4; rack-and-pinion hydraulic type with adjustable sweep andlatch speeds controlled by key-operated valves and forged-steel main arm. Comply withmanufacturer's written recommendations for size of door closers depending on size of door,exposure to weather, and anticipated frequency of use. Provide factory-sized closers,adjustable to meet field conditions and requirements for opening force.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. LCN Closers; an Ingersoll-Rand company.b. Rixson Specialty <strong>Door</strong> Controls; an ASSA ABLOY Group company.c. Ryobi.2.13 CLOSER HOLDER RELEASE DEVICESA. Closer Holder Release Devices: BHMA A156.15; Grade 1; closer connected with separate orintegral releasing and fire- or smoke-detecting devices. <strong>Door</strong> shall become self-closing oninterruption of signal to release device. Automatic release is activated by smoke detectionsystem or loss of power.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. LCN Closers; an Ingersoll-Rand company.b. Rixson Specialty <strong>Door</strong> Controls; an ASSA ABLOY Group company.2.14 OVERHEAD STOPS AND HOLDERSA. Overhead Stops and Holders: BHMA A156.8.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Architectural Builders <strong>Hardware</strong> Mfg., Inc.b. Glynn-Johnson; an Ingersoll-Rand company.c. Rockwood Manufacturing Company.2.15 DOOR GASKETINGRichard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 7

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-03A. <strong>Door</strong> Gasketing: BHMA A156.22; air leakage not to exceed 0.50 cfm per foot (0.<strong>00</strong>0774 cu. m/sper m) of crack length for gasketing other than for smoke control, as tested according toASTM E 283; with resilient or flexible seal strips that are easily replaceable and readily availablefrom stocks maintained by manufacturer.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. National Guard Products.b. Reese Enterprises, Inc.c. Zero International.2.16 THRESHOLDSA. Thresholds: BHMA A156.21; fabricated to full width of opening indicated.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. National Guard Products.b. Reese Enterprises, Inc.c. Zero International.2.17 METAL PROTECTIVE TRIM UNITSA. Metal Protective Trim Units: BHMA A156.6; fabricated from 0.050-inch- (1.3-mm-) thickstainless steel; with manufacturer's standard machine or self-tapping screw fasteners.1. Basis-of-Design Product: Subject to compliance with requirements, provide productindicated on schedule or comparable product by one of the following:a. Burns Manufacturing Incorporated.b. Hiawatha, Inc.c. Rockwood Manufacturing Company.2.18 FABRICATIONA. Manufacturer's Nameplate: Do not provide products that have manufacturer's name or tradename displayed in a visible location except in conjunction with required fire-rated labels and asotherwise approved by Architect.1. Manufacturer's identification is permitted on rim of lock cylinders only.B. Base Metals: Produce door hardware units of base metal indicated, fabricated by formingmethod indicated, using manufacturer's standard metal alloy, composition, temper, andhardness. Furnish metals of a quality equal to or greater than that of specified door hardwareunits and BHMA A156.18.C. Fasteners: Provide door hardware manufactured to comply with published templates preparedfor machine, wood, and sheet metal screws. Provide screws that comply with commerciallyrecognized industry standards for application intended, except aluminum fasteners are notpermitted. Provide Phillips flat-head screws with finished heads to match surface of doorhardware, unless otherwise indicated.1. Concealed Fasteners: For door hardware units that are exposed when door is closed,except for units already specified with concealed fasteners. Do not use through bolts forinstallation where bolt head or nut on opposite face is exposed unless it is the onlyRichard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 8

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-03means of securely attaching the door hardware. Where through bolts are used on hollowdoor and frame construction, provide sleeves for each through bolt.2. Fire-Rated Applications:a. Wood or Machine Screws: For the following:1) Hinges mortised to doors or frames.2) Strike plates to frames.3) Closers to doors and frames.b. Steel Through Bolts: For the following unless door blocking is provided:1) Surface hinges to doors.2) Closers to doors and frames.3) Surface-mounted exit devices.3. Spacers or Sex Bolts: For through bolting of hollow-metal doors.4. Fasteners for Wood <strong>Door</strong>s: Comply with requirements in DHI WDHS.2, "RecommendedFasteners for Wood <strong>Door</strong>s."5. Gasketing Fasteners: Provide noncorrosive fasteners for exterior applications andelsewhere as indicated.2.19 FINISHESA. Provide finishes complying with BHMA A156.18 as indicated in door hardware schedule.B. Protect mechanical finishes on exposed surfaces from damage by applying a strippable,temporary protective covering before shipping.C. Appearance of Finished Work: Variations in appearance of abutting or adjacent pieces areacceptable if they are within one-half of the range of approved Samples. Noticeable variationsin the same piece are not acceptable. Variations in appearance of other components areacceptable if they are within the range of approved Samples and are assembled or installed tominimize contrast.PART 3 - EXECUTION3.1 EXAMINATIONA. Examine doors and frames, with Installer present, for compliance with requirements forinstallation tolerances, labeled fire-rated door assembly construction, wall and floorconstruction, and other conditions affecting performance.B. Proceed with installation only after unsatisfactory conditions have been corrected.3.2 PREPARATIONA. Steel <strong>Door</strong>s and Frames: For surface applied door hardware, drill and tap doors and framesaccording to ANSI/SDI A250.6.Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 9

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-03B. Wood <strong>Door</strong>s: Comply with DHI WDHS.5 "Recommended <strong>Hardware</strong> Reinforcement Locationsfor Mineral Core Wood Flush <strong>Door</strong>s."3.3 INSTALLATIONA. Mounting Heights: Mount door hardware units at heights to comply with the following unlessotherwise indicated or required to comply with governing regulations.1. Standard Steel <strong>Door</strong>s and Frames: ANSI/SDI A250.8.2. Custom Steel <strong>Door</strong>s and Frames: HMMA 831.3. Wood <strong>Door</strong>s: DHI WDHS.3, "Recommended Locations for Architectural <strong>Hardware</strong> forWood Flush <strong>Door</strong>s."B. Install each door hardware item to comply with manufacturer's written instructions. Wherecutting and fitting are required to install door hardware onto or into surfaces that are later to bepainted or finished in another way, coordinate removal, storage, and reinstallation of surfaceprotective trim units with finishing. Do not install surface-mounted items until finishes have beencompleted on substrates involved.1. Set units level, plumb, and true to line and location. Adjust and reinforce attachmentsubstrates as necessary for proper installation and operation.2. Drill and countersink units that are not factory prepared for anchorage fasteners. Spacefasteners and anchors according to industry standards.C. Hinges: Install types and in quantities indicated in door hardware schedule but not fewer thanthe number recommended by manufacturer for application indicated or one hinge for every 30inches (750 mm) of door height, whichever is more stringent, unless other equivalent means ofsupport for door, such as spring hinges or pivots, are provided.D. Intermediate Offset Pivots: Where offset pivots are indicated, provide intermediate offset pivotsin quantities indicated in door hardware schedule but not fewer than one intermediate offsetpivot per door and one additional intermediate offset pivot for every 30 inches (750 mm) of doorheight greater than 90 inches (2286 mm).E. Lock Cylinders: Install construction cores to secure building and areas during constructionperiod.1. Replace construction cores with permanent cores as directed by Owner.2. Furnish permanent cores to Owner for installation.F. Key Control System: Tag keys and place them on markers and hooks in key control systemcabinet, as determined by final keying schedule.G. Thresholds: Set thresholds for exterior doors and other doors indicated in full bed of sealantcomplying with requirements specified in <strong>Section</strong> 07 92 <strong>00</strong> "Joint Sealants."H. Stops: Provide floor stops for doors unless wall or other type stops are indicated in doorhardware schedule. Do not mount floor stops where they will impede traffic.I. Perimeter Gasketing: Apply to head and jamb, forming seal between door and frame.J. Meeting Stile Gasketing: Fasten to meeting stiles, forming seal when doors are closed.K. <strong>Door</strong> Bottoms: Apply to bottom of door, forming seal with threshold when door is closed.Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 10

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-033.4 ADJUSTINGA. Initial Adjustment: Adjust and check each operating item of door hardware and each door toensure proper operation or function of every unit. Replace units that cannot be adjusted tooperate as intended. Adjust door control devices to compensate for final operation of heatingand ventilating equipment and to comply with referenced accessibility requirements.1. <strong>Door</strong> Closers: Adjust sweep period to comply with accessibility requirements andrequirements of authorities having jurisdiction.3.5 CLEANING AND PROTECTIONA. Clean adjacent surfaces soiled by door hardware installation.B. Clean operating items as necessary to restore proper function and finish.C. Provide final protection and maintain conditions that ensure that door hardware is withoutdamage or deterioration at time of Substantial Completion.3.6 DOOR HARDWARE SCHEDULE<strong>Door</strong> <strong>Hardware</strong> Set No. 01Locations: Storage Building (two openings); each to have the following:Qty. Item Manufacturer Product1 CONTINUOUS HINGE SELECT SL-3051 EXIT DEVICE VON DUPRIN 98 EO1 CYLINDER BEST 1E<strong>71</strong> PULL BURNS VRT22C1 CLOSER LCN 4041-CUSH X ST1 KICK PLATE ROCKWOOD K10501 THRESHOLD NGP 425RCE1 SET SEALS NGP 7<strong>00</strong>NA1 BOTTOM SEAL NGP 2<strong>00</strong>NAINSTALL WEATHERSTRIP BEFORE CLOSER<strong>Door</strong> <strong>Hardware</strong> Set No. 02Locations: SAR A, SAR B (two openings); each to have the following:Qty. Item Manufacturer Product1 CONTINUOUS HINGE SELECT SL-11HD1 DEADLOCK ADAMS RITE MS1850 X 40661 CYLINDER BEST 1E<strong>71</strong> PUSH/PULL ROCKWOOD RM2511 CLOSER LCN 40411 STOP ROCKWOOD 401<strong>Door</strong> <strong>Hardware</strong> Set No. 03Location: Control Booth (one opening); each to have the following:Qty. Item Manufacturer Product3 HINGE PBB BB811 LOCKSET BEST 93K7R1 STOP ROCKWOOD 401Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 11

REDAN HIGH SCHOOL INTERIOR RENOVATIONS & STORAGE FACILITY 02.26.13<strong>DeKalb</strong> <strong>County</strong> School SystemProject Number 421-111-03<strong>Door</strong> <strong>Hardware</strong> Set No. 04Location: Boys’ Lockers (one opening); each to have the following:Qty. Item Manufacturer Product1 CONTINUOUS HINGE SELECT SL-3051 DEADLOCK BEST 45H7RD1 PUSH ROCKWOOD 73C1 PULL ROCKWOOD BF112 X 70C1 CLOSER LCN 40411 KICK PLATE ROCKWOOD K10501 MOP PLATE ROCKWOOD K10501 STOP ROCKWOOD 401END OF SECTION <strong>08</strong> <strong>71</strong> <strong>00</strong>Richard Wittschiebe HandDOOR HARDWAREProject 201014 <strong>08</strong> <strong>71</strong> <strong>00</strong> - 12