Chapter 1 Safety Precautions

Chapter 1 Safety Precautions

Chapter 1 Safety Precautions

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

HSV-160B + SeriesFull Digital AC Servo Drive UnitUser'sManual(Version 1.0)Wuhan Golden Age Motor Technology Co.,Ltd.Nov. 2011

Contents6.2.2. Parameter recovery....................................................................... - 66 -<strong>Chapter</strong> 7 Parameter Setting..................................................................................................................................................................- 68 -7.1 Function menu........................................................................................... - 68 -7.2 Motion parameter mode...........................................................................- 68 -7.2.1 Elaborate on motion parameter....................................................- 72 -7.3 Expansion parameter mode..................................................................... - 80 -7.4 Control parameter mode.......................................................................... - 84 -<strong>Chapter</strong> 8 Operation Tuning..................................................................................-86-8.1 Power connection...................................................................................... - 86 -8.2 Trial Operation...........................................................................................- 88 -8.2.1 Checking before operation............................................................ - 88 -8.2.2 Power-on Trial Operation..............................................................- 89 -8.3 Simple wirings in the position control mode...........................................-92-8.4 Simple wirings in the speed control mode......................................................-94-8.5 Simple wirings in the torque mode.........................................................- 96 -8.6 Tuning.........................................................................................................- 98 -8.6.1 Basic control.................................................................................... - 99 -8.6.2 Electronic gear setting..................................................................- 100 -8.6.3 Tuning start-up and stop characteristic.......................................-101-8.7 Frequently Asked Problems...................................................................- 103 -8.7.1 Parameter default setting recovery..............................................-103-8.7.2 Deficient output contributions in the process of tuning...........-104-8.7.3 Current loop tuning........................................................................-104-8.7.4 Change of parameters should be done regardless of the motorand drive combination type...................................................................-105-<strong>Chapter</strong> 9 Diagnostics and Troubleshooting.....................................................-107-9.1 Protective diagnostic function..................................................................-107-9.2 Troubleshooting............................................................................................-109-<strong>Chapter</strong> 10 Service and Maintenance..................................................................-11515-10.1 Routine inspection......................................................................................-115-10.2 Regular checking........................................................................................-115-10.3 Replacing parts...........................................................................................-116-Annexure...................................................................................................................-116-- 3 -

<strong>Chapter</strong> 1 <strong>Safety</strong> <strong>Precautions</strong><strong>Chapter</strong> 1 <strong>Safety</strong> <strong>Precautions</strong>Thank you very much for your using AC Servo Drive Unit HSV-160B+. Weprovide servo drives and motors for common industrial applications.However, the following instructions must be strictly observed:‣ Do not place the servo drive and motor in the environmental conditionsof strong vibration.‣ Do not use the servo drive and motor for life safety concerned medicalequipment.‣ Do not subject the servo drive to the rain or direct sunshine, since it isnot waterproof structured.‣ Do not make any changes or modification to the servo drive and motor.Attention: Before correct installation and wiring, read through this manualcarefully. Before operation, you should have good knowledge of safetyinformation and precautions, and device usage.1.1 Warning symbolson the product△!Warning• Be careful of electricshock and personalinjury hazard.• Wait 5 minutes forwiring and coverremoval after powershutdown.- 4 -

<strong>Chapter</strong> 1 <strong>Safety</strong> <strong>Precautions</strong>1.2 Meanings of symbolsfor warning!Warning<strong>Safety</strong> sign board• Be careful ofelectric shock andpersonal injuryhazard.• Wait 3 minutes forwiring and coverremoval afterpower shutdown.Meaning of eachsafety signSymbol1.3 Explanation of safetyconcernedsymbolsDangerIncorrect use of the productcould result in hazards,personal injuries and evendeath.CautionIncorrect use of the productcould result in light ormedium level personalinjuries and damages to theproduct.1.4 <strong>Safety</strong> notice• Check and confirm on delivery- 5 -

<strong>Chapter</strong> 1 <strong>Safety</strong> <strong>Precautions</strong>Caution• Do not install the damaged servodrives; otherwise, you may getinjured.• Use the servo motor and drive inthe specified combination, otherwise,it could result in fire or fault.• InstallationCaution• Lift the bottom of the device fordisplacement. If you hold onlythe panel, the servo drive hostmay drop from your hand, andyou may get injured.• This product should be fit to thenoncombustible flat surface, suchas metals. Failure to follow thisinstruction could result in fire.• Make sure the inlet and outlet ofthe product are unobstructed.Prevent foreign bodies fromentering the product. Failure tofollow this instruction couldresult in aging of internalcomponents and thereby causefire and/or fault.• Keep the specified space forservo drive and the switchingcabinet and other devices whencarry out installation. Failure tofollow this instruction couldresult in fire and/or fault.• WiringDanger• Wiring is supposed to be done byelectrical engineers. Failure tofollow this instruction could resultin electric shock and/or fire.• Before wiring, confirm the poweris off. Failure to follow thisinstruction could result in electricshock and/or fire.• Power terminal and motorconnection terminal should befastened tightly. Failure to followthis instruction could result in- 6 -

<strong>Chapter</strong> 1 <strong>Safety</strong> <strong>Precautions</strong>electric shock and/or fire.• Do not touch the output terminalsdirectly or connect the outputwires with the servo drive outsideshell. Never short the outputterminals. Failure to follow thisinstruction could result in electricshock and/or short circuit.Caution• <strong>Safety</strong> devices like breakersshould be installed to avoid shortcircuit of external layout. Failureto follow this instruction couldresult in fire hazard.• Verify the power voltage of ACmain circuit is corresponding tothe nominal voltage of the servodrive. Failure to follow thisinstruction could result ininjuries and/or fire hazard.• Do not do the voltage resistancetest to the servo drive; otherwise,the semi-conductor componentsof the servo drive could bedamaged.• Do not connect the power cableswith output terminal U, V, W;otherwise, when voltage adds onthe output terminal, the internalparts of the servo drive could bedamaged.• Do not connect capacitor and(LC/LR) noise filter withterminal U, V, W in the outputloop; otherwise, the servo drivecould be damaged.• Do not connect electromagneticswitch or contactor with terminalU, V, W in the output loop. Inthe load-operation, the surgecurrent could activate the overcurrent protection circuit of theservo drive.- 7 -

<strong>Chapter</strong> 1 <strong>Safety</strong> <strong>Precautions</strong>• Debugging and OperationDanger• To avoid unexpected accidents,servo motor test run should becarried out respectively (free fromconnection to the transmissionshaft). Failure to follow thisinstruction could result in injuries.• Do not disassemble the servodrive with power present. Failureto follow this instruction couldresult in electric shock.• Do not approach to the machinein trial operation with powerpresent. (Take personal safety intoconsideration when performmechanical and electrical design).Caution• Do not touch the servo drive heatsink, brake resistor or the motorwith power present or justswitched off, since the temperatureof them could be high. Failure tofollow this instruction could resultin burns.• Before operating, reconfirm thetechnical datum of the servomotor and other devices. Failureto follow this instruction couldresult in injuries.• If it is necessary to use externalbrakes, prepare separately; do nottouch the brakes in operation.Failure to follow this instructioncould result in injuries.• Do not check signals in operation,otherwise, the servo drive could bedamaged.- 8 -

<strong>Chapter</strong> 1 <strong>Safety</strong> <strong>Precautions</strong>• TroubleshootingDanger• Wait 5 minutes for wire removalafter power shutdown of theservo drive, since the voltagemay still remain high for sometime. Failure to follow thisinstruction could result in electricshock.• Operations (such as wiring,installation, running, disassemblyand maintenance) must beperformed by the specifiedprofessional personnel. Failure tofollow this instruction couldresult in risks of electric shockand/or damages to the servodrive.Caution• The control circuit board adoptsCMOS integrated circuit (IC),therefore, you should takeanti-static measures inmaintenance, otherwise, theelectrostatic induction coulddamage the control circuit board.• Adoption of servo motorsCaution• The nominal voltage of the servomotor must be greater than theconstant torque loads valid.Otherwise, the servo motor couldbe damaged for long-timeoverload.• The ratio of load inertia andservo motor inertia should be lessthan the recommendedvalue.Otherwise, the devicecould be damaged.• Use the servo motor and drive inthe specified combination.Failure to follow this instructioncould result in damages to thedevice.- 9 -

<strong>Chapter</strong> 1 <strong>Safety</strong> <strong>Precautions</strong>• OthersDanger• Do not make changes ormodifications to the device byyourself. Failure to follow thisinstruction could result in risks ofelectric shock and injuries.- 10 -

<strong>Chapter</strong> 2 Overview<strong>Chapter</strong> 2 OverviewHSV-160B + is a new product of full-digital AC servo drive after HSV-11,HSV-16 and HSV-160 developed by Wuhan Golden Age Motor TechnologyCo., ltd.. It features all characteristics of compact structure,ease of use and high reliability.2.1 Product introductionHSV-160B + AC servo drive adopts the latest technological designs,such asDigital Signal Processing (DSP) for motion controller and Intelligent PowerModule (IPM). It features a few characteristics:• A small size body;• Easy to install and operate;• High reliability.Highlights of HSV-160B + AC servo drive:1) Easy and flexible controlTo meet different work requirements and/or environmental conditions, youcan make revisions to the servo drive parameters to change its operatingmode and/or internal parameters. You can also preset a few sets ofcharacteristic parameters, and alternate automatically according to themachining situations.2) Full status displayHSV-160B + AC servo drive provides a series of status display. It enablesusers to browse the related status parameters of the servo drive easily duringdebugging and operation. And it also provides a series of fault diagnosticinformation.3) Wide range of speed adjustment ratio (relative to the motor itselfand the feedback component selected).The setpoint of maximum rotary speed of the motor can reach 12000 rpm inHSV-160B + AC servo drive system, and the minimum is 1 rpm. The range of- 11 -

<strong>Chapter</strong> 2 Overviewspeed adjustment ratio is 1:12000.4) Small size, easy to installHSV-160B + AC servo drive adopts a compact structure and a small size body,which makes it easy to install and disassemble.5) Gain-switch functionTo improve the transient characteristic of the operating motor with dynamicloads, you can preset standby characteristic parameters, and alternateautomatically according to machining situations.6) User-defined Signal Inputs/Outputs functionHSV-160B+ AC servo drive system preset 13 types of input functions and 10output functions, of which, users can conveniently select 6 input functionsand 3 output functions for setting, and define the validity of I/O signals high(low) level.7) Servo motor code setting and autotuning function of the motorparametersHSV-160B + AC servo drive sets the motor code according to the motor type,and accesses to the motor parameters via autotuning.2.2Introduction of operating modeThere are five control modes for HSV-160B + AC servo drives:• Position control mode(pulse interface): HSV-160B + AC servo drive canreceive 3 types of pulse commands(orthogonal pulse, pulse + direction,positive and negative pulse) via setting internal parameters.• Speed control mode(analogue interface): HSV-160B + servo drive canreceive analogs whose amplitudes are not higher than 10v(that is from-10v to +10v) via setting the internal parameters to switch to the speedcontrol mode.• Torque control mode (analogue interface): HSV-160B + AC servo drivecan receive analogues whose amplitudes are less than 10 v(that is from-10v to +10v) via setting the internal parameters to switch to the torquecontrol mode.- 12 -

<strong>Chapter</strong> 2 Overview• JOG control mode: In this mode, users can operate HSV-160B + ACservo drive manually with a keypad. It is a way to check whether theinstallation and connection of servo drive unit are correct or not.• Internal speed control mode: In this mode, HSV-160B + AC servo drivecan run at the internal preset speed.- 13 -

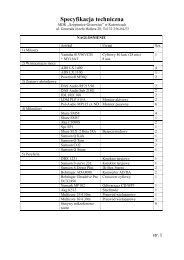

<strong>Chapter</strong> 3 Specification<strong>Chapter</strong> 3 Specification3.1 Servodrive specificationpecificationsDenomination explanation:HSV-160B + - XXX160B + type full digitalAC servo driveSpecifications:010, 020, 030, 050, 075Table 3.1 Servo drive operating currentMomentary WithstandServoContinuousCurrentCurrentDrive(A/30 min)(A/1min)Specification(virtual value)(virtual value)HSV-160B + -010 4.8 7.2HSV-160B + -020 6.9 10.4HSV-160B + -030 9.6 14.4HSV-160B + -050 16.8 25.2HSV-160B + -075 24.8 37.2Table 3.2 Servo drive specificationsPower Input3-phaseAC 220V (-15to +10%10%, 50/60 Hz)OperatingenvironmentControlmodeRegenerativebrakeAmbienttemperatureRelativehumidityIn operation: 0 to 55 ℃For storage: -20 ℃ to 80 ℃< 90 % (no icing)< 0.5G (4.9m/S 2 ), 10 to 60 HzVibration(noncontinuous operating)1Position control mode 2Speed control mode3Internal speed control mode 4JOG modeinternal\externalFor selection and connection of brake resistors, see theAnnexure- 14 -

<strong>Chapter</strong> 3 SpecificationCharacteristicsInput controlOutput controlPositioncontrolRampfunction(Accelerationanddeceleration)MonitoringfunctionSpeedfrequencyresponseSpeedfluctuationratioSpeedadjustmentPulsefrequency1Servo enable2Alarm clear300 Hz or higher< ±0.1(load: 0 to 100%);

<strong>Chapter</strong> 3 SpecificationProtectivefunctionOperationpanelAdaptiveloadinertia• Overspeed protection• Mains overcurrent, overvoltage and undervoltageprotection• Overload protection• Braking malfunction protection• Encoder malfunction protection• Control mains undervoltage protection• Overtemperature protection• Positioning out-of-tolerance protection etc.6 bit LED segment with 5 keys< 5 times of motor inertiaServo drive unit installation dimension (Unit: mm)- 16 -

<strong>Chapter</strong> 3 SpecificationFigure 3.1 HSV-160B + -010A servo drive installation dimensionAC SERVORSERIES+HSV-160B -010MSALENRSTPECOM COMMANDUVWPEENCODERFigure 3.2 HSV-160B + -020/030A servo drive installation dimension682701746AC SERVOSERIESHSV-160B + -030MSALEN178RSTPE12COMCOMMAND190UVWPEENCODER2-4.6- 17 -

<strong>Chapter</strong> 3 SpecificationFigure 3.3 HSV-160B + -050/075A servo drive installation dimensionAC SERVOSERIESRHSV-160B + -050MSALENRSTPECOMBK1BK2COMMANDUVWPEENCODER3.2 IsolatingtransformerspecificationHSV-160B + AC servo drive uses 3-phase or single phase AC 220v powersupply. 3-phase 380/220v servo isolating transformer is recommended, andthe capacity of isolating transformer depends on the servo drive systemcapacity. When you select the isolating transformer, it is necessary to take theservo drive system capacity for each axis into account comprehensively.You can consider step by step in the following way:1) Select suitable motors based on the mechanical load inertia, torque andtrasmission method adopted.2) Select the servo drive type based on the selected motors.3) Calculate the servo isolating transformer capacity based on the motortechnical datum.Example: If a system adopts three HSV-160 B + AC servo drives whose motorpowers are P1, P2, P3, the servo isolating transformer power must observe thefollowing formula:- 18 -

<strong>Chapter</strong> 3 SpecificationP0 >(P1+P2+P3) * η("η" is a conversion coefficient, and generally, adopts a value 0.6 to 0.8)4) Select the servo isolating transformer specification corresponds to thecalculated servo isolating transformer capacity.- 19 -

<strong>Chapter</strong> 4 Installation<strong>Chapter</strong> 4 Installation4.1 Check on deliveryOn receipt of products, users must check and confirm the following items:Items to checkContent (for reference)Whether the products are Visual inspection to check whether the productsdamaged or notdamaged or not during transportationWhether the products areCheck the nameplates of servo drive units anddelivered in accordance withservo motorsthe indent or notWhether the accessories are Check the packing list and make sure that thecomplete or notaccessory type and quantity is correct.Whether the motor rotor can Check and make sure that the motor rotor can bebe easily turned by hand easily turned by hand, except motors with brakes.Note: For the items mentioned above, if there's any problem, please feel freeto contact with the supplier or us.Attention• Do not install servo drives and servo motors which are damagedor with incomplete parts.• Use the specified combination of servo drives and servo motors.• Do not touch the motor rotor by hand directly, otherwise, it couldcause corrosion.- 20 -

<strong>Chapter</strong> 4 Installation4.2 Installation environmentCaution• The servo drive are supposed to beinstalled in the well protectedswitching cabinet to prevent dust,corrosive gas, conductive foreignbodies, fluids and inflammables fromentry.• The servo drives are supposed to beinstalled in accordance with thespecified direction and side distanceto ensure good heat dissipationconditions.• The servo drives and motors aresupposed to be free from vibrationand shock.• The servo drives are not supposed tobe installed near combustibles, inorder to avoid fire hazard.4.2.1 Protection requirementsStructural protection are not specifically designed for the servo drives,therefore, it is supposed to be installed in the well protected switchingcabinet to prevent corrosion, combustible gas, conductive foreign bodies,metal powder, atomized oil and other fluids from entry of the servo drive .4.2.2 Temperature requirements• Ambient temperature: 0℃ to 50℃• <strong>Safety</strong> long-time operating temperature: below 45℃• Ensure good heat dissipation.4.2.3 Vibration and shock loadingAvoid vibration during servo drive installation, and adopt Vibration dampingmeasures to restrain the vibration below 0.5G (4.9m/S 2 ). No vibration andshock loading is permissible during servo drive installation.4.3 Servo driveinstallationAttention• Servo drives are supposed to be installed in the well protected electricalcabinets.- 21 -

<strong>Chapter</strong> 4 Installation• Servo drives are supposed to be installed in accordance with the specifieddirection and distance to ensure good heat dissipation conditions.• The servo drives are not supposed to be installed adjacent to combustibles,in order to avoid fire hazard.4.3.1 Installation method1) Installing the deviceAdopt base plate installation method, and install the devie in a verticalposition. See Figure 4.1(4.2,4.3) for installing the device.2) Installation spacingFigure 4.4(4.6) shows the installing spacing for a solo servo drive and Figure4.5(4.7) shows the installing spacing for multiple units. In actual installation,keep the spacing as large as possible to ensure good heat dissipationconditions.3) VentilationIn the electrical cabinet, airflow to the heat sink should be maintained toensure adequate cooling of the ambient temperature of the device.- 22 -

<strong>Chapter</strong> 4 InstallationFigure 4.1 Schematic drawing of HSV-160B + -010 AC servo drive base plate mountingCombination of bolts withwasher: M4×14Standard:GB/T9074.8-1988Quantity: 4- 23 -

<strong>Chapter</strong> 4 InstallationFigure 4.2 Schematic drawing of HSV-160B + -020/030 AC servo drive base platemountingCombination of boltswith washer: M4×14Standard:GB/T9074.8-1988Quantity: 4- 24 -

<strong>Chapter</strong> 4 InstallationFigure 4.3 Schematic drawing of HSV-160B + -050/075 AC servo drive base platemountingCombination of boltswith washer: M4×14Standard:GB/T9074.8-1988Quantity: 4- 25 -

R<strong>Chapter</strong> 4 InstallationFigure 4.4 Installation spacing for a solo HSV-160B + -020/030 AC servo driveAC SERVOSERIESHSV-160B + -050MSALENRSTPEBK1BK2UVWPECOM COMMAND ENCODERFigure 4.5 Installation spacing for the HSV-160B + -020/030 AC servo drive multipleunitsAC SERVOAC SERVOAC SERVOSERIESSERIESSERIESHSV-160B + -030HSV-160B + -030HSV-160B + -030MSALENMSALENMSALENRSTPE12COMCOMMANDRSTPE12COMCOMMANDRSTPE12COMCOMMANDUVWPEENCODERUVWPEENCODERUVWPEENCODER- 26 -

RRRR<strong>Chapter</strong> 4 InstallationFigure 4.6 Installation spacing for a solo HSV-160B + -050/075 AC servo driveAC SERVOSERIESHSV-160B + -050MSALENRSTPECOMBK1BK2COMMANDUVWPEENCODERFigure 4.7 Installation spacing for the HSV-160B + -050/075 AC servo drive multipleunitsAC SERVOAC SERVOAC SERVOSERIESSERIESSERIES+ +HSV-160B -050HSV-160B -050 HSV-160B -050+MSALENMSALENMSALENRRRSSSTTTPEBK1BK2UVWPECOM COMMAND ENCODERPEBK1BK2UVWPECOMCOMMAND ENCODERPEBK1BK2UVWPECOMCOMMAND ENCODER- 27 -

<strong>Chapter</strong> 4 Installation4.4 Installation of servo motorsAttention• To prevent the motor from vibration and impact, knocking on the motorrotor or encoder is forbidden.• When transport the motor, you should not drag at the motor rotor, theoutlet wires, or the encoder.• Motor rotor cannot be overloaded, otherwise, the motor could bedamaged.• Make sure the motors are fastened, and take measures to avoid loose ordrop out.4.4.1 Installation environment1) ProtectionIf the servo motor is not waterproof type, you should prevent liquids splashon the motor during installation and operation, especially avoid entry ofgrease into the motor internal via lead wires or the motor rotor.Note: If users demand for waterproof type servo motors, please declare in theindent.2) Temperature and relative humidityAmbient temperature should be kept between 0 and 40 ℃ (No icing). Themotor temperature increases as the operating time last for long, therefore,enforcing heat dissipation should be taken into account if the ambient spaceis inadequate or other devices also heat the air. The relative humidity shouldnot be higher than 90% and no condensation.3) VibrationAvoid vibration for the servo motor installation. Vibration should be lessthan 0.5G (4.9m/S 2 ).4.4.2 Servo motor installation method1) Way of installationGK6 motor series can be installed in a horizontal position or a vertical- 28 -

<strong>Chapter</strong> 4 Installationposition.2) Installation instructions:• When you assemble or disassemble the belt drive of the motor, do notknock on the motor or rotor to avoid damage to the encoder. And usehelical drawing tools for thermal expansion joint assembly anddisassembly.• GK6 motors can't afford overload in the axial and radial direction.Recommendation: Use resilient expansion joint to connect the loads.• When mounting the motors, you need to use spring plug to fasten thebolts, and thereby avoid loose of drop-out.- 29 -

<strong>Chapter</strong> 5 Wiring<strong>Chapter</strong> 5 WiringWarning• Wiring and checking personnel must be qualified for this job.• Wait 5 minutes for wiring and checking after power off to avoid electricshock.Attention• Wiring is supposed to be done according to the terminal voltage andpolarity to avoid damage to the device and/or personal injuries.• The high frequency oscillated current flows through the servo motor, andthe leakage current will be heavy. Therefore, the servo motor earthingterminal and the servo drive earthing terminal (PE) should be togetherreliably grounded.Attention• When assemble/disassemble the mechanical connection parts of the motorrotor, do not use the hammer to knock on the rotor direclty, otherwise, themotor encoder could be damaged.• Align the end faces of the motor rotor to the best condition,otherwise,vibration could arise or the motor bearing could be damaged.- 30 -

5.1 Standard wiring<strong>Chapter</strong> 5 WiringThe external connection of the servo drive depends on the selected controlmode.5.1.1 Position control modeFor standard wiring (a) in the position control mode, see Figure 5.1; forstandard wiring (b), applicable to Siemens controller 801, in the positioncontrol mode, see Figure 5.2.5.1.2 Speed and torque control modeFor standard wiring in the speed and torque control mode, see Figure 5.3.5.1.3 Conductor configuration1) Mains terminals• Cross section of the wires for terminal R, S, T, PE, U, V, W ≥ 1.5 mm 2(AWG14-16).• Grounding: The cross section of the grounding wires should be as largeas possible. The servo drive and motor are supposed to be connected tothe PE terminal, and thereby grounded. Grounding resistor

<strong>Chapter</strong> 5 Wiring• Wiring layout: The signal wirings should be kept away from the powercables to prevent the entry of interference.• Install surge absorbers with inductive components (coils) for relatedcircuits. Freewheeling diodes are antiparallelly connected to the DCcoils, and RC absorbed circuits are parallelly connected to the AC coils.Caution• U, V, W must be connected to the motor windings exactly in correspondingorder. Note that you can not adjust the positions of the three terminals tomake the motor run in the reverse direction. This is different from theasynchronous motors.• Cables and lead wires are supposed to be fixed avoiding the heat sink ofthe drive and the servo motor. Otherwise, the insulation property could bereduced due to overtemperature.• There is large-capacity of electrolytic capacitance storing in the servodrive, even after power removal, the voltage supply will remain high for aperiod of time. Do not touch the servo drive or motor within 5 minutesafter power removal.- 32 -

<strong>Chapter</strong> 5 WiringFigure 5.1Standard wiring (a) in the position control modeAC 交 流 Servo 伺 服 驱 Drive 动 器HSV-160160B-010/020/030010/020/030/050/075/050/075Golden age motor登 奇 电 机Single phaseor 3-phase单 相 或 三 相AC220VNFBMCRSTPEUVWPEUWVPEM3 ~External braking外 接 制 动 电 阻resistorBK1BK2Encodersignalfeedback编 码 器 信 号反 馈positioncommand(plus)positioncommand(sign)位 置 指 令PLUS位 置 指 令SIGN• Servo enable伺 服 使 能报 警 清 除• Alarm cleared• Deviation偏 差 计 数 器 清 零counter clear• Command 指 令 脉 冲 禁 止pulseCCW 驱 动 禁 止prohibition• CCW driveprohibition• CW driveprohibition• 24v Mainsearthing定 位 完 成 / 速 度 到 达• Target-position/Target-speedachieve伺 服 报 警• Drive ready• Drive Alarm伺 服 准 备 好A+ 32A- 33B+ 18B- 36Z+ 35Z- 34CP+ 14CP- 15DIR+ 16DIR- 17GD 23GD 24ENA-CLCLEEINHL-CCWGETREADYALMCOMMAND123457892.7K2.7K2.7K2.7K2.7K+24V ISO1104 1N4148+24 V ISO42 31104 1N4148+24V ISO42 31104 1N4148+24V ISO42 31104 1N4148+24 V ISO42 31104 1N4148+24V ISO42 314ENCODER16,17 +5V18,19 +5V23,24 GND25 GND1 A+2 A-3 B+4 B-5 Z+6 Z-7 U+8 U-9 V+10 V-11 W+12 W-13 OH126 OH214,15 PECW 驱 动 禁 止L-CW 6故 障 连 锁 端 子2 3104 1N41482.7K4 READYCOM 193 COM24V 电 源 地 COM 202 MC11 MC212 +5V13 GND2 A+3 A-4 B+5 B-16 Z+17 Z-6 U+7 U-8 V+9 V-10 W+11 W-14 电 机 过 热15 电 机 过 热1 PEmotor overheat• 伺 服 准 备 Drive 好 ready• 24V 电 源 24v 地 mains earthing• 故 障 连 锁 Fault interlock• 故 障 连 锁 Fault interlock- 33 -

<strong>Chapter</strong> 5 WiringFigure 5.2 Standard wiring (b), applicable to Siemens controller 801AC Servo drive交 流 伺 服 驱 动 器HSV-160160B-010/010/020/030020/030/050/075/050/075Golden Age motor登 奇 电 机Single or单 相 或 三 相3-phase AC220vAC220VNFBMCRSTPEUVWPEUWVPEM3 ~Externalbraking 外 接 制 动 电 阻resistorBK1BK2Z pulse outputPositioncommand Z 脉 冲 输 出PLUS 位 置 指 令PLUSPosition 位 置 指 令Command SIGNSIGN24V 电 源 地24v mainsearthing• Drive enable 伺 服 使 能• Alarm cleared• Deviation报 警 清 除counter clear• Command pulse偏 差 计 数 器 清 零prohibition• Command pulseprohibition 指 令 脉 冲 禁 止• CCW driveprohibition CCW 驱 动 禁 止• CW driveprohibition CW 驱 动 禁 止• 24v mainsearthing24V 电 源 地• Target-position-ac定 位 完 成 / 速 度 到 达hieve/target-speed-achieve 伺 服 准 备 好• Drive ready• Drive alarm 伺 服 报 警Z 21CP+(801) 26CP-(801) 25DIR+(801) 29DIR-(801) 30COM 19EN 1A-CL 2CLEE 3INH 4L-CCW 5L-CW 6COM 20GET 7READY 8ALM 9COMMAND+24V ISO142 3104 1N41482.7K+24V ISO142 3104 1N41482.7K+24V ISO142 3104 1N41482.7K+24V ISO142 3104 1N41482.7K+24V ISO142 3104 1N41482.7K+24V ISO142 3104 1N41482.7KENCODER16,1718,1923,24故 障 连 锁 端 子+5V+5VGND25 GND1 A+2 A-3 B+4 B-5 Z+6 Z-7 U+8 U-9 V+10 V-11 W+12 W-13 OH126 OH214,15 PEFault interlock terminals4 READY3 COM2 MC11 MC212 +5V13 GND2 A+3 A-4 B+5 B-16 Z+17 Z-6 U+7 U-8 V+9 V-10 W+11 W-14 电 机 过 热15 电 机 过 热1 PEmotor overheat伺 • 服 准 备 Servo 好 ready24V • 电 源 24v 地 mains故 障 连 锁earthing故 障 连 锁• Fault interlock• Fault interlock- 34 -

<strong>Chapter</strong> 5 WiringFigure 5.3 Standard wiring in the speed and torque control mode交 AC流 servo 伺 服 驱 Drive 动 器HSV-160160B-010/010/020/030020/030/050/075/050/075Golden Age motor登 奇 电 机single or单 3-phase 相 或 三 相AC 220vAC220VNFBMCRSTPEUVWPEUWVPEM3 ~External braking外 接 制 动 电 阻resistorBK1BK2Encodersignalfeedback编 码 器 信 号反 馈Analoguevoltagecommand-10 to +10v模 拟 电 压 指 令-10V~+10V• Servo伺 enable 服 使 能• Alarm cleared报 警 清 除• Deviationcounter clear偏 差 计 数 器 清 零• Command pulseprohibition 指 令 脉 冲 禁 止• CCW driveprohibition CCW 驱 动 禁 止• CW driveCW 驱 动 禁 止prohibition• 24v mainsearthing伺 服 报 警A+A-B+B-Z+Z-AN+AN-GNGNENA-CLCLEEINHL-CCWL-CWGETREADYALMCOMMAND323318363534121327281234567892.7K2.7K2.7K2.7K2.7K2.7K+24V ISO1104 1N4148+24V ISO2 31104 1N4148+24V ISO2 31104 1N4148+24V ISO2 31104 1N4148+24V ISO2 31104 1N4148+24V ISO2 31104 1N41482 3444444ENCODER16,17 +5V18,1923,24+5VGND25 GND123456789101112132614,15故 障 连 锁 端 子A+A-B+B-Z+Z-U+U-V+V-W+W-OH1OH2PE4 READYCOM 193 COM24V 电 源 地 COM 202 MC11 MC2• Target-position-achieve/target-speed-ac定 位 完 成 / 速 度 到 达hieve伺 服 准 备 好• Drive ready• Drive alarmFault interlock terminals12 +5V13 GND2 A+3 A-4 B+5 B-16 Z+17 Z-6 U+7 U-8 V+9 V-10 W+11 W-14 电 机 过 热15 电 机 过 热1 PEmotoroverheat伺 Drive 服 准 备 ready 好24V24v电 mains源 地earthing故 障 连 锁Fault interlock故 障 连 锁Fault interlock- 35 -

5.2 Signals and functions<strong>Chapter</strong> 5 Wiring5.2.1 HSV-160B + -010/020/030 AC servo drive terminal configurationFigure 5.4 shows configuration of HSV-160B + -010/020/030 AC servo driveinterface terminals, including mains terminals, serial-port communicationterminals (COM), signal control socket (Command), encoder interface andfault interlock terminals.Figure 5.4 HSV-160B + -010/020/030 AC servo drive interface terminal configurationMains terminals电 源 端 子4352RSTPEB K1B K261COM19 361 18C OM MA ND14 26UVWPE1 13ENCODER12Fault 故 interlock 障 连 锁 端 子 terminals ( 端 子 顺 序 (The 是 驱 动 terminal 安 装 后 以sequence 1-2-3-4 is 外 1-2-3-4 向 里 为 准 ) looking from theexternal to the internal) after driveinstallation.34- 36 -

<strong>Chapter</strong> 5 Wiring5.2.2 HSV-160B+-050/075 AC servo drive terminal configurationFigure 5.5 shows HSV-160B + -050/075 servo drive interface terminalconfiguration, including mains terminals, serial-port communicationterminals (COM), control terminals (Command), encoder signal terminalsand fault interlock terminals.A C S E R V OS E R IE SRH S V -1 6 0 B + -0 5 0MSA LE NRSTP EC O MB K 1B K 2UVWP EC O M M A N D E N C O D E R41MC- 37 -

<strong>Chapter</strong> 5 WiringFigure 5.5 HSV-160B + -020/030 AC servo drive interface terminal configurationMains 电 源 terminals 端 子431R522S6134TPECOM19 365BK1678BK2UV1 18COMMAND14 26910WPE1 13ENCODER1234Fault interlock terminals 故 障 连 锁 (The 端 子 terminalsequence ( 端 子 is 顺 1-2-3-4 序 是 驱 动 looking 安 装 后 from 以 1-2-3-4 the external 外 向 里 tothe internal 为 准 ) after drive installation)- 38 -

<strong>Chapter</strong> 5 WiringPlugs, lugs and pins of the COMMAND and ENCODER sockets are shownas follows:Figure 5.6 Lugs and pins of the (Command) control terminals (looking in the face of thelugs)Figure 5.7 Plug of the control terminals (Command) (looking in the face of the plug)Figure 5.8 Lugs of the encoder socket (looking in the face of the plug)- 39 -

<strong>Chapter</strong> 5 WiringFigure 5.9 Plug of the encoder (looking in the face of the plug)5.2.3 HSV-160B + -010 AC servo drive mains terminalsTable 5.1 HSV-160B + -010/020/030 mains terminalsTerminalNo.TerminalMarkSignalDesignation1 R2 S3 T4 PE5 BK16 BK2Main circuitpower(Single or3-phase)SystemgroundingExternalbrakingresistorDecriptionMain circuit power input terminalsupply: AC220V/50HzSingle phase power supply is notrecommended, which only can beused in low power occasions.Note:Do not connect the mainsinput terminal with the motoroutput terminal U, V, W.Grounding terminal.Grounding resistor

<strong>Chapter</strong> 5 Wiring4 PESystemgroundingSystemgroundingGrounding terminals.Grounding resistance

<strong>Chapter</strong> 5 Wiring5 BK16 BK27 U8 V9 WExternal brakingresistanceServo motoroutput10 PE GroundingGroundingThe external andinternal brakingresistance are supposedto be connectedparallelly. The internalbraking resistance is200w 7Ω. For selectionand connection of , seethe Annexure.Warning: Do not shortcircuit BK1 and BK2,otherwise, the drivecould be burnt.Servo motor outputterminals are supposedto be connected withterminal U, V, Wcorrespondingly in theright order.Grounding terminals.Grounding resistance

<strong>Chapter</strong> 5 Wiring1, 5 GNDSignalgroundingrealize serial-portcommunication.Data signal groundingIf you want to use serial-port communication function, please contact ourafter-sale service or development department for the communicationsoftwares. For connection of communication cables, see the drawing below:PC 机 串 口 端 子PC serial-port terminal驱 Drive 动 器 COM COM terminal 端 子RXD22 RXDTXD33TXDGND51,5GNDDB9 pins 头 孔键 盘 插 座Keypad socket5.2.6 Fault interlock terminalsFigure 5.4 Fault interlock terminalsTerminalNo.TerminalMarkSignalDesignation4 READYDrive ready foroutput3 COM 24 V power input2 MC1 Fault interlockDescriptionDrive ready for terminaloutputSRDY ON: It indicates thatpower supply is normal, noalarm occurs, and the drive isready for the output of signal"ON";SRDY OFF: It indicates that nopower supply is available oralarm occurs, so the drive isready for the output of signal"OFF".Power supply of the inputterminal is used to drive theoptical couplerDC 24V, current ≥ 100mAFault interlock outputterminals output relay.- 43 -

<strong>Chapter</strong> 5 Wiring1 MC2Relay connection breaks off inthe event of drive fault.5.2.7 Control Signal terminals (COMMAND)Table 5.5 Control terminals (COMMAND)TerminalNo.TerminalMarkSignalDesignation1* EN Drive enablesignal2* A-CL Alarm clearsignal3* CLEE4* INH5* L-CCWDeviationcounter clearsignalCommandpulseprohibitionsignalCCW servodriveprohibitionsignalDescriptionInput terminal of driveenableEN ON: Servo driveoperating is permitted.EN OFF: If the servo driveshut off,operating stops,the motor will be in thefree state.Note 1:Before you changethe state from EN OFF toEN ON, the motor shouldbe at a standstill.Note 2: After tuning toEN ON state, wait atleast 50ms to inputcommands.Note 3: You can shieldthis signal via parameterSTA-6 or always keep theswitch "ON".Input terminal of alarmclearACL ON: System alarmclearedACL OFF: Hold systemalarmInput terminal of positiondeviation counter clearCLEE ON: In the positioncontrol mode, positiondeviation counter clear.Input terminal of positioncommand pulseprohibitionINH ON: Command pulseinput prohibitionINH OFF: Command pulseinput effectInput terminal of L-CCW(counter-clockwise direction)drive prohibitionOFF: CCW drive permittedON: CCW drive prohibited- 44 -

<strong>Chapter</strong> 5 Wiring6* L-CW7* GETCW servodriveprohibitionsignalTarget-positionachieveoutputsignalTarget-speedachieveoutputsignal8* READY Drive ready foroutput signalNote 1: This signal isused in the event ofmechanical limit exceed.In the switch-ONcondition, motor torqueoutputs 0 in CCWdirection;Note 2:Youcan shieldthis signal via parameterSTA-8 or always keep theswitch "OFF".Input terminal of L-CW(clock wise direction) driveprohibitionOFF: CW drive is permittedON: CW drive is prohibitedNote 1:This signal is usedfor mechanical limitexceed. In the switch-ONcondition, motor torqueoutputs 0 in CWdirection;Note2:Youcan shield thissignal via parameterSTA-9 or always keep theswitch "OFF".Output terminal ofTarget-position-achieveIf the position deviationcounter value is within thepreset positioning area, thetarget-position-achieveterminal outputs signal"ON".Output terminal oftarget-speed-achieveWhen the target-speed isreached or exceeded, thisterminal outputs signal"On".Output terminal of drivereadySRDY ON: Power supplyis normal, no alarm occurs,and the drive is ready forthe output of signal "ON"SRDY OFF: No powersupply is available oralarm occurs, so the driveis ready for the output ofsignal "OFF".- 45 -

<strong>Chapter</strong> 5 Wiring9* ALM Drive alarmoutput signal10 ReservedOutput terminal of drivealarmALM OFF: When no drivealarm occurs, this terminalwill output "OFF".ALM ON: When drivealarm occurs, this terminalwill output "ON".11 Reserved12 AN+Analoginput positivesignal13 AN-Analoginput negativesignal14 CP+ Command pulse16 DIR+1715 CP-DIR-32 A+33 A-18 B+36 B-35 Z+input signal(PLUS mode)Command pulseinput signal(SIGN mode)Encoder A+phase outputsignalEncoder A-phase outputsignalEncoder B+phase outputsignalEncoder B-phase outputsignalEncoder Z+phase outputsignalAnalog input commandpositive.Connect with PCanalogue command outputterminalAnalog input commandnegative.Input terminal of externalcommand pulses.Note 1: Set pulse inputmode via parameterPA221 Command pulse +Sign mode.2 CCW/CW commandpulse mode.3 2-phase commandpulse mode.Servo motor encoder A+phase output terminalServo motor encoder A-phase output terminalServo motor encoder B+phase output terminalServo motor encoder B-phase output terminalServo motor encoder Z+phase output terminal- 46 -

<strong>Chapter</strong> 5 Wiring34 Z-3126 Reserved25 Reserved29 Reserved30 ReservedEncoder Z-phase outputsignalServo motor encoder Z-phase output terminal27,28 GN Analog signalground23,24 GD Mains output "-"signal21,22 Z Z pulse outputsignal19,20 COM Power inputsignal groundAnalog signal groundterminalControl circuit referencegroundEncoder Z pulse output toSiemens 801 SystemPower ground of the inputterminal.It is used to drive theoptoelectronic coupler ofthe input terminal.DC24V power ground,current ≥ 100 mA5.2.8 Encoder signal terminalsTable 5.6 Encoder signal terminalsTerminalTerminalSignalNo.MarkDesignation1 A+ Encoder A+ input2 A- Encoder A- input3 B+ Encoder B+ input4 B- Encoder B- input5 Z+ Encoder Z+ input6 Z- Encoder Z- input- 47 -DescriptionConnect with servomotor optical encoderA+Connect with servomotor photoelectricencoder A-Connect with servomotor photoelectricencoder B+Connect with servomotor photoelectricencoder B-Connect with servomotor photoelectricencoder Z+Connect with servomotor photoelectricencoder Z-

<strong>Chapter</strong> 5 Wiring7 U+ Encoder U+ input8 U- Encoder U- input9 V+ Encoder V+ input10 V- Encoder V- input11 W+ Encoder W+ input12 W- Encoder W- inputConnect with servomotor photoelectricencoder U+Connect with servomotor photoelectricencoder U-Connect with servomotor photoelectricencoder V+Connect with servomotor photoelectricencoder V-Connect with servomotor photoelectricencoder W+Connect with servomotor photoelectricencoder W-13 OH1 Thermal resistor Servo motor thermal26 OH2 Thermal resistor resistor output20, 21,2216, 17,18, 1923,24,255V2Encoder powerfeedback+5V Power output "+"GND Power output "-"14,15 PE Shielding layerEncoder powerfeedback, the servodrive automaticallyperforms voltagecompensationaccording to theencoder power.Servo motorphotoelectric encoderuses +5 V power;If the cable is long,you should usemultiple cables toconnect parallellyConnect with the servomotor external shellNote:1) Control signal terminals No.1 to No.6 are used to specify input terminalsignals. The details can be defined via parameterto. Table 5.5 shows the default definition of the terminal signal.2) Control signal terminals No. 7 to 9 are used to specify terminal outputsignals. The details can be defined via parameterto. Table 5.5 shows the default definition of the terminal signal.3) You can customize the Input/Output signal of the control signalterminals, either "low level access" or "high level access". If the- 48 -

<strong>Chapter</strong> 5 Wiringcorresponding PB parameter is positive, it indicates "low level access";If it is negative, it indicates " high level access". See 7.3 Expansionparameter mode for details.5.3 Interface circuit5.3.1 Switch value input interfaceFigure 5.10 Switch value input interfacePC device上 位 装 置Servo 伺 服 drive 驱 动 器+24V+24V2.7k 2.7k104GNDGND1) Power supply from servo drive internal is DC 24 V, current ≥ 100mA.2) Pin 19 and 20 pins of the control terminal should be duly connectedwith the PC 24 V ground.Note: Incorrect connection of 24 V ground will result in the abnormalfunction of the servo drive.5.3.2 Switch value output interface- 49 -

<strong>Chapter</strong> 5 WiringFigure 5.11 Switch value output interfacePC device 上 位 装 置Servo伺 drive 服 驱 动 器+24V20Ωmax50mA24VGA: Relay connectionPC device 上 位 装 置伺 服 驱 动 器Servo drive+5V+24Vmax50mA20ΩGND24VGB: Optoelectronic coupler connection1) The external power supply DC 24V should be provided by users. Note:If you invert the connection of power polarities, the servo drive could bedamaged.2) Output uses open collector circuit form. The max. current is 50 mA andthe external power supply is DC 24V. Therefore, switch value outputsignal load should observe the limit. Exceeding the limit or connectingthe output with the mains directly will result in damage of the servodrive.3) If you use relay like inductive load, the freewheeling diodes should beconnected with the load at both ends in inverted parallel. If thefreewheeling diodes connect reversely, the servo drive could bedamaged.5.3.3 Pulse array input interface- 50 -

<strong>Chapter</strong> 5 WiringFigure 5.12 Differential drive mode of pulse input interfacePC 上 device 位 装 置Servo伺 drive 服 驱 动 器CP+CP-100ΩΩ100ΩΩDIR+DIR-100ΩΩ100ΩΩFigure5.13 Single-ended drive mode of pulse input interfacePC上 位 装 置Servo 伺 服 drive 驱 动 器VCCCP+100ΩΩRCP-100ΩΩDIR+100ΩΩRDIR-100ΩΩ1) In order to send the pulse data correctly, it is suggested to selectdifferential drive mode for the input interface. (especially when thesignal wires are long).2) In the differential drive mode, use AM26LS31 or RS422 line to drive.3) Single-ended drive mode will lower the action frequency. As pulsesinput in the circuit, the drive current varies between 10 and 15 mA. Themax. external voltage supply should not be greater than 25 V, based on- 51 -

<strong>Chapter</strong> 5 Wiringwhich, we can calculate the value of the resistance.Data summarised via our experience (for your reference):VCC=24 V, R=1.3 to 2 kVCC=12V, R=510 to 820ΩVCC=5V, R=82 to 120Ω4) Adopt single-ended drive mode, the external power should be providedby the users. Note: If you invert the connection of power polarities, theservo drive could be damaged.5.3.4 Servo motor photoelectric encoder input interfaceFigure 5.14 Servo motor photoelectric encoder input interface+5V10K10KA+(B+、Z+ )+100Ω-A(B、Z)A-(B-、 Z-)5.3.5 Analog command input interfaceFigure 5.15 Analog command input interfacea: Analog differential input interfacePC上 位 装 置Servo drive伺 服 驱 动 器+-AN+AN-50K50K+-AN CMDGN10Kb: Analog single-ended input interface- 52 -

<strong>Chapter</strong> 5 WiringPC上 位 装 置Servo drive伺 服 驱 动 器+-AN+AN-50K50K+-AN CMDGN10K1) If the analog input interface adopts differential mode, weather to usedifferential input interface or single-ended input interface depends on theconnecting methods. The resistor is 765 KΩ and the input voltage supplyrange from -10 V to + 10 V or 0 V to + 10V.2) In the differential connection mode, the analog grounding wire and theinput terminal negative should be connected at the controller side.Besides, three wires are required for the connection of controller and theservo drive.3) In the single-ended mode, the analog grounding wire and the inputterminal negative should be connected at the controller side. Besides,two wires are required for the connection of the controller and the servodrive.4) Differential connection mode excels single-ended connection mode,since it can inhibit interference of common mode.5) The input voltage supply can not exceed the range: -10 V to +10 V,otherwise, the drive could be damaged.6) It is suggested to use shielding cables for connection in order to reducenoise interference.7) Existing of zero drift at the analog input interface is normal, but zerodrift compensation can be made via adjusting parameter PA8.8) The analog interface is not isolated (non-insulated).5.3.6 Analog command output interfaceFigure 5.16 Analog command output interface- 53 -

<strong>Chapter</strong> 5 Wiring5.3.7 Position feedback signal output interfaceFigure 5.17 Position feedback signal output interface (a)PC device上 位 装 置Servo drive伺 服 驱 动 器A+A-AB+B-BZ+Z-ZAM26LS32AM26LS31GNDFigure 5.18 Position feedback signal output interface (b)PC device上 位 装 置Servo drive伺 服 驱 动 器2 2 0 ΩA +IN 4 1 4 8A -A2 2 0 ΩB +IN 4 1 4 8B -B2 2 0 ΩZ+IN 4 1 4 8Z-Z6 N 1 3 7 A M 2 6 LS 3 1- 54 -

<strong>Chapter</strong> 5 Wiring1) Encoder position feedback signals output via differential driveAM26LS31.2) Controller input interface may use AM26LS32 receiver, which issupposed to be connected with the terminal resistor about 330Ω.3) The controller grounding wires should be reliably connected with theservo drive grounding wires.4) Non-isolated output.5) The controller input interface may also use photoelectric coupler forreceipt, however, it is supposed to be the high speed photoelectriccoupler like 6N137.5.3.8 Open collector output interface for the encoder Z-phase signal6) The encoder Z-phase signal outputs via open collector. When theencoder Z-phase signal arises, it outputs "ON" signal to conduct theaccess, otherwise, it outputs "OFF" signal to stop the access.7) Non-isolated output ( not insulated).8) In PC, the width of the Z-phase signal pulse is normally narrow,therefore, you should use high speed photoelectric coupler receiver like6N137.Figure 5.19 Open collector output interface for the encoder Z-phase signalPC device上 位 装 置Servo drive伺 服 驱 动 器+ 5Vmax 2 5 Vmax 5 0 mAZC O MZG N D- 55 -

<strong>Chapter</strong> 6 Operation and Display<strong>Chapter</strong> 6 Operation and Display6.1 Keypadoperation and display• Figure 6.1 shows the panel.Figure 6.1 HSV-160B + -010/020/030/50/075A AC Servo drive panelThe drive panel comprises 6 LED segment displays and 5 keys (,, , M,S), which are used to show various status of the system and parametersettings etc. Functions of the keys:M: Mode changing in the main menu categoryS: Entry of the submenu, or return, or input saving▲: Increase in serial number or value, or forward to the next option▼: Decrease in serial number or value, or back to the previous option: Replacement• After connecting the drive power, the 6 LED segment will appear on thedisplay.• Users are supposed to operate on the multi-level menus. The first-levelmenu is the main menu which includes five operation modes. In eachoperation mode, there's a function submenu. Figure 6.2 shows the mainmenu diagram:- 56 -

<strong>Chapter</strong> 6 Operation and DisplayFigure 6.2 HSV-160B + Series servo drive main menuStatus display modePressMMotion parameter modeExpansion parameter modeAuxiliary function modePress SPress SSubmenuStatus control mode• Press M to change the operation mode in the main menu. Via pressing,, you can enter the function submenu.• Select in the main menu, press ,to enter the displaymode. HSV-160B + AC servo drive has 19 displays (see table 6.1). Userscan select the required display usage via pressing ,and then press Sto observe the status information of the servo drive in the selecteddisplay mode. To quit the selected display mode, press S again; Toreturn to the main menu, press M.- 57 -

<strong>Chapter</strong> 6 Operation and DisplayFigure 6.3 Status monitoring mode menu and demonstrationsSPosition deviation: -634 pulsesActual speed: -463 r/minDisplay of motor torque (Unit:0.1%)Target position command pulses:1436875Actual feedback position pulses:1436875Position command inputfrequency: 75 KppsTarget speed command: -463r/minDisplay of motor current: 1.2 AAlarm code. "0": No alarmreported.Input interface statusOutput interface statusU-phase momentary currentfeedbackCurrent position of motormagnetic poleMotor absolute positionmechanical anglePumping braking load ratioSMotor actual load ratio in thepast 10s.Reserved- 58 -

<strong>Chapter</strong> 6 Operation and DisplayTable 6.1 Display modes listS.N.Segment DisplayDescription1 Display of position tracking error (Unit: pulse)2 Display of actual speed (Unit: 1r/min)3 Display of motor torque (Unit: 0.1%)4 Display of position specified 4 bits (low)5 Display of position specified 4 bits (high)6 Display of position feedback 4 bits (low);7 Display of position feedback 4 bits (high)Display of position command input frequency:8(Unit: 0.1 Kpps);9 Display of speed command (Unit: r /min);10 Display of motor current (Unit:0.1A);11 Display of alarm interface status;12 Display of input interface status;13 Display of output interface status;14Display of U-phase current feedback (Unit: digital,"32767" indicates the max. positive current);15 Display of motor magnetic pole position;16Display of motor absolute position mechanicalangle;17 Display of pumping braking load ratio (Unit: %)18Display of motor actual load ratio in the past 10s(Unit: %)19 ReservedNote:1) When the motor operates in the clockwise direction (reverse),displays decimal; when the motor operates in the counterclockwise direction,displays integer.2) If the display of increases 10000, then the display of- 59 -

<strong>Chapter</strong> 6 Operation and Displaywill increase 1.3) If the display of increases 10000, then the display ofwill increase 1.4) displays the command frequency, unit: 0.1 KPPS. Forexample, the century star triggers pulses, displays 840,value can be calculated by the following formula:(840 × 0.1 × 1000 × 60) / 10000 = 840 × 0.1 × 6 = 84 × 6 = 5045) displays speed command, unit: r/min. For example,=100, will display 10 (when = 0).6) displays hardware alarm interface status. When the lamp(alarm indicator) on the panel is red, it means a servo drive hardwarealarm is reported. Alarms can be reported via this monitoring display, forexample . After trouble shooting and fault clearance, theservo drive system can be recovered via alarm reset function in theauxiliary mode or servo drive powerdown recovery.7) displays the input interface status. It shows the input voltagesituations of the 6 pins, DIN1 to DIN6. For example, if the DIN1 inputvoltage value = 24v (the input optical coupler is disconnect), thecorresponding segment displays lower parts blink; If the input voltagevalue = 0v( the input optical coupler is connected), the correspondingsegment displays upper parts blink.- 60 -

<strong>Chapter</strong> 6 Operation and DisplayFigure 6.4 Indication of the input interface statusBits:Note:Statushigh level(1): lowerpart blinks;low level(0): upperpart blinks• High level (1) indicates the voltage value with which the optical couplercannot be connected. Generally, it is 24v;• Low level (0) indicates the voltage value with which the optical couplercan be connected. Generally, it is 0v;• Input of which voltage value can effect the function depends on thevalue of the 6 parameters, to . If the parameterset values are positive, the function effects when input 0v; If the setparameter set values are negative, the function effects when input 24v.As for DIN1 to DIN6 represent which function, it depends on theabsolute values of the parameters to .8) indicates output interface status. When the correspondingoutput function performs, the upper part of the digital segment displays.Input of which voltage can effect the function depends on the pos. or neg.of the set values of the parameters PB21 to PB23.- 61 -

<strong>Chapter</strong> 6 Operation and DisplayFigure 6.5 Indication of input interface statusBits:9) displays motor magnetic pole position. When the motoroperates counter clockwise at low speed, it blinks 3-1-5-4-6-2 sequentialnumbers in turn; when the motor operates clockwise at low speed, itblinks 2-6-4-5-1-3 invert sequential numbers in turn.• You can select in the main menu, and then press , toenter the motion parameter mode. HSV-160B + AC servo drive has intotal 44 motion parameters.StatusFigure 6.6 Motion parameter mode menuON: upper part blinks;OFF: lower part blinksPresspress M• Select parameter in the motion parameters and set itsvalue to , and then you may enter expansion parameter mode.HSV-160B + AC servo drive has 28 expansion parameters (including 2reserved parameters).- 62 -

<strong>Chapter</strong> 6 Operation and DisplayFigure 6.7 I/O parameter setting mode menuPressPress M• You can select in the main menu, and then press , toenter the auxiliary mode. HSV-160B + has 7 auxiliary operation functions,see Table 6.2)Figure 6.8 Auxiliary operation mode menuPressPress MTable 6.2 Auxiliary mode listDisplayModeControl parametersavingJOG operationmodeAlarm reset modeFunctionSave the preset drive controlparameters to EEPROMDrive and motor operate at the presetspeed in the JOG modeDrive reset, clear the history faults- 63 -

<strong>Chapter</strong> 6 Operation and DisplayInternal testingmodeParameter defaultsrecoveryCalibrate theencoder 0 positionParameterautotuningDrive internal open loop testing(Note: This mode is not applicable tolong time operation)All PA parameters reset to factorydefault valuesCalibrate the motor encoder 0positionAutotuning drive parameters to matchwith the motor load inertia• You can select in the main menu, and then press, toenter the control parameter mode. HSV-160B + AC servo drive has 16control parameters including 6 reserved parameters.Figure 6.9 Control parameter mode menuPressPress M• 6-bit LED segment displays various status and datum of the servo drivesystem. When "A" appears at the first bit, it indicates an alarm isreported, and the rest segment indicates the alarm number.Figure 6.7 Alarm display• After trouble shooting and fault clearance, the servo drive system can berecovered via alarm reset function in the auxiliary mode or servo drivepowerdown recovery.6.2 Parameter managementAttention• After parameter revision, you should select "EE-WRI" in theauxiliary mode, and then press S to activate the revised parameter.• Parameter setting takes effect immediately, so wrong setting could- 64 -

<strong>Chapter</strong> 6 Operation and Displayresult in unexpected actions of the device or even accidents.6.2.1. Parameter change and saving1) Motor and drive code & expansion parameter changing and savingTo change the paramterand the expansion parameters fromto , select in the first layer, and thenpress , to select. Press S, the parameter value is displayed.Press , to change the parameter value. Pressing or once, theparameter value changes 1; Keep pressing or , the parameter valuechanges continuously. Press , the modifying position moves one bit left(left cycle). When you change the parameter, the LED display right enddecimal point is bright. If you set = , you can changethe value of the parametervia operating ditto. Press M to switch toexpansion parameter , and you can modify expansion parametersvia operating ditto; Otherwise, press S to return to parameter selection menuwithout effecting. To save the parameter modification or setting, first youneed to input the password to the parameter , andthen press M to switch tomode. Press S to save themodification or set value to the drive EEPROM. After saving complete, thesegment displays ; Or if it fails, the segment displays .Press M, you can switch to other modes; Or press , to change the motionparameters.2) Modifying and saving motion parametersTo modify and save the control parameters: to ,to , to , and control statusparameter to . First, select in the first layer,press , to select the parameter number. Press S to view the parametervalue. Press、 to change the parameter value. Press or once, the- 65 -

<strong>Chapter</strong> 6 Operation and Displayparameter value changes 1; Keep pressing or , the parameter valuechanges continuously. Press , the modifiying position moves one bit left(left cycle). When you change the parameter, the LED display right enddecimal point is bright. And then you can change the parameter via operatingditto. Press S to return to the parameter selection menu without effecting. Tosave the parameter modification or setting, first you need to input thepassword to the parameter , and then press M toswitch tomode. Press S to save the modification or set value tothe drive EEPROM. After saving complete, the segment displays ;Or if it fails, the segment displays . Press M, you can switch toother modes; Or press , to change the motion parameters.6.2.2. Parameter recoveryPress M to switch to mode, select in the first layer,and press , to select the parameter. Press S, the segmentdisplays .The parameter recovery is completed. However, it takeseffect only after saving. Press S again, and then press M to switch to. Press or to select the parameter, and set or change its value.Press S to return to the parameter without effecting.To save the parameter modification or setting, first you need to input thepassword to the parameter , and then press M toswitch tomode. Press S to save the modification or set value tothe drive EEPROM. After saving complete, the segment displays .Parameter recovery saving is complete. Reconnect the power supply afterpowerdown, the parameters will recover to defaults. If the saving fails, thesegment displays. Parameter recovery saving fails. Reconnectthe power supply after powerdown, the parameters can not recover todefaults.Parameter defaults depend on the servo motor brands selected. Now we use- 66 -

<strong>Chapter</strong> 6 Operation and DisplayHuada servo motors and Golden servo motors. The servo motor brand can betold via the kilobit value of the parameter. If you use Huadaservo motors, the parameters recover to Huada motor parameter defaults; Ifyou use Golden servo motors, the parameters recover to Golden motorparameter defaults.- 67 -

<strong>Chapter</strong> 7 Parameter Setting<strong>Chapter</strong> 7 Parameter SettingAttention• The technical persons who attend parameter adjustment shouldunderstand the indications of the parameters. Wrong setting couldresult in damages and/or injuries.• Suggestion: After parameter adjustment, first carry out the free-loadtest run of the motor.7.1 Function menuHSV-160 B + has various parameters, with which you can adjust or set thedrive performance and functions. In this chapter, it describes the usages andfunctions of various parameters. It is crucial to master the optimal use of theparameters and the operation of the drive.HSV-160B + parameters can be divided into three categories: First, motionparameters; Second, expansion parameters; Third, control parameters. Thesethree categories respectively corresponding to the three parameter modes,namely, motion parameter mode, expansion parameter mode and controlparameter mode. And the parameters can be checked, set and adjusted viadrive panel keys or computer serial ports.Table 7.1 Explanation of parameter categorizingCategoryDisplayParameterNo.Motionparameter0 to 43modeExpansionparameter0 to 23modeControlparameter0 to 15modeBriefDescriptionYou can ajust various characteristics,set control operation methods andmotor related parameters.You can set the second gain, thethird gain, and the I/O interfacefunction etc.You can select alarm shieldingfunction or selection methods ofinternal control function etc.7.2 Motion parameter modeHSV-160 B + type servo drive has 44 motion parameters (thereof, 1 is- 68 -

<strong>Chapter</strong> 7 Parameter Settingreserved). The definitions are as follows:• Table 7.2 shows the drive factory defaults when it is in combination withGolden Age motor GK 6060-6 (3 Nm, 2000 rpm). If combined withother motor type, the usage and value of the parameters marked with "*"may be different.• In the column "control modes applicable": "P" stands for positioncontrol mode; "S" stands for speed control mode; "T" stands for torquecontrol mode.Table 7.2 Motion parameter listParameterNo.0123456789Name of theParameterPositionloopproportionalgainPositionloopfeedforwardgainVelocityloopproportionalgainVelocityloopintegral timeconstantVelocityfeedback filterfactorMax. torqueoutput valueAccelerationtime constantVelocitycommand inputgainVelocitycommand zerodriftcompensationTorquecommand inputgainControlmodesapplicable- 69 -RangeofparametervalueFactorydefaultsUnitP 20 to 10000 400* 0.1HzPP, S0 to150200 to200000 %2500*P, S 5 to 500 20* msP, S 0 to 7 0P, S, T 30 to 500 250 1%P, S 1 to 32000 200 msS 1 to 9000 2000S-1023to 1023T 1 to 300 200 1%0

<strong>Chapter</strong> 7 Parameter Setting10111213Torquecommand zerodriftcompensationRangeof positioningcompletionRange ofpositioningout-of-tolerancePositioncommand pulsenumeratorfrequencyT-1023 to1023P 0 to 32767 20 PulseP 1 to 32767 20000 PulseP 1 to 32767 101415161718Positioncommand pulsedenominatorfrequencyMax. torqueoutput value inthe positivedirectionMax. torqueoutput value inthe negativedirectionMax.velocity limitSystemoverload torquesettingP 1 to 32767 1P, S, T 0 to 500 250 1%P, S, T -500 to 0 -250 1%P, S, T100 to120002500 1 r/minP, S, T 10 to 120 120 0.1 %19Softwareovertemperaturetime setting20 Internal speed S212223JOG modeoperationP, S 40 to 32000 4000 1 ms-32000 to32000P, S 0 to 2000 300Positioncommandpulse inputP 0 to 2 1method 5)Control methodselection 4) P, S, T 0 to 3 00 0.1 r/min1r/min- 70 -

<strong>Chapter</strong> 7 Parameter Setting24252627282930Servomotor magneticpolelogarithm 3) P, S, T 1 to 4 3Encoder2)resolutionP, S, T 0 to 3 2Encoderzero positionoffset 1)CurrentcontrolproportionalgainCurrentcontrol integraltimeThe secondpositioncommand pulsenumeratorfrequencyThe thirdpositioncommand pulsenumeratorfrequency31 Reserved3233Torquecommand filtertime constantPositionfeedforwardfilter timeconstantP, S, T-32767 to32767P, S 10 to 32767 2500150 PulseP, S 1 to 2047 45 0.1 ms/unitP 1 to 32767 1P 1 to 32767 1P, S 0 to 500 1 0.1 msP, S 0 to 3000 0 1 ms34Softwareversion/user'spasswordP, S 0 to 2806 1001. Passwordfor modifyingexpansionparameters ormotor relatedparameters:2003.2. Passwordforparametersaving:1230.35Positioncommand forsmoothingfiltertimeP 0 to 3000 0 1 ms- 71 -

<strong>Chapter</strong> 7 Parameter Setting36Communicationbaud rate- 72 -0 to 3 237 Axis address P, S 1 to 15 13839404142Decelerationtime constantThe fourthpositioncommand pulsenumeratorfrequncyBrake outputdelayVelocitythresholdallowed forbrake outputRange oftarget-speedachieve43 Drive type code P, SS 1 to 32000 200 msP 1 to 32767 1P, S 10 to 2000 200 Unit: msP, S 10 to 300 100P, S 1 to 500 101000 to25502206Unit:1rpmUnit:1rpmKilobit: "1"indicates"Huadamotor";"2"indicates"Golen Agemotor";Hundred bit:"0" = 10A"1" = 20A"2" = 30A"3" = 50A"4" = 75A"5" = 100Atens placeand unitsorderindicate themotor type.Note:To enable the parameters marked with 1), 2), 3), 4), 5) after changing, youshould save the changes first and then restart. To enable other parameters,you can direct make changes on-line. However, the changes can not beautomatically saved.7.2.1 Elaborate on motion parameterTable 7.3 Parameter function listRangeS.NParameterFunctionDefaultof the.Nameparameter0Position loopproportionalgain1 Set position controller proportional gains2 The gain and rigidity increase as the set40020 to10000Unit:

<strong>Chapter</strong> 7 Parameter Setting12345Position loopfeedforwardgainVelocity loopproportionalgainVelocity loopintegral timeconstantSpeedfeedback filterfactorMax. outputtorquepercentagesettingvalue increases, and in the same frequencycommand pulse condition, the position lag isless. But if the set value is too great, theoscillation or overshooting may arise.3Parameter values depend on the drive typeand load conditions.1Set position loop feedforward gain.2When set 100%, it indicates the position lagis zero in any command pulse frequencycondition.3As the position loop feedforward gainincreases, the position controller responsespeed enhances, but the oscillation may occureasily.4When no fast response characteristic isrequired, the parameter value is normally set to0.1Set the velocity controller proportional gain.2The gain and rigidity increase as the setvalue increases. The parameter values dependon the drive system type and load conditions. Ingeneral, the set value should increase as theload inertia increases.3Set a great value as possible, provided nooscillation of the system occurs.1Set velocity controller integral time constant.2The integral speed increases as the set valuedecreases. The parameter values depend on thedrive system type and load conditions. Ingeneral, the set value should increase as theload inertia increases.3Set a small value as possible, provided nooscillation of the system occurs.1Set speed feedback low pass characteristic.2As the set value increases, the cut-offfrequency lowers, and the motor noisedecreases. If the load inertia is great, the setvalue can be duly reduced. If the set value istoo great, the response slows down and theoscillation could arise.3As the set value reduces, the cut-offfrequency increases, and the response speedenhances. If high speed response is required,the set value can be duly reduced.1Set the internal torque limit of the servomotor.2The set value is the max. permissiblenominal input current of the motor.3Whensoever, the limit is valid.4"30 to 500" indicates the set range: 30 % to500 % of the drive's max. output current.Max. output torque = IRmotor*PA5Thereof, IRmotor indicates the motor nominalcurrent (expansion parameter PB24). Ingeneral, you can select Max. output current =3*IR. Unit of parameter PA5: 1%.02000050.1 Hz0 to 150indicatesthe range0 to 150 %200 to200005 to 500mS0 0 to 930030to 500- 73 -

<strong>Chapter</strong> 7 Parameter Setting6789101112Accelerationtime constantVelocitycommandinput gainVelocitycommand zerodriftcompensationTorquecommandinput gainTorquecommandzero driftcompensationRange ofpositioningcompletionPositioningdeviationout-of-tolerancedetection range1The set value indicates the acceleration timerequired by the motor to speed up from 0 to2000 r/min.2The characteristic of acceleration anddeceleration is linear.1Set the relation between analog speedcommand voltage and rotary speed.The set value indicates the correspondingrotary speed when the voltage supply is +10V.(Unit: 1 r/min)2It is available only under analog speed inputmode.In the analog speed control mode, via thisparameter, you can adjust the analog speedcommand input zero drift. Adjusting methodsare as follows:1 Shorting the analog control input terminaland the signal ground terminal.2Set the parameter value to stop the motor.1Set the relation between analog torquecommand voltage and the torque. The set valueindicates the corresponding torque when thevoltage supply is +10 V.2It is available only in the analog torque inputmode.3"0 to 300" indicates the range: 0 to 300% ofthe drive's max. ouput current.In the torque control mode, use this parameterto adjust the analog torque command input zerodrift. The adjusting methods are as follows:1Shorting the analog control input terminaland the signal ground terminal.2Set this parameter value to stop the motor.1Set pulse range of positioning completion inthe position control mode.2This parameter provides a basis for the driveto judge whether positioning is completed ornot in the position control mode. If theremaining pulse quantity displays on theposition deviation counter is not greater thanthe set value, the drive takes it as positioningcompleted. The positioning complete switchoutputs signal "ON"; Otherwise, it outputssignal "OFF".3In the position control mode, it outputspositioning completion signal.1Set the positioning deviationout-of-tolerance.2In the position control mode, if the display ofthe positioning deviation counter excelled thisparameter value, the alarm of positioningdeviation out-of-tolerance is reported.200 1 to 32000 ms2000 0 to 90000-1023 to1023200 10 to 30002020000-1024 to10230 to 30000Pulses1 to 32767Pulses- 74 -

<strong>Chapter</strong> 7 Parameter Setting13Positioncommandpulsenumeratorfrequency1Set the position command pulsefractional-octave-band. (electronic gear)2In the position control mode, via setting theparameter No.13 and No. 14, the device can bematched with various pulse types, and theoptimal control resolution (angle/pulses) can beachieved.3 P×G=N×C×4P: Input command pulses;G: Electronic gear ratioG= Frequency division numerator/ frequencydivision denominatorN: Number of turns of the motorC: Photoelectricity encoder winding/round,for this systemC=25004 For example, if the input command pulse is6000, the servo motor rotates per revolution.Set the value of parameter No.13 = 5, and No.14 = 3.1 1 to 32767141516PositioncommandpulsedenominatorfrequencyCCW torquelimitCW torquelimitN×C×4 1×2500×4 5G== =P 6000 35The recommended range for the electronicgear ratio should be:1≤ G ≤ 50501 See the parameter No. 13 1 1 to 327671Set the internal torque limit of the servomotor in the CW direction.2The set value is the max. input current of theservo motor.3If the set value excels the max. output torquepermitted by the system, the actual torque limitshould be the max. output torque permitted bythe system.4"0 to 500" corresponds to the range "0 to500%" of the drive max. output current in thepositive direction.CCW torque max. output current =IRmotor*PA15Thereof, IRmotor indicates the motor nominalcurrent (expansion parameter PB24). In general,the max. output current in the pos. direction = 3 *IRmotor. The unit of the PA15 is 1%.250 0 to 5001 Set the internal torque limit of the servomotor in the CW direction.2 The set value is the max. input current ofthe servo motor.3.If the set value excels the max. outputtorque permitted by the system, the actualtorque limit should be the max. output torque-250 -500 to 0permitted by the system.4"-500 to 0" corresponds to the range:"-500%to 0" of the max. output current of the servodrive in the negative direction.CW torque max. output current = IRmotor *- 75 -

<strong>Chapter</strong> 7 Parameter Setting171819Max. speedlimitOverloadtoleranceSoftwareoverload timesetting20 Internal speed212223JOG operationspeedPositioncommandpulse inputmethodControl modesselectionPA16Thereof, IRmotor indicates the motor nominalcurrent. In general, the max. output current inthe neg. direction = 3 * motor nominal current.1 Set the max. speed limit of the servo motor.2 Regardless of the rotatory direction.3 If the set value is greater than the nominalrotatory speed, the nominal rotary speed will betaken as the actual max. speed limit.Unit: 1 r/min1Set the servo motor torque value for overloadprotection.2The set value indicates the long-timeoverload input current permitted by the motor.3Whensoever, this limit is valid.4The set value is the motor nominal torquepercentage.Motor max. output torque = IRmotor * PA 18Thereof, IRmotor indicates the nominal currentof the motor. In general, motor max. outputtorque = 2 * motor nominal current. Unit of PA18is 1%.1Set the permissible overload time by thesystem.2The set value indicates the quantity counted inone time unit, and the unit of the value is 1 ms,i.e.: the set value=1000, it indicates that overloadtime permissible is 1s.3Whensoever, this limit is applicable.1 Internal speed setting.2 In the internal speed control mode, select theinternal speed as the speed command.Unit: 0.1 r min1 Set the operation speed in the JOG mode2 Unit: 1 r/min1Set the form of the position command inputpulse.2Select one of the 3 input methods viaparameter setting:0: 2-phase orthogonal pulse input1: Pulse + direction (P or N)2: CCW pulses/CW pulses3 Looking from the axial direction of themotor, CCW is defined as positive direction;4 Looking from the axial direction of themotor, CW is defined as negative direction.Use this parameter to select the control mode ofthe servo drive:"0" indicates position control mode. In thismode, the drive can receive position pulse inputcommand;"1" indicates analog speed control mode. In thismode, the drive can receive analog speedcommand;"2" indicates analog torque control mode. Inthis mode, the drive can receive analog torquecommand;"3" indicates internal speed control mode. Inthis mode, set the digital speed command via2500100 to12000200 10 to 2004000040 to32000-32000 to32000300 0 to 20001 0 to 20 0 to 3- 76 -

<strong>Chapter</strong> 7 Parameter SettingParameter 20.24252627282930Motormagnetic polelogarithmEncoderresolutionEncoder zeroposition offsetCurrentcontrol loopproportionalgainCurrentcontrol loopintegral timeThe secondpositioncommandpulsenumeratorfrequencyThe thirdpositioncommandpulsenumeratorfrequencySet the motor magnetic pole logarithm:1: the magnetic pole logarithm of the servomotor is 1;2: the magnetic pole logarithm of the servomotor is 2;3: the magnetic pole logarithm of the servomotor is 3;4: the magnetic pole logarithm of the servomotor is 4.Set the motor photoelectricity windings:0 indicates the encoder resolution is 1024pulse/r;1 indicates the encoder ;resolution is 2000 pulse/r2 indicates the encoder resolution is 2500pulse/r;3 indicates the encoder resolution is 6000pulse/r.Set encoder zero position offset:For Golden age motor, the set value is 150For Huada motor, the set value is -1650"-32767 to 32767" correspond to the anglerange "-180 to 180".1Set the current control loop proportionalgain.2If the current noise is too big whilst themotor operation, the set value can be dulyreduced.3If the set value is too small, the speedresponse could lag behind.1Set the current control loop integral time.2If the current noise is too big whilst themotor operation, the set value could be dulyincreased.3If the set value is too big, the speed responsecould lag behind.Set the second position command pulsenumerator frequency.Set the third position command pulsenumerator frequency.4 1 to 42 0 to 3150250004511-32767 to3276710to 327671to20471to327671to3276731 Reserved32Torquecommandfilter timeconstant1Set the filter time constant in the torquecommand mode2As the time constant decreases, the responsespeed of the controller increases, but it couldresult in instability and oscillation of thesystem.3If low response characteristic is not required,00 to 255indicatesthe range 0to 25.5ms- 77 -

<strong>Chapter</strong> 7 Parameter Settingthis parameter value is normally set to 0.33343536Position loopfeedforwardfilter timeconstantSoftwareversion/user'spasswordPositioncommandsmoothingfilter timeCommunicationbaud rate1Set the filter time constant of the positionloop feedforward.2As the time constant decreases, the responsespeed of the controller increases, but it couldresult in instability and oscillation of thesystem.3If low response characteristic is not required,this parameter value is normally set to 4.Display of default software version;For parameter saving, the password is 1230For checking and changing PB expansionparameters and the servo motor type, thepassword is 20031Set the filter time constant in the positioncommand mode.2As the filter time constant decreases,response speed of the controller increases.3As the filter time constant increases,response speed of the controller slows down.Set the communication baud rate:0: 2400 bps1: 4800 bps2: 9600 bps3: 19200 bps010000 to 255indicatesthe range 0to 25.5ms0 to28060 to30002 0 to 337 Axis address Set the axis address 1 1 to 153839Decelerationtime constantThe fourthpositioncommandpulsenumeratorfrequency1The set value indicates the deceleration timerequired by the motor to reduce the speed from2000 to 0 r/min.2The characteristic of acceleration anddeceleration is linear.Set the fourth position command pulsenumerator frequency.20011 to 32000ms1to3276740Brake outputdelayOutput brake time delay after the drive shutdown.20010 to2000ms4142Speedthresholdpermitted forbrake outputRange oftarget-speedachieveBrake activates when the actual value is underthe set value.1Set the target speed.2In the speed control mode, if the actualmotor speed is lower than the set value, thetarget-speed-achieve switch outputs signal"On"; Otherwise, it outputs signal "OFF".3In the position control mode, this parameteris invalid.4This parameter is regardless of rotarydirection.Unit: 1 r/min1001010to300rpm1 to 500rpm- 78 -