Best Practices for Maintenance of Transmission Lines

Best Practices for Maintenance of Transmission Lines

Best Practices for Maintenance of Transmission Lines

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

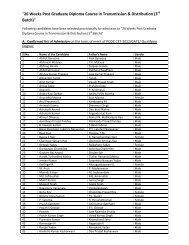

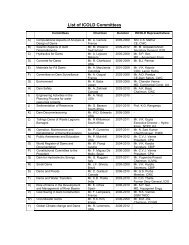

Report <strong>of</strong> the Interactive workshop on“<strong>Best</strong> <strong>Practices</strong> <strong>for</strong> <strong>Maintenance</strong> <strong>of</strong> <strong>Transmission</strong> <strong>Lines</strong>”29-30 June 2010, at CBIP New DelhiThe committee <strong>for</strong> CIGRE India and Central Board <strong>of</strong> Irrigation & Power Organised two days Interactive workshopon “<strong>Best</strong> <strong>Practices</strong> <strong>for</strong> <strong>Maintenance</strong> <strong>of</strong> <strong>Transmission</strong> <strong>Lines</strong>” on 29 -30th June 2010 in the Conference Hall <strong>of</strong> CentralBoard <strong>of</strong> Irrigation & Power, Malcha Marg, New Delhi.From L-R - Shri V.K. Kanjlia, Secretary, CBIP, Mr. Benoit, GroupeSICAME (CATU), Shri R.N. Nayak, Director (Opn.), PowergridShri S.K. Negi, MD, GETCO, Shri L.N. Agrawal, Sr. VP, IndiabullsThe workshop was organized with the aim to interact & discuss the best practices <strong>for</strong> maintenance <strong>of</strong> transmissionlines amongst the Power Utilities/ Corporations, SEBS, State Govts., IPPs, Energy Planners, Private Entrepreneurs,Developers, Manufacturers, Consultants, Construction Companies, Industry Associations, Technical, Financialand Training Institutions etc.Shri R.N. Nayak, Director(Operation), Power GridCorporation <strong>of</strong> India Limited andShri S.K. Negi, MD, GETCO werethe guest <strong>of</strong> Honor and addressedthe participants during Openingsession <strong>of</strong> the workshop.Shri R.N. Nayak, Director (Opn.),POWERGRIDShri S.K. Negi, MD, GETCOShri V.K. Kanjlia, Secretary,CBIP delivered welcomeaddress and Vote <strong>of</strong> thankswas proposed by Shri P.P.Wahi, Director, CBIPShri V.K. Kanjlia, Secretary, CBIPShri P.P. Wahi, Director, CBIPShri L.N. Agrawal, Sr. VP, IndiabullsMr. L.N. Agrawal, Sr. VicePresident India Bulls and Mr.Benoit,Manager,GroupeSICAME (CATU) alsoaddressed the participantsduring Opening session.Mr. Benoit, Manager, GroupeSICAME(CATU)

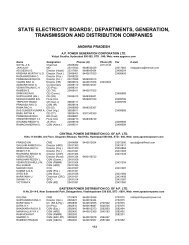

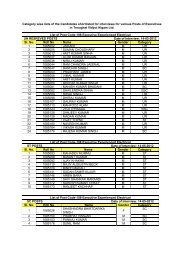

TOPICS covered in the workshop are: <strong>Maintenance</strong> procedures <strong>of</strong> EHV transmission<strong>Lines</strong> Probable causes <strong>of</strong> failure <strong>of</strong> the transmission linecomponents Condition monitoring <strong>of</strong> EHV transmission lines Counter measures <strong>for</strong> pollution Insulator- washing/cleaning Emergency restoration <strong>of</strong> damaged transmissionlines Helicopter maintenance techniques Composite / Polymer insulators Hot- line maintenance Preventive maintenance schedules <strong>of</strong><strong>Transmission</strong> <strong>Lines</strong> Case studiesFACULTY who delivered lecture are: Mr. S.K. Negi, MD, GETCO Mr. L.N. Agrawal, Sr. VP, IndiaBulls Mr. Rajeev Kumar , CM(OS), POWERGRID Mr. Gopal Ji , AGM(Engg.), POWERGRID Mr. Benoit, Manager, GroupeSICAME (CATU) Mr. Bhavesh Makwana, Director, Madhav EngineersPvt. Ltd. Mr. Rajesh Kumar, GM(Engg.), POWERGRID Mr. Rajiv Gandhi, CM(Engg.), POWERGRID Mr. V.K.Khare,GM(O&M), POWERGRID Mr. R.B. Singh, AGM(OS), POWERGRID Mr. Krishna Vaidya, Executive Director, TaurusTechnologies Mr. Rajeev Mathur, PCI Ltd. Mr. A. Natrajan, General Manager, WS Industries (I)Ltd.Shri Rajesh Kumar, General Manager(Engineering), Power Grid and NationalRepresentative in CIGRE Study Committee B2 onOver Head <strong>Lines</strong> is sitting in the audienceView <strong>of</strong> audienceReport on the Proceeding <strong>of</strong> workshop by Reporteur Shri Anil Sinha, ConsultantThe workshop was divided in to one inaugural and six technical sessions, spread over two days. The inaugural sessionsaw many dignitaries grace the dais. The list included: Mr R N Naik, Director, PGCIL, Mr S K Negi, MD, GETCO, Mr L NAgrawal, Sr VP, India Bulls, Mr Benoit, Area Mgr, CATU and Mr V K Kanjlia, Secretary, CBIP. Mr P P Wahi, Director,CBIP, conducted the workshop.Mr Kanjlia initiated the topic and in<strong>for</strong>med that the current inter-regional transmission capacity is around 38000 MW, thecountry is adding 765 kV lines, along with HVDC links. He put emphasis on proper maintenance practices <strong>for</strong> the countryto reap full benefit <strong>of</strong> the available infrastructure. Mr Agrawal advocated revision <strong>of</strong> the available CBIP manual on<strong>Transmission</strong> Line <strong>Maintenance</strong>. Among other topics, the manual should cover Disaster Management. He advised that thefeedback from the O&M engineers should be one important input <strong>for</strong> Design Engineering <strong>of</strong> <strong>Transmission</strong> <strong>Lines</strong>.Thereapart, the manual should now cover the newer 765 kV & HVDC lines, as well. He recalled his association with thewriting <strong>of</strong> the current version <strong>of</strong> the manual and advised chapter-wise revision. In his view, we should consider theexample <strong>of</strong> other nations to calculate availability figure.Mr Benoit emphatically drew the attention towards safety and safe practices during maintenance. Mr Naik reminded theparticipants <strong>of</strong> approximately 80000 route-km <strong>of</strong> transmission lines being added in the next 3 to 4 years. The countryalready has lines <strong>of</strong> voltage ranging from 66 kV to 765 kV, with 1200 kV in planning. We also have HVDC line up to 800kV. Among the common issues narrated by him were, Erosion <strong>of</strong> tower legs, Theft <strong>of</strong> metal, Pollution, etc. He drew theattention <strong>of</strong> the workshop towards the need <strong>for</strong> innovative maintenance practices to take care <strong>of</strong> the huge installed base.PGCIL has been considering novel methods, which included even the use <strong>of</strong> Aircrafts, Helicopters and UnmannedDrones. Of these, the use <strong>of</strong> helicopter has been found feasible. PGCIL has been undertaking hotline maintenance,resulting in 99.97% availability <strong>of</strong> the lines. Mr Naik suggested Vegetation management around the lines, Thermographyto detect hot-spots, Measures to reduce Insulator failures, and the use <strong>of</strong> robots <strong>for</strong> maintenance activity in future.Mr Negi took pride in in<strong>for</strong>ming the gathering <strong>of</strong> the present good power scenario in Gujrat. The state provides 24x7, nobreaksupply, whereby, residents do not need Voltage Stabilisers or Inverters. Among the locational issues, he spoke <strong>of</strong>the long coast line and wide-spread marshes, supplementing the industrial pollution and fog. Gujrat is also prone to

Cyclones and other detrimental weather phenomena. So maintenance <strong>of</strong> transmission lines is particularly important inGujrat. He pointed out that good maintenance starts at good design practice, and expects good execution. Thereafter, oneis required to consider Temperature variation, Pollution and Water-logging, among other issues.Mr Agrawal started the technical session with an ‘Overview <strong>of</strong> best maintenance practices’. Considering the fact that he isa major contributor to the CBIP maintenance manual on transmission lines, his considered views on the topic were verywell received by the participants. Mr Agrawal in<strong>for</strong>med that even a de-energised line has 1 to 5 kV induced voltage. Hencecare must be exercised. He advised the use <strong>of</strong> modern techniques, e.g., Thermegraphy, and Corona camera. Any contactjoint, including mid-span joints, should have less than 5 Ω resistance. If the resistance is over 30Ω, a hot spot willdevelop. On the issue <strong>of</strong> Hotline washing, the outer two limbs are aminable to helicopter based washing, but the middleline washing is difficult. There is an ever-present danger <strong>of</strong> Earth-line fouling. Other issues to keep in mind are: the size <strong>of</strong>the fuel-tank and the water tank, proximity <strong>of</strong> a helipad, etc. In his opinion the use <strong>of</strong> de-miniralised water is not requiredas the helicopter is not grounded. Mr Agrawal referred to hot-line maintenance <strong>of</strong> 400 kV and above lines. The twomethods suggested were: Bare-hand method & Hot-stick method. In the case <strong>of</strong> de-energised circuit <strong>of</strong> a double circuitline, with the other circuit live, the important aspects are: the use <strong>of</strong> portable earthing, creation <strong>of</strong> equi-potential zone,removal <strong>of</strong> line reactors. The tower earthing is expected to be good. Along with maintenance, other activities, e.g.,Conductor repair, jointing, insulator replacement, etc may also be undertaken at the same time.Mr Rajeev Kumar, Ch. Manager, PGCIL gave an illuminating presentation on ‘Helicopter <strong>Maintenance</strong> Techniques’. Healso advised that cleaning <strong>of</strong> the transmission line is imperative to keep up the per<strong>for</strong>mance level. The more prevelentpollutants affecting a line are:IndustrialVehicularOpen burning <strong>of</strong> agriculture wasteBird droppingsPresence <strong>of</strong> moisture aids the settling <strong>of</strong> the pollutant on the line and insulators. There<strong>for</strong>e the foggy winter days are bad<strong>for</strong> the line. Manual cleaning <strong>of</strong> the line is feasible, but generally requires a shutdown. The persons undertaking the jobmust be highly skilled. But it does give better results compared to the helicopter based method, which is also muchcostlier. A helicopter uses up around 100 liters <strong>of</strong> de-minaralised water per tower and can clean 3 to 4 towers per trip. Thearial cleaning requires DGCA clearance and every trip needs ATC permission. The helicopter has maintain very strictclearances, making it a highly skilled job. To date, no Indian pilot has undertaken this work.Settling <strong>of</strong> pollutant on the insulators can be reduced by the use <strong>of</strong> polymer type insulators. To a question, Mr RajeevKumar clarified that washing <strong>of</strong> the insulators is done starting from bottom upward. This reduces the chances <strong>of</strong> a flashover.He also referred to the use <strong>of</strong> the ERS (Emergency Restoration System). The detailed presentation on the subject wasgiven later in the day.Mr. S K Negi’s (MD, GETCO) presentation was on the ‘<strong>Best</strong> <strong>Practices</strong> <strong>for</strong> <strong>Maintenance</strong> <strong>of</strong> <strong>Transmission</strong> <strong>Lines</strong>’, which isalso topic <strong>of</strong> the workshop. He continued with his statement <strong>of</strong> the inaugural session that good maintenance starts with agood design. Among his suggestions are:Create awareness to reduce pollution.Undertake asset management to identify risk spots, then attack the critical zones.River crossings are high risk locations.Do a root-cause analysis <strong>of</strong> every recorded lie fault, and try to identify if the fault relates to a part lot-wise ormake-wise.The current data points to insulator failure being the single largest root-cause. Experience shows that pre-monsoonpreventive maintenance is most effective. The use <strong>of</strong> polymer insulators in 86 lines led to the trippings drop from 172 toonly 4.The next presentation, on ‘Probable causes <strong>of</strong> failure <strong>of</strong> the <strong>Transmission</strong> Line Towers’, was by Mr Gopal Ji, AGM,PGCIL. He stated that PGCIL has faced 130 tower failures since 1993. Most were <strong>of</strong> suspension towers. The analysis <strong>of</strong>the causes gives the sources as:Hardware, Nut/ Bolts, FastnersInsulator string breakageTheft <strong>of</strong> metal members/ sabotage by bad elimentsNatural disastersMetal corrosionDesign defects

Mr Gopal Ji explained in detail the role <strong>of</strong> wind in the design <strong>of</strong> the towers. The guidelines on this account have changed.So also has changed the wind map <strong>of</strong> the country, affecting the design parameters. PGCIL has identified the affectedtowers and is working to strengthen them.The presentation by Mr Benoit, Area Manager, CATU, was in two parts with the headings ‘Introduction on Electrical<strong>Maintenance</strong> Operation & Safety while working on live Sub-stations and <strong>Lines</strong>’ and ‘Minimum Personal ProtectiveEquipment & Accessories <strong>for</strong> working on Live Sub-stations, <strong>Transmission</strong> <strong>Lines</strong> and Poles: Respect <strong>of</strong> IEC Norms &Recommendations’. Mr Benoit took the subject in depth, listing the hazards in electrical maintenance and describing thedifferent scenarios. As pointed out by him, electrical accident has effects, e.g., Heating, Pressure or Explosion, Luminousoutput or flash, and Ionization. The prevention <strong>of</strong> accident can be effected by maintaining a safe distance, by switching <strong>of</strong>fpower, and by isolating the risk area. The effect <strong>of</strong> an electrical accident on humans includes tingling, shock, contractionand more. Mr Benoit advised use <strong>of</strong> Personal Protective Equipment and following the mandated safety procedure <strong>for</strong>accident avoidance.In the second presentation, Mr Benoit gave an overview <strong>of</strong> the services and the products in the portfolio <strong>of</strong> his company.He gave graphic description <strong>of</strong> the use equipment, e.g., Gloves. Boots, Stools, Mat, Voltage Detector, Insulating Sticks,Short-circuit & Earthing Systems, etc.Mr. Bhavesh Makwana <strong>of</strong> Madhav Engineering gave a nice presentation on ‘Hot Line <strong>Maintenance</strong>’. His companyprovides Tools, <strong>Maintenance</strong> services and Hands-on Training in cooperation with their <strong>of</strong>fshore partners. He alsodemonstrated a couple <strong>of</strong> case studies in support <strong>of</strong> his claims. His portfolio includes activities/ tools such as StringRemoval, Scaffolding, Washing, Conductive Suit, and more.Mr Rajeev Kumar <strong>of</strong> PGCIL gave a detailed presentation on the deployment <strong>of</strong> ‘Emergency Restoration System (ERS)’.The participants showed a lot <strong>of</strong> interest in the ERS. PGCIL maintains 14 sets <strong>of</strong> ERS in different locations in the country.Each set can set up up to 12 towers in an emergency situation. The towers are pre-assembled sections, which can befitted together at site, and supported by a set <strong>of</strong> guy-wires. The use <strong>of</strong> such towers serves to provide quick emergencysupport in the case <strong>of</strong> the failure <strong>of</strong> one <strong>of</strong> more towers.A tower may fail due to a natural disaster or due to some anti-social activity. PGCIL, with its 74000 circuit km <strong>of</strong> EHV &HVDC lines & around 150000 towers, is prone to such accidents. To maintain better availability <strong>of</strong> its lines, the use <strong>of</strong> ERSis necessary. While normal restoration <strong>of</strong> a tower could take up to 3 weeks, by using ERS, the line may be restored in 4-5days, including transport time. The same ERS may be used <strong>for</strong> lines <strong>of</strong> 11 kV to 500 kV. The ERS towers are made <strong>of</strong> alight Aluminum alloy. It requires no foundation.The process <strong>of</strong> ERS deployment requires the following steps:Access the damageClear the location or find clear space to erect ERSCollect the required parameters <strong>for</strong> the ERS Computer based Design programmeUse the programme to do load analysis and check clearancesDesign and then locate space to locate and fix the guy linesMr Rajeev Kumar described the three methods available <strong>for</strong> erecting the ERS towers at site, namely, Gimble based,Crane lifting, & Winch-line method. The choice <strong>of</strong> method is as per locational requirement.PGCIL has used the ERS on 72 occasions, till date. They are willing to provide the ERS to other organizations in anemergency situation.The workshop was attended by about 80 participants from all over the country and the presentations were very muchappreciated by the participants. A CD <strong>of</strong> all the presentation made during the workshop was distributed to the participants.This workshop was grand success with the guidance & excellent support by Shri Rajesh Kumar, GeneralManager (Engineering), Power Grid Corporation <strong>of</strong> India and National Representative in CIGRE Study CommitteeB2 on Overhead <strong>Lines</strong>.

SOCIETY CIGRE INDIACIGRE (Conseil International des Grands Réseaux Électriques - International Council on Large Electrical Systems) is one<strong>of</strong> the leading worldwide Organizations on Electric Power Systems, covering their technical, economic, environmental,organisational and regulatory aspects. CIGRE aims to:Facilitate and develop the exchange <strong>of</strong> engineering knowledge and in<strong>for</strong>mation, between engineering personneland technical specialists in all countries as regards generation and high voltage transmission <strong>of</strong> electricity.Add value to the knowledge and in<strong>for</strong>mation exchanged by synthesizing state-<strong>of</strong>-the-art and world practices.Make managers, decision-makers and regulators aware <strong>of</strong> the synthesis <strong>of</strong> CIGRE's work, in the area <strong>of</strong> electricpower.Thus, CIGRE’s mission is to enable collection and dissemination <strong>of</strong> knowledge in it’s domain. An important tool to furtherthis mission is the bi-annual Sessions held in Paris, in the later half <strong>of</strong> August <strong>of</strong> the respective year. This year the CIGRESession 2010 is scheduled <strong>for</strong> 22.-27. August 2010. The members worldwide contribute papers describing latestinnovations and experiences in the area <strong>of</strong> interest. The council selects a bouquet <strong>of</strong> papers covering the entire spectrum,<strong>for</strong> deliberations during the session. Prior to the actual session a number <strong>of</strong> specialists in the relevant areas study thepapers and report the requirement <strong>of</strong> additional in<strong>for</strong>mation/ clarifications/ enhancements there to. These questions/comments are then distributed to the local CIGRE organisations in the member countries.CBIP, which is the National Committee <strong>of</strong> CIGRE in India, had organised this National Conference with two-fold aim.To spread the latest knowledge in this field, as per the papers being taken up at the CIGRE Session 2010, to theIndian Power Sector.To solicit the views <strong>of</strong> the Indian Power Sector on the stand to be taken by the Indian Members <strong>of</strong> the various StudyGroups <strong>of</strong> CIGRE, on the queries raised, during the session.The idea is not just to broad-base the knowledge exchange, but also to ensure presentation <strong>of</strong> the India-specific point <strong>of</strong>view to the international audience.CIGRE has 16 study groups, each specializing in one specific domain. India has a member in each <strong>of</strong> these groups.Accordingly, CBIP/ CIGRE-India divided this three-day conference in to sections. The respective CIGRE Group memberchaired the session. The participants were acquainted with the papers selected by CIGRE Group, by way <strong>of</strong> a summarypresentation <strong>of</strong> each paper and the queries there to. The audience was then invited to present their views in respect <strong>of</strong> thequeries, including, any India-specific issues. Over the years this <strong>for</strong>mat has emerged as the most effective. Theparticipation to the conference was open to the Power Sector, irrespective <strong>of</strong> their membership <strong>of</strong> CIGRE. This enabledeven the non-members to take advantage <strong>of</strong> the knowledge exchange, as well as, to contribute to the <strong>for</strong>mulation <strong>of</strong> theIndian Stand-Point at the main session at Paris. With a large participation <strong>of</strong> around a hundred, and an extremely livelydebate all through, the aim <strong>of</strong> this National Conference was very well achieved. All the participants deserve thanks andacknowledgement <strong>for</strong> their contribution.

The conference started with the Inaugural Session with Mr. B P Rao, CMD, BHEL, Mr N N Misra, ED, NTPCL, Dr. V.K.Garg, Chairperson, Regulatory Commission, Goa & UT and Mr V K Kanjlia, Secretary, CBIP on the Dias.Mr P P Wahi, Director, CBIP, conducted the session. The distinguished penal lauded the aim <strong>of</strong> the conference andexhorted the participants to take advantage <strong>of</strong> the opportunity presented and contribute to the aim <strong>of</strong> the conference.After the Inaugural session came the technical sessions. These were in the given order.Study Group A1- Rotating Machines, chaired by Mr A K Gupta, GM, NTPC Ltd., with the support <strong>of</strong> Mr D K Chaturvedi,DGM, NTPC Ltd.Study Group A2 – Trans<strong>for</strong>mers, chaired by Mr M Vijaykumaran, AREVA and supported by Mr M L Jain, EMCO.Study Group A3 – High Voltage Equipment, chaired by Mr N N Misra, ED, NTPC Ltd., supported by Mr S P Hambarde,AGM, NTPC Ltd.Study Group B1 – Insulated Cables, chaired by Mr Deepal Shah, Country Manager, Brugg Cables.Study Group B2 – Overhead <strong>Lines</strong>, chaired by Mr Rajesh Kumar, GM, PGCIL and supported by Mr Rajeev Gandhi, CM,PGCIL.Study Group B3 – Substations, chaired by Mr D Raina, GM, Tata Power, supported by Mr Maharaja, Tata Power. Mr Negi<strong>of</strong> GETCO was also present on the Dias.Study Group B5 – Protection and Automation, chaired by Mr S G Patki, GM, Tata Power, with Mr M V Kini & Mr H BMukund. Later Mr Mata Prasad also joined the panel.Study Group D1 – Material or Emerging Techniques, chaired by Mr Jitin Sunder, BHEL, with Mr Seifert, LAPP Insulators,and Mata Prasad also on the dias.Study Group C2 – System Operation and Control, chaired by Mr S K Soonee, CEO, POSOCO, supported by Mr VivekPanday, PGCIL.Study Group C1 – System Development & Economics, chaired by Mr Y K Sehgal, ED, PGCIL, and supported by Mr SubirSen, DGM, PGCIL.

Study Group C6 – Distributed Systems & Dispersed Generation, chaired by Mr K V S Baba, GM PGCIL, supported by MrDhananjay Kumar, PGCIL.Study Group D2 – In<strong>for</strong>mation Systems & Telecommunications, Mr N S Sodha, GM, PGCIL, supported by Mr A K Mishra,DGM, PGCIL. Mr Sodha supplemented by a brief presentation on ‘Smart Grid’ & ‘Phaser Measurement’. Mr Saran <strong>of</strong>PGCIL gave a small presentation on the Communication Network <strong>of</strong> PGCIL.Study Group B4 - HVDC and Power Electronics, chaired by Mr R P Sasmal, ED, PGCIL. Mr Sasmal also conducted a shorttutorial on HVDC.Study Group C5 – Electricity Market & Regulation, chaired by Mr S K Soonee, CEO, POSOCO, and supported by Mr S CSaxena, PGCIL.The presentation <strong>of</strong> every session is included in the Compact Disk supplied to the participants. The Summary <strong>of</strong> the papers<strong>for</strong> presentation at the CIGRE session, and the Queries are included there in.Apart from these sessions, there was an interesting and in<strong>for</strong>mative presentation on Composite Insulators by Mr J MSeifert, Director R&D and Quality Engineering, LAPP Insulators GmbH, Germany. Among the interesting in<strong>for</strong>mationprovided by Mr Seifert: Ceramic Insulators are in use since 1910. Silicon Surface treatment provides Hydrophobicity. Composites started in 1955, with improvements in the material continuing. The Industry Standards <strong>for</strong> Composite Insulators are in place since last 15 years. Germans like to innovate in big steps, and come out with ‘Versions’. Japanese, on the other hand, practice theKeizan technique <strong>of</strong> continuous improvement. There are two methods <strong>of</strong> producing Composite Insulators, Injection Molding or Extrusion. The Composite Insulators are not to be cleaned, as the Hydrophobicity is transferred to the deposited pollutionlayer. Cleaning would destroy this property. At higher voltages, the Glass or Ceramic Insulator would be 50% or more long, when compared to a CompositeInsulator.Mr P P Wahi, Director, CBIP, appealed to the participants to take up membership <strong>of</strong> CIGRE and/ or CBIP, in the interest <strong>of</strong>spreading the technology related in<strong>for</strong>mation to a wider audience. In his support he made a presentation on CIGRE andCBIP.All the sessions invited keen contribution by the participants. They were interested in understanding the new technologypresented and readily gave their views on the observations contained in the papers. Many interesting cross debates tookplace, at times going much beyond the scope <strong>of</strong> the CIGRE papers. Some <strong>of</strong> the issues taken up <strong>for</strong> debate included: Life-time management <strong>of</strong> old machines. PDM <strong>for</strong> Generators & Trans<strong>for</strong>mers. Guidelines <strong>for</strong> the installation <strong>of</strong> filters in the old machines. Hydrogen cooled Machines. Use <strong>of</strong> Trans<strong>for</strong>mers much beyond their project life. Use <strong>of</strong> FO sensors <strong>for</strong> temperature/ thermal event detection. Damage to 400 kV cable due to wrong transportation. Shortage <strong>of</strong> Supervisory Experts. Bird-pecking on Composite Insulators. Gas Insulated <strong>Transmission</strong> Line vs Cable. Suggested use <strong>of</strong> Numerical Relays in the place <strong>of</strong> Protection Relays. Need to re-look the Substation clearances, in view <strong>of</strong> the voltage up-conversions. Use <strong>of</strong> IEC 61850 leading to reduction in cabling at the substation. The suggested use <strong>of</strong> PMUs, while the analysis technology is lacking. The limit on Composite Insulator temperature to max. 55 0 C, even as the conductor temperature rises to over200 0 C. The requirement to integrate every new station with the State Estimator. The need to measure temperature and humidity at every station.In view <strong>of</strong> the large-scale interest created in the proceedings <strong>of</strong> the conference, participants felt that the three-day periodallotted was on the lower side, and should be enhanced in future.M/s NTPC Ltd, BHEL and Power System Operation Corporation (POSOCO) were the Co-organiser and M/s ReliancePower <strong>Transmission</strong> Limited were the co-sponsor <strong>for</strong> the conference. Total 125 pr<strong>of</strong>essionals participated in theconference.