GSP Company Presentation - Grup Servicii Petroliere SA

GSP Company Presentation - Grup Servicii Petroliere SA

GSP Company Presentation - Grup Servicii Petroliere SA

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

<strong>GSP</strong> <strong>Presentation</strong>

2<br />

<strong>Company</strong> Overview<br />

• Established in 2004<br />

• Member of Upetrom Group<br />

• Experienced management team with a long history and track record in a variety of segments of the oil & gas industry<br />

• Strong operating platform built for growth<br />

• Controls a high quality fleet of diversified onshore and offshore assets enabling the group to offer turnkey solutions<br />

• Strategically located in a fast growing region<br />

• Strong customer base with a dominant market position in the Black Sea and growing market position in the North Sea, Azov<br />

Sea, Marmara Sea and South East Mediteranean markets<br />

• Solid contract coverage for both vessels and rigs<br />

• Member of the International Association of Drilling Contractors (IADC), International Maritime Contractors Association<br />

(IMCA), International Pipe Line and Offshore Contractors Association (IPLOCA), International Well Control Forum (IWCF)<br />

• HSEQ Management System is certified as being in full compliance with ISO 9001, ISO 14001, BS OH<strong>SA</strong>S 18001 and ISM Code<br />

requirements. FPAL has audited our HSE MS - scored 9.1 from a maximum score of 9.4<br />

• More than 1,500 employees<br />

• HQ in Constanta Romania, subsidiary offices in Moscow, Rotterdam, Aberdeen, Dubai, Mexico, Tunis, Oslo, Valetta,<br />

Limassol, Tripoli<br />

• Deloitte has been <strong>GSP</strong>’s auditor since 2004<br />

Short History<br />

In 2004, following the privatization of National Oil <strong>Company</strong>, Petrom, <strong>GSP</strong> employed 90% of the personnel of its Offshore<br />

Drilling Branch, Petromar - the entire offshore drilling, maintenance and maritime crew members and the onshore technical<br />

assistance & engineering personnel, and took over six offshore drilling rigs, five offshore support vessels and a crane barge.<br />

Today, a significant part of <strong>GSP</strong>`s top and middle management gathers offshore engineering specialists who developed their<br />

careers within Petromar or IFLGS Bucharest (the operational base of the Drilling and Special Geological Operations<br />

Enterprise). The above mentioned companies were established in the 1970s and have a long history in the offshore drilling<br />

industry, both being branches of the National oil company, Petrom.<br />

www.gspoffshore.com

3<br />

Key Customers<br />

www.gspoffshore.com

4<br />

<strong>Company</strong> Profile<br />

<strong>Grup</strong> <strong>Servicii</strong> <strong>Petroliere</strong> (<strong>GSP</strong>) headquarters are located in Constanta Harbor, Romania.<br />

<strong>GSP</strong> provides a wide range of integrated services in the following business areas:<br />

• Offshore Drilling<br />

• Offshore Construction<br />

• Support Vessels<br />

• Well Services / P&A / Decommissioning<br />

• Hydro-technical Construction<br />

• Engineering<br />

• Subsea Installation<br />

• Offshore Windmill Construction & Installation<br />

• Training<br />

<strong>GSP</strong> is a member of International Association of Drilling Contractors - IADC<br />

www.gspoffshore.com

5<br />

Our Business<br />

DRILLING ACTIVITIES<br />

• Directional and Horizontal Drilling<br />

• Maintenance and Repairs<br />

• Offshore and Onshore Wells Design<br />

• Rig Moving Operations<br />

• Ordinary and Continuous Coring<br />

• Engineering and Technical Consultancy<br />

• Side Tracking and Re-entries<br />

• Fishing Jobs<br />

• Drilling Fluids Engineering<br />

• Conductor Hammering<br />

• Wells Production Stimulation<br />

OFFSHORE CONSTRUCTION<br />

• Engineering and Design of Offshore Installations<br />

• Onshore Fabrication and Assembly Yards (Berth 34<br />

Constanta, Midia North Constanta, Agigea South Constanta)<br />

• Midia Pipeyard and Machine Shop<br />

• Onshore Heavy Lift Equipment up to 550 t<br />

• Load-out, Sea fastening and Transportation<br />

• On Site Installation, Wind turbine erection<br />

• Subsea Pipe Line, Umbilical and Cable Laying<br />

• Saturation diving and ROV operation<br />

• Commissioning and Operation<br />

• Manpower<br />

www.gspoffshore.com

6<br />

Our Business<br />

SHIPPING<br />

• AHTS, AHT and PSV vessels<br />

• Offshore Personnel Carrier and offshore<br />

MEDEVAC vessel<br />

• Construction Vessels<br />

• DP2 Flex-Lay / J-Lay Pipelay Vessel<br />

• Ocean transport Submersible Barge<br />

• Top Flat Barge (incl.250 and 550 t cranes)<br />

• Top Flat Sliding Barge<br />

• Marine Floating Crane 100 t<br />

• Barge Shearleg Crane 1800 t<br />

• Derrick Lay Barge<br />

TRAINING<br />

• Training in well control<br />

• Training in operating the driller’s cabin controls (Cyber Chair)<br />

• Safe operation of onshore and offshore cranes<br />

• Training in HSE<br />

• On-the-job training<br />

• Drilling Superintendent module training<br />

• Safe operation of DP/non-DP operated vessels<br />

• Safe operation of ROV<br />

• Anchor handling and Dynamic Positioning<br />

• Heavy lift operations<br />

• Survival at sea<br />

• Fire fighting<br />

www.gspoffshore.com

7<br />

Our Business<br />

HYDROTECHNICAL CONSTRUCTION WORKS<br />

• Water capture for creating domestic usage water networks<br />

or industrial usage water networks<br />

• Dam construction for production of electric energy<br />

• Protection against flooding by regulation of watercourses<br />

• Drainage and shore protection<br />

• Development of water transportation by dredging works<br />

and channel construction<br />

• Development of nautical recreation and sport areas<br />

• Breakwater construction for harbor protection<br />

• Quays, harbor platforms, maintenance dredging of harbors<br />

• Environmental water works<br />

• Rehabilitation of shoreline areas<br />

• Preservation of beach areas<br />

WELL INTERVENTION SERVICES<br />

• Engineering and Design of Workover<br />

• Workover Operation<br />

• Coil Tubing: Fishing, Acid and Nitrogen Pumping<br />

• Wells Production Stimulation (Fracking, Acidisation)<br />

• Fishing Jobs<br />

• Wire Line Operation<br />

• Subsea well intervention<br />

• High-pressure/high-temperature wells<br />

• Horizontal and extended-reach intervention<br />

• Large well-bores and high-capacity<br />

production wells<br />

• Multi-lateral well intervention<br />

• Training of personnel<br />

• Manpower<br />

www.gspoffshore.com

www.gspoffshore.com<br />

<strong>GSP</strong> Construction and Workshop<br />

Facilities:<br />

• <strong>GSP</strong> Central Production Facility, Berth 34<br />

• <strong>GSP</strong> North Production Facility, Midia<br />

• <strong>GSP</strong> South Production Facility & Shipyard, Agigea

9<br />

<strong>GSP</strong> Production Facilities<br />

The location provides fast river /canal connection with Western<br />

Europe and directly with Rotterdam port, through the Rhine-Main<br />

canal.<br />

Rotterdam<br />

Constanta<br />

Google Earth®<br />

Constanta<br />

<strong>GSP</strong> North<br />

Production Facility,<br />

Midia<br />

<strong>GSP</strong> Central<br />

Production Facility,<br />

Berth 34<br />

<strong>GSP</strong> South<br />

Production Facility<br />

& Shipyard, Agigea<br />

20 Km<br />

7 Km<br />

Google Earth®<br />

www.gspoffshore.com

10<br />

<strong>GSP</strong> Central Production Facility - Berth 34, Constanta Harbor<br />

• Multipurpose workshop for industrial buildings<br />

• The workshop is endowed with a ten tons gantry<br />

• A heavy duty open concrete platform completes the production area<br />

• Berth facilities allow execution of various types of offshore construction as well as vessel and offshore drilling<br />

rig overhaul projects<br />

<strong>GSP</strong> TRAINING<br />

CENTER<br />

WORKSHOP<br />

<strong>GSP</strong><br />

HEADQUARTERS<br />

QUAY<br />

total area – 15,100 sqm.<br />

www.gspoffshore.com

11<br />

<strong>GSP</strong> Central Production Facility - Berth 34, Constanta Harbor<br />

• Offshore Prefabrication and Construction<br />

• Jack-up rig Overhaul and Upgrading<br />

• Barge Conversion<br />

• Complete Drilling Package Outfitting<br />

for jack-ups and Drillships<br />

• Offshore Oilfield equipment Repairs<br />

• NDT<br />

• Steelwork<br />

WORKSHOP<br />

• Tubular and Valves Checking and Repairs<br />

• Hydraulic Equipment Checking and Repairs<br />

• Electrical Equipment Checking, Measurement,<br />

Rewind and Repairs<br />

• Engines Maintenance and Repairs<br />

• Cranes and Lifting Equipment Checking and Repairs<br />

• Refrigeration Plant Maintenance and Repair Work<br />

• Carpentry<br />

total area – 15,100 sqm<br />

<strong>GSP</strong> HEADQUARTERS<br />

www.gspoffshore.com

12<br />

<strong>GSP</strong> Central Production Facility - Berth 34, Constanta Harbor<br />

• concrete & asphalt pavement 8, 300 sqm<br />

• maximum allowed load 30 tons / sqm<br />

• total berth length 100 m<br />

• quay water depth 12 m<br />

New construction & assembly hall – 4,500 sqm:<br />

• production area - 2 000 sqm (fully heated)<br />

• one gantry - 10 tons<br />

• offshore welding school (fully heated)<br />

• storage areas - 300 sqm<br />

• workshops<br />

• boiler room, locker rooms, lavatories<br />

Main office – 3,970 sqm:<br />

• reception<br />

• meeting rooms<br />

• offices<br />

• boiler room<br />

• design rooms<br />

• IT rooms<br />

total area – 15,100 sqm<br />

Working on<br />

<strong>GSP</strong> Saturn Rig<br />

Upgrade Project<br />

www.gspoffshore.com

13<br />

<strong>GSP</strong> Central Production Facility - Berth 34, Constanta Harbor<br />

www.gspoffshore.com

14<br />

<strong>GSP</strong> Training Center - Berth 34, Constanta Harbor<br />

gsptrainingcenter.com<br />

<strong>GSP</strong> Training Centre is the first step in the <strong>GSP</strong>’s endeavor to build a complete set of facilities capable to offer a<br />

comprehensive training package, including the following:<br />

• Introduction to Well Control<br />

• Electronic Drilling System<br />

• Top Drive System<br />

• Vocational training for roughneck<br />

• Vocational training for motorman<br />

• On shore crane operator<br />

• Towing Operation course<br />

• Dynamic Positioning Familiarization<br />

• Dynamic Positioning Advanced<br />

• Non-Destructive Testing<br />

• Welding Courses<br />

total area – 2,450 sqm<br />

www.gspoffshore.com

15<br />

<strong>GSP</strong> Training Center - Berth 34, Constanta Harbor<br />

gsptrainingcenter.com<br />

Simulator room:<br />

Equipped with the DrillSIM-6000 capable to offer full Well Control training and training in Cyber Base operating controls<br />

• 2310 square meters total area<br />

• 120 seats in four training halls<br />

• 20 seats in conference room<br />

• 14 design offices<br />

• 50 seats in cafeteria<br />

total area – 2,450 sqm<br />

www.gspoffshore.com

16<br />

<strong>GSP</strong> Training Center - Berth 34, Constanta Harbor<br />

gsptrainingcenter.com – future capabilities<br />

Offshore Bridge Simulator<br />

DNV Class A offshore bridge • DP • Anchor<br />

Handling • Towing • Fore and aft stations<br />

Anchor Handling<br />

Actual anchor handling aft bridge simulation<br />

installation<br />

ROV Simulator<br />

Engineering Simulator<br />

Screen based simulator framework • FM Engine<br />

Room Sim • FM Liquid Cargo Handling Sim<br />

Offshore Simulator Example<br />

Maneuvering from the aft bridge station – actual<br />

customer installation photograph<br />

Crane Simulator<br />

Rig Cranes • Vessel Cranes •<br />

Heavy Lift floating cranes •<br />

Mobile land cranes<br />

www.gspoffshore.com

17<br />

<strong>GSP</strong> North Production Facility - Midia Base<br />

Midia Base is a unique industrial facility / harbor in Romania, integrating all required services to support our offshore<br />

drilling activity.<br />

These facilities are also available to provide:<br />

• Well intervention services in the Black Sea<br />

• Construction of modules for the petrochemical industry in Eastern Europe and the Middle East<br />

total area – 373,766 sqm<br />

www.gspoffshore.com

18<br />

<strong>GSP</strong> North Production Facility - Midia Base<br />

• Offshore prefabrication and construction<br />

• Jack-up rigs overhaul<br />

• Land rig overhaul with the support<br />

of Upetrom 1 Mai<br />

• Offshore oilfield equipment storage<br />

and repairs<br />

• NDT<br />

• Steel works<br />

• Tubulars and valves storage,<br />

checking and repairs<br />

• Pipe coating, pipe storage<br />

• Hydraulic and equipment storage, checking and repair<br />

• Electrical equipment storage, checking, measurement,<br />

rewind and repairs<br />

• Engines storage, maintenance and repairs<br />

• Cranes and lifting equipment<br />

• Refrigeration plant maintenance and repair works<br />

• Carpentry<br />

total area – 373,766 sqm<br />

www.gspoffshore.com

19<br />

<strong>GSP</strong> North Production Facility - Midia Base<br />

• crushed stone pavement area 310,000 sqm<br />

• maximum allowable load 15 tons / sqm<br />

• concrete pavement 45,000 sqm.<br />

• maximum allowable load 30 tons / sqm<br />

Construction & assembly hall – 7,500 sqm:<br />

• production area – 3,500 sqm<br />

• storage areas – 3,350 sqm<br />

• workshops<br />

• offshore welding school<br />

• automatic line for tubular drilling equipment check & repair<br />

• drilling school (similar offshore rig equipment)<br />

• offices<br />

• boiler room, locker rooms, lavatories<br />

Offices - 900 sqm:<br />

• meeting rooms<br />

• mess rooms<br />

• office rooms<br />

• locker rooms<br />

• lavatories<br />

total area – 373,766 sqm<br />

total berth length 1,100 m<br />

quay water depth 7 m<br />

www.gspoffshore.com

20<br />

<strong>GSP</strong> North Production Facility - Midia Base<br />

Development Phases<br />

Phase I<br />

Existing Operation Base<br />

Phase III<br />

Final Development Phase<br />

Phase II<br />

www.gspoffshore.com

21<br />

<strong>GSP</strong> South Production Facility & Shipyard, Agigea<br />

<strong>GSP</strong> Shipyard located in Constanta Sud – Agigea Port offers the necessary infrastructure to support offshore construction<br />

with a complex steelwork facility endowed with an extensive fleet of heavy lift cranes.<br />

The Constanta South – Agigea Port facility includes a multipurpose workshop and a heavy duty open platform,<br />

as well as the necessary infrastructure and utilities<br />

• crushed stone pavement area 34 000 sqm<br />

• maximum allowable load 30 tons / sqm<br />

• pile reinforced area 2,400 sqm<br />

• maximum allowable load 200 tons / sqm<br />

• concrete pavement 9,400 sqm<br />

• maximum allowable load 30 tons / sqm<br />

working on<br />

<strong>GSP</strong> Bigfoot 1<br />

Project<br />

total area – 70,265 sqm<br />

total berth length 1,037 m<br />

quay water depth 7 m<br />

www.gspoffshore.com

22<br />

<strong>GSP</strong> South Production Facility & Shipyard, Agigea<br />

New built construction & assembly hall - 3,000 sqm:<br />

• production area 2,250 sqm<br />

• two 40 ton gantries<br />

• storage areas<br />

• workshops<br />

• offices<br />

• mess room<br />

• boiler room, locker rooms, lavatories<br />

working on<br />

the Jacket for<br />

Akcakoca Project<br />

total area – 70,265 sqm<br />

New built yard quarter - 900 sqm:<br />

• meeting rooms<br />

• mess rooms<br />

• office rooms<br />

• locker rooms<br />

• lavatories<br />

www.gspoffshore.com

23<br />

<strong>GSP</strong> South Production Facility & Shipyard, Agigea<br />

Pictures<br />

Overall picture - 01.2010<br />

Working on the jacket for<br />

Akçakoca Project - 03.2010<br />

Working on <strong>GSP</strong> Bigfoot 1 Project - 02.2010<br />

Working on the topside for<br />

Akçakoca Project - 03.2010<br />

www.gspoffshore.com

24<br />

<strong>GSP</strong> Fleet<br />

Jack up rigs<br />

Vessels<br />

<strong>GSP</strong> Saturn: Built in 1988, rebuilt in 2009, cantilever type, ABS class<br />

<strong>GSP</strong> Jupiter: Built in 1987, rebuilt in 2007, cantilever type, ABS class<br />

<strong>GSP</strong> Orizont: Built in 1982, rebuilt in 2010, cantilever type, GL class<br />

<strong>GSP</strong> Atlas: Built in 1985, rebuilt in 2007, cantilever type, GL class<br />

<strong>GSP</strong> Prometeu: Built in 1984, upgraded in 2003, ABS class<br />

<strong>GSP</strong> Fortuna: Built in 1984, upgraded in 2011, cantilever type, ABS class<br />

<strong>GSP</strong> Britannia: Built in 1968, rebuilt in 1984, upgraded in 2011, cantilever type, ABS class<br />

<strong>GSP</strong> King: AHTS offshore support vessel, built in 2005, Singapore, ABS class<br />

<strong>GSP</strong> Queen: AHTS offshore support vessel, 8000HP. Built in 2005 Singapore, ABS class<br />

<strong>GSP</strong> Vega: AHTS offshore tug/supply vessel built in 1983. 12800HP, DnV class<br />

<strong>GSP</strong> Alcor: AHTS offshore vessel, built in 2010, ABS Class<br />

<strong>GSP</strong> Orion: Offshore supply vessel built in 1983. Major upgrade 2009. DnV class<br />

<strong>GSP</strong> Licorn: Tug and supply vessel built in 1995. BV class<br />

<strong>GSP</strong> Perseu: Tug and supply vessel built in 1994. BV class<br />

<strong>GSP</strong> Phoenix: Passenger and supply vessel, built in 1995. BV class<br />

<strong>GSP</strong> Lyra: High speed passenger and MEDEVAC vessel<br />

www.gspoffshore.com

<strong>GSP</strong> Fleet<br />

Construction<br />

Vessels:<br />

Offshore heavy<br />

lift cranes:<br />

ROVs:<br />

<strong>SA</strong>T Diving<br />

System<br />

Onshore<br />

heavy lift<br />

cranes:<br />

<strong>GSP</strong> Falcon: DP2 Flex-Lay / J-Lay Pipelay Vessel<br />

<strong>GSP</strong> Bigfoot 1: DP3 Derrick / Pipe Lay Barge<br />

<strong>GSP</strong> Bigfoot 2: Semi-submersible, Heavy lift, Transportation Barge<br />

<strong>GSP</strong> Neptun: 1800T floating shearleg crane, built in 1998, upgraded in 2010<br />

<strong>GSP</strong> Granit: 100 tons floating crane<br />

<strong>GSP</strong> ROV Triton XLR Perry Slingsby<br />

<strong>GSP</strong> ROV Triton XLX Perry Slingsby<br />

<strong>GSP</strong> ROV Mohican Inspection Class ROV<br />

<strong>GSP</strong> ROV Navajo<br />

<strong>GSP</strong> Sat 1 12 man saturation diving system, operating water depth 300 m.<br />

Liebherr LG 1550: Onshore crane with 550 tons lifting capacity<br />

Liebherr LR 1300: 4 crawler cranes with 300 tons lifting capacity<br />

Liebherr LR 1280: Crawler crane with 280 tons lifting capacity<br />

Liebherr LR 1200: Crawler crane with 200 tons lifting capacity<br />

Liebherr LR 1250: Crawler crane with 250 tons lifting capacity<br />

Liebherr LTM 1070: All terrain mobile crane with a 50 metres length<br />

telescopic boom and 70 tons lifting capacity<br />

TEREX A 300: Hydraulic rough terrain crane with 30 tons lifting capacity<br />

MDK 504: TAKRAF crane type with 27 tons lifting capacity<br />

All our assets are compliant with:<br />

• MODU Code requirements<br />

• ISM (International Safety Management Code)<br />

• ISPS (International Ship and Port Facility Security Code)<br />

• SOLAS (Safety Of Life At Sea)<br />

• MARPOL (Maritime Pollution)<br />

• IMO (International Maritime Organization)<br />

• COLREG (Collision Regulations)<br />

• Load Line Conventions<br />

• International Conventions of Tonnage measurements of ships<br />

25 www.gspoffshore.com

26<br />

<strong>GSP</strong> Fleet – Rigs<br />

<strong>GSP</strong> Saturn<br />

Rig Type Four legs, self<br />

elevating unit, cantilever<br />

Design Sonnat Offshore <strong>Company</strong><br />

Builder Galatzi Shipyard, Romania<br />

Year built 1988, rebuilt in 2009<br />

Class ABS<br />

Flag Panama<br />

Accommodation for 100<br />

Helideck 80 x 80 ft, rated for PUMA<br />

<strong>SA</strong> 330 B / BELL 212–412<br />

helicopter<br />

Max Drill depth 30,000 ft<br />

Max Water Depth 300 ft (91 m)<br />

<strong>GSP</strong> Jupiter<br />

Rig Type Four legs, self e<br />

levating unit, cantilever<br />

Design Sonnat Offshore <strong>Company</strong><br />

Builder Galatzi Shipyard, Romania<br />

Year built 1987, rebuilt in 2007<br />

Class ABS<br />

Flag Malta<br />

Accommodation for 95+2 Hospital<br />

Helideck 80 x 80 ft, rated for PUMA<br />

<strong>SA</strong> 330 B / BELL 212–412<br />

helicopter<br />

Max Drill depth 30,000 ft<br />

Max Water Depth 300 ft (91 m)<br />

<strong>GSP</strong> Orizont<br />

Rig Type Four legs, self<br />

elevating unit, cantilever<br />

Design Sonnat Offshore <strong>Company</strong><br />

Builder Galatzi Shipyard, Romania<br />

Year built 1982, rebuilt in 2007<br />

Class ABS<br />

Flag Malta<br />

Accommodation for 95+2 Hospital<br />

Helideck 80 x 80 ft, rated for PUMA<br />

<strong>SA</strong> 330 B / BELL 212–412<br />

helicopter<br />

Max Drill depth 30,000 ft<br />

Max Water Depth 300 ft (91 m)<br />

<strong>GSP</strong> Atlas<br />

Rig Type Four legs, self<br />

elevating unit, cantilever<br />

Design Sonnat Offshore <strong>Company</strong><br />

Builder Galatzi Shipyard, Romania<br />

Year built 1985, rebuilt in 2007<br />

Class Germanischer Lloyd<br />

Flag Malta<br />

Accommodation 90+2 Hospital<br />

Helideck 80 x 80 ft, rated for PUMA<br />

<strong>SA</strong> 330 B / BELL 212–412<br />

helicopter<br />

Max Drill depth 25,000 ft<br />

Max Water Depth 300 ft (91 m)<br />

www.gspoffshore.com

27<br />

<strong>GSP</strong> Fleet – Rigs<br />

<strong>GSP</strong> Prometeu<br />

Rig Type Four legs, self elevating<br />

unit<br />

Design Sonnat Offshore<br />

<strong>Company</strong><br />

Builder Galatzi Shipyard,<br />

Romania<br />

Year built 1984, upgraded in 2003<br />

Class ABS<br />

Flag Malta<br />

Accommodation 90 + 2 Hospital<br />

Helideck 80 x 80 ft, rated for<br />

PUMA <strong>SA</strong> 330 B/BELL 212–412<br />

Max Drill depth 20,000 ft<br />

Max Water Depth 300 ft (91 m)<br />

<strong>GSP</strong> Fortuna<br />

Rig Type Three legs, self<br />

elevating unit, cantilever<br />

Design Friede & Goldman<br />

Builder Astilleros Corientes<br />

ARG.<br />

Year built 1984, upgraded in<br />

2011<br />

Class ABS<br />

Flag Vanuatu<br />

Accommodation 88<br />

Helideck70 ft diameter, rated<br />

for Sikorsky S-61 helicopter<br />

Max Drill depth 25,000 ft<br />

Max Water Depth 300 ft (91 m)<br />

<strong>GSP</strong> Britannia<br />

Rig Type Four legs, self<br />

elevating unit, cantilever<br />

Design Breit Engineering Inc.<br />

Builder Norsmec Redcar UK<br />

Year built 1968, rebuild in 1984,<br />

upgraded in 2011<br />

Class ABS<br />

Flag Vanuatu<br />

Accommodation 104<br />

Helideck 75 x 75 ft, rated for<br />

Sikorsky S-61 helicopter<br />

Max Drill depth 20,000 ft<br />

Max Water Depth 200 ft (61 m)<br />

www.gspoffshore.com

28<br />

<strong>GSP</strong> Fleet – AHTS Vessels<br />

<strong>GSP</strong> King<br />

AHTS Offshore Support Vessel,<br />

class ABS, towing, fire fighting<br />

and antipollution vessel<br />

Class 1, DPS-2, main engines<br />

2 X 4,000 KW @750 rpm,<br />

Wartsila 8L32<br />

Built in 2005 by Jaya<br />

Shipbuilding & Engineering<br />

Pte. Ltd., Singapore.<br />

Duties<br />

offshore drilling rig towing and<br />

positioning, rescue, supply<br />

transport for offshore activities.<br />

<strong>GSP</strong> Queen<br />

AHTS Offshore Support Vessel,<br />

class ABS, towing, fire fighting<br />

and antipollution vessel<br />

Class 1, 8,000 HP, DPS-2,<br />

effective power 2 X 2,925 kW<br />

Built in 2005 by Jaya<br />

Shipbuilding & Engineering<br />

Pte. Ltd., Singapore.<br />

Duties<br />

offshore drilling rig towing and<br />

positioning, rescue missions,<br />

supply transport for offshore<br />

activities.<br />

<strong>GSP</strong> Alcor<br />

AHTS Offshore Support Vessel,<br />

class ABS, class notation A1E<br />

Offshore Support Vessel, Fire<br />

Fighting Class 1 + AMS + DPS-1,<br />

offshore support, towing, fire<br />

fighting and antipollution<br />

vessel. Main generators 3 x 350<br />

kW @ 1,500 rpm / 415 V / 3Ph /<br />

50 Hz Caterpillar C18<br />

Built in 2009 at Fujian, China.<br />

Duties<br />

offshore drilling rig towing and<br />

positioning, anchor handling,<br />

rescue missions, supply<br />

transport for offshore activities.<br />

<strong>GSP</strong> Vega<br />

AHTS Offshore Tug/Supply<br />

Vessel, class DnV., DP1<br />

firefighting, antipollution, rescue<br />

vessel with 150 persons<br />

capacity<br />

Class 1A1 ICE-C Tug Supply<br />

Vessel E0 DYNPOS AUT,<br />

designed and built in 1983 by<br />

Bolsoenes Verft, Norway. Main<br />

engines 4 x MAK Diesel 3,200<br />

BHP, total 12,800 HP<br />

Duties<br />

offshore drilling rig towing and<br />

positioning, rescue, supply<br />

transport for offshore activities.<br />

www.gspoffshore.com

29<br />

<strong>GSP</strong> Fleet – Survey & PSV ,Crew & MEDEVAC Vessels<br />

<strong>GSP</strong> Phoenix<br />

Passenger and supply vessel,<br />

Built 1995<br />

Effective power 2,800kW,class<br />

BV.<br />

Length 73.33 m, width 13.63 m,<br />

maximum passenger 99 persons.<br />

Duties<br />

personnel and supply transport<br />

for offshore drilling and<br />

production rigs.<br />

<strong>GSP</strong> Orion<br />

Supply vessel class DnV +1A1<br />

OILREC SF EO DINAPOS-AUT<br />

Built 1983, by Sigbjørn Iversen,<br />

Norway. Major upgrade in 2009.<br />

Main propulsion system, Rolls<br />

Royce Bergen DE 5,160HP.<br />

Duties<br />

Offshore support including Oil<br />

Spill Recovery (OSR) capability<br />

under EM<strong>SA</strong> coordination,<br />

covering the EU border at the<br />

Black Sea.<br />

<strong>GSP</strong> Licorn<br />

Tug and supply vessel, class BV<br />

Built 1995<br />

Effective power 2 x 1,814 kW,<br />

length 60.79 m, width 13.59 m,<br />

maximum 38 persons.<br />

Duties<br />

supply transport, assistance<br />

during towing and positioning<br />

of offshore drilling rigs<br />

and support for drilling<br />

and production rigs.<br />

<strong>GSP</strong> Perseu<br />

Tug and supply vessel,class BV<br />

Built 1994<br />

Effective motor power 2 x 1,814<br />

kW, length 60.92 m, width 13.59<br />

m, minimum crew 13.<br />

Duties<br />

supply transport, assistance<br />

during towing and positioning of<br />

offshore drilling rigs, assistance<br />

and support<br />

for drilling and production rigs.<br />

<strong>GSP</strong> Lyra<br />

Special Offshore Vessel (Crew and MEDEVAC)<br />

Built 1988 by Baatutrustning AS-Rubbestadneset Yard, Norway, upgraded in 1991, Class IRS, 45t net tonnage.<br />

Passengers & crew capacity 101 persons (96 passengers, 5 crew).<br />

Duties<br />

personnel transportation service for offshore installation projects, as well as for shallow water offshore rigs<br />

crew transport and MEDEVAC missions.<br />

www.gspoffshore.com

30<br />

<strong>GSP</strong> Fleet – Construction Vessels<br />

<strong>GSP</strong> Falcon<br />

DP2 Flex-Lay / J-Lay Pipelay Vessel<br />

Class DNV 1A1, ICE-1B, HELDK,<br />

DYNPOS ATUR.<br />

Built in 1976, major upgrade and<br />

conversion into offshore construction<br />

vessel in 1994, rigid pipe lay system<br />

installed in 1996.<br />

Main power system: 2 x AEG, 7,000 HP;<br />

propulsion: 7 thrusters (5 x 1,305 kW,<br />

1 x 1,200 KW, 1 x 1,540 kW).<br />

Duties:<br />

Installation of rigid pipelines, flexible<br />

flowlines and umbilicals; flexible lay<br />

capacity 1,600 tons, and rigid lay of 4 to<br />

14 inch pipe welded, tested and coated<br />

conventional horizontal firing line and<br />

overboarded via radius controllers and<br />

straightener and J-Lay ramp located<br />

at stern of ship.<br />

<strong>GSP</strong> Bigfoot 1<br />

DP3 Derrick/Pipe Lay Barge<br />

Class ABS +A1 Barge, E; DPS-2;<br />

UWILD,CRC<br />

Built in 2010 in <strong>GSP</strong> Shipyard, upgraded<br />

in 2011, Heavylift 400 MT offshore mast<br />

crane, 60 MT pipe handling crane,<br />

Length (excluding stinger) 135.00 m, 6 x<br />

2,200 kW Rolls Royce Azimuth Thrusters,<br />

Kongsberg DPS Class 3, 270 MT<br />

pipelaying capacity, 6 x 50 MT Pipe Repair<br />

Davits, A&R Winch capacity of 300 MT,<br />

three sections 90 m Stinger, helideck for<br />

Sikorsky S-61N & S-92, accommodation<br />

for 240 POB.<br />

Duties<br />

Pipelay, heavy lift works. The pipelay<br />

system is based on the single joint S-lay<br />

principle. The barge is capable of<br />

installing 6” to 60” diameter pipelines.<br />

<strong>GSP</strong> Bigfoot 2<br />

Semi-submersible, Heavy lift,<br />

Transportation Barge<br />

Class Lloyd’s Register, class notation<br />

+100A1 submersible pontoon, maximum<br />

operating depth<br />

12.26 meters to bottom of keel, deck<br />

strengthened<br />

up to 15,000 kg / m2.<br />

Length 122.45 m<br />

Built 1977 in Japan<br />

Rebuilt in <strong>GSP</strong>’s North Production Facility<br />

– Midia Base.<br />

Duties<br />

dry heavy marine transportation – offshore<br />

drilling rigs, offshore production structures<br />

and modules such as jackets, topsides,<br />

other heavy floating and non-floating<br />

cargoes, using the float on / float off<br />

method, other offshore installation works.<br />

www.gspoffshore.com

31<br />

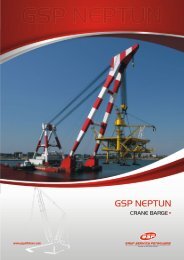

<strong>GSP</strong> Fleet – Crane Barges<br />

<strong>GSP</strong> Neptun<br />

1,800 tons floating crane,<br />

Built in 1998, upgraded in 2010<br />

Lifting speed / load 1.8 m / min., lifting speed /<br />

unload 3.6 m / min., lifting height 76.00 m.<br />

Length (LOA) 83 m, width 36 m,<br />

gross tonnage 6,557t.<br />

Accommodation: 9 persons.<br />

Duties<br />

offshore construction – platform installation,<br />

rebuilding and removal.<br />

<strong>GSP</strong> Granit<br />

100 tons floating crane,<br />

Built in 1973<br />

Length 40,66 m<br />

Width 20.02 m<br />

Effective motor power 2 x 331 kW,<br />

Accommodation: Crew only – 16<br />

www.gspoffshore.com

32<br />

<strong>GSP</strong> Fleet – ROV & Sat Diving<br />

The ROVs (Remotely operated vehicle) <strong>GSP</strong> owns and operates incorporate latest generation robotic technologies being able<br />

to operate in the safest manner in the toughest weather conditions and challenging environment.<br />

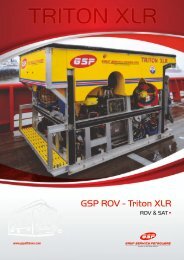

<strong>GSP</strong> operates four ROVs:<br />

Perry<br />

Slingsby<br />

Triton XLR,<br />

Medium Duty<br />

Work Class<br />

ROV,<br />

3,000 msw,<br />

125 HP<br />

Perry<br />

Slingsby<br />

Triton XLX,<br />

Heavy Duty<br />

Work Class<br />

ROV, 3,000<br />

msw,<br />

150 HP<br />

<strong>GSP</strong>’s diving services have the reputation for both excellence<br />

and highly trained and passionate personnel and most advanced<br />

technologies and equipment.<br />

<strong>GSP</strong> operates a modularized saturation diving system designed<br />

to be installed on various construction and support vessels,<br />

depending on project requirements.<br />

The 12 man saturation diving system was designed and built<br />

by LexMar Engineering, and is IMCA and ABS compliant.<br />

It allows divers to undertake subsea surveys, light construction works,<br />

inspections, maintenance and repair up to 300 meters water depth.<br />

Mohican Inspection<br />

Class ROV system,<br />

2,000 msw,<br />

incorporating an<br />

enhanced propulsion<br />

system which allows it<br />

to continue working in<br />

high current conditions<br />

Navajo<br />

compact<br />

size and<br />

weight<br />

portable<br />

ROV system,<br />

300 msw<br />

www.gspoffshore.com

www.gspoffshore.com<br />

<strong>GSP</strong> Activities<br />

• Offshore Construction<br />

• Offshore Drilling

34<br />

DLS Project – Black Sea, Russian Federation<br />

Ultimate Client: Gazprom, Russian Federation<br />

The Dzhubga – Lazarevskoye – Sochi gas pipeline is part of the Program for Construction of Olympic Facilities<br />

and Development of Sochi as a Mountain-Climatic Resort, approved by the Government of the Russian Federation.<br />

The gas pipeline is designed to provide a reliable energy supply to Sochi and other areas, including delivery of gas<br />

to the Olympic facilities which are under construction; it gives a powerful impulse to the implementation of gas supply<br />

in both private and public households of Sochi and the Tuapse District, particularly facilitating the power supply on the<br />

Black Sea coast of the Caucasus.<br />

The total length of the gas pipeline is 177 kilometers, including the 159.5 kilometer offshore section. The pipeline route runs<br />

on the Black Sea bottom following the coastline (approximately 4.5 kilometers away from the coast) to the Kudepsta gas<br />

distribution station near Sochi. The 24 inches gas pipeline will have an annual throughput capacity of approx. 3.8 billion<br />

cubic meters.<br />

<strong>GSP</strong>, as contractor for the offshore works, installed the submarine pipelines (159.5 km), including welding,<br />

non-destructive testing, inspection, pipe transport, installation of five shore approaches,<br />

pipeline tie-ins, ROV operations, surveys, trenching and pipeline hydrotesting.<br />

www.gspoffshore.com

35<br />

Akcakoca Oil Field Project – Black Sea, Turkey<br />

Client: TPAO, Turkey<br />

The Akcakoca site is located in a water depth of 95 metres, approximately 14 km from shore. The Akcakoca gas project<br />

included fabrication, transport, installation and hook-up of a 4-leg jacket over the two predrilled wells, AKC-3 and AKC-4, and<br />

drilling three new directional wells, using <strong>GSP</strong>’s self contained modular drilling rig <strong>GSP</strong> 31, which will also be used for<br />

completing<br />

and maintaining all wells.<br />

The four leg cross-braced jacket supports a two level trussed deck, also fabricated, installed and hooked-up by <strong>GSP</strong>.<br />

<strong>GSP</strong> Bigfoot 1 installed subsea pipelines of 12’’ and 7 kilometers and made tie-ins to the existing offshore pipeline system via<br />

a piggable wye connection, for transporting the produced gas from the Akcakoca platform to the Cayagzi gas processing plant<br />

located onshore near Akcakoca town.<br />

<strong>GSP</strong> carried out all fabrication, construction, installation, drilling and pipelay for the project.<br />

www.gspoffshore.com

36<br />

Galata Project – Black Sea, Bulgaria<br />

Client: Melrose Resources, England<br />

In early 2009, Melrose Resources commenced a development program to convert the Galata field offshore Bulgaria<br />

to a gas storage facility.<br />

<strong>GSP</strong> was awarded the contract for engineering, procurement, fabrication, transportation, offshore installation and testing<br />

of the pipelines 8.5 km x 6” from Galata Platform to Wellhead Kavarna 2, and 14.5 km x 10” from Galata Platform to Wellhead<br />

Kaliakra 2, with associated piggyback liquid lines.<br />

Pipeline installation was performed by <strong>GSP</strong> Bigfoot 1 in water depths ranging from 36 to 80 meters.<br />

www.gspoffshore.com

Drilling Projects<br />

Since its establishment, <strong>Grup</strong> <strong>Servicii</strong> <strong>Petroliere</strong> has been a leader in offshore drilling<br />

operations. Projects carried out by <strong>GSP</strong> include:<br />

• Offshore exploration drilling campaign on the Bulgarian continental shelf between<br />

2004 and 2005, for Melrose Resources;<br />

• Offshore horizontal sidetracking and directional drilling in Salman and Esfandihar<br />

fields in the Persian Gulf between 2004<br />

and 2005 for PEDCO Iran;<br />

• Offshore drilling campaign on the Turkish continental shelf in 2006 for TPAO;<br />

• Vertical and directional exploration and production drilling, well completion,<br />

production tests with two MODUs<br />

in the Black Sea, <strong>GSP</strong> Jupiter and <strong>GSP</strong> Saturn, in various offshore fields between<br />

2006 and 2007 for Petrom;<br />

• Exploration drilling operations in Doina field, Black Sea, the well completion and the<br />

production tests at the beginning<br />

of 2008, for Midia Resources (a subsidiary of Sterling);<br />

• Onshore directional drilling campaign on the Mamu and Bustuchin locations, for the<br />

development of the natural gas reserve in 2008 and 2009 for Petrom;<br />

• Offshore drilling campaign started in 2011 with two MODUs, <strong>GSP</strong> Atlas and <strong>GSP</strong><br />

Orizont in the Gulf of Mexico, in the Canterell perimeter. <strong>GSP</strong> was awarded a long<br />

term contract by Petroleos Mexicanos.<br />

• Offshore drilling campaign started in 2012 with MODU <strong>GSP</strong> Saturn in the North Sea,<br />

on the continental shelves of The Netherlands, Germany, Denmark, and United<br />

Kingdom. <strong>GSP</strong> was awarded the 12 months contract (with consecutive extension<br />

options for 2 x 12 months) by Wintershall Noordzee.<br />

<strong>GSP</strong>’s personnel was involved since 1976 in the offshore operations carried out by the<br />

Drilling and Special Geological Operations Enterprise (IFLSG) and Petrom’s Offshore<br />

Drilling Branch.<br />

37 www.gspoffshore.com

38<br />

Drilling Projects<br />

<strong>GSP</strong> has been involved in the most important offshore drilling projects in the Black Sea area, on the continental shelves of<br />

Romania, Bulgaria, and Turkey, rapidly growing into the regional leader of the offshore drilling industry. Simultaneously, the<br />

<strong>Company</strong> carried out extended operations on the Greek continental shelf in the Mediterranean as well as in the Persian Gulf.<br />

<strong>GSP</strong> has considered from the very beginning the drilling opportunities outside its home market, focusing on the Gulf of Mexico<br />

and the North Sea as strategic target markets. <strong>GSP</strong> is now a global offshore drilling contractor, operating worldwide.<br />

A few offshore fields where <strong>GSP</strong> was the drilling contractor for the production development:<br />

Black Sea:<br />

• Pescaruş, Lebada Vest and Lebăda Est,<br />

Sinoe, Delta, Orion for Petrom;<br />

• Doina for Midia Resources, Ayazli,<br />

Akkaya, Bayahauli for Toreador Resources;<br />

• Ayazli and Igneada for TPAO;<br />

• Cayagzi for Madison Oil;<br />

• Samontino and Galata for Melrose Resources;<br />

• Yury Shimanov for Petreco;<br />

• Kallirahi and Epsilon for Kavala Oil.<br />

Persian Gulf:<br />

• Saravan for Repsol YPF;<br />

• Salman, Esfandiar and Foroozan for PEDCO;<br />

• Reshadat and Hengam for IOOC;<br />

The offshore operations carried out in Midia, Neptun, Pelican<br />

perimeters on the Romanian continental shelf, and Shabla<br />

and Galata on the Bulgarian one were carried out before<br />

2004 by the actual <strong>GSP</strong>’s offshore drilling<br />

& engineering professional body.<br />

www.gspoffshore.com

39<br />

<strong>GSP</strong> activities in the Black Sea<br />

www.gspoffshore.com

www.gspoffshore.com<br />

<strong>GSP</strong> Investment Policy<br />

• Current / Ongoing Investments<br />

• Planned Investments<br />

• Future Potential Investments

41<br />

Investment Policy<br />

Since 2004, <strong>GSP</strong> has invested almost one billion USD in the acquisition and modernization of its vessels and drilling rigs,<br />

including extensive upgrades of <strong>GSP</strong> Jupiter and <strong>GSP</strong> Saturn rigs and conversion of <strong>GSP</strong> Bigfoot 1 and <strong>GSP</strong> Bigfoot 3.<br />

<strong>GSP</strong> puts strong emphasis on its workforce and will continue to invest in the training and education of its employees to<br />

ensure the highest quality of operations.<br />

<strong>GSP</strong> has a long term investment plan including the continuous modernization of the equipment onboard of the drilling rigs.<br />

<strong>GSP</strong> is the dedicated investment vehicle for the group’s non transportation offshore assets<br />

All investments made must meet <strong>GSP</strong>’s long term strategic objectives and return requirements<br />

<strong>GSP</strong> JUPITER pre and post upgrade<br />

<strong>GSP</strong> <strong>SA</strong>TURN pre and post upgrade<br />

December 2006 December 2007<br />

September 2008 June 2009<br />

www.gspoffshore.com

42<br />

Special Investments<br />

<strong>GSP</strong> Tbn Derrick - J-Lay - Heavy Lift Vessel<br />

(future capability Ultra Deep water J-Lay pipeline)<br />

• Tremendous ability to resist extreme wind and wave with huge hull size<br />

able to accomplish various missions like hoisting, survey and salvage under all marine depth whatever from shallow water<br />

(less than 400m) or deep water (400m – 1500m) or extremely deep water (over 1500m)<br />

• Self- propelled. When operating, the vessel can be positioned<br />

either by anchor or by DP System<br />

can turn 360 degree on the spot.<br />

The sailing speed is up to<br />

11-13 knot, and reaches over<br />

20 knots by DP system<br />

• Heavy Lift Capacity<br />

12000 ton at 120 meter high,<br />

it’s able to deal with hyper module<br />

lifting and installation, jacket positioning,<br />

platforms removal and all other heavy<br />

lifting job on sea<br />

• Deep water work capacity<br />

able to undertake heavy<br />

salvage in 3000 meter<br />

under water or over<br />

www.gspoffshore.com

43<br />

Special Investments<br />

<strong>GSP</strong> Tbn Derrick - J-Lay - Heavy Lift Vessel<br />

(future capability Ultra Deep water J-Lay pipeline)<br />

Length overall 297.55 m<br />

Length BP 290.25 m<br />

Moulded Breadth 58.00 m<br />

Moulded Depth 28.80 m<br />

Design Draft 13.5m<br />

Scantling Draft 17.6 m<br />

Operation draft 17.6 m<br />

Navigation draft 13.5 m<br />

Complement 380 p(CREW 72 P, Worker 308 P)<br />

Type of Main Engine B&W 7S80MC<br />

Rated Power 21120 KW / 69.2 rpm (MCR),<br />

19010 KW / 66.8 rpm (90% MCR)<br />

Service Speed not less 12 kn<br />

Stationary Over Stern: Rated Lifting Load 12,000t@54m<br />

Available Radius from shipboard: 25 m<br />

Revolving Rated Lifting Load 7,000t@44m<br />

Lifting Height with Full Load 12,000 t<br />

Above Waterline 120 m<br />

Below Waterline 150 m<br />

Deep Water Operation 3,000 m or more<br />

Relevant Lifting Load 1,500 t – 10,000 t<br />

www.gspoffshore.com

44<br />

Planned Investments<br />

<strong>GSP</strong> Venus<br />

self propelled<br />

dynamically<br />

positioned drillship<br />

<strong>GSP</strong> Titan<br />

Multi Purpose<br />

Offshore Construction<br />

Diving Operations -<br />

Subsea Installation –<br />

Multi Laying Vessel<br />

<strong>GSP</strong> Caspian<br />

drilling barge<br />

Length overall 208.0 m<br />

Breadth moulded 35.0 m<br />

Depth at side 18.2 m<br />

Scantling draught 12.5 m<br />

Operational draft 9.0m – 12.00m<br />

Speed 14 knots<br />

Accommodation 200 persons<br />

Power 6 x 7400 kW<br />

Main thrusters 3 x 5500 kW<br />

Retractable thrusters 3 x 3200 kW<br />

Bow thruster 1 x 2500 kW<br />

Length overall 173.30 m<br />

Length BP 161.30 m<br />

Breadth 32.00 m<br />

Depth to 1st deck 14.40 m<br />

Depth to 2nd deck 10.80 m<br />

Frame spacing 700 mm<br />

Complement 240 POB<br />

Type of Main Engines: WARTSILA 8L32<br />

Service Speed 17.5 Knots<br />

Length 140 m<br />

Breadth moulded 48 m<br />

Depth at side 15 m<br />

Scantling draught 10.6 m<br />

Operational draught for deepwater 10.0 m<br />

Operational draught for shallow water 1.8 m<br />

Displacement at operational deep draught Approx. 68,900 t<br />

Deadweight at operational deep draught Approx. 56,500 t<br />

Displacement at shallow draught Approx. 16,500 t<br />

Deadweight at shallow draught Approx. 12,800 t<br />

www.gspoffshore.com

45<br />

Planned Investments<br />

A fleet of self supporting barges to do complete Pipelay Projects in the Caspian Sea<br />

• Pipelay Complex consist of three standard barges<br />

• Accommodation barge, consist of two standard barges<br />

• Trenching barge, consist of two standard barges<br />

• Pipe supply barge, one short barge (5 off)<br />

Pipelay<br />

Complex<br />

Length 137.6m, Width 49.4m<br />

3000m2 deck space<br />

1500t Deadweight @ 1.4m draft<br />

2200t Deadweight @ 1.5m draft<br />

19000t Deadweight @<br />

freeboard draft (4m)<br />

Arthropod 600<br />

Offshore<br />

Support barge<br />

Length 137.6m Width 32.7m<br />

2600m2 deck space<br />

1000t Deadweight @ 1.5m<br />

draft<br />

12000t Deadweight @<br />

freeboard draft (4m)<br />

Shallow Water Pipe<br />

Supply Barges<br />

Length 99.2m, Width 16m,<br />

Depth 7.2m<br />

450t Deadweight @ 1.5m draft<br />

4100t Deadweight @ freeboard<br />

draft (4m)<br />

5 barges in the fleet<br />

Trenching<br />

Barge<br />

Length 137.6m Width 32.7m<br />

2600m2 deck space<br />

1000t Deadweight @ 1.5m<br />

draft<br />

12000t Deadweight @<br />

freeboard draft (4m)<br />

The ‘Arthropod 600’ is capable of trenching pipelines from 12” to 50” OD at a maximum burial<br />

depth of 3.5 m (bottom of trench).<br />

www.gspoffshore.com

Thank you!<br />

www.gspoffshore.com<br />

15 Oct 2012