WireWorks⢠Panel System - KI.com

WireWorks⢠Panel System - KI.com

WireWorks⢠Panel System - KI.com

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Planning GuideWireWorks <strong>Panel</strong> <strong>System</strong>

2IntroductionThe WireWorks <strong>Panel</strong> <strong>System</strong> is <strong>com</strong>pletely modular innature, designed for office environments that requirefrequent reconfiguration. The modularity of WireWorkspanels stems from separate frame, tile, and trim systemsthat assemble entirely with only a rubber mallet. Ascrewdriver and wrench are required to assembleoverheads and install worksurfaces. A pre-wired powersystem can be run in the modular units at four standardheights. Hundreds of data cables can be managedthroughout the panel system. WireWorks ac<strong>com</strong>modatesall standard types of cables. WireWorks also supports <strong>KI</strong>’sModular Data <strong>System</strong>.The WireWorks frame is simple to assemble anddisassemble since it is based on only four basic parts (thefull vertical post, half vertical post, corner connector blockand horizontal rail). Horizontal rails are designed to beadded and removed without disturbing the vertical postsor power/data cables managed throughout the system. Allcables are laid into the system without threading throughthe frame to greatly enhance the ability to reconfigure thesystem with minimal disruption and downtime. Verticalposts can later be stacked one on top of another to easilychange panel height.<strong>Panel</strong>s <strong>com</strong>e in three different styles to offer the user<strong>com</strong>plete control over the office environment. Monolithic,segmented, and stackable styles are based on the samebasic parts so they can easily be mixed and matched tomaximize flexibility and value. Tiles are available intackable acoustical fabric, tackable high-performanceacoustical fabric, upholstered raceway, glass and openstyles. Segmented and stackable panels can be any<strong>com</strong>bination of these styles. Monolithic panels providepower inside of the base raceway. Segmented orstackable panels allow power at base, ADA, worksurface,and standing height. Storage accessories on monolithicpanels are hung ‘on-module’ using the slots in the verticalposts. Segmented or stackable panels can ac<strong>com</strong>modatethese accessories both ‘on-module’ as well as ‘offmodule’allowing overheads and panels of differentwidths to be used together and moved horizontally withminimal effort.WireWorks is the essence of modularity andreconfiguration simplicity in today’s ever changing officeenvironment.

3Table of ContentsIntroduction . . . . . . . . . . . . . . . . . . . . . . .2Product Overview . . . . . . . . . . . . . . . . .4PANEL CONFIGURATIONS . . . . . . . . . . . . . . .4STACKABLE SECTIONS . . . . . . . . . . . . . . . . .8DOOR COMPONENTS . . . . . . . . . . . . . . . . . . .9INTERSECTION CONDITIONS . . . . . . . . . . . .10WALL MOUNT COMPONENTS . . . . . . . . . . .14STACKABLE INTERSECTIONS . . . . . . . . . . . .14PANEL COMPONENTS . . . . . . . . . . . . . . . . .16WORKSURFACE AND ACCESSORIES . . . . . .23STORAGE AND ACCESSORIES . . . . . . . . . . .29Planning Guidelines . . . . . . . . . . . . .38PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .38ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . .62DATA CABLE . . . . . . . . . . . . . . . . . . . . . . . .77Technical Specifications . . . . . . . . .86PANELS . . . . . . . . . . . . . . . . . . . . . . . . . . . .86ELECTRICAL . . . . . . . . . . . . . . . . . . . . . . . .89WORKSURFACES . . . . . . . . . . . . . . . . . . . . .90STORAGE . . . . . . . . . . . . . . . . . . . . . . . . . .92PAPER MANAGEMENT . . . . . . . . . . . . . . . . .93

4Product OverviewPANELPRECONFIGURATIONSFabric <strong>Panel</strong>sFace Style: MonolithicBasic Model: PMMA & PMMHMonolithic panels consists of full fabric tiles on both sidesand 6" base with base power available. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 30”, 42”, 54”, 66” & 84”Face Style: Monolithic/Fully SegmentedBasic Model: PMFA & PMFHMonolithic/fully segmented panels consist of one fullfabric side, one fully segmented side and a 6" base withbase power available. Fully segmented panels consist of12" tiles. Quantity of 12" tiles is dependent upon panelheight. 84" high panels include one 18" tile on top. Tilesare field replaceable.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 30”, 42”, 54”, 66” & 84”Face Style: Monolithic/Half SegmentedBasic Model: PMHA & PMHHMonolithic/half segmented panels consist of one full fabricside, one half segmented side and a 6" base with basepower available. Half segmented panels consist of 24"fabric tile on bottom and tiles in 12" increments. Quantityof 12" tiles is dependent upon panel height. 84" highpanels include one 18" tile on top. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 42”, 54”, 66” & 84”Face Style: Half SegmentedBasic Model: PHHA & PHHHHalf segmented/half segmented panels consist of two halfsegmented sides and a 6" base with base power available.Half segmented panels consist of 24" fabric tile on bottomand tiles in 12" increments on top. Quantity of 12" tiles isdependent upon panel height. 84" high panels include one18" tile on top. Tiles are field replaceable.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 42”, 54”, 66” & 84”

5Product OverviewFace Style: Half Segmented/Fully SegmentedBasic Model: PHFA & PHFHHalf segmented/fully segmented panels consist of onehalf segmented side, one fully segmented and a 6" basewith base power available. Half segmented panels consistof 24" fabric tile on bottom and tiles in 12" increments.Fully segmented panels consist of 12" tiles. Quantity of 12"tiles is dependent upon panel height. 84" high panelsinclude one 18" tile on top. Tiles are field replaceable.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 42”, 54”, 66” & 84”Face Style: Fully SegmentedBasic Model: PFFA & PFFHFully segmented/fully segmented panels consist of twofully segmented sides and a 6" base with base poweravailable. Fully segmented panels consist of 12" tiles.Quantity of 12" tiles is dependent upon panel height. 84"high panels include one 18" tile on top. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 30”, 42”, 54”, 66” & 84”PANELPRECONFIGURATIONSGlass <strong>Panel</strong>sFace Style: Full GlassBasic Model: PGFull glass panels consist of a full height glass tile and 6"base with base power available.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 54”, 66” & 84”Face Style: Monolithic/GlassBasic Model: PMMGA & PMMGHGlass/monolithic panels consist of 24" fabric tile onbottom of both sides and remainder of panel is glass.Base is 6" with base power available. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 54”, 66” & 84”

6Product OverviewPANELPRECONFIGURATIONSGlass <strong>Panel</strong>sFace Style: Monolithic/Fully Segmented/GlassBasic Model: PMFGA & PMFGHGlass/monolithic and fully segmented panels consist of24" tile on bottom of one side and two 12" tiles on bottomof other side and remainder of panel is glass. Base is 6"with base power available. Tiles are field replaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 54”, 66” & 84”Face Style: Fully Segmented/GlassBasic Model: PFFGA & PFFGHGlass/fully segmented panels consist of two 12" tiles onbottom of both sides and remainder of panel is glass.Base is 6" with base power available. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 54”, 66” & 84”PANELPRECONFIGURATIONSOpen & Open/Glass <strong>Panel</strong>sFace Style: Fully OpenBasic Model: POFully open panels consist of a full height open tile. Base is6" with base power available.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 30”, 42”, 54”, 66” & 84”Face Style: Open/MonolithicBasic Model: POMMA & POMMHOpen/monolithic panels consist of 24" open tile on bottomand remainder of panel is a single fabric tile on both sides.Base is 6" with base power available. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 42”, 54”, 66” & 84”

7Product OverviewFace Style: Open/Monolithic and Fully SegmentedBasic Model: POMFA & POMFHOpen/monolithic and fully segmented panels consist of24" open tile on bottom and remainder of panel is a singlefabric tile on one side and fabric tiles in 12" increments onthe other side. Quantity of 12" tiles is dependent upon panelheight. 84" high panels include one 18" tile. Base is 6"with base power available. Tiles are field replaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 54”, 66” & 84”Face Style: Monolithic/Open <strong>Panel</strong>sBasic Model: PMMOA & PMMOHMonolithic/open panels consist of 24" fabric tile onbottom on both sides and open tile on top. Base is 6" withbase power available. Tiles are field replaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 42”, 54”, 66” & 84”Face Style: Open/Fully SegmentedBasic Model: POFFA & POFFHOpen/fully segmented panels consist of 24" open tile onbottom and remainder of panel is fabric tiles in 12"increments on both sides. Quantity of 12" tiles isdependent upon panel height. 84" high panels include one18" tile. Base is 6" with base power available. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 54”, 66” & 84”Face Style: Monolithic and Fully Segmented/OpenBasic Model: PMFOA & PMFOHMonolithic and fully segmented/open panels consist of a24" fabric tile on one side of bottom, two 12" tiles on theother side of bottom and remainder of panel is open tile.Base is 6" with base power available. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 42”, 54”, 66” & 84”

8Product OverviewPANELPRECONFIGURATIONSOpen & Open/Glass <strong>Panel</strong>sFace Style: Fully Segmented/OpenBasic Model: PFFOA & PFFOHFully segmented/open panels consist of two 12" fabrictiles on bottom of both sides and remainder of panel is anopen tile. Base is 6" with base power available. Tiles arefield replaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 42”, 54”, 66” & 84”Face Style: Open/GlassBasic Model: POGGlass/open panels consist of 24" open tile on bottom andremainder of panel is glass. Base is 6" with base poweravailable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 54”, 66” & 84”STACKABLE SECTIONSAcoustical Stackable SectionBasic Model: PSA & PSHTackable tiles are mounted on vertical posts with supertough nylon hooks. Includes horizontal rail. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 12”, 18” & 24”Open Stackable SectionBasic Model: PSOOpen tile is mounted on vertical posts with super toughnylon hooks. Includes horizontal rail. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 12”, 18” & 24”Glass Stackable SectionBasic Model: PSGFull glass tile is mounted on vertical posts with supertough nylon hooks. Includes horizontal rail. Tiles are fieldreplaceable.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 12”, 18” & 24”

9Product OverviewDOOR COMPONENTSDoorBasic Model: PDRLaminate surface on door. Locking and non-lockingoptions. 42" door meets all ADA requirements.Note: Door includes trim and horizontal rail. Verticalposts must be ordered separately.Height: 80” door height (for 84” panel height)Widths: 30” opening (for 36” panel) & 36” opening (for 42” panel)Door ThresholdBasic Model: PDRTHExtruded aluminum door threshold with rubber sealstrip. Attaches to bottom of door frame.Widths: 36” (used with 30” opening) & 42” (used with 36” opening)

10Product OverviewINTERSECTIONCONDITIONS180° 2-Way In-line ConnectionBoth <strong>Panel</strong>s Same HeightBasic Model: PFPIncludes full post, light shield and adjustable glide.Heights: 30”, 42”, 54”, 66” & 84”End-of-Run ConditionBasic Model: PEPIncludes end-of-run trim, top cap, full-height post, lightshield and adjustable glide. Unupholstered only.Heights: 30”, 42”, 54”, 66” & 84”180° In-line ConnectionTwo Different HeightsBasic Model: PFPVIncludes full post, in-line height change trim, in-lineheight change bottom cap, in-line height change topcap, light shield and adjustable glide. Unupholsteredonly.Heights: 30”, 42”, 54”, 66” & 84”Off-Module PostBasic Model: POMPIncludes off-module top trim end cap, off-module halfpost, light shield and adjustable glide.Heights: 30”, 42”, 54”, 66” & 84”

11Product Overview90° 2-Way “L” CornerBoth <strong>Panel</strong>s Same HeightBasic Model: PCP90 or PCPF90Includes two half posts, 90° corner base, 90° top cap,hardware, universal trim, light shield and adjustableglide. Unupholstered or upholstered.Heights: 30”, 42”, 54”, 66” & 84”180° 2-Way In-line SpacerTwo Different HeightsBasic Model: PSPV180 or PSPVF180Includes 3-way base, one way top cap, two half posts,hardware, universal trim, light shield and adjustableglide. Unupholstered or upholstered.Heights: 30”, 42”, 54”, 66” & 84”90° 2-Way “L” CornerTwo Different HeightsBasic Model: PCPV90 or PCPVF90Includes one way top cap, 90° corner base, heightchange, two half posts, hardware, universal trim, lightshield and adjustable glide. Unupholstered orupholstered.Heights: 30”, 42”, 54”, 66” & 84”180° 2-Way In-line SpacerBoth <strong>Panel</strong>s Same HeightBasic Model: PSP180 or PSPF180Includes 180° top cap, 3-way trim & base, two halfposts, hardware, universal trim, light shield andadjustable glide. Unupholstered or upholstered.Heights: 30”, 42”, 54”, 66” & 84”

12Product OverviewINTERSECTIONCONDITIONS3-Way “T” Intersection with 3-Way CapAll <strong>Panel</strong>s Same HeightBasic Model: PTP3W or PTPF3WIncludes 3-way top cap, base, three half posts,hardware, universal trim. Unupholstered orupholstered.Heights: 30”, 42”, 54”, 66” & 84”3-Way “T” Intersection with Dead End CapTwo Different HeightsBasic Model: PTPV1W or PTPVF1WIncludes dead end top cap, three half posts, 3-waybase, hardware, universal trim. Unupholstered orupholstered. Can be assembled two ways, as shown.Heights: 30”, 42”, 54”, 66” & 84”3-Way “T” Intersection with 90° Top CapTwo Different HeightsBasic Model: PTPV90 or PTPVF90Includes 90° top cap, 3-way base, three half posts,hardware, universal trim. Unupholstered orupholstered.Heights: 30”, 42”, 54”, 66” & 84”3-Way “T” Intersection with 180° Top CapTwo Different HeightsBasic Model: PTPV180 or PTPVF180Includes 180° top cap, 3-way base, three half posts,hardware, universal trim. Unupholstered orupholstered.Heights: 30”, 42”, 54”, 66” & 84”

13Product Overview4-Way “X” Intersection with 4-Way Top CapAll <strong>Panel</strong>s Same HeightBasic Model: PXP4WIncludes 4-way top cap & 4-way light block, four halfposts, hardware. Unupholstered only.Heights: 30”, 42”, 54”, 66” & 84”4-Way “X” Intersection with 180° Top CapTwo Different HeightsBasic Model: PXPV180 or PXPVF180Includes 180° top cap, 4-way light block, four half posts,hardware, universal trim. Unupholstered or upholstered.Heights: 30”, 42”, 54”, 66” & 84”4-Way “X” Intersection with 3-Way Top CapTwo Different HeightsBasic Model: PXPV3W or PXPVF3WIncludes 4-way light block, 3-way top cap, four halfposts, hardware, universal trim. Unupholstered orupholstered.Heights: 30”, 42”, 54”, 66” & 84”4-Way “X” Intersection with 90° Top CapTwo Different HeightsBasic Model: PXPV90 or PXPVF90Includes 90° top cap, 4-way light block, four half posts,hardware, universal trim. Unupholstered orupholstered.Heights: 30”, 42”, 54”, 66” & 84”

14Product OverviewWALL MOUNTCOMPONENTSAdjustable Wall MountBasic Model: PWMAttaches to building wall to ac<strong>com</strong>modate theattachment of a half post frame <strong>com</strong>ponent. Includeshalf post and mounting hardware.Heights: 30”, 42”, 54”, 66” & 84”Wall TrackBasic Model: PWTSingle-slotted track ac<strong>com</strong>modates wall mounting ofoverhead <strong>com</strong>ponents and worksurfaces. No attachmenthardware included.Heights: 30”, 66” & 84” onlySTACKABLEINTERSECTIONS180° 2-Way In-Line ConnectionBoth <strong>Panel</strong>s Same HeightBasic Model: PSFPIncludes two stackable half posts, two stackable heightchange trim, corner connector block. Unupholstered only.Heights: 12”, 18” & 24”End-Of-Run ConditionBasic Model: PSEPIncludes stackable end-of-run trim, stackable full post.Unupholstered only.Heights: 12”, 18” & 24”

15Product OverviewSTACKABLEINTERSECTIONS180° 2-Way In-Line SpacerBoth <strong>Panel</strong>s Same HeightBasic Model: PSSP or PSSPFIncludes stackable in-line trim, two stackable half posts,corner connector block. Use top caps from existing lowerpanels. Unupholstered or upholstered.Heights: 12”, 18” & 24”3-Way “T” Intersection with 3-Way CapAll <strong>Panel</strong>s Same Height - AAABasic Model: PSTP3W or PSTPF3WIncludes stackable universal trim (height change), threestackable half posts, corner connector block. Use topcaps from existing lower panels. Unupholstered orupholstered.Heights: 12”, 18” & 24”90° 2-Way “L” CornerBoth <strong>Panel</strong>s Same HeightBasic Model: PSCP or PSCPFIncludes two pieces of stackable universal trim (heightchange), two stackable half posts, corner connectorblock. Use top caps from existing lower panels.Unupholstered or upholstered.Heights: 12”, 18” & 24”4-Way “X” Intersection with 4-Way Top CapAll <strong>Panel</strong>s Same HeightBasic Model: PSXP4WIncludes four stackable half posts, corner connector block,4-way light block. Use top caps from existing lowerpanels. Unupholstered only.Heights: 12”, 18” & 24”Stackable Adjustable Wall MountBasic Model: PSWMIncludes mounting plate and stackable half posts.Hardware for wall attachment not included. Attaches astackable panel to a wall at the start of a run.Adjustable up to 1" to correct wall deflection. Steelconstruction with painted finish.Heights: 12”, 18” & 24”

16Product OverviewPANEL COMPONENTSFrame ComponentsFull Vertical PostBasic Model: 46.0000.XX (XX = height in inches)Joins two full height panels in-line. Includes light blockand adjustable glide.Heights: 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72”, 78” & 84”Stackable Half Vertical PostBasic Model: 46.0001.XX (XX = height in inches)Adds height to a half vertical post. Bottom portion fitsinto half vertical post underneath it. Includes light block.Heights: 12”, 18” & 24”Half Vertical PostBasic Model: 46.0001.XX (XX = height in inches)One used for each panel in an intersection condition.Includes light block and adjustable glide.Heights: 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72”, 78” & 84”Corner Connector BlockBasic Model: 46.0022Connects half posts together at an intersection.Corner Height Change Connector BlockBasic Model: 46.0021Connects half posts together at an intersection whenpanels are different heights. Integral "U" shaped channelmanages 24 - 0.20 dia cables between top troughs ofadjacent panels.Stackable Full Vertical PostBasic Model: 46.0000.XX (XX = height in inches)Adds height to a full vertical post. Bottom portion fitsinto full vertical post underneath it. Includes light block.Heights: 12”, 18” & 24”Horizontal RailBasic Model: 46.0002.XX (XX = width in inches)Creates the panel width. Also provides mountinglocation for power. Rails can be added at any time.Widths: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”

17Product OverviewPANEL COMPONENTSFrame ComponentsShoulder BoltBasic Model: 46.0023Connects through half posts into corner connectorblock to create intersection conditions.PANEL COMPONENTSTile ComponentsTackable Acoustical TilesBasic Model: UP65NRC & UP80NRCHangs on the frame to provide aesthetics and soundabsorption. Provides a 3 /8" gap between vertical postand tile to allow passage of data cables. Tiles are fieldreplaceable. NRC of .65 or .80.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72” & 78”Open TileBasic Model: POTCreates pass-throughs when positioned above theworksurface and enhances air circulation whenpositioned below the worksurface. Allows for 24 - 0.20dia data cables to be managed vertically on both sidesof opening.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72” & 78”Glass TileBasic Model: PGTCreates windows. Allows for 24 - 0.20 dia data cablesto be managed vertically on both sides of glass.Width: 12”, 18”, 24”, 30”, 36”, 42” & 48”Height: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72” & 78”Raceway TileBasic Model: PRTUFabric covered steel tile used in conjunction with rigidwireways and receptacles. Can be hung anywhereexcept lowest position. Provides a gap 1" betweenvertical post and tile to allow passage of flexible powerconduit. Knockouts for bezels are concealed by fabricuntil removed in the field.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 12”

18Product OverviewPANEL COMPONENTSTrim ComponentsUniversal Trim (Full Height)Basic Model: UTF or UTFFTrims 90°, 180°, 3-way & 4-way panel intersections.Extruded PVC with trim color permeated throughout theentire part or fabric covered.Heights: 24”, 30”, 36”, 42”, 48”, 54”, 60", 66", 72" & 78"(Specify height 6" less than panel height.)One Way Top CapBasic Model: 46.0090.XX (XX = trim color code)Finishes the top at a 90°, 180°, T, or X intersectionwhere one panel is taller than all of the other panels.Nylon with trim color permeated throughout the entirepart.Universal Trim (Height Change)Basic Model: UTHTrims 90°, 180°, 3-way & 4-way panel intersectionswith variable heights. Extruded PVC with trim colorpermeated throughout the entire part or fabric covered.Height: 6", 12”, 18”, 24”, 30”, 36”, 42”, 48” & 54”(Specify height equal to height difference between panels.)180° Top CapBasic Model: 46.0089.XX (XX = trim color code)Finishes top between two same-height panels in a 180°intersection. Nylon with trim color permeatedthroughout the entire part.90° Top CapBasic Model: 46.0088.XX (XX = trim color code)Finishes top between two same-height panels in a 90°intersection. Nylon with trim color permeatedthroughout the entire part.Universal Trim (Stackable)Basic Model: UTHSTrims 90°, 180°, 3-way & 4-way panel intersections.Extruded PVC with trim color permeated throughout theentire part or fabric covered.Heights: 12", 18" & 24"(Specify height equal to height difference between panels.)3-Way Top CapBasic Model: 46.0091.XX (XX = trim color code)Finishes top between three same-height panels in a 3-way intersection. Nylon with trim color permeatedthroughout the entire part.Top CapBasic Model: 46.0040.XX (XX = trim color code)Finishes horizontal trim on top of panels. Extruded PVCwith trim color permeated throughout the entire part.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”4-Way Top CapBasic Model: 46.0092.XX (XX = trim color code)Finishes top between four same-height panels in a 4-way intersection. Nylon with trim color permeatedthroughout the entire part.

19Product OverviewEnd Trim with CapBasic Model: PETFinishes vertical end of full height panels. Extruded PVCwith trim color permeated throughout the entire part.Includes molded top cap.Height: 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72”, 78” & 84”(Specify height equal to height of panel.)90° Base TrimBasic Model: 46.0039.XX (XX = trim color code)Finishes base corners of two panels at 90° angle. SuperTough Nylon with trim color permeated throughout theentire part.Height: 6”Stackable End TrimBasic Model: PSETFinishes vertical end of stackable panels. Extruded PVCwith trim color permeated throughout the entire part.Height: 12”, 18” & 24”3-Way “T” Base TrimBasic Model: 46.0038.XX (XX = trim color code)Finishes base of three panel intersection. Super ToughNylon with trim color permeated throughout the entirepart.Height: 6”Base Trim/RacewayBasic Model: 46.0017.XX (XX = width in inches)Encloses rigid wireway at bottom of panel. All raceways(30" and wider) include two filler plates on each sideinto which bezels for receptacles can be placed. Fillerplates can be opened or closed as required. Raceways24" wide include one filler plate per side. Raceways 12"& 18" wide do not include filler plates or holes. Allraceways utilize hinged doors instead of covers. Allraceways have a solid bottom. Extruded PVC with trimcolor permeated throughout the entire part.Width: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”In-Line Height Change TrimBasic Model: PVETFinishes vertical end of different height panels,including stackable sections. Extruded PVC with trimcolor permeated throughout the entire part.Height: 6”, 12”, 18”, 24”, 30”, 36”, 42”, 48” & 54”

20Product OverviewPANEL COMPONENTSElectrical ComponentsRigid Wireway Add-on KitsBasic Model: PRW8Distributes 8-wire power and allows receptaclemounting. Includes two super tough nylon mountingclips. Wireway can be mounted inside the base racewayor any raceway tile.For <strong>Panel</strong> Widths: 24”, 30”, 36”, 42”, 48”, 54” & 60”Receptacles & BezelsBasic Model: PRCP815Attaches to wireways of powered panels. Rated at 15amps @120 volts. #4 and #5 circuit receptacles arestamped with orange lettering to indicate independent,neutral and isolated ground. Includes filler plate whichcan be removed to accept standard modular furnituredata plates, or reversed to allow cables to pass directlythrough raceway tile or door. Receptacles and bezelscan be used at any height. Bezel and filler plate arenylon with trim color permeated throughout.Power Pass ThroughBasic Model: PPT8Provides continuation of power between two poweredpanels. Consists of flexible conduit with eightconductors and a connector on each end. Receptacle accessis not provided.For <strong>Panel</strong> Widths: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”8 Wire Power/Data Separation SeptumBasic Model: PDS8Steel septum provides separation between power anddata in base raceway. Black only.Hint: A steel trough is supplied with raceway tiles toprovide separation at other electrical heights.For <strong>Panel</strong> Widths: 12”, 18”, 24”, 30”, 36”, 42”, 48”, 54” & 60”15 Amp Surge Suppression Module and BezelBasic Model: PRCPS815Attaches to wireways of powered panels nearest theinfeed. Provides protection against electrical surges.Module occupies a receptacle location but cannot beused as a receptacle. LED indicates if module needs tobe replaced. Includes filler plate which can be removedto accept standard modular furniture data plates, orreversed to allow tile or door. Receptacles and bezelscan be used at any height.20 Amp Receptacle and BezelBasic Model: PRCP820.1Attaches to wireways of powered panels. Rated at 20amps @ 120 volts. Available for circuits 1, 2, and 3only. Includes filler plate which can be removed toaccept standard modular furniture data plates, orreversed to allow cables to pass directly throughraceway tile or door. Receptacles and bezels can beused at any height. Simplex receptacle only.

21Product OverviewUniversal Base InfeedBasic Model: PRCP820Fills one receptacle hole at base only. Includes bezel andfiller plate. Color specific. 6' in length. Entry can berotated for a left, right or straight position.<strong>Panel</strong> Power Connectors:Short Vertical JumperBasic Model: PVJMP8.23Jumps power from ADA to belt, or belt to standingheight.Length: 23”Top FeedBasic Model: PTF8Includes electrical infeed, extruded aluminum powerpole and panel & ceiling trim. Two cavity design keepspower separate from data. Each cavity can manage fourpower infeeds or 36 - 0.20 dia cables. Color specific.Length: 7” & 10”<strong>Panel</strong> Power Connectors:Long Vertical JumperBasic Model: PVJMP8.53Jumps power from base to ADA, belt or standingheight.Length: 53”Data FeedBasic Model: PDFIncludes extruded aluminum power pole and panel &ceiling trim. Two cavity design keeps power separatefrom data. Each cavity can manage four power infeedsor 36 - 0.20 dia cables. Color specific.Length: 7” & 10”<strong>Panel</strong> Power Connectors:Short Horizontal JumperBasic Model: PHJMP8.17For in-line and inside 90° corner intersections.Length: 17”<strong>Panel</strong> Power Connectors:Long Horizontal JumperBasic Model: PHJMP8.21For outside 90° corners and straight through “T”intersections.Length: 21”

22Product OverviewPANEL COMPONENTSData ManagementComponentsAcoustical Tile Vertical Cable GuideBasic Model: 46.0097.PCKClips into slots in vertical post. Allows cables to be laidin between vertical posts and acoustic tile. Cannot beused with raceway tile. Each 12" of panel height willac<strong>com</strong>odate two guides for every vertical post. Sold inpacks of 25.Acoustical Tile 90° Cable GuardBasic Model: 46.0096.PCKClips into slots in vertical half post. Allows cables to belaid in between vertical half posts and acoustic tile at theinside of a 90° corner. Cannot be used with racewaytile. Need two guides per 12" high tile. Sold in packs of25.Acoustical Tile Horizontal Cable SupportBasic Model: 46.0099.PCKClips into bottom midpoint of horizontal rail. Aligns withvertical cable guides to keep cables supported atmidpoint of panel. Cable supports gang vertically. Canalso support loops of cable. Cannot be used withraceway tile, when cable trough is utilized. Sold in packsof 25.Horizontal Rail Cable GuardBasic Model: 46.0098.PCKClips into end notch of horizontal rail. Protects cableswhen managed from top trough through notch to adifferent height within the panel. Sold in packs of 25.Top Trough Cable Guard - Full PostBasic Model: 46.0047Inserts into top of full post. Protects cables in toptrough from steel edges of vertical post. Included withpurchase of vertical post.Top Cap 90° Cable GuardBasic Model: 46.0200.PCKClips between vertical half posts in alignment with toptrough. Protects cables when managed 90° betweentop troughs of adjacent panels. Sold in packs of 25.Raceway Tile Cable TroughBasic Model: 46.0072Manages cables behind raceway tile. Included withpurchase of raceway tile.Top Trough Cable Guard - Half PostBasic Model: 46.0048Inserts into top of half post. Protects cables in toptrough from steel edges of vertical post. Included withpurchase of vertical post.

23Product OverviewWORKSURFACES/ACCESSORIESWorksurfaces consist of 1 1 /4" particleboard with high-pressure laminate. Edges are available in flat vinyl T-edge(BN), 3 mm PVC edges (3L) and postformed/elliptical front edges with color matched vinyl edge banding (PL).Edge availability may vary with each worksurface type. Refer to the WireWorks Price List for available edge types.Rectangular WorksurfacesBasic Model: PWRIncludes worksurface supports. Cantilevers allowmounting to panels at 1" height increments.Worksurfaces are predrilled for suspended pedestals.60" worksurfaces contain two steel reinforcing bars. Allsurfaces 66" and longer are provided with an additionalleft hand cantilever bracket. Optional 3" diametergrommet is available on vinyl T-edge worksurfaces.Postformed/elliptical and 3mm PVC edge worksurfacesup to 54" have one 2 1 /2" x 6" grommet, 60" to 96" havetwo grommets.Width: 24”, 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72”, 78”, 84”, 90” & 96”Depth: 24” & 30”“P” Shaped Peninsula WorksurfacesBasic Model: PWPTIncludes worksurface supports. Round end issupported by 3" diameter metal column with adjustableglide. Glide adjusts 4" in height. Cantilevers allowmounting to panels at 1" height increments. 72"worksurfaces contain two steel reinforcing bars.Worksurfaces have one 2 1 /2" x 6" grommet centered onrear edge.24”D x 48”W x 60”L24”D x 48”W x 72”L30”D x 48”W x 72”L(Left shown)Flat Vinyl T-Edge (BN)3mm PVC Edge (3L)Postformed/EllipticalEdge (PL)Mitered Rectangular WorksurfacesBasic Model: PWMIncludes worksurface supports. Cantilevers allowmounting to panels at 1" height increments.Worksurfaces are predrilled for suspended pedestals.All surfaces 66" and longer are provided with anadditional left hand cantilever bracket. Worksurfaces upto 78" have one 2 1 /2" x 6" grommet, 84" to 96" have twogrommets.Width: 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72”, 78”, 84”, 90” & 96”Depth: 24” & 30” (30” width not available with 30” depth)Piano Peninsula WorksurfacesBasic Model: PWPIncludes worksurface supports. Cantilevers allowmounting to panels at 1" height increments. 72"worksurfaces contain two steel reinforcing bars. Roundend is supported by 3" diameter metal column withadjustable glide. Glide adjusts 4" in height.Worksurfaces have one 2 1 /2" x 6" grommet centered onrear edge.24”D x 48”W x 60”L24”D x 48”W x 72”L30”D x 48”W x 72”L(Left shown)(Left)(Right)

24Product OverviewWORKSURFACES/ACCESSORIESRadius Corner Peninsula WorksurfaceBasic Model: PWRCIncludes worksurface supports. Cantilevers allowmounting to panels at 1" height increments. 60"worksurfaces contain two steel reinforcing bars. Allsurfaces 66" and longer are provided with an additionalleft hand cantilever bracket. Worksurfaces have onegrommet on 48" wide and two grommets on 60" and72" wide.Width: 48”, 60” & 72”Depth: 24” & 30”Conference End WorksurfacesBasic Model: PWCIncludes worksurface supports. Conference Endworksurfaces attach to the ends of two panel hungworksurfaces 24" or 30" deep at 29" to 33" in height.Includes two 3" diameter metal columns with adjustableglides. Glide adjusts 4" in height. Includes brackets toattach to adjacent worksurfaces.Width: 51 1 /2” (to span two 24" deep worksurfaces)Depth: 25" or 31"Width: 63 1 /2” (to span two 30" deep worksurfaces)Depth: 31" or 37"(Left shown)Radius Shoe WorksurfacesBasic Model: PWSPIncludes worksurface supports. Cantilevers allowmounting to panels at 1" height increments. 60"worksurfaces contain two steel reinforcing bars. Allsurfaces 66" and longer are provided with an additionalleft hand cantilever bracket. Worksurfaces have one2 1 /2" x 6" grommet centered on side and rear edges.Width: 48”Length: 60”, 66”, 72” & 84”Depth: 24” & 30” (60” width not available with 30” depth)51 1 /2" width 63 1 /2" width“D” Shaped Peninsula WorksurfacesBasic Model: PWPIncludes worksurface supports. D-shapedworksurfaces end mount to panels. Cantilevers allowmounting to panels at 1" height increments. The roundend is supported by a 3" diameter metal column withadjustable glide. Glide adjusts 4" in height. Includesmounting hardware. 72" worksurfaces contain two steelreinforcing bars. Flat vinyl T-edge is available with a 3"diameter grommet (30" or 36" edge only).Width: 48”, 60” & 72”Depth: 30” & 36” (48” width not available with 36” depth)(Left shown)Square Shoe WorksurfacesBasic Model: PWSSIncludes worksurface supports. Cantilevers allowmounting to panels at 1" height increments. 60"worksurfaces contain two steel reinforcing bars. Allsurfaces 66" and longer are provided with an additionalleft hand cantilever bracket. Worksurfaces have one2 1 /2" x 6" grommet centered on side and rear edges.Width: 48”Length: 60”, 66”, 72” & 84”Depth: 24” & 30” (60” width not available with 30” depth)(Left shown)

25Product Overview“D” Shaped Peninsula WorksurfaceMounts to Another WorksurfaceBasic Model: PWSMPIncludes worksurface support. D-shaped worksurfacesside mount to worksurfaces at 29–33" height. Theround end is supported by a 3" diameter metal columnwith adjustable glide. Glide adjusts 4" in height. 72"worksurfaces contain two steel reinforcing bars.Includes mounting hardware.Width: 48”, 60” & 72”Depth: 30”Diagonal 90° Corner WorksurfaceBasic Model: PWDWorksurfaces provide a straight front edge to accesscorner work area. A left-hand cantilever is provided forrear corner. Worksurface is predrilled to acceptadjustable keyboard tray. Cantilevers allow mounting at1" height increments. Vinyl T-edge worksurface has 3"diameter grommet. PVC and postformed edgeworksurfaces have one 2 1 /2" x 6" grommet located 12"from rear corner along right rear edge.Width: 36”, 42” & 48”Depth: 24” & 30”See Price List for exact sizes.Dual Curvlinear 90° Corner Worksurface withPositionMateBasic Model: PWDCRear surface remains stationary and front surfaceprovides height and tilt adjustment. Variable heightadjustment mechanism adjusts 5 3 /4" below and 7"above surface. Tilt adjustment of 9° positive and 15°negative. Spring assist mechanism will lift five poundsof equipment located on the keyboard surface. Highercapacity mechanisms are available as a special order.Worksurfaces have one 2 1 /2" x 6" grommet located 12"from rear corner along right rear edge.24” x 42” x 24” 30” x 48” x 30”24” x 48” x 24”Flat Vinyl T-Edge (BN)3mm PVC Edge (3L)Postformed/EllipticalEdge (PL)Curvlinear 90° Corner WorksurfaceBasic Model: PWCIncludes worksurface supports. A left-hand cantilever isprovided for rear corner. Cantilevers allow mounting at1" height increments. Worksurface is predrilled toaccept adjustable keyboard arm. Worksurfaces haveone 2 1 /2" x 6" grommet located 12" from rear corneralong right rear edge.Width: 36”, 42” & 48”Depth: 24” & 30”See Price List for exact sizes.Wing Option 90° Corner WorksurfaceBasic Model: PWWIncludes worksurface support. Front edge ofworksurface is recessed. Worksurface is predrilled toaccept adjustable keyboard tray. A left-hand cantileveris provided for rear corner. Worksurface is predrilled toaccept adjustable keyboard arm. Cantilevers allowmounting at 1" height increments. PVC and postformededge worksurfaces have one 2 1 /2" x 6" grommetlocated 12" from rear corner along right rear edge.24” x 42” x 24” 30” x 48” x 24”24” x 48” x 30” 30” x 48” x 30”24” x 48” x 24”

26Product OverviewWORKSURFACES/ACCESSORIESStraight CountertopsBasic Model: PWCTCountertop extends 4" over the top of the panel to<strong>com</strong>ply with ADA guideline 4.4.1. Brackets, which aremounted on inside of station, include steel locking clipsto prevent dislodgement. Countertops accept task light.*If countertop is installed adjacent to an in-line heightchange full post, a notch must be specified on the left,right or both sides of the worksurface.Width: 24”, 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72”, 78” & 84”Depth: 16”90° Countertops - Wheelchair HeightBasic Model: PWCTWC90For use with 30" high panels to place countertop nohigher than 34" to <strong>com</strong>ply with ADA guideline 4.32.4.Countertop extends no more than 4" into the aisle to<strong>com</strong>ply with ADA guideline 4.4.1. Two-piece miteredsurface with 90° right angle (wheelchair height).Brackets, which are mounted on inside and outside ofstation, include steel locking clips to preventdislodgement.*If countertop is installed adjacent to an in-line heightchange full post, a notch must be specified on the left,right or both sides of the worksurface.Width: 24”, 30” & 36”Depth: 16”90° CountertopsBasic Model: PW90Two-piece mitered surface with 90° right angle. To beused with 36" or 42" high panels. Brackets are mountedon inside of station, include steel locking clips toprevent dislodgement.*If countertop is installed adjacent to an in-line heightchange full post, a notch must be specified on the left,right or both sides of the worksurface.Width: 24”, 30” & 36”Depth: 16”Straight Countertops - Wheelchair HeightBasic Model: PWCTWCFor use with 30" high panels to place countertop nohigher than 34" to <strong>com</strong>ply with ADA guideline 4.32.4.Countertop extends no more than 4" into the aisle to<strong>com</strong>ply with ADA guideline 4.4.1. Brackets, which aremounted on inside and outside of station, include steellocking clips to prevent dislodgement.*If countertop is installed adjacent to an in-line heightchange full post, a notch must be specified on the left,right or both sides of the worksurface.Width: 24”, 30”, 36”, 42”, 48”, 54”, 60”, 66”, 72”, 78” & 84”Depth: 16”Worksurface Support <strong>Panel</strong>(Fabric/Laminate) or (Laminate/Laminate)Basic Model: PWSSP or PWSSLSupport panel provides additional worksurface supportin extensive worksurface loading applications. Mountsto panels and worksurface. Adjustable glides provideleveling capability. Specify left- or right-hand dependingupon side of worksurface to which the support panelmounts.Height: 26” & 29”Depth: 24” & 30”*Note: Each notch includes one grommet cover. Coveris used when countertop is moved away from an in-lineheight change.

27Product OverviewCarouselBasic Model: CARContains cable access hole. Allows for 350° rotation.Grommets - Field InstalledBasic Model: WSGGrommets can be field-installed in worksurfaces toprovide cable access where needed. For flat vinyl T-edge surfaces only.CPU SlingBasic Model: CPU-SLINGVertically supports and stores CPU below theworksurface. Straps have positive locking clamps.Provides 5 1 /2" of forward travel and 359° swivel.Maximum weight capacity is 75 lbs. Available in blackonly. Re<strong>com</strong>mended for 30" deep worksurfaces.Ac<strong>com</strong>modates CPU with maximum circumference of65".Worksurface Support BracketBasic Model: PWSBProvides auxiliary support to front edge of worksurfacewhere pedestals or equipment requires additionalworksurface support. Return panel must be equal toworksurface depth.Adjustable/Secureable CPU HolderBasic Model: PACPUThe adjustable/securable CPU holder is available inthree models: the basic with a slide mechanismpermitting 5" of forward travel, the basic with adjustablecovers for enhanced aesthetics and the basic withcovers and security kit. The CPU holder willac<strong>com</strong>modate CPUs that are vertical 11" to 21",horizontal 2" to 10 1 /2" and a depth of 16" maximum forthe security kit. Covers and security kits are alsoavailable for retrofit or replacement to the basic unit.Available in black only.Worksurface Vertical FillerBasic Model: WSVFSteel bracket connects worksurface at 27" height to 29"heights. Fills gap between surfaces to preventaccidental dropping of work tools or paper.BasicWorksurface Wire ManagerBasic Model: WWMConstructed of easy-to-use, high quality black velcro.Harness is fastened to table bottom with pressuresensitive adhesive. Shipped assembled. Black only.Basicwith coversBasicwith covers & security kit

28Product OverviewKEYBOARD ARMSFully Adjustable Keyboard TrayBasic Model: PFAKPMAdjustable keyboard tray mounts under 24" and 30"deep worksurfaces. Provides height adjustability, tiltand storability through 359° rotation. Standard withblack anti-skid/anti-static pad and molded palm rest.Sliding Keyboard Drawer w/Mouse SurfaceBasic Model: PKBDMSliding keyboard drawer with non-handed mousingsurface. Mounts under 24" and 30" deep worksurfaces.Standard with black anti-skid/anti-static pad andmolded palm rest. Available in black only.Full Adjustable Keyboard Tray w/MouseSurfaceBasic Model: PKBMCombination keyboard and non-handed mouse traymounts under 24" and 30" deep worksurfaces. Armswivels, retracts and has height and tilt adjustments.Standard with black anti-skid/anti-static pad andmolded palm rest. Available in black only.Optional Palm RestBasic Model: IWRFits on all keyboard trays and keyboard drawers. Blackonly.Sliding Keyboard DrawerBasic Model: PKBDSliding keyboard drawer mounts under 24" and 30"deep worksurfaces. Standard with black anti-skid/antistaticpad and molded palm rest.Center DrawerBasic Model: 3CMNOne piece molded construction with ball-bearingslides. Available with key alike.

29Product OverviewOVERHEADSTORAGE/ACCESSORIESWireWorks overhead cabinets and shelves are designed to allow the same overhead to be used on-module or offmodule,by simply changing mounting brackets.Low ShelfBasic Model: PLSSteel end panels and bottom shelf. Accepts shelfdividers. End panel bracket design prevents accidentaldislodging of <strong>com</strong>ponents. Shelf depth is 13 1 /4".Includes 5" high back. Overhead tackboard andoverhead tool rail can be suspended from underside ofthe shelf.Width: 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 9 1 /2”Fabric Overhead CabinetBasic Model: PRDFSteel end panels, bottom and top shelf with powdercoatfinish. Fabric-covered front. Double bit lock isincluded. End panel bracket design prevents accidentaldislodging of <strong>com</strong>ponents. Door stores recessed withPVC handle exposed. Shelf depth is 13 1 /4". Overheadtackboard and overhead tool rail can be suspendedfrom underside of the cabinet. Key alike is available.Width: 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 16 1 /2”Depth: 14 1 /2”Regular ShelfBasic Model: PRSSteel end panels and bottom shelf. Accepts shelfdividers. End panel bracket design prevents accidentaldislodging of <strong>com</strong>ponents. Shelf depth is 13 1 /4".Includes full back. Overhead tackboard and overheadtool rail can be suspended from underside of the shelf.Width: 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 16 1 /2”Steel Overhead CabinetBasic Model: PRDSSteel bottom, top shelf, and front with powder-coatfinish. Double bit lock is included. Door stores recessedwith PVC handle exposed. Shelf depth is 13 1 /4".Overhead tackboard and overhead tool rail can besuspended from underside of the cabinet. Key alike isavailable.Width: 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 16 1 /2”Depth: 14 1 /2”Laminate Overhead CabinetBasic Model: PRDLSteel end panels, bottom and top shelf with powdercoatfinish. High-pressure laminate front surface.Double bit lock is included. End panel bracket designprevents accidental dislodging of <strong>com</strong>ponents. Doorstores recessed with PVC handle exposed. Shelf depthis 13 1 /4". Overhead tackboard and overhead tool rail canbe suspended from underside of the cabinet. Key alikeis available.Width: 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 16 1 /2”Depth: 14 1 /2”Shelf DividersBasic Model: NSDSteel shelf dividers with powder-coat finish. Fits on allshelves and cabinets.Width: 7 1 /4”Height: 11 1 /2”

30Product OverviewLIGHTSCountertop Task LightsTask lights attach to the underside of countertops. ULlisted. Includes 8' cord.For use with Countertop Width: 24”, 30”, 36”, 42”, 48”, 54” & 60”Shelf/Cabinet Task LightsTask lights mount flush with underside of shelves andoverhead cabinets. UL listed. Includes 9' cord.For use with Cabinet Width: 30”, 36”, 42”, 48”, 54” & 60”Magnetic Ballast, Normal Power FactorBasic Model: CTLNMagnetic high-power factor ballast with rapid start coolwhite lamp.Normal Power Factor/2-Step DimmingBasic Model: CTLVMagnetic high-power factor/2-step dimming (Hi/Low)with rapid start cool white lamp.Electronic Ballast, Normal Power FactorBasic Model: CTLEElectronic ballast with rapid start cool white lamp.Magnetic Ballast, Normal Power FactorBasic Model: NTLNMagnetic high-power factor ballast with rapid start coolwhite lamp.Normal Power Factor/2-Step DimmingBasic Model: NTLVMagnetic high-power factor/2-step dimming (Hi/Low)with rapid start cool white lamp.Electronic Ballast, Normal Power FactorBasic Model: NTLEElectronic ballast with rapid start cool white lamp.MARKERBOARDSMarkerboardsBasic Model: PMB.PM or PMB.OMIncludes markers and an eraser. Includes mountingbrackets. White porcelain paint finished board surface.(.PM) hangs on-module. (.OM) hangs off-module.Width: 30”, 36”, 42”, 48”, 54” & 60”Height: 32”Markerboard/Tackboard BracketsBasic Model: 46.0078.<strong>KI</strong>TTo be used with markerboard PMB.PM or tackboardPTBXXXX/PM.Basic Model: 46.0371.<strong>KI</strong>TTo be used with markerboard PMB.OM or tackboardPTBXXXX/OM.TACKBOARDS<strong>Panel</strong> Mounted TackboardBasic Model: PTBXXXX/PM or PTBXXXX/OMConstructed of 3 /4" tackable core and covered with fabric.Includes mounting brackets. Not available withcountertops. PTBXXXX/PM hangs on-module.PTBXXXX/OM hangs off-module.Width: 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 12”, 16”, 30” & 48” (60” width not available with 48” height)Overhead TackboardBasic Model: PTBOTackboard is suspended from underside of overheadcabinet or shelf. Constructed of 3 /4" tackable core andcovered with fabric. Includes mounting brackets.Width: 24”, 30”, 36”, 42”, 48”, 54” & 60”Height: 12”

31Product OverviewPAPER MANAGEMENT/ACCESSORIESTool RailBasic Model: PPMTRTool rail attaches on-module to vertical posts of panel.Extruded aluminum with four slots for papermanagement and accessories. Includes mountingbrackets.Width: 18”, 24”, 30”, 36”, 42”, 48”, 54”, 60” & 72”(Width or tool rail must match width of panel.)Height: 4fi”Steel Base Vertical StorageBasic Model: PPMVPainted steel bottom/back unit. Sides are injectionmolded. Includes removable hanging bracket. Includesidentification clip.Steel Base Paper Tray – Letter SizeBasic Model: PPMHLTPainted steel bottom/back unit. Sides are injectionmolded. Includes removable hanging brackets.Stackable. Includes identification clip.Steel Base Diagonal Storage UnitBasic Model: PPMDPainted steel bottom/back unit. Front is injectionmolded. Includes removable hanging bracket. Dividerscan be used in left or right position. Includes 3identification clips. Set of three dividers.Steel Base Paper Tray – Legal SizeBasic Model: PPMHLGPainted steel bottom/back unit. Sides are injectionmolded. Includes removable hanging brackets.Stackable. Includes identification clip.

32Product OverviewPAPER MANAGEMENT/ACCESSORIESHanging Folder HolderBasic Model: PPFHSuspends from tool rails to support hanging filefolders. Plastic construction. One pair in each set.1"W x 2"H x 8 1 /2"DTelephone CaddyBasic Model: PPTCThe telephone caddy is adjustable to ac<strong>com</strong>modatephones up to 10 3 /4" deep. Caddys include three hooksfor suspending from tool rails.8 1 /2"W x 2"H x 9 1 /2"DPlastic Paper TrayBasic Model: PPLLSuspends from tool rail or freestanding onworksurfaces or shelves. Plastic construction.9 1 /2"W x 2"H x 14"DCD HolderBasic Model: PPDHThe CD holder includes two hooks for mounting to toolrails. Holder ac<strong>com</strong>modates up to 10 CDs. Holders canbe used freestanding on worksurfaces and shelves.5 1 /2"W x 2"H x 7"DDiagonal Storage UnitBasic Model: PPDSSuspends from tool rail or freestanding onworksurfaces or shelves. Plastic construction. Threeslanted partitions per unit.7"W x 2 1 /2"H x 12 1 /2"DAccessory TrayBasic Model: PPATThe accessory tray includes three hooks for mounting totool rails. Trays have <strong>com</strong>partments to holdmiscellaneous items. Trays can be used freestanding onworksurfaces and shelves.9 1 /2"W x 2"H x 10"DPlastic Vertical Storage UnitBasic Model: PPVSSuspends from tool rail or freestanding onworksurfaces or shelves. Injection molded plasticconstruction.5"W x 9"H x 10 1 /2"DPencil CupBasic Model: PPPCThe pencil cup for storage of pens and pencils. Includesone hook to mount on tool rail.4"W x 4"H x 3 1 /2"D

33Product OverviewSTORAGE PEDESTAL/ACCESSORIESThree Drawer Pedestal - Mobile or FreestandingBasic Model: S7P/XXXXMPBF & S7P/XXXXFPBFOne 3" pencil drawer. One 6" box drawer. One 12" filedrawer with hanging folder partition. Counterbalanceweight included in mobile unit. Counterbalance weightre<strong>com</strong>mended when freestanding unit is not underworksurface. Available with key alike option.Width: 15”Depth: 21 5 /8” & 27 5 /8”Height: 24 5 /8” (Mobile) 22 1 /4” (Freestanding)Three Drawer Pedestal - Mobile or FreestandingBasic Model: S7P/XXXXMBBF & S7P/XXXXFBBFTwo 6" box drawers. One 12" file drawer with hanging folderpartition. Counterbalance weight included inmobile unit. Counterbalance weight re<strong>com</strong>mendedwhen freestanding unit is not under worksurface.Available with key alike option.Width: 15”Depth: 21 5 /8” & 27 5 /8”Height: 27 9 /16” (Mobile) 25 3 /16” (Freestanding)Two Drawer EDP Pedestal - Mobile orFreestandingBasic Model: S7P/XXXXMBE & S7P/XXXXFBEOne 6" box drawer. One 15" EDP drawer with print-outhanging partition. Counterbalance weight included inmobile unit. Counterbalance weight re<strong>com</strong>mendedwhen freestanding unit is not under worksurface.Available with key alike option.Width: 15”Depth: 21 5 /8” & 27 5 /8”Height: 24 5 /8” (Mobile) 22 1 /4” (Freestanding)Three Drawer EDP Pedestal - Mobile or FreestandingBasic Model: S7P/XXXXMPBE & S7P/XXXXFPBEOne 3" pencil drawer. One 6" box drawer. One 15" EDPdrawer with print-out hanging partition. Counterbalanceweight included in mobile unit. Counterbalance weightre<strong>com</strong>mended when freestanding unit is not underworksurface. Available with key alike option.Width: 15”Depth: 21 5 /8” & 27 5 /8”Height: 27 9 /16” (Mobile) 25 3 /16” (Freestanding)Two Drawer Pedestal - Mobile or FreestandingBasic Model: S7P/XXXXMFF & S7P/XXXXFFFTwo 12" file drawers with hanging folder partitions.Counterbalance weight included in mobile unit.Counterbalance weight re<strong>com</strong>mended whenfreestanding unit is not under worksurface. Availablewith key alike option.Width: 15”Depth: 21 5 /8” & 27 5 /8”Height: 27 9 /16” (Mobile) 25 3 /16” (Freestanding)20" Two Drawer EDP Pedestal - HangingBasic Model: S7P/XXXXHPEOne 3" pencil drawer. One 15" drawer with printouthanging partition. Available with key alike option.Width: 15”Depth: 17 5 /8”, 21 5 /8” & 27 5 /8”Height: 19 3 /16”

34Product OverviewSTORAGE PEDESTAL/ACCESSORIES20" Two Drawer Pedestal - HangingBasic Model: S7P/XXXXHBFOne 6" box drawer. One 12" file drawer with hangingfolder partition. Available with key alike option.Width: 15”Depth: 17 5 /8”, 21 5 /8” & 27 5 /8”Height: 19 3 /16”25" Two Drawer Pedestal - HangingBasic Model: S7P/XXXXHFFTwo 12" file drawers with hanging folder partition.Available with key alike option.Width: 15”Depth: 17 5 /8”, 21 5 /8” & 27 5 /8”Height: 25 1 /16”22" Two Drawer EDP Pedestal - HangingBasic Model: S7P/XXXXHBEOne 6" box drawer. One 15" EDP drawer with printouthanging partition. Available with key alike option.Width: 15”Depth: 17 5 /8”, 21 5 /8” & 27 5 /8”Height: 22 1 /8”25" Three Drawer Pedestal - HangingBasic Model: S7P/XXXXHBBFTwo 6" box drawers. One 12" file drawer with hangingfolder partition. Available with key alike option.Width: 15”Depth: 17 5 /8”, 21 5 /8” & 27 5 /8”Height: 25 1 /16”22" Three Drawer EDP Pedestal - HangingBasic Model: S7P/XXXXHPBFOne 3" pencil drawer. One 6" box drawer. One 12" filedrawer with hanging folder partition. Available with keyalike option.Width: 15”Depth: 17 5 /8”, 21 5 /8” & 27 5 /8”Height: 22 1 /8”25" Three Drawer Pedestal - HangingBasic Model: S7P/XXXXHPBEOne 3" pencil drawer. One 6" box drawers. One 15" EDPdrawer with printout hanging partition. Available with keyalike option.Width: 15”Depth: 17 5 /8”, 21 5 /8” & 27 5 /8”Height: 25 1 /16”

35Product Overview28" Two Drawer Pedestal - SupportingBasic Model: S7P/XXXXWFFTwo 12" file drawers with hanging folder partitions.Includes four leveling glides. Available with key alikeoption.Width: 15”Depth: 21 5 /8” & 27 5 /8”Height: 27 3 /4”Glide KitBasic Model: S7P/GKAdds 1 /8" to 1 inch pedestal height. Four per kit.Caster KitBasic Model: S7P/CKConverts freestanding pedestals to mobile units. Adds2 5 /16" to pedestal height. Must use with counterbalanceweight.28" Three Drawer Pedestal - SupportingBasic Model: S7P/XXXXWBBFTwo 6" box drawers. One 12" file drawer with hangingfolder partition. Includes four leveling glides. Availablewith key alike option.Width: 15”Depth: 21 5 /8” & 27 5 /8”Height: 27 3 /4”Counterbalance WeightBasic Model: S7P/CBWFor mobile and freestanding units. Included with mobilepedestals; re<strong>com</strong>mended with freestanding unit.For 24” & 30” deep units28" Three Drawer EDP Pedestal - SupportingBasic Model: S7P/XXXXWPBEOne 3" pencil drawer. One 6" box drawers. One 15" EDPdrawer with printout hanging folder partition. Includesfour leveling glides. Available with key alike option.Width: 15”Depth: 21 5 /8” & 27 5 /8”Height: 27 3 /4”Pencil TrayBasic Model: S7P/PENTRAYFor 3" pencil drawer and 6" box drawers. Molded plasticconstruction. Field installable. Black finish only.

36Product OverviewSTORAGE PEDESTAL/ACCESSORIES6" PartitionBasic Model: S7PD6For 6" box drawers. Dark Tone enamel finish only. Steelconstruction.Hanging Folder PartitionBasic Model: S7PD12For 12" file drawers. Dark Tone enamel finish only. Steelconstruction.Freestanding FilesBasic Model: S7L/XXXXXXDSteel files available in 2, 3, 4 and 5 high with 12"drawers. Top location on 5 high units is receding doorand roll out shelf. Lock and interlock are standard.Available with key-alike option. Counterbalance weightsre<strong>com</strong>mended and must be orderd separately.Width: 30”, 36” & 42”Height: 27”, 39 1 /4”, 51 1 /2” & 63 3 /4”Depth: 18”EDP Hanging PartitionBasic Model: S7PD15For 15" EDP drawers. Dark Tone enamel finish only.Steel construction.Type K Folder BarsBasic Model: S7L/334FBKSet of two allows front-to-back filing per row. For lateralfiles only. Dark Tone Enamel.Counterbalance for Lateral File UnitsBasic Model: S7L/CBWRe<strong>com</strong>mended for all freestanding 2-, 3- and 4- highfile units with rollout shelves.File DividersBasic Model: S7L/33412DVDark Tone Enamel. For use with lateral files only.

37Product Overview

38Planning GuidelinesPANEL SUPPORT ANDLOADINGThe following figures show the maximum and minimum requirements for safe loading and supporting of panels.Review them carefully to insure panel stability:Unloaded <strong>Panel</strong> Runs Starting With Wall MountsReturn panel must be equal to, or within 18" of the height ofthe main panel run.Return panels can be any height when they return inopposite directions as shown at left.Unloaded Freestanding Runs With Returns At Both EndsReturn panel(s) must be equal to, or within 18" of theheight of the main panel run, UNLESS the main panel runis tight against a building wall. If the main run is tightagainst the building wall, the return panels can be anyheight.Return panels can be any height when they return inopposite directions as shown at left.

39Planning GuidelinesWorksurface Loaded <strong>Panel</strong>s Starting With Wall MountsReturn panel must be equal to, or within 18" of the heightof the main panel run.Return panels can be any height when they return inopposite directions as shown at left.Worksurface Loaded Freestanding Runs With Returns At Both EndsWhen loading freestanding panels with worksurfaces,return panels must be used on both ends. An option onone end is to use worksurface support panels (PWSSP orPWSSL) in some situations.Return panel(s) must be equal to, or within 18" of theheight of the main panel run, UNLESS the main panel runis tight against a building wall. If the main run is tightagainst the building wall, the return panels can be anyheight.Return panels can be any height when they return inopposite directions as shown at left.

40Planning GuidelinesPANEL SUPPORT ANDLOADINGStorage Unit Loaded <strong>Panel</strong> Runs Starting With Wall Mounts – One or Two Units Per <strong>Panel</strong>Return panel must be equal to, or within 18" of the heightof the main panel run, and must be on the same side asthe storage units. All adjacent overhead units must haveoverhead ganger plates attached between them.Return panels must be equal to, or within 18" of the heightof the main panel run when they return in oppositedirections as shown at left. All adjacent overhead unitsmust have overhead ganger plates attached betweenthem.Storage Unit Loaded Freestanding Runs With Returns At Both Ends – One or Two Units Per <strong>Panel</strong>Return panels must be equal to, or within 18" of the heightof the main panel run. Return panels must be specified ateach end of the storage unit panel run, and must be onthe same side as the storage units. All adjacent overheadunits must have overhead ganger plates attached betweenthem.Return panels must be equal to, or within 18" of the heightof the main panel run. Return panels must be specified ateach end of the storage unit panel run. All adjacentoverhead units must have overhead ganger platesattached between them.

41Planning GuidelinesSTORAGE UNITSStorage Unit Loaded <strong>Panel</strong> Runs With Three Or More Storage Units Per <strong>Panel</strong>The following number of storage units will fit on the specified height panels.<strong>Panel</strong> HeightLow ShelvesStacked Tight10” Req’dLow Shelves withFolders14” Req’dRegular Shelves orReceding DoorCabinets17” Req’d48” 4 3 254” 4 3 260” 5 4 366” 6 4 372” 6 4 378” 7 5 484” 7 5 4When three or more storage units are mounted on one side of a panel, storage units must be panel wrapped with returnpanels at least 30" wide and equal to or within 12" of the height of the panel the storage units are mounted on.Return panel(s) must be equal to, or within 12" of theheight of the main panel run.An overhead with receding door located in a corner must be adjacent to a perpendicular panel of no less than 30 incheswide if the open door is to clear a second overhead positioned at 90° from the first (see below).<strong>Panel</strong> Wrapping Lateral FilesWhen panel wrapping one lateral file, the panel behind the file can be the same size as the width of the file (30", 36", or42"). The return panels on each side of the lateral file will stay in place when carpet grippers are used.When panel wrapping more than one lateral file that have been placed side by side, use panels behind the files that areat least 6" wider than the file.EXAMPLE:Two 30" lateral files = 60" wideUse a panel <strong>com</strong>bination that equals at least 66" behind the files.The reason for the 6" difference is that no matter how tight the files are ganged together, the small air space between thefiles adds up, and the return panels on each side will not stay in position.

42Planning GuidelinesPANEL MOUNTINGGUIDELINESVertical Stacking of On-Module ComponentsThe following charts are designed to provide a quick reference source as to the hang on capacity of WireWorks panels.The first table shows the actual number of inches available on each size panel to hang <strong>com</strong>ponents. The hang-oncapacity of each panel size is less than the height of the panel, because of the raceway at the bottom of the panel.<strong>Panel</strong> HeightActual Hang On Space30” 24”36” 30”42” 36”48” 42”54” 48”60” 54”66” 60”72” 66”78” 72”84” 78”The following table shows the actual number of inches in height each product takes up on a panel. In addition to theactual heights, any special clearance inches are also listed.Be sure to check the specifying section on loaded panels to be sure you are adequately supporting the panels.Product Vertical Size Special NotesWorksurface withWorksurfaces are usually mounted at about 30” high, so figure thatcantilever bracket13”you have used up the lower 25” of available hang-on space.Countertop withstandard ADAbracket6” of bracket plus 2” The 8” total includes 6” of hang-on space used by the bracket plus 2”of worksurface of worksurface and top cap that is above the bracket.Low Shelves 10”Regular Shelves 16”If you are storing anything taller than 7”, use the height of the objectplus 3”.If you are storing anything taller than 13”, use the height of the objectplus 2”.Storage OverheadUnit17”Tackboards 12”, 16”, 30” & 48”Two on-module tackboards cannot be hung adjacent to each other atthe inside of a 90° corner.Markerboards 32”

43Planning GuidelinesWEIGHT CAPACITIESNotes About Hang-On ComponentsWireWorks hang-on <strong>com</strong>ponents (excluding markerboards, tackboards and tool rails) include a specially designedhanger bracket to prevent accidental dislodgement from the panel or wall track.All WireWorks <strong>com</strong>ponents meet or exceed the BIFMA (Business and Institutional Furniture Manufacturers Association)standards for hang-on <strong>com</strong>ponents.BIFMA has two load tests for hang-on <strong>com</strong>ponents:1. Functional Load - at this load the test furniture must still be useable with no deformation or breakage.2. Proof Load - at this load the test furniture must still be safely usable, but deformation is allowed.The following are the BIFMA test loads for two categories of hang-on <strong>com</strong>ponents, worksurfaces and overhead storageunits.Worksurfaces:Functional Load:Proof Load:4.5 lbs/linear inch for 60 minutes7.0 lbs/linear inch for 15 minutes(300 lb minimum)Worksurface Length Functional Load Proof Load24” 108 lbs 300 lbs30” 135 lbs 300 lbs36” 162 lbs 300 lbs42” 189 lbs 300 lbs48” 216 lbs 336 lbs54” 243 lbs 378 lbs60” 270 lbs 420 lbs66” 297 lbs 462 lbs72” 324 lbs 504 lbs84” 378 lbs 588 lbs90” 405 lbs 630 lbs96” 432 lbs 672 lbsOverhead Storage Units:Functional Load 3.0 lbs/linear inch for 60 minutesProof Load 5.0 lbs/linear inch for 15 minutesWorksurface Length Functional Load Proof Load24” 72 lbs 120 lbs30” 90 lbs 150 lbs36” 108 lbs 180 lbs42” 126 lbs 210 lbs48” 144 lbs 240 lbs54” 162 lbs 270 lbs60” 180 lbs 300 lbsNote: The lifting force required to open an overhead door (based upon a 48" unit) is 6.0 lbs.

44Planning GuidelinesWALL MOUNTINGAdjustable Wall Mount KitsThe adjustable wall mount can make up for a wall being up to 1.25" out of plumb.An adjustable wall mount adds 1.25" - 2.50" to the length of a panel run (see below).If two wall mounts are being used on one panel run between two building walls (see below) and the panel run length<strong>com</strong>es up less than 6" short of the total distance, the following solution has been used.The customer shims out the wall using layers of wood and the wall mount is then attached to the shim.Note: Shim to be provided by installer.

45Planning GuidelinesWall TrackWall track allows you to mount WireWorks hang on <strong>com</strong>ponents directly onto a wall without the use of WireWorkspanels. The wall track <strong>com</strong>es in 30", 66" & 84" lengths but can be cut to shorter lengths for hanging worksurfaces only.Wall track should always run all the way to the floor.Wall track MUST be anchored into one of the following wall types:a. A concrete wall using a good quality concrete anchor installed to the manufacturer's re<strong>com</strong>mendation.b. A dry wall surface that is over a minimum 3 /8" thick plywood. Secure the wall track using a good quality hollow wallanchor (toggle bolt) installed according to the manufacturer's re<strong>com</strong>mendations.c. A dry wall surface where all of the wall track is mounted directly into the wood or steel wall studs. Secure the walltrack to the wood stud using at least a #10 x 2 1 /2" wood screw, or a good quality hollow wall anchor (toggle bolt)installed in the steel stud to the manufacturer's re<strong>com</strong>mendations.Note: All holes in the wall track should be used regardless of the length.If possible, it is re<strong>com</strong>mended to also specify worksurface supporting pedestals to provide added support to wall trackmounted worksurface.Wall track is single slotted (see description section) however, one piece of wall track can actually support two adjacenthang on <strong>com</strong>ponents (see below).Worksurface that are hung on wall track will have a space about 2" wide between the back of the worksurface and thewall.

46Planning GuidelinesSTAC<strong>KI</strong>NG SECTIONGUIDELINESThe following specifications apply to stackable sections. Stackable sections must always remain below the ceiling. Tostack on top of a fully assembled panel at least 7" of clearance should be left between the top of the panel and theceiling. If less clearance is available, the panel frame must be disassembled before adding or removing stackingsections.Load Bearing ApplicationsStacking sections are designed to be load bearing,however, only one stacking section is allowed at or belowthe height of the load bearing <strong>com</strong>ponents. Unloadedreturn panels can utilize any number of stacking sections.Non-Load Bearing ApplicationsWhen panels will not be bearing loads, any number ofstacking sections may be used, however, you still mustkeep return panels within 18" in height from the main runfor stability reasons. <strong>Panel</strong>s can be stacked to a maximumheight of 12' and must be below the ceiling.

47Planning GuidelinesDOOR GUIDELINES<strong>Panel</strong> doors are available in 36" and 42" widths. The actual door openings are 30" and 36" respectively. Unless acustomer specifies the smaller door, the larger size (42) should be used to allow for handicap accessibility.<strong>Panel</strong> doors <strong>com</strong>e in right-hand (R), and left-hand (L)versions (see at left).An easy way to remember the difference is: which handwould you have on the door knob as you walk into theroom and open the door away from you.A 36" door occupies the same amount of room as astandard 36" panel. The same is true of 42" doors.Always try to place the hinge side of the panel door so it ispart of a “T” or “Corner” configuration (see at left).The panel that the door opens against, must be an 84" tallpanel, and either be at least as wide as the panel doorwidth, or be part of a panel run that is larger than thepanel door width. The panel that adjoins the door on thelatch side should be 84" tall.If a panel door is requested in the middle of a straightpanel run, an 84" tall panel equal to or greater than thewidth of the panel door, should be placed on the hingeside so the door opens against it (see at left).

48Planning GuidelinesDOOR GUIDELINESPSSP3029-LUse worksurface support brackets or worksurfacesupport panels whenever a worksurface adjoins or hangson a run of panels containing a door.PSB-RA panel door may be used with a wallmount to connectthe panel door to a column or wall. Mounting must beeither parallel to the column or perpendicular to the wall.A panel door cannot be used with an off-module postunless a panel is used between the door and the panelbeing mounted to.OFF-MODULE POST66"PSSP3029-LNever reduce panel heights at a 90° intersectioncontaining a door panel. (example: a corner office withwindows) Always round a corner with a 84" high panelequal or greater in width than the door. At that point alower panel could be used.84"PSB-R84"

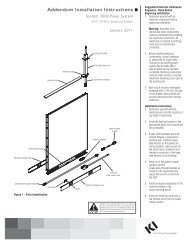

49Planning GuidelinesENHANCEDHORIZONTAL RAILGUIDELINESEach Enhanced Horizontal Rail can be identified by the unique labels that appear on both sides of the horizontal rail.Figures 8 and 9.“enhanced”horizontal rails(#46.0636.WW)Rules:• Any return between 48" and 96" in length requiresenhanced horizontals.• Any return greater than 48" requires enhancedhorizontals on both panels that make up the return.• Two enhanced horizontals are required per panel, oneat the top and the other at the bottom.“standard”horizontalrailsidentifyinglabelidentifyinglabelDefinition of Return: A panel or <strong>com</strong>bination of panels thathas one of its ends connected to a run of panels while theother end is unsupported.• Cannot exceed a total length of 8'• Cannot consist of more than two panels• Cannot support overhead storage• Cannot support worksurfaces or countertopsExamples: Where neededThis <strong>com</strong>bination of two panelsis wider than 48", thereforeboth panels require EnhancedHorizontals.54-96"“enhanced”horizontal railsFigure 8This single panel is wider than48", therefore requiresEnhanced Horizontals.54-60"welded plateFigure 9identifyinglabelThis <strong>com</strong>bination of two panelsis adjacent to a worksurface,but still requires EnhancedHorizontals in both panels.24"54-96"ENHANCED HORIZONTALTo be used at top and bottom of selected panels.Refer to space plan to identify correct panels.<strong>KI</strong>-60940This <strong>com</strong>bination of two panelsattaches the adjacentworksurfaces to a panel with aworksurface support bracket(WSB), but still requiresEnhanced Horizontals in bothpanels.24-30"54-96"

50Planning GuidelinesRECONFIGURINGPANELSThe following are <strong>com</strong>mon reconfigurations to illustrate how easy modifying your existing layout can be. Every originallayout and initial installation of WireWorks is different, so the steps listed below may vary in specific environments.Hint: Worksurface cantilever brackets have elongated slots, rather than holes, for attachment screws. These slots allowfor worksurfaces to be pulled away from the panel one inch so tiles can be removed from the panel without removingthe worksurface entirely.Adding a Stacking SectionAdd a stacking section to the top of an existing monolithic panel in which the top horizontal rail contains cables.1. Remove top trim from the panel that will receivestacking sections and the adjacent panels.2. Remove tiles from both sides of these panels. Toremove tiles from panels which support rectangularworksurfaces without disturbing the equipment on theworksurface, loosen the screws on cantilever bracket justenough to slide the worksurface forward one inch.3. Remove cables from the top horizontal rail of all panelsaffected and let hang.4. Remove the top horizontal rail from the panelsimmediately adjacent to the run of stacking sections.Note: On monolithic panels it is necessary to always havea minimum of two horizontal rails. Before removing thetop horizontal rail of any monolithic panel, first install ahorizontal rail at another height.

51Planning Guidelines5. Install vertical cable guides on vertical posts of thestacking section.Note: Vertical cable guides occupy the same slots in thevertical posts as the brackets for all hanging <strong>com</strong>ponents.In order to insure that overheads and tackboards can behung from the vertical posts, it is best to locate the verticalcable guides 49 inches from the floor. Refer to GuideDiagram on page 82.6. Reroute cables down through the notch at the end ofthe removed horizontal rails of the adjacent panels thenreattach these rails. Then, reroute cables behind verticalcable guides below the stacking sections.7. Remove the cable guards from the top of each of thevertical posts that will be receiving a stacking vertical post.Install stacking vertical posts, horizontal rails and tiles.8. Reuse the top trim from previous panels and installnew “change of height end-of-run caps”.9. Replace monolithic tiles. Slide worksurfaces back tooriginal position and tighten screws.

52Planning GuidelinesRECONFIGURINGPANELSReducing Height of a Monolithic <strong>Panel</strong>Reduce height of monolithic panel in the middle of a run in which the top horizontal rail contains cables.1. Remove top trim from all panels that will be reduced inheight and adjacent panels.2. Remove tiles from both sides of the reduced heightpanels, and from the adjacent panels. To remove tilesfrom panels which support rectangular worksurfaceswithout disturbing the equipment on the worksurface,loosen the screws on cantilever bracket just enough toslide the worksurface forward one inch.3. Remove cables from the top horizontal rail of all panelsaffected and let hang.4. Remove the top horizontal rail from the panelsimmediately adjacent to the reduced height panels.Note: On monolithic panels it is necessary to always havea minimum of two horizontal rails. Before removing thetop horizontal rail of any monolithic panel, first install ahorizontal rail at worksurface height.5. Install vertical cable guides on vertical posts of thestacking section.Note: Vertical cable guides occupy the same slots in thevertical posts as the brackets for all hanging <strong>com</strong>ponents.In order to insure that overheads and tackboards can behung from the vertical posts, it is best to locate the verticalcable guides 49 inches from the floor. Refer to GuideDiagram on page 82.

53Planning Guidelines6. Reroute cables down through the notch at the end ofthe removed horizontal rails of the adjacent panels thenreattach these rails. Then, reroute cables behind verticalcable guides below the reducing sections.7. Relocate top horizontal rail to new lower position onreduced height panels.8. The new reduced height panel can reuse the top trimfrom the taller version by cutting the trim to the properlength. Install in-line height change trim on both posts ofthe reduced height, then trim the top trim to fit.Note: The new in-line height change trim can be orderedas a kit of parts or as separate pieces.9. Replace monolithic tiles. Slide worksurfaces back tooriginal position and tighten screws.

54Planning GuidelinesRECONFIGURINGPANELSAdding a Walkthrough in Middle of RunAdd a walkthrough in the middle of a run of monolithic panels in which the top horizontal rail contains cables.Walkthrough can be used with or without door.1. Remove top trim from panel that will be removed andnext two panels on both sides of walkthrough.2. Remove tiles from both sides of all of these panels. Toremove tiles from adjacent panels which supportrectangular worksurfaces without disturbing theequipment on the worksurface, loosen the screws oncantilever bracket just enough to slide the worksurfaceforward one inch.3. Remove cables from the top horizontal rail of allpanels affected and let hang.4. Remove the top horizontal rail from the panels whichare immediately adjacent to the run of increased heightpanels (<strong>Panel</strong>s directly adjacent to walkthrough must bestacked to match walkthrough height).Note: On monolithic panels it is necessary to always havea minimum of two horizontal rails. Before removing thetop horizontal rail of any monolithic panel, first install ahorizontal rail at worksurface height.5. Install vertical cable guides on vertical posts at ends ofthe stacking section.Note: Vertical cable guides occupy the same slots in thevertical posts as the brackets for all hanging <strong>com</strong>ponents.In order to insure that overheads and tackboards can behung from the vertical posts, it is best to locate thevertical cable guides 49 inches from the floor. Refer toGuide Diagram on page 82.

55Planning Guidelines6. Add stacking vertical posts to walkthrough andadjacent panels to extend walkthrough panel height to 84".7. Remove top horizontal rail of walkthrough andadjacent panels and relocate at top of stacking sections tobridge the space over removed panel.Note: On monolithic panels it is necessary to always havea minimum of two horizontal rails. Before removing thetop horizontal rail of any monolithic panel, first install ahorizontal rail at worksurface height.8. Reroute cables down through the notch at the end ofthe removed horizontal rails of adjacent panels thenreattach these rails. Then, reroute cables behind verticalcable guides, up through notches in adjacent stackingpanels, and through the horizontal rail over walkthrough.9. Replace monolithic tiles. Reuse the top trim from theprevious panel for the top of the horizontal rail and addchange in height trim to the stacking sections.Note: If the opening will not be used with a door, thenspecify door passthrough trim in either 36" or 42" width.

56Planning GuidelinesRECONFIGURINGPANELSAdding Power to Monolithic <strong>Panel</strong> at ADA, Belt or Stand-up HeightAdd ADA, Belt or Stand-up height rigid wireways to a monolithic panel.1. Remove tiles from the side(s) of the panel whichprovides receptacles. To remove tiles from panels whichsupport rectangular worksurfaces without disturbing theequipment on the worksurface, loosen the screws oncantilever bracket just enough to slide the worksurfaceforward one inch.2. Install a horizontal rail and rigid wireway withreceptacles at the desired height(s).

57Planning Guidelines3. Use either vertical or horizontal jumpers to connectrigid wireway(s) to power of same or adjacent panel.4. Add additional horizontal rails, raceway tiles andacoustic tiles to remainder of panel.