PDF (47.97 KB) - VESTAMID

PDF (47.97 KB) - VESTAMID

PDF (47.97 KB) - VESTAMID

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Product InformationProduct Information<strong>VESTAMID</strong>® HTplusM1033Glass-fiberreinforced polyphthalamide compound for injection molding<strong>VESTAMID</strong> HTplus M1033 is a glass-fiberreinforced (30%), heat-stabilized polyphthalamidecompound (PPA) for injection molding.This compound is especially suitable formanufacturing parts subjected to hightemperature.<strong>VESTAMID</strong> HTplus M1033 is supplied ascylindrical pellets in polyethylene packaging.Drying at 120°C for at least 4 hours beforeprocessing is recommended.For information about processing of<strong>VESTAMID</strong> HTplus M1033, please follow thegeneral recommendations for PPA in ourinformation „Handling and Processing of<strong>VESTAMID</strong> HTplus.“For further information, please contact our experts in the department Market Developmententof the High Performance Polymers Business Line.<strong>VESTAMID</strong> ® = registered trademark of the Evonik Degussa GmbH September 2008

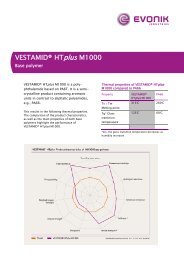

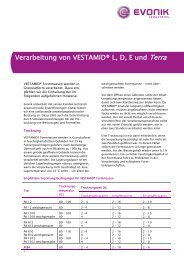

PropertyTest methodinternationalnationalUnit<strong>VESTAMID</strong>HTplusM1033Density 23°C ISO 1183 DIN EN ISO 1183 g/cm 3 1.44Tensile testStress at breakStrain at breakISO 527-1ISO 527-2DIN EN ISO 527-1DIN EN ISO 527-2MPa%1802Tensile modulus ISO 527-1ISO 527-2DIN EN ISO 527-1DIN EN ISO 527-2MPa 11200Flexural testFlexural strengthISO 178 DIN EN ISO 178MPa 260Flexural modulus ISO 178 DIN EN ISO 178 MPa 10000CHARPY impact strengthISO 179/1eUDIN EN ISO 179/1eU23°C-40°CkJ/m 2kJ/m 245 C 1)40 C 1)CHARPY notched impact strengthISO 179/1eADIN EN ISO 179/1eA23°C-40°CkJ/m²kJ/m²7 C 1)7 C 1)Vicat softening temperatureISO 306 DIN EN ISO 306Method AMethod B10 N50 N°C°C313284Melting rangeISO 11357DSC2 nd heating°C 300-315Pigmentation may affect values.1) C = Complete break, incl. hinge break HThe results shown have been generated from a low number of production lots. Therefore, they are preliminary and not yet the result of astatistical evaluation. Therefore they must not be used to establish specifications.® = registered trademarkThis information and all further technical advice are based on Evonik Degussa’s present knowledge and experience. However, EvonikDegussa assumes no liability for providing such information and advice including the extent to which such information and advice mayrelate to existing third party intellecttual property rights, especially patent rights. In particular, Evonik Degussa disclaims all conditionsand warranties, whether expressed or implied, includeing the implied warranties of fitness for a particular purpose or merchantability.Evonik Degussa shall not be responsible for consequential, indirect or incidental damages (including loss of profits) of any kind. EvonikDegussa reserves the right to make any changes according to technological progress or further developments. It is the customer’sresponsibility and obligation to carefully inspect and test any incoming goods. Performance of the product(s) described herein should beverified by testing and carried out only by qualified experts. It is the sole responsibility of the customer to carry out and arrange for anysuch testing. Reference to trade names used by other companies is neither a recommendation, nor an endorsement of any product anddoes not imply that similar products could not be used.Evonik Degussa GmbH BL High Performance Polymers 45764 Marl GermanyPhone +49 2365 49-9878 Fax +49 02365 49-5992www.evonik.com/hp