11. Interfacial Mechanism and Kinetics of Phase-Transfer Catalysis

11. Interfacial Mechanism and Kinetics of Phase-Transfer Catalysis

11. Interfacial Mechanism and Kinetics of Phase-Transfer Catalysis

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

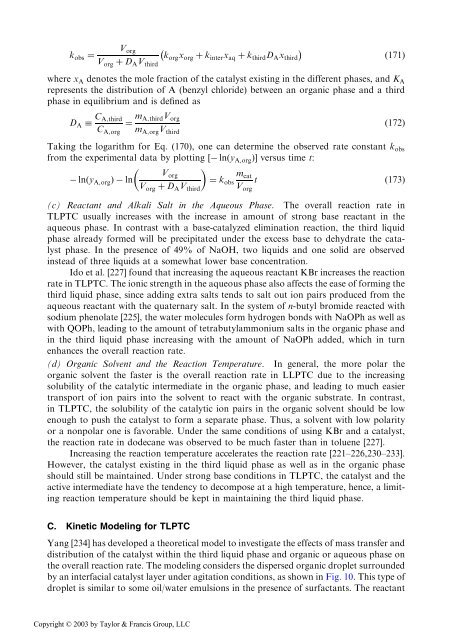

V orgk obs ¼V org þD A V thirdk org x org þk inter x aq þk third D A x thirdð171Þwhere x A denotes the mole fraction <strong>of</strong> the catalyst existing in the different phases, <strong>and</strong> K Arepresents the distribution <strong>of</strong> A(benzyl chloride) between an organic phase <strong>and</strong> athirdphase in equilibrium <strong>and</strong> is defined asD A C A;thirdC A;org¼ m A;thirdV orgm A;org V thirdð172ÞTaking the logarithm for Eq. (170), one can determine the observed rate constant k obsfrom the experimental data by plotting ½ lnðy A;org ÞŠversus time t:V orgmlnðy A;org Þ ln¼k catV org þD A V obs tð173Þthird V org(c) Reactant <strong>and</strong> Alkali Salt in the Aqueous <strong>Phase</strong>. The overall reaction rate inTLPTC usually increases with the increase in amount <strong>of</strong> strong base reactant in theaqueous phase. In contrast with abase-catalyzed elimination reaction, the third liquidphase already formed will be precipitated under the excess base to dehydrate the catalystphase. In the presence <strong>of</strong> 49% <strong>of</strong> NaOH, two liquids <strong>and</strong> one solid are observedinstead <strong>of</strong> three liquids at asomewhat lower base concentration.Ido et al. [227] found that increasing the aqueous reactantKBrincreases the reactionrateinTLPTC.Theionicstrengthintheaqueousphasealsoaffectstheease<strong>of</strong>formingthethird liquid phase, since adding extra salts tends to salt out ion pairs produced from theaqueous reactant with the quaternary salt. In the system <strong>of</strong> n-butyl bromide reacted withsodium phenolate [225], the water molecules form hydrogen bonds with NaOPh as well aswith QOPh, leading to the amount <strong>of</strong> tetrabutylammonium salts in the organic phase <strong>and</strong>in the third liquid phase increasing with the amount <strong>of</strong> NaOPh added, which in turnenhances the overall reaction rate.(d) Organic Solvent <strong>and</strong> the Reaction Temperature. In general, the more polar theorganic solvent the faster is the overall reaction rate in LLPTC due to the increasingsolubility <strong>of</strong> the catalytic intermediate in the organic phase, <strong>and</strong> leading to much easiertransport <strong>of</strong> ion pairs into the solvent to react with the organic substrate. In contrast,in TLPTC, the solubility <strong>of</strong> the catalytic ion pairs in the organic solvent should be lowenough to push the catalyst to form aseparate phase. Thus, asolvent with low polarityor anonpolar one is favorable. Under the same conditions <strong>of</strong> using KBr <strong>and</strong> acatalyst,the reaction rate in dodecane was observed to be much faster than in toluene [227].Increasing the reaction temperature accelerates the reaction rate [221–226,230–233].However, the catalyst existing in the third liquid phase as well as in the organic phaseshould still be maintained. Under strong base conditions in TLPTC, the catalyst <strong>and</strong> theactive intermediate have the tendency to decompose at ahigh temperature, hence, alimitingreaction temperature should be kept in maintaining the third liquid phase.C. Kinetic Modeling for TLPTCYang[234]hasdevelopedatheoreticalmodeltoinvestigatetheeffects<strong>of</strong>masstransfer<strong>and</strong>distribution <strong>of</strong> the catalyst within the third liquid phase <strong>and</strong> organic or aqueous phase ontheoverallreactionrate.Themodelingconsidersthedispersedorganicdropletsurroundedbyaninterfacialcatalystlayerunderagitationconditions,asshowninFig.10.Thistype<strong>of</strong>droplet is similar to some oil/water emulsions in the presence <strong>of</strong> surfactants. The reactantCopyright © 2003 by Taylor & Francis Group, LLC