MODUBLOC MB SE-SV BLU SERIES - Riello by Unimech Thailand

MODUBLOC MB SE-SV BLU SERIES - Riello by Unimech Thailand

MODUBLOC MB SE-SV BLU SERIES - Riello by Unimech Thailand

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

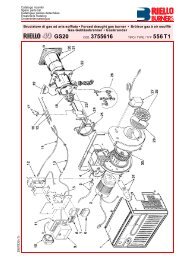

Low NOx Modulating Gas Burners<strong>MODUBLOC</strong> <strong>MB</strong> <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong> <strong>SE</strong>RIESSpecificationSTATE OF SUPPLYMonoblock forced draught gas burner with modulating operation, fully automatic, made up of:- Fan with reverse curve blades high performance with low sound emissions- Air suction circuit lined with sound-proofi ng material- Air damper for air setting controlled <strong>by</strong> a high precision servomotor- Air pressure switch- Fan starting motor at 2900 rpm, three-phase 230/400 - 400/690 V with neutral, 50Hz- Low emission mobile combustion head, that can be set on the basis of required output, fi tted with:- stainless steel end cone, resistant to corrosion and high temperatures- ignition electrodes- fl ame stability disk- Automatic regulator for gas delivery, controlled <strong>by</strong> a high precision servomotor- Maximum gas pressure switch, with pressure test point, for halting the burner in the case of over pressure on the fuel supplyline- Module for air/fuel setting and output modulation with incorporated PID control of temperature or pressure of the heat generator- Burner safety control box for controlling the system safety- Photocell for fl ame detection- Star/triangle starter for the fan motor- Main electrical supply terminal board- Burner on/off switch- Auxiliary voltage led signal- Manual or automatic output increase/decrease switch- Burner working led signal- Contacts motor and thermal relay with release button- Motor internal thermal protection- Motor failure led signal- Burner failure led signal and lighted release button- Led signal for correct rotation direction of fan motor- Emergency button- Coded connection plugs-sockets- Burner opening hinge- Lifting rings- IP X0D (IP 40) protection level.Standard equipment:- 1 fl ange gasket- 8 screws for fi xing the fl ange- 1 thermal screen- 4 screws for fi xing the burner fl ange to the boiler- Instruction handbook for installation, use and maintenance- Spare parts catalogue.344

Low NOx Modulating Gas Burners<strong>MODUBLOC</strong> <strong>MB</strong> <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong> <strong>SE</strong>RIESAvailable modelsBurnersCODE MODEL HEAT OUTPUTNATURAL GASTOTALELECTRICALPOWERCERTIFICATION(kW) (Nm 3 /h) (kW)3897900 <strong>MB</strong>8<strong>SE</strong> <strong>BLU</strong> TC FR FS1 3/400/50 230/50-60 900/3330-8400 90/330-840 18 CE 0085 B001753897910 <strong>MB</strong>8<strong>SE</strong> <strong>BLU</strong> TC FR FS2 3/400/50 230/50-60 900/3330-8400 90/330-840 18 CE 0085 B001753897905 <strong>MB</strong>8<strong>SE</strong> <strong>BLU</strong> TC FL FS1 3/400/50 230/50-60 900/3330-8400 90/330-840 18 CE 0085 B001753897915 <strong>MB</strong>8<strong>SE</strong> <strong>BLU</strong> TC FL FS2 3/400/50 230/50-60 900/3330-8400 90/330-840 18 CE 0085 B001753896600 <strong>MB</strong>10<strong>SE</strong> <strong>BLU</strong> TC FR FS1 3/400/50 230/50-60 1100/4000-9200 110/400-920 22 CE 0085 BM03473896610 <strong>MB</strong>10<strong>SE</strong> <strong>BLU</strong> TC FR FS2 3/400/50 230/50-60 1100/4000-9200 110/400-920 22 CE 0085 BM03473896605 <strong>MB</strong>10<strong>SE</strong> <strong>BLU</strong> TC FL FS1 3/400/50 230/50-60 1100/4000-9200 110/400-920 22 CE 0085 BM03473896615 <strong>MB</strong>10<strong>SE</strong> <strong>BLU</strong> TC FL FS2 3/400/50 230/50-60 1100/4000-9200 110/400-920 22 CE 0085 BM03473896700 <strong>MB</strong>12<strong>SE</strong> <strong>BLU</strong> TC FR FS1 3/400/50 230/50-60 1500/4800-10050 150/480-1000 27 CE 0085 B044003896705 <strong>MB</strong>12<strong>SE</strong> <strong>BLU</strong> TC FL FS1 3/400/50 230/50-60 1500/4800-10050 150/480-1000 27 CE 0085 B044003896710 <strong>MB</strong>12<strong>SE</strong> <strong>BLU</strong> TC FR FS2 3/400/50 230/50-60 1500/4800-10050 150/480-1000 27 CE 0085 B044003896715 <strong>MB</strong>12<strong>SE</strong> <strong>BLU</strong> TC FL FS2 3/400/50 230/50-60 1500/4800-10050 150/480-1000 27 CE 0085 B044003897920 <strong>MB</strong>8<strong>SV</strong> <strong>BLU</strong> TC FR FS1 3/400/50 230/50-60 1300/3380-8000 99/338-800 18 CE 0085 B02303897925 <strong>MB</strong>8<strong>SV</strong> <strong>BLU</strong> TC FL FS1 3/400/50 230/50-60 1300/3380-8000 99/338-800 18 CE 0085 B02303897930 <strong>MB</strong>8<strong>SV</strong> <strong>BLU</strong> TC FR FS2 3/400/50 230/50-60 1300/3380-8000 99/338-800 18 CE 0085 B02303897935 <strong>MB</strong>8<strong>SV</strong> <strong>BLU</strong> TC FL FS2 3/400/50 230/50-60 1300/3380-8000 99/338-800 18 CE 0085 B02303896620 <strong>MB</strong>10<strong>SV</strong> <strong>BLU</strong> TC FR FS1 3/400/50 230/50-60 1100/4000-8860 110/400-886 22 CE 0085 B002313896630 <strong>MB</strong>10<strong>SV</strong> <strong>BLU</strong> TC FR FS2 3/400/50 230/50-60 1100/4000-8860 110/400-886 22 CE 0085 B002313896625 <strong>MB</strong>10<strong>SV</strong> <strong>BLU</strong> TC FL FS1 3/400/50 230/50-60 1100/4000-8860 110/400-886 22 CE 0085 B002313896635 <strong>MB</strong>10<strong>SV</strong> <strong>BLU</strong> TC FL FS2 3/400/50 230/50-60 1100/4000-8860 110/400-886 22 CE 0085 B002313896720 <strong>MB</strong>12<strong>SV</strong> <strong>BLU</strong> TC FR FS1 3/400/50 230/50-60 1505/4800-10050 150/480-1000 27 CE 0085 B0044103896725 <strong>MB</strong>12<strong>SV</strong> <strong>BLU</strong> TC FL FS1 3/400/50 230/50-60 1505/4800-10050 150/480-1000 27 CE 0085 B0044103896730 <strong>MB</strong>12<strong>SV</strong> <strong>BLU</strong> TC FR FS2 3/400/50 230/50-60 1505/4800-10050 150/480-1000 27 CE 0085 B0044103896735 <strong>MB</strong>12<strong>SV</strong> <strong>BLU</strong> TC FL FS2 3/400/50 230/50-60 1505/4800-10050 150/480-1000 27 CE 0085 B004410NOTEG20 net calorifi c value: 10 kWh/Nm 3 - Density: 0,71 kg/Nm 3The burners of <strong>MB</strong> <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> series are in according to 90/396 - 89/336 (2004/108) - 73/23 (2006/95) EC Directive and EN 676 Norm.346

Low NOx Modulating Gas Burners<strong>MODUBLOC</strong> <strong>MB</strong> <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong> <strong>SE</strong>RIESAvailable modelsGas TrainsGAS TRAIN GAS TRAIN NATURAL GAS LPG NOTECODE *MODELBURNER(type)ADAPTER(code)BURNER(type)ADAPTER(code)MULTIBLOC3970225 <strong>MB</strong>C 1200 <strong>SE</strong> 50 CT<strong>MB</strong> 8 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong><strong>MB</strong> 10 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong>3000826 (“I”) type (1)COMPO<strong>SE</strong>D3970226 <strong>MB</strong>C 1900 <strong>SE</strong> 65 FC CT3970227 <strong>MB</strong>C 3100 <strong>SE</strong> 80 FC CT3970228 <strong>MB</strong>C 5000 <strong>SE</strong> 100 FC CT* gas trains are 230V/50Hz - 220V/60Hz electrical supply(1) Seal control incorporated<strong>MB</strong> 8 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong><strong>MB</strong> 10 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong>3010221 (“I”) type3010225 (“Z”) type(1)<strong>MB</strong> 12 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong><strong>MB</strong> 8 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong><strong>MB</strong> 10 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong><strong>MB</strong> 12 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong><strong>MB</strong> 8 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong><strong>MB</strong> 10 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong><strong>MB</strong> 12 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong>3010222 (“I”) type3010226 (“Z”) type3010223 (“I”) type3010227 (“Z”) type(1)(1)LOW NOx GASTo select the gas train please refer to the technical data leafl et and/or instruction manual.347

Low nox Modulating Gas Burners<strong>MODUBLOC</strong> <strong>MB</strong> <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong> <strong>SE</strong>RIESBurner accessoriesDTI module (Data Transfer Interface)This electronic module can transfer multiple signals from different local modules to a BMSsupervisor software system (Building Management System).BurnerModule codeu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> 3010234I/O digital moduleDigital modules I/O transfer in-coming and out-going information from the boiler room or from thesystem in general to a remote supervisor system.BurnerModule codeu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> 3010233I/O analogic moduleI/O Analog modules transfer in-coming and out-going information to a remote supervisorsystem.BurnerModule codeu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> 3010232EGA module (Exhaust Gas Analyser)Four different EGA modules are available to measure some of the exhaust gas substances andtheir temperature.Burner Analysed gas Module codeu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> CO, CO 2 , O 2 on demandu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> CO, CO 2 , O 2 , NO 20019488u <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> CO, CO 2 , O 2 , SO 2 on demandu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> CO, CO 2 , O 2 , NO, SO 2 on demandBelden 9501 type leadsAll the connections for the above modules must be done using a BELDEN 9501 type lead(available in coils of 50 m).Burnerlead codeu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> 3010239348

Low NOx Modulating Gas Burners<strong>MODUBLOC</strong> <strong>MB</strong> <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong> <strong>SE</strong>RIESBurner accessoriesAccessories for modulating operationMain management module allows a modulating operation with use of probes chosen on thebasis of the application.BURNER PROBE TYPE RANGE (°C) (bar) PROBE CODEu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> Temperature 0 ÷ 400°C 3010187u <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> Pressure 0 ÷ 3 bar 3010246u <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> Pressure 0 ÷ 18 bar 3010186u <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> Pressure 0 ÷ 30 bar 3010188Burner supportFor easier maintenance, a mobile burner support has been designed, which means the burnercan be dismantled without the need for forklift trucks.BURNERSUPPORT CODEu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> 3010385LOW NOx GASInverter moduleThe inverter allows the variation of the amount of combustion air through a variable speed actionof the fan motor.BURNERCODEu <strong>MB</strong> 8 <strong>SV</strong> <strong>BLU</strong> 3010446u <strong>MB</strong> 10 - 12 <strong>SV</strong> <strong>BLU</strong> 3010447Sound proofing boxIf noise emission needs reducing even further, sound-proofi ng boxes are available.BURNERAVERAGE NOI<strong>SE</strong>REDUCTION [dB(A)] (*)BOX CODEu <strong>MB</strong> 8 - 10 - 12 <strong>SE</strong> - <strong>SV</strong> <strong>BLU</strong> 10 3010401(*) according to EN 15036-1 standard349

Low NOx Modulating Gas Burners<strong>MODUBLOC</strong> <strong>MB</strong> <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong> <strong>SE</strong>RIESGas train accessoriesAdaptersIn certain cases, an adapter must be fi tted between the gas train and the burner, when thediameter of the gas train is different from the set diameter of the burner.Below are given the adapters than can be fi tted on the various burners:BURNER GAS TRAIN ADAPTER DIMENSIONS ADAPTERTYPE Øi Øo A B C CODEDN DN mm mm mmu <strong>MB</strong> 8-10 <strong>SE</strong>-<strong>SV</strong> <strong>BLU</strong> <strong>MB</strong>C 1200 I 2”(1) 80 -- -- -- 3000826u All models(1) Unless fl ange<strong>MB</strong>C 1900 I 65 80 320 -- -- 3010221<strong>MB</strong>C 3100 I 80 80 320 -- -- 3010222<strong>MB</strong>C 5000 I 100 80 320 -- -- 3010223<strong>MB</strong>C 1900 Z 65 80 400 480 225 3010225<strong>MB</strong>C 3100 Z 80 80 400 480 225 3010226<strong>MB</strong>C 5000 Z 100 80 400 480 225 3010227Stabiliser springTo vary the pressure range of the gas train stabilisers, accessory springs are available. Thefollowing table shows these accessories with their application range. Please refer to the technicalmanual for the correct choice of spring.GAS TRAIN SPRING SPRING CODEu <strong>MB</strong>C 1900u <strong>MB</strong>C 3100u <strong>MB</strong>C 5000White from 4 to 20 mbar 3010381Red from 20 to 40 mbar 3010382Black from 40 to 80 mbar 3010383Green from 80 to 150 mbar 3010384350