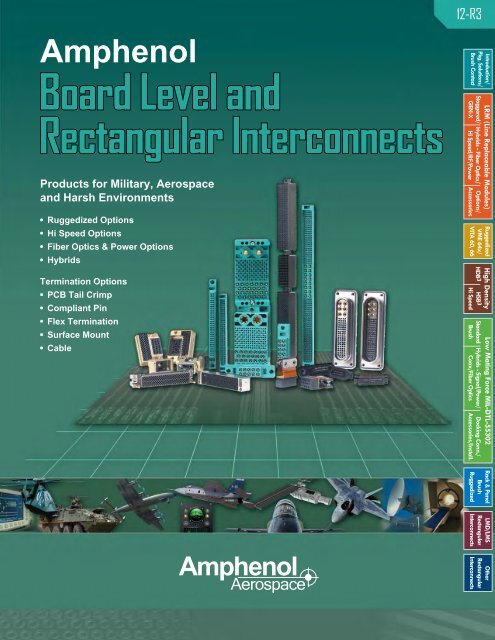

Board Level and Rectangular Interconnects - Amphenol Aerospace

Board Level and Rectangular Interconnects - Amphenol Aerospace

Board Level and Rectangular Interconnects - Amphenol Aerospace

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

The Interconnection Leader<strong>Amphenol</strong> is the world leader in the design, manufacture,<strong>and</strong> supply of high-performance interconnect systemsfor military <strong>and</strong> commercial aerospace harshenvironment applications.Key markets supported are Avionics, Radar, Communications, Ordnance, Missiles, Engines,Ground Vehicles <strong>and</strong> Tanks, Space, <strong>and</strong> all levels of Aviation. <strong>Amphenol</strong> is a technologyinnovator that designs to meet customers’ needs from program inception.AvionicsMilitary AircraftCommercial AirSpaceVehiclesNavalMissiles & OrdnanceMissile DefenseC4IUAV’sREQUEST A QUOTEContact our customer service representatives forpricing <strong>and</strong> availability at:• Call 800-678-0141 (ask for customer service)• E-mail cservice@amphenol-aao.com• Request a Quote online atwww.amphenol-aerospace/rfq.aspTECHNICAL SUPPORTDo you have a technical question pertaining to atype or style of a connector?• Call 800-678-0141 (ask for customer service)• Fill out a techical support form online at www.amphenol-aerospace.com/techsupportform.asp

About <strong>Amphenol</strong> ® <strong>Aerospace</strong>YOUR SOURCE FOR INTERCONNECT PRODUCTS<strong>Amphenol</strong><strong>Aerospace</strong>CONTACT US:<strong>Amphenol</strong> <strong>Aerospace</strong>40-60 Delaware AvenueSidney, NY 13838-1395Customer Service: Mon.-Friday 8 am - 5 pmPhone: (800)678-0141Fax: (607)563-5157Online: www.amphenol-aerospace.comABOUT AMPHENOL AEROSPACE:<strong>Amphenol</strong> <strong>Aerospace</strong>, a Division of <strong>Amphenol</strong> Corporation, is oneof the largest manufacturers of interconnect products in the worldfor the Military, Commercial <strong>Aerospace</strong> <strong>and</strong> Industrial markets.<strong>Amphenol</strong> designs, manufactures <strong>and</strong> markets circular <strong>and</strong>rectangular, electronic, fiber optic, EMI/EMP filter, <strong>and</strong> a variety ofspecial applications connectors <strong>and</strong> interconnect systems.Our 675,000 square foot facility is nestled at the foothills of theCatskill Mountains in Sidney NY. The <strong>Amphenol</strong> complex housesstate-of-the-art manufacturing technologies including CNCmachining, die-casting, molding, impact <strong>and</strong> extruding, plating,screw machining <strong>and</strong> process controls. Our fully equipped materialevaluation lab <strong>and</strong> engineering organization utilize the latest incomputer aided design software <strong>and</strong> analysis tools, allowing us todesign, test, <strong>and</strong> qualify advanced interconnect systems.<strong>Amphenol</strong>’s interconnect products are supplied to thous<strong>and</strong>s ofOEMs worldwide <strong>and</strong> are supported by our worldwide sales <strong>and</strong>engineering force, including the largest global network of electronicdistributors.<strong>Amphenol</strong> Canada Corp. (ACC)facility in Toronto, ONOffers a comprehensive range of filtered<strong>and</strong> rectangular connector products forcommercial, military <strong>and</strong> aerospaceapplications.<strong>Amphenol</strong> Backplane Systems (ABS)facility in Nashua, NHHouses the manufacturing, design <strong>and</strong>engineering of backplane systems.<strong>Amphenol</strong> Printed Circuits, (APC)facility in Nashua, NHManufactures, designs <strong>and</strong> engineers flexcircuit products <strong>and</strong> printed circuit boards.AMPHENOL AEROSPACE’S PHILOSOPHYAs a basic business philosophy, <strong>Amphenol</strong> <strong>Aerospace</strong> is dedicated to concentratingon those advanced <strong>and</strong> challenging market segments that dem<strong>and</strong> an extraordinarylevel of supplier support <strong>and</strong> reaction. Our approach to implement this strategy isbased on the following key principles:FOCUS: Concentrate all resources on serving a limitednumber of tightly defined markets, <strong>and</strong> underst<strong>and</strong>ing theneeds of those markets.INNOVATION: Provide these markets new, creative solutionsin both products <strong>and</strong> services.RESPONSIVENESS: Identify <strong>and</strong> respond to the market <strong>and</strong>product needs more rapidly than any other supplier.<strong>Amphenol</strong> <strong>Aerospace</strong>, <strong>Amphenol</strong> Commercial Air <strong>and</strong> <strong>Amphenol</strong>Industrial Operations Main Facility in Sidney, N.Y. USA<strong>Amphenol</strong> facility in Nogales,MexicoHouses the manufacture of severalindustrial <strong>and</strong> aerospace product lines.<strong>Amphenol</strong> Nexus Technologiesin Stamford, CTDesigns <strong>and</strong> manufactures audioconnectors for military, aviation, medical,telecommunications, auto racing, powerboats & farm equipment.<strong>Amphenol</strong> Borisch in Gr<strong>and</strong>Rapids, MIA full service electronics manufacturerspecializing in defense contractors withwiring harnesses, circuit boards <strong>and</strong> otherelectrical hardware.QUALITY ASSURANCE:<strong>Amphenol</strong> <strong>Aerospace</strong> has been awardedboth AS9100 - Revision B <strong>and</strong> ISO9001:2000 QualityAssurance Certifications.Performance is the sum of these principles. It is the measureof how well we continually <strong>and</strong> consistently implement ourbasic strategy <strong>and</strong> key principles.Introduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com1

<strong>Board</strong> <strong>Level</strong> <strong>and</strong> <strong>Rectangular</strong> <strong>Interconnects</strong>IntroductionQUICK REFERENCE TO THIS CATALOG BY PRODUCTS<strong>Amphenol</strong><strong>Aerospace</strong>Introduction/Package Solutions/Brush Contact TechnologyLRM (Line Replaceable Modules)with Brush Contacts/ LRM Hybrids/Options/AccessoriesVME/VITA <strong>Interconnects</strong>High Density HDB 3 & HSB 3 (HighSpeed) with Brush ConnectorsLow Mating Force Connectorswith Brush Contacts & Hybrids/Accessories/InstallationRuggedized Brush Rack &Panel ConnectorsLMD/LMS Modular <strong>Rectangular</strong><strong>Interconnects</strong>Other <strong>Board</strong> <strong>Level</strong> &<strong>Rectangular</strong> <strong>Interconnects</strong>Pages1-3 . .. .. .Introduction, Table of Contents/Quick Reference4, 5 . .. .. .Customized Package Solutions <strong>and</strong> IntegratedSystems6.. .. .. .. .New/Featured Products7, 8 . .. .. .Brush Contact - The Superior Choicefor <strong>Board</strong> <strong>Level</strong> <strong>Interconnects</strong>Pages9-12 .. .. .LRM Styles, Design Flexibility/ LRM Product Evolution13, 14 .. .LRM Design Engineering, Manufacturing15-25 .. .Staggered Grid LRMs25, 26 .. .GEN-X Grid LRMs27-30 .. .LRM Hybrids: Fiber Optics/Hi Speed Contacts/RF/High Power31-35 .. .New Hi Speed Gigastak & Digistak36 .. .. .. .Hi Speed Modeling/Testing37-40 .. .LRM Options: Flex, Compliant Pins, PC Tails,ESD Protection/Accessories & Tools41 .. .. .. .Aid in Selection/Ordering of LRM/LRU <strong>Interconnects</strong>Pages42 .. .. .. .Introduction43 .. .. .. .VME64x <strong>Interconnects</strong>44-46 .. .VME P0/J0, VITA-66.1,VIPER TM (VITA compatible) <strong>Interconnects</strong>Pages47-49 .. .HDB 3 /HSB 3 High Density Features,Options, Performance50-53 .. .HDB 3 Connectors: Styles & How to Order54-58 .. .HSB 3 Connectors: Styles & How to Order59 .. .. .. .Hardware for HDB 3 & HSB 3Pages60-62 .. .Low Mating Force Connector Features,Performance, Materials, Design Flexibility63-84 .. .4 Body Styles: How to Order/Contact Arrangements85, 86 .. .Smaller Sizes with .100 X .100 sq. inch grid87, 88 .. .Hybrids: Brush Contacts in Combinationwith Other Contact Types/Small Color-Coded Brush Connectors89 .. .. .. .Docking Connectors with Brush Contacts90-95 .. .Low Mating Force Connector Accessories & InstallationPages96, 97 .. .Ruggedized, Non-Floating BrushRack & Panel Connectors Features & Options98 .. .. .. .Performance Data/ Hybrids with RADSOK ®Pages99-101 . .LMD & LMS Connector Features, Benefits & Performance102-106 Housings How to Order <strong>and</strong> Module Arrangements107-109 Accessories <strong>and</strong> Assembly Instructions110. .. .. .LMS In-Line Splice ConnectorPages111. .. .. ..Introduction112-113 ..Heat Sink/Metal Manufacturing114, 115..ARINC Rack & Panel, R27, R39,R58, R393 Connectors116. .. .. ..ARINC Filter <strong>Rectangular</strong>s, Micro-D,Microminiature & D-Sub Connectors117. .. .. ..Backplane Systems & Enclosures118, 119..UHD & NAFI <strong>Interconnects</strong>120, 121..Printed Circuit <strong>Board</strong>s & FlexCircuitryPages122. .. .. ..Integrated Systems123. .. .. ..Quadrax Hi Speed Contactsfor PCB Attachment124, 125..RADSOK ® Interconnect Solutionsfor High Power126. .. .. ..RF High Frequency Contactsfor LRM <strong>Interconnects</strong>127. .. .. ..Cylindrical Connectors forPrinted Circuit <strong>Board</strong> Attachment128. .. .. ..<strong>Amphenol</strong>’s Broad ProductOffering of Circular <strong>Interconnects</strong>Introduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com3

<strong>Amphenol</strong><strong>Aerospace</strong>Customized Interconnect Package Solutions<strong>and</strong> Integrated SystemsEVERYTHING YOU NEED, INSIDE & OUTSIDE THE BOXIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesRuggedizedVME64x /VITA 60, 66High DensityHSB3 HDB3Hi Speed<strong>Amphenol</strong> Corporation’s broad technical, product <strong>and</strong> manufacturingresources enable <strong>Amphenol</strong> <strong>Aerospace</strong> to provideexceptional performance in the area of customized systemdevelopment-application specific packaging which blends bothCorporate <strong>and</strong> <strong>Amphenol</strong> <strong>Aerospace</strong> products <strong>and</strong> designinnovations. We provide customers with rapid, well engineered<strong>and</strong> cost-effective custom interconnect solutions.I/O FRONT PANELCIRCULARCONNECTORSRugged, environmentallysealed I/Oconnectors, filtered<strong>and</strong> non-filtered.Available in a varietyof styles <strong>and</strong> classesincluding threaded <strong>and</strong>bayonet coupling.HI-SPEEDCONTACTSRF, Coax, Triax,Twinax,Quadrax <strong>and</strong> new 10-Ghigh speed contactsavailable.FLEX CIRCUITRYRigid-Flex circuit interconnectsfeaturing blind <strong>and</strong> buried vias,microvias, bookbinder <strong>and</strong> othercutting-edge technologiesincluding large format panels.Low Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>FIBER OPTICSFOR HARSHENVIRONMENTSVery high densitiescan be achieved withMT FerruleTermini.METALMACHININGFaceplates,enclosures,bus bars, heatsinks <strong>and</strong>stiffenermachiningcapabilities.Multiple platingoptions available.PRINTED CIRCUITBOARDS FORBACKPLANES &DAUGHTER-CARDSFabrication capabilitiesinclude a widevariety of materials toenable increasing signalspeeds, deep microvias,buried, blind <strong>and</strong> back-drilled vias, sequential,lamination, panel sizes from 18” x 24” up to24” x 54”, <strong>and</strong> layer counts up to 60 with aboard thickness of 0.400”. Multiple platingoptions available.The products shown on this page <strong>and</strong> the next represent some of the broad offeringsfrom the divisions of: <strong>Amphenol</strong> <strong>Aerospace</strong>, <strong>Amphenol</strong> Backplane Systems,<strong>Amphenol</strong> Printed Circuits <strong>and</strong> <strong>Amphenol</strong> Canada; who work together as a systemlevelteam to work with customers for their enclosure integration of interconnects.LRMDesigned to meet thehigh-density needs of today’sintegrated electronicmodules, this straddle-mountconnector uses the BristleBrush contact, a provenmilitary avionics solutionsthat meets MIL-DTL-55302requirements. The lowmating force, extendedservice life <strong>and</strong> stableelectrical performance of theBrush contact enables theperformance dem<strong>and</strong>ed byLine Replaceable Module(LRM) applications. Hybridsavailable with fiber optics <strong>and</strong>high power RADSOK ® .4Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Customized Interconnect Package Solutions<strong>and</strong> Integrated Systems, cont.A BROAD OFFERING OF INTERCONNECTS<strong>Amphenol</strong><strong>Aerospace</strong>MIL-83513 MICRO DAssembled to flex I/Otransition to outside ortake signals off thebackplane.BLINDMATE RACK & PANELCONNECTORS:ARINC 600, 404 & 83527Designed per ARINC 600 or ARINC 400 specifications.Single double, triple or quad bay insertstyles available. Customize insert arrangementsto include signal, power, coax, <strong>and</strong> quadraxcontacts, or fiber optic termini.NAFI & UHDMedium to high density connectorswith fork <strong>and</strong> blade contacts. Modulecard with straddle-mount <strong>and</strong>through hole termination <strong>and</strong> solderlesspress-fit backplane contacts.EMI shielding, coax, fiber optic, <strong>and</strong>power contacts availableIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66GIGASTAK, GIGASTAK-LG &DIGISTAKThe highly reliable LRM Brush connector withcStack TM termination technology - giving theuser hi-speed signal options up to 6.25 Gb/s<strong>and</strong> a solderless termination to their CCA.Designed for 100 ohm differential impedance.Provides optimized cross-talk.VITA 60/64 VIPERHigh density, modular 6+ Gbps, highvibration performing, ESD shieldedconnector meeting the specifications forVITA 46 <strong>and</strong> 48 in both 3U <strong>and</strong> 6Uconfigurations. Developed using provenmechanical <strong>and</strong> signal integrity withunmatched performance in the industry.High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302RUGGEDIZED VME64XRuggedized replacement forst<strong>and</strong>ard VME connectors.Improved reliability <strong>and</strong> performanceto meet avionic environmentalpackaging requirements.Shown right is another <strong>Amphenol</strong>integrated system box thatincludes both circular <strong>and</strong>rectangular interconnects, flex<strong>and</strong> backplanes in a custommetal enclosure. See moreinformation on IntegratedSystems <strong>and</strong> Package Solutionsfrom <strong>Amphenol</strong> in the Other<strong>Rectangular</strong> <strong>Board</strong> <strong>Level</strong> &<strong>Rectangular</strong> Interconnect Sectionof this catalog, page 122.Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com5

<strong>Amphenol</strong><strong>Aerospace</strong><strong>Board</strong> <strong>Level</strong> <strong>and</strong> <strong>Rectangular</strong> <strong>Interconnects</strong>NEW/FEATURED PRODUCTSIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesRuggedizedVME64x /VITA 60, 66High DensityHSB3 HDB3Hi SpeedLow Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong><strong>Amphenol</strong> has become the leader in interconnection products through its long history ofengineering expertise for product solution solving.New <strong>and</strong> innovative solutions are under development every day within our highly skilledengineering departments who are teamed with marketing product managers <strong>and</strong>production specialists. They are always striving to meet new customer requirements inever changing markets.The teams have a customer-driven approach to produce the end result: quality interconnectproducts that meet or exceed customer dem<strong>and</strong>s.Below are some of the newer product solutions that have been developed in response toour customers’ ever evolving requirements for board level <strong>and</strong> rectangular interconnects.New/Featured ProductHDB 3 /HSB 3 High Density <strong>and</strong> High SpeedBrush Connector SeriesPage 47Tighter .070 inch X .060 inch staggered grid spacingprovides higher density in a compact-height board levelconnector.New/Featured ProductHigh Speed GigaStak TM , Gigastak-LG TM ,DigiStak TM <strong>and</strong> DigiStak-X TM LRM ConnectorsPages 31-36High speed inserts providedata transference of up to6.25 Gb/s.Giga1100110100100tak01100110011001101Built for speedNew/Featured ProductLRM Connectors with High Power RADSOK ®ContactsPage 30High Amperage RADSOK ® socket contacts are designedinto LRM connectors for higher power applications. TheRADSOK ® socket imparts high current flow across theconnection with minimal voltage loss with its hyperbolic,stamped grid configuration.New/Featured ProductVITA-66.1 Fiber Optic <strong>Interconnects</strong>Page 44A reliable high speed connection for the most extremecommercial <strong>and</strong> military environments. This ruggedizedinterconnect is among the highest density of connectorproducts on the market.New/Featured ProductVIPER ® High-Speed<strong>Interconnects</strong>Pages 45 & 46A shielded, high density, hi-speedmodular interconnect with press-fittermination. VITA 46, VITA 48 <strong>and</strong> VITA60 foot-print compatability. Designed for10 + Gb/s data rate performance.For assistance with your specific interconnection requirements, give a call tothe <strong>Amphenol</strong> sales representative in your area,(go online to amphenol-aerospace.com) or call for product assistance at<strong>Amphenol</strong> <strong>Aerospace</strong>, 800-678-0141 or 607-563-5011.Solution:Higher contact densityplus lower mated height -thus maximizing boardspace.Solution:Hi Speed performance in aruggedized connector.Utilizes new cStack TMtermination - solderlessinterconnectionbetween flex <strong>and</strong> board.Solution:High Amperage RADSOK ®socket contactsallow for passingof larger amountsof current withlower matingforces thanst<strong>and</strong>ard contacts.Solution:Higher Density in arectangular board levelconnector package.Solution:To meet <strong>and</strong> exceed therequirements for today’shigh performance, highspeed applications.6Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Brush Contact TechnologyA SUPERIOR CHOICE FOR BOARD LEVEL INTERCONNECTS<strong>Amphenol</strong><strong>Aerospace</strong>Low Mating ForceConnectors withBristle Brushcontact technology.Many styles areavailable, includingstyles that havearrangements ofbrush, fiber optic,coax <strong>and</strong> othercontact types.The <strong>Amphenol</strong> ® Brush Contact Technology has proven advantagesover st<strong>and</strong>ard pin & socket contacts <strong>and</strong> <strong>Amphenol</strong> has avery broad family of brush contact products which are shown inthis catalog.The Bristle Brush contact is used in military avionics packages<strong>and</strong> meets the requirements of MIL-DTL-55302. It provides highdensity in tight spacing, low mating/inmating forces, provendurability <strong>and</strong> long contact life. Applications for <strong>Amphenol</strong>connectors with brush contacts include:• Medical equipment• IC chip testers• Telecommunications• Military <strong>and</strong> Commercial Aviation• Military Ground Vehicles• GPS systemsBRUSH CONTACTSCONVENTIONAL PIN AND SOCKET CRIMPCONTACTSBrush vs. Conventional Contacts• Brush Contact Innovation• Multiple contact interfaces - Str<strong>and</strong>s of high tensile wireare bundled together to form brush-like contacts. Byintermeshing two multi-str<strong>and</strong> wire bundles, anelectrical connection is made.• Provides redundant current paths, 14-70 (points ofcontact) per mated contact with a gas tight junction• Very smooth (low friction) interfaceConventional Pin/Socket• Machined surface finish on both parts• Higher friction <strong>and</strong> wear• Limited number of contact sitesIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Multiple str<strong>and</strong>s of high tensile strength wires bundled together,provide superior electrical connection with low mating force.Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com7

<strong>Amphenol</strong><strong>Aerospace</strong>Brush Contact TechnologyFEATURES & BENEFITS, AMPHENOL’S CAPABILITIESIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesRuggedizedVME64x /VITA 60, 66High DensityHSB3 HDB3Hi SpeedLow Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.<strong>Amphenol</strong> ® B3 Bristle Brush ContactAdvantages:Low Mating & Unmating Forces• Smooth, low friction interfaces• 70% to 90% reduction in mating/unmating forcesfrom conventional pin-socket contacts• 1.5 oz. maximum forces per contact pair (oneounce typical)• Easy mating/unmating makes high circuit countspractical (25 lbs. typical for 400 contacts)• Mechanical mating aids not required• No need for external board support structures forconnectors up to 7 inches long. A center support isrecommended for Mother <strong>Board</strong> Connectors over7 inches.Proven Durability <strong>and</strong> Long Contact Life• 100,000 mating cycles even when hot swapped• Documented intermittency free performance –no 10 nano second discontinuities during 50mcycles of 0.010 displacement• Overall cost effectiveness (reduced life cyclecosts)Multiple Points of Contact ProvideSuperior Electrical Capability• 14-70 points of contact per mated contact• Stable, low resistance – 20 milliohms max.• Redundant current paths results in lower totalresistance• Proven electrical <strong>and</strong> gas tight contact sites<strong>Amphenol</strong> rectangular products group, including low mating force PCBconnectors, LRM connectors <strong>and</strong> the OBIS Backplane with brushcontacts <strong>and</strong> MT ferrule fiber optics.LMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Rack & PanelBrushRuggedizedHigh technology production centers at the <strong>Amphenol</strong> home facility <strong>and</strong> itssatellite facilities create volume runs that are cost effective <strong>and</strong> meeton-time delivery dem<strong>and</strong>s.Other<strong>Rectangular</strong><strong>Interconnects</strong><strong>Amphenol</strong> offers configurations of LRM connectorsthat combine the brush contact in some inserts alongwith other types of contacts in other inserts.8Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

<strong>Amphenol</strong>Line Replaceable Module (LRM)TABLE OF CONTENTS<strong>Amphenol</strong> LRM <strong>Interconnects</strong>• Table of Contents . . . .. . .. . .. . .. . .. . .. . .. . .. . .. . .. 9• Introduction - LRM Styles <strong>and</strong> Design Flexibility ...10• LRM Product Evolution ......................11, 12• <strong>Amphenol</strong> Leads in <strong>Board</strong> <strong>Level</strong> Technology. 13, 14• LRM Module Connector General Information .....15• LRM Backplane Connector General Information. 16Staggered Grid LRM• Staggered Grid LRM <strong>and</strong> Staggered GridAirflow-thru Contact Patterns/Comparison . .. . 17, 18• Staggered Grid Arrangements . . . .. . .. . .. . .. . 19, 20• Staggered Grid Airflow-thru Arrangements<strong>and</strong> Custom Shells ..............................21• Staggered Grid Termination Options . . . .. . .. . .. . .22• Staggered Grid Performance, Materials ..........23GEN-X Grid LRM• Comparison of Staggered Grid LRMvs GEN-X LRM..............................24, 25• GEN-X Pattern, Arrangements. . . .. . .. . .. . .. . .. . .26LRM Interconnect Options - Fiber Optics /High Speed / RF / High Power• Fiber Optics .................................27, 28• RF Modules, LRMs with High Speed Contacts. . . . 29• Power Supply Modules, LRMs with RADSOK ® ....30• Hi-Speed Gigastak TM , Digastak TM LRMs<strong>and</strong> cStack TM Technology .....................31-36LRM Options, Accessories, Tools• Flex Circuitry, Backplanes with CompliantPins, I/O Modules with PC Tails ..................37• Electrostatic Discharge (ESD) Protection .........38• LRM Accessories <strong>and</strong> Tools .................39, 40Aid in Selection/Ordering of LRM/LRU<strong>Interconnects</strong> from <strong>Amphenol</strong> . .. . . .. . . .. .41LRM Typical Markets:• Military & Commercial Avionics• Military Vehicles• Missiles/Ordnance• Missile Defense• C4ISR• Space (Satellites)• Radar<strong>Amphenol</strong><strong>Aerospace</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com9

<strong>Amphenol</strong><strong>Aerospace</strong><strong>Amphenol</strong> ® Line Replaceable Module (LRM)High Performance <strong>Board</strong> <strong>Level</strong> <strong>Interconnects</strong>INTRODUCTION - LRM STYLES & DESIGN FLEXIBILITYIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesRuggedizedVME64x /VITA 60, 66Staggered Grid LRMGEN-X Grid LRMHigh contact density in SEM-E<strong>and</strong> custom form factorsHigher contact density <strong>and</strong>improved electrical performance<strong>Amphenol</strong> ® LRM Surface Mount Connectors meet thehigh density needs of today’s integrated electronicmodules.<strong>Amphenol</strong> goes beyond the usual board level productoffering: <strong>and</strong> that is what you would expect from aworldwide interconnect product leader.MODULAR AVIONICS ARCHITECTURALPOSSIBILITIESWith its flexibility in design, <strong>Amphenol</strong> LRM interconnects arecapable of meeting the wide variety of user requirements fora board mount connector.• Thous<strong>and</strong>s of combinations of inserts are possible -tailored to meet user needs• LRM interconnects can be designed in 1, 2, 3 (<strong>and</strong> more)bay configurations with many shell designs available• LRM digital (brush) inserts can be combined with insertsfor power, fiber optics, RF, high speed <strong>and</strong> high amperageRADSOK ® contactsHigh DensityHSB3 HDB3Hi SpeedHigh Speed LRMInserts with 3.125 Gb/s <strong>and</strong> 6.25Gb/s data rate capability, with flextermination. Can be added toexisting LRM configurations.DESIGN FLEXIBILITYFiber opticMT ferrulesSt<strong>and</strong>ard brush contactsin a differential pair insertLow Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.LRM INTERCONNECTS FEATUREAMPHENOL’S BRUSH CONTACT TECHNOLOGYMultiple str<strong>and</strong>s of high tensile strength wire bundled together toform brush-like contacts. See the Introduction & Brush ContactTechnology section of this catalog for further description.RADSOK ®high amperagecontactsSix bayconnectorshellFlex terminationPartially populated brushcontact bay to facilitate highvoltage transmissionRack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>• With its low mating force, stable electrical performance <strong>and</strong>extended service life, the B 3 Brush contact is the st<strong>and</strong>ardcontact for the LRM.• Digital (Brush) inserts can be combined with each other orwith inserts for power, RF, fiber optic <strong>and</strong> high speedcontacts.High speeddifferential pairbrush contactsOther<strong>Rectangular</strong><strong>Interconnects</strong>NOTE: This catalog section supersedes <strong>Amphenol</strong>’s older individual catalog on LRM products, 12-037.2 inserts with st<strong>and</strong>ardbrush contacts10Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

<strong>Amphenol</strong> ® Line Replaceable Module (LRM)<strong>Interconnects</strong>LRM PRODUCT EVOLUTION<strong>Amphenol</strong><strong>Aerospace</strong><strong>Amphenol</strong> has been committed to keeping pace with the ever-changing dem<strong>and</strong>s of therectangular connector marketplace. Starting with the development of the B3 contact, incorporatedinto the low mating force PCB connectors, <strong>and</strong> later with the development of the linereplaceable module (LRM), <strong>Amphenol</strong> has led the way in the avionics packaging industry forhigh quality rectangular products. This page <strong>and</strong> the following page give an overview of therectangular product evolution.Low Mating Force Connector with Bristle Brush Contacts*• Developed in the 1980’s to provide solutions to problems caused by the highmating <strong>and</strong> unmating forces of conventional pin <strong>and</strong> socket contact pairs.• 4 Body styles: mother board (MB), daughter board (DB), PC connector, input/output connector• Molded of thermoplastic material• 2, 3 <strong>and</strong> 4 row configurations, 10 to 100 contacts per row in one contact rowincrements• 100 inch center to center contact spacing, square grid• Qualified to MIL-DTL-55302/166, /167, /168, /169, /170Line Replaceable Module (LRM) Connectors with Chevron Grid**• Developed to meet the avionics packaging requirements for a surface mount,high contact density PCB connector in a SEM-E form factor.• Digital insert pattern grid: 6 rows, 0.075” spacing along rows, 0.075” betweenrows with 0.025” offset.** This is an older design of the LRM <strong>and</strong> is typically not used today.Staggered <strong>and</strong> GEN-X designs have replaced the Chevron design(Consult <strong>Amphenol</strong> for further details)LRM Connectors with Staggered Grid• Advanced design to provide higher contact density for high speed integratedcircuitry in SEM-E <strong>and</strong> custom form factors.• Digital insert pattern grid is in 8 rows: 0.100 inch spacing along the row with0.050 inch between rows, rows offset 0.050 inch. Typical st<strong>and</strong>ardarrangements would have 80 or 108 or 152 or 180 digital brush contacts.• Options include various shell designs options to accommodate a wide rangeof PC board/heat sink combinations• Surface mount termination on module connectors, PCB or complianttermination on backplane connectors• <strong>Amphenol</strong> ESD protection (in module connector)- Designed for level 2 (flight line) maintenance• Provides routing channels for backplane<strong>Amphenol</strong> Staggered Grid Connectorsare the connector of choice for the F-16<strong>and</strong> F-22 Aircraft. The following were thecriteria that determined the selection ofthe connector for the F-16, F-22 <strong>and</strong> F-35aircraft:• Reliability: Impervious to frettingcorrosion, Micro-arching• ESD Protection* See the Brush Contact Technology section,<strong>and</strong> the Low Mating Force MIL-DTL-55302 section of this catalog.Low Mating Force Connectors - the firstdevelopment of rectangulars with Brushcontacts.Staggered Grid LRM was chosen for the F-16 <strong>and</strong> F-22 AircraftLRM Chevron Grid (150+180 contact pattern)(<strong>Amphenol</strong>’s first LRM design)LRM Staggered Grid (180 contact pattern)<strong>Amphenol</strong>’s higher density LRM with moreadvantages.<strong>Amphenol</strong> LRM Evolution continues on next page.Introduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com11

<strong>Amphenol</strong><strong>Aerospace</strong><strong>Amphenol</strong> ® Line Replaceable Module (LRM)<strong>Interconnects</strong>LRM PRODUCT EVOLUTION, CONTINUEDIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesRuggedizedVME64x /VITA 60, 66High DensityHSB3 HDB3Hi SpeedLow Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Certainly not st<strong>and</strong>ing still, <strong>and</strong> continuing to exp<strong>and</strong> product offering,<strong>Amphenol</strong> now provides LRMs with higher contact densities, special purposeconfigurations <strong>and</strong> high speed inserts.LRM Connectors with GEN-X Grid• Higher contact density <strong>and</strong> improved electrical performance• All the features of staggered LRM, including ESD protection (module connector)• Available in SEM-E <strong>and</strong> custom form factors• 236 contact pattern grid in 8 rows: 0.075 inch spacing along the row with 0.060inch between rows, rows offset 0.0375 inchLRM Staggered Grid Airflow-thru Connectors• LRM Staggered Airflow-thru inserts are available for wider board packages up to0.425 in. These accommodate st<strong>and</strong>ard B 3 tails in staggered pattern, but withincreased spacing in the center, to accommodate airflow through heatsinksLRM Connectors with Fiber Optics• Custom combinations of digital contacts <strong>and</strong> fiber optic termini were offered asthe product line further developed in the ‘90’s.• Configurations included:• MIL-T-29504/4, /5, /14 & /15 termini• MT ferrule arrangements (2-24 fiber lines per ferrule)LRM Connectors to Accommodate RF Contacts• LRM inserts are available with RF contacts:• Size 16 M39029/79 & /80 shielded contacts• Size 12 coax for DC-2 GHz; size 8 coax for DC-32 GHz• SMPM coax contacts*• LRM Power Supply Modules• Custom designs of LRMs have been developed with270VDC sections which are capable of providingcorona-free operation at 100,000 feet. They utilize size 22D contacts<strong>and</strong> are available in both crimp <strong>and</strong> compliant pin terminations.LRM with High Amperage RADSOK ® Contacts• The RADSOK ® contact technology enables high current flow withminimal voltage loss <strong>and</strong> low insertion force<strong>Board</strong> <strong>Level</strong> <strong>Interconnects</strong> of 2010 <strong>and</strong> Beyond -More <strong>and</strong> more the customer has dem<strong>and</strong>eda high level of flexibility, with designs thatincorporate higher speeds <strong>and</strong> specialfeatures going beyond the st<strong>and</strong>ard LRM.Configurations such as:• High speed GigaStak ® LRM connectors- capable of data rates up to 6.25 Gb/s,<strong>and</strong> DigiStak ® LRM connectors capableof data rates up to 3.125 Gb/s• High speed shielded contacts -coax, triax, twinax, differential twinax, <strong>and</strong>quadrax contacts available in inserts of the LRM• Combinations of power contacts, st<strong>and</strong>ard brush,high power, differential pair brush, <strong>and</strong> fiber optic terminiLRM with Fiber Optic MT FerrulesHigh Speed GigaStak ® , capable ofdata rates of 6.250 Gbps• Incorporation of Flex Circuits for more versatility of PC board terminations• Custom shells with multiple bay configurations, special keyingcomponents or special guide/ground pins• Compliant pin contacts for press-fit termination to circuit boards.LRM GEN-X Grid (236 contact pattern)Even higher densities with all the benefits ofthe Staggered Grid.LRM Staggered Grid Airflow-thruLRM with RF ContactsLRM backplane (left) <strong>and</strong> module connector (right)incorporating high amperage RADSOK ® contacts(crimp style shown).LRM special 6 bay design with RADSOK ® contacts,st<strong>and</strong>ard brush contacts, <strong>and</strong> flex circuitry terminationto module circuit card assembliesOther<strong>Rectangular</strong><strong>Interconnects</strong><strong>Amphenol</strong> Backplane Capabilities<strong>Amphenol</strong> backplanes incorporate a wide range of our interconnects.See Other <strong>Rectangular</strong> <strong>Interconnects</strong> Section of this catalog, page 117, for moreinformation on <strong>Amphenol</strong> backplanes.* See Other <strong>Rectangular</strong> <strong>Interconnects</strong>Section, page 126 for moreinformation on SMPM contacts.12Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

<strong>Amphenol</strong> Leads in <strong>Board</strong> <strong>Level</strong>Product TechnologyLRM DESIGN ENGINEERING<strong>Amphenol</strong><strong>Aerospace</strong>We take pride that <strong>Amphenol</strong> <strong>Aerospace</strong> is the undisputedleader in interconnect systems for aerospace/harshenvironment applications. Such applications require a highdegree of engineering sophistication <strong>and</strong> precision manufacturingcapability that only a company that has been inthe interconnection product design <strong>and</strong> manufacturingbusiness for over 50 years can offer.We have earned the reputation as the leader in the militaryelectrical connection arena especially for military cylindricalconnectors, <strong>and</strong> are fast becoming the leader for rectangular<strong>and</strong> surface mount interconnects.Our LRM <strong>and</strong> VME64x* products are used on majorprograms that include the following <strong>and</strong> more:• F-35 • JTRS • EA18G• F-16 • M1A2 Tank • EA6B• F-15 • F-117 • MEADS• F/A-22 • AH-64 APACHE • G/ATOR• F/A-18 • ASRAAM • EQ-36• B2 • B52Expert design <strong>and</strong> applications engineering provides solidmodeling <strong>and</strong> full Pro-Engineer ® capabilities to developnew interconnection designs <strong>and</strong> perform structuralanalysis. Marketing product managers team with skilledengineers <strong>and</strong> production specialists in a customer-drivenapproach to produce the end result: defect-free parts, costeffectiveness, shorter lead <strong>and</strong> delivery times, <strong>and</strong> satisfiedcustomers.The photo top right shows the CST Microwave Studio ®signal integrity modeling <strong>and</strong> simulation software at<strong>Amphenol</strong>. This state-of-the-art technology allows characterizationof current connector designs <strong>and</strong> rapidly aids inthe development of new high speed signal designs. Itconsists of a 3D, full-wave electromagnetic field solver forsimulating electricalperformance, producingSPICE models <strong>and</strong> eyediagrams.<strong>Amphenol</strong>’s capability fortesting of it’s wide range ofcylindrical <strong>and</strong> rectangularconnector products alsoincludes vibration <strong>and</strong>shock testing, humidity,engagement/separationforce evaluation, durabilitytesting, as well as saltspray/fog, corona, ESD,optical performancetesting <strong>and</strong> altitudesimulation.* VME64x products are covered on page 43.Close-up photo showing verticalmachining of heatsink housingsdone at <strong>Amphenol</strong>.Engineers working at the signal integrity modeling <strong>and</strong> simulationsoftware suite at <strong>Amphenol</strong> <strong>Aerospace</strong> Operations. (See page 28for more information on <strong>Amphenol</strong>’s testing of Hi-Speed LRMconnectors).Above <strong>and</strong> below are production areas for LRM interconnects <strong>and</strong>heatsinks. Note the orange balls on the machines - these are usedas a quick checking device for processes.Introduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com13

<strong>Amphenol</strong><strong>Aerospace</strong><strong>Amphenol</strong> Leads in <strong>Board</strong> <strong>Level</strong>TechnologyLRM MANUFACTURING EXPERTISEIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesRuggedizedVME64x /VITA 60, 66<strong>Amphenol</strong> <strong>Aerospace</strong> is highly integrated to design,manufacture, assemble <strong>and</strong> ship an extensivevariety of line replaceable module <strong>and</strong> backplaneconnectors. We also supply a wide range ofheatsink hardware associated with this type ofconnector. The photo on right shows severalheatsink forms used in the manufacture of LRMinterconnects. For more information on heatsinks,see the Other <strong>Board</strong> <strong>Level</strong> <strong>and</strong> <strong>Rectangular</strong><strong>Interconnects</strong> Section, pages 112 & 113.Manufacturing equipment photos shown belowdemonstrate <strong>Amphenol</strong>’s high technology capability.Focus is always on cost effective production <strong>and</strong>continuous improvement of processes. Manufacturingcapabilities include state-of-the-art roboticallycontrolled milling machines <strong>and</strong> CNC machining, aswell as impact <strong>and</strong> extruding, plating, screwmachining, <strong>and</strong> process control.Variety of heatsinks <strong>and</strong> connector shells manufactured by <strong>Amphenol</strong>.Low Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHigh DensityHSB3 HDB3Hi SpeedHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>CMM measuring is done to check machined parts.THE ADVANTAGE OF AMPHENOL’S WIDE DIVISIONALCAPABILITY<strong>Amphenol</strong> divisions work together to provide a very broad manufacturingcapability for board level interconnects:• <strong>Amphenol</strong> <strong>Aerospace</strong> (AAO)* has leading expertise in theproduction of line replaceable module inter-connects, VME64xinterconnects <strong>and</strong> low mating force brush connectors.• <strong>Amphenol</strong> Backplane Systems (ABS)** has leading expertise in themanufacture of custom backplane assemblies - high density,ruggedized, board to backplane interconnects.• <strong>Amphenol</strong> Printed Circuits (APC)*** has leading expertise in themanufacture of flex circuitry products used in connector-to-boardattachment.These companies of <strong>Amphenol</strong> Corporation combine to providedesign, applications engineering, fabrication, value-added assembly<strong>and</strong> testing to meet customer requirements as well as to developproducts for emerging technologies.* This catalog covers the rectangular interconnect products offered by AAO division. Go online at www.amphenol-aerospace to see the wide range of cylindrical <strong>and</strong> other interconnect products offered byAAO. And see the Other <strong>Rectangular</strong> Products section at the end of this catalog for other <strong>Amphenol</strong>divisions offerings of rectangular interconnects.** For more information on backplane assemblies: page 117 <strong>and</strong> online at www.amphenol-abs.com.*** For more information on flex circuit products: page 121 <strong>and</strong> online at www.amphenolapc.com.<strong>Amphenol</strong>’s high technology computer driven equipmentfor manufacturing heatsinks.Checking for dimensional accuracy of LRMparts <strong>and</strong> heatsinks.14Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

LRM Module ConnectorGeneral InformationSTAGGERED GRID DOUBLE BAY SHOWN<strong>Amphenol</strong><strong>Aerospace</strong>The following is the LRM Module Connector identification<strong>and</strong> naming convention. The illustration is a double baymodule with a staggered grid pattern.Introduction/Pkg. Solutions/Brush ContactPOLARIZATIONKEYS (4)SHELL TYPE 2(TOP)SHELLATTACHINGSCREWSINSERT POSITION“A” BETA ENDSPLIT TYPE REFINSERT POSITION“B” BETA ENDSPLIT TYPE REFINSERT POSITION“A” ALPHA ENDSPLIT TYPE REFINSERT POSITION“B” ALPHA ENDSPLIT TYPE REFSIDE “B”GUIDE PIN (2)LRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesSIDE “A”SHELL TYPE 1(BOTTOM)RuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi Speed“B” PCB“A” PCBSOLDERPADS FORCONTACT TAILSSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedTOP HALF OFCUSTOMER DESIGNED COVERREFERENCEBOTTOMCOVERREFERENCELMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>HEATSINKOther<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com15

<strong>Amphenol</strong><strong>Aerospace</strong>LRM Backplane ConnectorGeneral InformationSTAGGERED GRID DOUBLE BAY SHOWNIntroduction/Pkg. Solutions/Brush ContactThe following diagram shows an exploded view of anLRM staggered grid backplane connector in a two bayconfiguration.LRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesBACKPLANE CONNECTOR SHELL(TYPICAL CONTAINMENT OF 2 BAY INSERTASSEMBLY SHOWN)RuggedizedVME64x /VITA 60, 66BRUSH PINSLow Mating Force MIL-DTL-55302Other<strong>Rectangular</strong><strong>Interconnects</strong>LMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.Rack & PanelBrushRuggedizedHigh DensityHSB3 HDB3Hi SpeedBACKPLANE PCBSTAGGERED STYLEINSERT ASSEMBLY(360 BRUSH CONTACTSSHOWN)16Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Staggered Grid LRM &Staggered Grid Airflow-thruCONTACT PATTERNS<strong>Amphenol</strong><strong>Aerospace</strong>STAGGERED GRID DESCRIPTIONThe LRM st<strong>and</strong>ard staggered grid patternemploys surface mount leads on .025 inchcenterlines (pitch). Insert patterns of digitalbrush contacts are in 80, 108, 152 <strong>and</strong> 180contact counts. See typical arrangementdrawings on pages 19 <strong>and</strong> 20.ConnectorCenterlineSTAGGERED.050TYP.075TYP.050TYP.150 TYP( 3X .050 ).150 TYP( 3X .050 )Introduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesAll dimensions in inches..050 TYP.100 TYPRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedTwo bay, 360 contact, module connector with st<strong>and</strong>ard staggered grid patternSTAGGERED AIRFLOW-THRU GRIDDESCRIPTIONThe staggered grid airflow-thru inserts weredesigned to accommodate wider boardpackaging <strong>and</strong> airflow-thru heatsinks. Insertpatterns of digital brush contacts are sameas the staggered grid pattern (80, 108, 152<strong>and</strong> 180 contact counts). See typicalarrangement drawings on page 21.ConnectorCenterlineSTAGGERED AIRFLOW-THRU.050TYP.250TYP.150 TYP( 3X .050 )St<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedized.050TYP.150 TYP( 3X .050 )LMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Staggered grid airflow-thru backplane insert.All dimensions in inches..100 TYP.050 TYPOther<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com17

<strong>Amphenol</strong><strong>Aerospace</strong>Staggered Grid LRM &Staggered Grid Airflow-thruCONTACT PATTERNS/COMPARISONIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesStaggered Grid (St<strong>and</strong>ard)Staggered Grid for St<strong>and</strong>ard<strong>Board</strong> Packages.075.050.100.0875.1875.1375.0375.375Staggered Grid Airflow-ThruStaggered Grid Air-flow for Wider<strong>Board</strong> Packages.100.050.175.250.125.225.275.550Other<strong>Rectangular</strong><strong>Interconnects</strong>LMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>High DensityHSB3 HDB3Hi SpeedRack & PanelBrushRuggedizedLow Mating Force MIL-DTL-55302Docking Conn./Accessories/Install.Hybrids - Signal/Power/Coax/Fiber OpticsSt<strong>and</strong>ardBrushRuggedizedVME64x /VITA 60, 661 21 218Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Staggered Grid LRMTYPICAL ARRANGEMENTS<strong>Amphenol</strong><strong>Aerospace</strong>Example of a backplane connector in a 2 bay arrangement with insertsof staggered brush contacts <strong>and</strong> coax (size 12) contacts.80 brush contacts108 brush contacts152 brush contacts180 brush contacts108 brush contacts plus 6 sz. 12 power orcoax contacts108 brush contacts plus 8 coax contactsStaggered Grid LRM interconnects can be one,two or three bay configurations, <strong>and</strong> specialadditional bay arrangements. The typical arrangementsshown here are depicted in one baydrawings. <strong>Amphenol</strong>’s design flexibility also allowfor combinations of contact types. These arrangementsrepresent the versatility that can be arrivedat by arranging digital (brush) inserts with insertsfor power, RF, fiber optic <strong>and</strong> high speed contactsin various combinations within a typical bay.Consult <strong>Amphenol</strong> <strong>Aerospace</strong> for assistance indesigning the LRM that best meets your specificapplication needs. See page 41 for an aid inselection <strong>and</strong> ordering.152 brush contacts plus 2 sz. 12 power or coax contacts152 brush contacts plus 4 sz. 16 power orcoax contacts152 brush contacts plus 2 sz. 12 power or coax contacts108 brush contacts plus 270 VDC power inputIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-5530280 brush contacts plus 10 coax contacts80 brush contacts plus 270 VDC power inputRack & PanelBrushRuggedized80 brush contacts plus 12 sz. 12 power or coax contacts22 sz. 12 power contactsLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com19

<strong>Amphenol</strong><strong>Aerospace</strong>Staggered Grid LRMTYPICAL ARRANGEMENTSIntroduction/Pkg. Solutions/Brush Contact144 brush contacts plus 4 fiber optic terminiLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/Accessories108 brush contacts plus 4 coax contacts<strong>and</strong> 4 fiber optic termini80 brush contacts plus 6 coax contactsExample of a 3 bay module connector with an insert for MT fiber opticferrules <strong>and</strong> inserts for brush LVDs <strong>and</strong> digital contacts.Example of a 2 bay staggered grid module connector.RuggedizedVME64x /VITA 60, 66High DensityHSB3 HDB3Hi Speed108 brush contacts plus an insert for 2 fiber opticMT ferrules*Low Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.6 cavities for fiber optic MT ferrules*8 brush LVDS differential pairs plus an insert for2 fiber optic MT ferrules*fiber opticMT ferrules(8) grounded contacts(8) differentialpairsExample of a staggered grid module <strong>and</strong> backplane with 108 brush contacts<strong>and</strong> an insert for 7 size 20 crimp contacts for high voltage applications.Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>16 LVD pairs(16) grounded contacts(16) differentialpairsOther<strong>Rectangular</strong><strong>Interconnects</strong>* MT ferrules are not supplied by <strong>Amphenol</strong> <strong>Aerospace</strong>.see page 28 for more information on LRMs with MTferrules.20Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Staggered Grid Airflow-thru LRMARRANGEMENTS, CUSTOM SHELLS<strong>Amphenol</strong><strong>Aerospace</strong>The typical Airflow-thru arrangements are with brush contacts. Thearrangements shown at left for staggered grid Airflow-thru aretypical of what has been developed for customer requirements.80 brush contacts(airflow-thru)108 brush contacts(airflow-thru)Introduction/Pkg. Solutions/Brush ContactStaggered Grid Airflow-thrupattern - in a module on right,<strong>and</strong> in a backplane on left.Note the increased spacing inthe center. This is designedfor wider board packages, <strong>and</strong>accommodates airflow-thruheatsinks. (See illustration onpage 18).LRMs with airflow-thru inserts can be custom designed incombination with power contacts, such as the example below.152 brush contacts (airflow-thru)180 brush contacts (airflow-thru)LRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66Module <strong>and</strong> backplane connectors with staggered airflow-thru inserts. Shown are216 brush contacts <strong>and</strong> inserts for size 12 RADSOK ® crimp contacts.<strong>Amphenol</strong> designs <strong>and</strong> builds custom shellconfigurations such as the module face plate<strong>and</strong> its mating backplane connector.This custom Airflow-thru modulecontains RADSOK ® highamperage socket contacts insizes 8 <strong>and</strong> 12.See more description ofRADSOK ® contacts, page 124.Underside of Backplane, showingsize 8 & 12 RADSOK ® contactswith compliant termination.Backplane connectorModule connectorCloseup ofinsert withcompliantpin terminationpower contacts.Center inserts contain 108brush contacts, staggered gridHigh DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com21

<strong>Amphenol</strong><strong>Aerospace</strong>Staggered Grid LRMTERMINATION OPTIONSIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesRuggedizedVME64x /VITA 60, 66The following is a guide to the part number suffixes to be used when ordering LRM Connectors. Due to the complexity<strong>and</strong> number of variations within the part numbering, it is necessary to consult <strong>Amphenol</strong> <strong>Aerospace</strong> for assistancewhen building these part numbers. See page 41 for an aid in selection <strong>and</strong> ordering, <strong>and</strong> call <strong>Amphenol</strong> at 607-563-5011 for technical support.MODULEHEATSINKTHICKNESSBOARD PACKAGETHICKNESSAn example of a typical <strong>Amphenol</strong> ModuleAn example of a typical <strong>Amphenol</strong> Backplanepart number is: 10-507XXX-X( )( ) part number is:10-507XXX-X( )( )10-507 .....Designates <strong>Amphenol</strong>LRM ConnectorsBACKPLANETERMINATIONSTICKOUT10-507 .....Designates <strong>Amphenol</strong>LRM ConnectorsHigh DensityHSB3 HDB3Hi SpeedLow Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>XXX-X ......Module Insert ArrangementNumber - To be assigned by <strong>Amphenol</strong>.( ) ............Heatsink Thickness Suffix for ModulesSuffix Description1 .125 ±.0052 .100 ±.0053 .075 ±.0054 .062 ±.005( ) ............<strong>Board</strong> Package Thickness Suffix forModulesDescriptionSuffix St<strong>and</strong>ardStaggered1 Surface Mount /.090 – .130 Package2 Surface Mount /.130 – .190 Package3 Surface Mount /.190 – .250 Package4 Surface Mount /.060 – .100 Package5 Surface Mount /.100 – .160 Package6 Surface Mount /.160 – .220 Package* .175 is added for increased center spacing in theairflow-thru staggered styleDescriptionAirflow-thruStaggered*Surface Mount /.265 – .305 PackageSurface Mount /.305 – .365 PackageSurface Mount /.365 – .425 PackageSurface Mount /.235 – .275 PackageSurface Mount /.275 – .335 PackageSurface Mount /.335 – .395 PackageXXX-X ......Backplane Insert ArrangementNumber - To be assigned by <strong>Amphenol</strong>.( ) ............Termination Style Suffix for BackplanesSuffix Description1 .021 ±.002 Dia. PCB Tail2 .016 ±.002 Dia. PCB Tail5 Compliant( ) ............Termination Stickout Suffix forBackplanesSuffixDescription1 .150 ±.020 (PCB)2 .200 ±.020 (PCB)3 .250 ±.020 (PCB)4 .300 ±.020 (PCB)5 .350 ±.020 (PCB)6 .400 ±.020 (PCB)7 .185 ±.020 (PCB)8 .450 ±.020 (PCB)9 .500 ±.020 (PCB)C .157 ±.020 (Compliant, No Wrap)D .217 ±.020 (Compliant, 1 Wrap)E .317 ±.020 (Compliant, 2 Wrap)F .417 ±.020 (Compliant, 3 Wrap)Other<strong>Rectangular</strong><strong>Interconnects</strong>22Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Staggered Grid LRMTYPICAL PERFORMANCE, MATERIALS LIST<strong>Amphenol</strong><strong>Aerospace</strong>Table 1 below identifies the typical electrical, mechanical <strong>and</strong> environmental performance of an <strong>Amphenol</strong> 2 bay LRMconnector assembly with 360 brush contacts in staggered grid. This data was program specific <strong>and</strong> does not reflect actualperformance limitations. Table II below provides a materials list for the components of staggered grid LRM connectors.PartBrush wiresTABLE I: PERFORMANCEELECTRICAL PERFORMANCEElectrical ParametersPerformanceCurrent carrying capability10°C temperature rise at 2A <strong>and</strong> 30°C rise at 3AContact resistance30 milliohms max. per contact, 25 milliohms max. averageDielectric withst<strong>and</strong>ing voltage at sea level100 VRMS, 60 HzDielectric withst<strong>and</strong>ing voltage at altitude100 VRMS, 60 Hz at 70,000 ft.Insulation Resistance1000 megohm minimum at 100V d.c.Electrostatic Discharge Protection (module only)± 25,000 minimum air <strong>and</strong> direct discharge (see pg. XX for details)MECHANICAL PERFORMANCEMechanical ParametersPerformanceContact retention (solder type backplane assembly)Maximum displacement of 0.010” at 1 pound loadMating <strong>and</strong> unmating forcesMaximum 40.0 pounds mating <strong>and</strong> unmatingVibration (Sinusoidal, 20g peak max.) No electrical discontinuity >1 µSVibration (R<strong>and</strong>om, 11.6g RMS max.) No electrical discontinuity >1 µSShock (50g max. shock pulse) No electrical discontinuity >1 µSSolderabilityMinimum 95% solder coverageResistance to soldering heat260°C dip for 10 secondsENVIRONMENTAL PERFORMANCEEnvironmental ParametersPerformanceTemperature life250 hours at 125°C maximumConnector durability500 cycles mating <strong>and</strong> unmatingSalt fog exposure48 hours maximum direct exposure (5% NaCl)Thermal shock500 cycles at +125°C / –65°CHumidity exposure 240 hours at 90 - 98%Contamination exposure S<strong>and</strong> <strong>and</strong> dust per MIL-STD-202 Method 110Resistance to solventsBoiling Trichloroethylene fumes <strong>and</strong> solutionModule contactsBackplane contacts(Complianttermination)Backplane contacts(PCB termination)InsulatorsOrganizerTABLE II: MATERIALS LISTENVIRONMENTAL PERFORMANCEMaterial / Finish DescriptionBeryllium copper per ASTM B197; finish is gold per ASTM B488 over nickel per AMS-QQ-N-290. (The exposed ends of thebrush wires need not be plated).Beryllium copper per ASTM B534 C17500, or C17510 except temper HTC; finish on contact body is matte tin-lead perASTM B579; finish on termination end is 60/40 or 63/37 tin-lead dip per J-STD-004, -005 <strong>and</strong> -006.Contact barrel: brass per ASTM B4531/B453M-01 similar to UNS C33500; finish is tin-lead per SAE-AMS-P-81728(min. 15% ±5% lead) over nickel. Contact tail: beryllium copper per ASTM B-534 alloy 17510 HT; finish is gold per ASTM B-488over nickel per AMS-QQ-N-290. Contact sleeve: stainless steel per AMS 5514; finish is black oxide per MIL-DTL-13924 <strong>and</strong>conformally coated per MIL-I-46058.Contact body: brass similar to UNS C33500; finish is gold over nickel; termination end is 60/40 or 63/37 tin lead dip.Contact sleeve: stainless steel per AMS 5514; finish is black oxide per MIL-DTL-13924 <strong>and</strong> conformally coated per MIL-I-46058.Polyphenylene Sulfide or Liquid Crystal Polymer per MIL-M-24519Polyphenylene Sulfide or Liquid Crystal Polymer per MIL-M-24519Shells Aluminum alloy 6061-T6 per AMS 4150; finish is electroless nickel per SAE AMS 2404.ESD shieldsPolarization keysGuide pinsAluminum alloy 6061-T6 per AMS 4150; finish is hardcoat anodize per MIL-A-8625 with epoxy final coat. Ground tabs arechromate treated (irridite).Stainless steel per AMS 5640; finish is black oxide per MIL-DTL-13924. Key retaining ring is Polyamide (nylon 12) with50% glass filled fibers.Beryllium copper alloy per ASTM B196, finish is gold per ASTM B 488 over nickel per AMS-QQ-N-290.Introduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com23

<strong>Amphenol</strong><strong>Aerospace</strong>Staggered Grid LRM vs GEN-X GridGEN-X PROVIDES HIGHER CONTACT DENSITYIntroduction/Pkg. Solutions/Brush ContactStaggered Grid Contact DensityGEN-X Contact DensityLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/Accessories.075.050.100.0875.1875.1375.0375.375.070.0375.075.095.215.035 .155.430RuggedizedVME64x /VITA 60, 66Staggered Grid Module TerminationGEN-X Module TerminationHigh DensityHSB3 HDB3Hi SpeedTwo Surface MountPlanesFour Surface MountPlanesHEATSINKLow Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.1 21 2 3 4MAIN RIGIDPCBFLEXCIRCUITRYINTERFACERIGID PCBOther<strong>Rectangular</strong><strong>Interconnects</strong>LMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Rack & PanelBrushRuggedized24Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Staggered Grid LRM vs GEN-X GridGEN-X PROVIDES HIGHER CONTACT DENSITY<strong>Amphenol</strong><strong>Aerospace</strong>Staggered Grid Tail to Tail PlacementStaggered Grid LRM has0.025 tail to tail centerlinespacingGEN-X Tail to Tail PlacementGEN-X Grid LRM has0.0375 tail to tail centerlinespacingIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedGEN-X is Designed to Terminate to Rigid-Flex PCB AttachmentINTERFACE RIGID PCBMODULEINSERT ASSEMBLYSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302MAIN RIGID PCBHEATSINKFLEXCIRCUITRYRack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com25

<strong>Amphenol</strong><strong>Aerospace</strong>GEN-X Grid LRMCONTACT PATTERN & ARRANGEMENTSIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesThe LRM GEN-X pattern employssurface mount leads on a .0375inch center line (module connector),yet provides higher contact densitythan the Staggered grid pattern.GEN-X provides all the same featuresas the staggered grid LRM:• GEN-X digital (brush) inserts areavailable in 118 <strong>and</strong> 236 pin contactcounts.• Digital contacts can also be combined withinserts for fiber optics, RF, poser <strong>and</strong> highspeed contacts.• Various combinations of inserts can beprovided in 1, 2 or 3 bay shell configurations.• Typical insert arrangements shown here aredepicted in one bay drawing.Example of a 3 bay GEN-X backplane connector.GEN-X.060SpacingRuggedizedVME64x /VITA 60, 66High DensityHSB3 HDB3Hi SpeedConsult <strong>Amphenol</strong> <strong>Aerospace</strong> for assistancein designing the LRM that best meets yourspecific application needs. See page 41 foran aid in selection <strong>and</strong> ordering of LRM <strong>and</strong>LRU interconnects..430.035.070Low Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.Rack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>118 brush contacts236 brush contacts140 brush contacts plus an insert for 2fiber optic MT ferrules*212 brush contacts plus 2 sz. 16 power orcoax contactsAll dimensions in inches..075170 brush contacts plus 6 sz. 16 power orcoax contacts170 brush contacts plus 4 fiber optic termini<strong>and</strong> 2 sz. 16 contacts.0375 OffsetExample of a 2 bay GEN-X module connector.Other<strong>Rectangular</strong><strong>Interconnects</strong>* MT ferrules are not supplied by <strong>Amphenol</strong> <strong>Aerospace</strong>.see page 28 for more information on LRMs with MT ferrules.26Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

LRM Interconnect OptionsLRMS WITH FIBER OPTIC TERMINI<strong>Amphenol</strong><strong>Aerospace</strong>High speed fiber optic transmission is available within LRM connectors for use inadvanced avionics systems. Optical performance of fiber optic termini within inLRM connectors are the same as termini used in circular connectors.*Insertion losses range from .3dB to

<strong>Amphenol</strong><strong>Aerospace</strong>LRM Interconnect OptionsLRMS WITH INSERTS FOR MT FERRULE FIBER OPTICSIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/GEN-XHybrids - Fiber Optics/Hi Speed/RF/PowerOptions/AccessoriesRuggedizedVME64x /VITA 60, 66High DensityHSB3 HDB3Hi SpeedLow Mating Force MIL-DTL-55302St<strong>and</strong>ardBrushHybrids - Signal/Power/Coax/Fiber OpticsDocking Conn./Accessories/Install.Through <strong>Amphenol</strong>’s LRM design flexibility,inserts are available to house high speed MT ferrules whichcan have 12 or 24 fiber lines per ferrule. MT ferrules are notsupplied by <strong>Amphenol</strong>; they must be purchased separately.Termini for rectangular LRM connectorsare determined by insert <strong>and</strong> shell style ofthe connector.Staggered Grid Patterns with MT FerruleFiber Optics(These drawings are also shown with other staggered gridpatterns on pages 19 <strong>and</strong> 20).Insert with cavitiesfor 6 fiber optic MTferrulesInsert with 8 brushdifferential pairs plusan insert for 2 fiberoptic MT ferrulesInsert for 108 brushcontacts plus an insertfor 2 fiber optic MTferrulesGEN-X Patterns with MT Ferrule Fiber Optics(These drawings are also shown with other GEN-Xpatterns on page 26).140 brush contactsplus an insert for2 fiber optic MTferrulesExample of an LRM module connector with MT fiber optic inserts in combinationwith inserts for brush LVDs <strong>and</strong> digital contacts.LRM Module Insert Assemblywith MT TerminiFRONTINSERTMT FERRULEWITH RIBBONSPRINGLRM Backplane Insert Assemblywith MT TerminiREAR INSERTPIN CLAMPSTRAINRELIEFRack & PanelBrushRuggedizedLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong><strong>Amphenol</strong> can supply optical backplane assemblies; see moreinformationin the Other <strong>Board</strong> <strong>Level</strong> <strong>and</strong> <strong>Rectangular</strong> <strong>Interconnects</strong>Section on page 117.FRONTINSERTMT FERRULEWITH RIBBONREARINSERT28Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

LRM Interconnect OptionsRF MODULES, LRMS WITH HIGH SPEED CONTACTS<strong>Amphenol</strong><strong>Aerospace</strong>LRM inserts have been designed to accommodate thefollowing RF <strong>and</strong> high speed coaxial contacts:• Size 16 M39029/79 & /80 shielded contacts• Size 12 coax for DC-65 GHz• Size 8 coax for DC-32 GHz• SMPM RF contacts*• Hybrid arrangements with RF or high speed shieldedcontacts <strong>and</strong> brush contact combinationsStaggered Grid Patterns with RF/Coaxial Contacts(These drawings are also shown with other staggered gridpatterns on pages 19 <strong>and</strong> 20).108 brush contacts plusan insert for 8 SMPM*style RF contacts80 brush contacts plusan insert for 10 SMPM*style RF contacts80 brush contacts plusan insert for 6 RFcontacts108 brush contacts plusinserts for 4 shieldedcontacts <strong>and</strong> 4 fiber optictermini152 brush contacts plusan insert for 2 SMPM*style RF contacts152 brush contacts plusan insert for 4 sz. 16shielded contacts* See more information on SMPM RF contacts in Other <strong>Rectangular</strong><strong>Interconnects</strong> Section, page 126. SMPM RF contacts can be supplied by<strong>Amphenol</strong> SV Microwave. Phone: 561-840-1800Website: www.svmicrowave.com<strong>Amphenol</strong> has also developed inserts with brush differentialpair contacts that are 100 ohm matched impedance. Thesesupport data rates with excess of 1.2 Gbps.RF module <strong>and</strong> backplane with size 8 coaxial contactsStaggered grid module with cavities for size 12 coaxial contactsGEN-X Patterns with RF/Coaxial Contacts(These drawings are also shown with other GEN-X patterns onpage 26).212 brush contacts plusan insert for 2 sz. 16shielded contacts170 brush contacts plusan insert for 6 sz. 16shielded contactsIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Staggered Grid Patterns with LVDS Differential Pairs(These drawings are also shown with other staggered grid patterns onpage 20).Rack & PanelBrushRuggedized8 brush differential pairs plusan insert for 2 fiber optic MTferrules16 LVDS differential pairsModule <strong>and</strong> backplane with LVDS differential pair brushcontactsLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>Other<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com29

Hi-Speed LRM ConnectorsNEW LRMS PROVIDE HIGHER SPEED DATA TRANSFERENCENew/Featured Product<strong>Amphenol</strong>’s LRM connectors meet today’s need for high speedinterconnects for harsh environments. Constantly evolving <strong>and</strong>striving to meet the needs of higher data transfer rates within aboard level product, <strong>Amphenol</strong> has developed LRM’s to meet thischallenge. These LRMs are designed, or can be configured, toachieve data rates up to 6.25 Gb/s <strong>and</strong> include all the features ofour rugged <strong>and</strong> reliable staggered grid LRM series:• Brush contact interface• ESD protection (<strong>Level</strong> 2 flight line classification)• Connector float• Guide pins <strong>and</strong> polarization keys• Metal shells• Modular design (hybrid configuration available)• Accepts wide range of board packages• Accomodations for custom modular offsetsIn addition, the new GigaStak TM , GigaStak-LG TM <strong>and</strong> DigiStak TMSeries incorporate <strong>Amphenol</strong>’s cStack TM solderless terminationtechnology (see page 35 for details).VersatilityUnique flex <strong>and</strong> cStack terminations accommodate a variety ofmounting configurations <strong>and</strong> a wide range of board packages.Connectors can terminate in a variety of ways:• “traditional” 2 board/heatsink package• to one or both sides of a single board• as an offset board packageDigiStak module connectors allow mating to existing configurationsof backplane connectors (users can upgrade solder terminationmodule connectors to the solderless cStack termination).The Hi-Speed Family of LRM Connectors <strong>and</strong> associateddata rates includes:• Gigastak TM - 6.25 Gb/s• Gigastak LG TM - 3.125 Gb/s• Digistak TM & Digistak-X TM - 3.125 Gb/s• St<strong>and</strong>ard Staggered Grid - 1.25 Gb/sExample of a Hi-Speed Hybrid ConnectorHi-Speed InsertsGigaStak TMDigiStak TM<strong>Amphenol</strong><strong>Aerospace</strong>DigiStak TMDigiStak TM InsertsGigaStakLG TMGigaStak TM Hi-Speed Inserts (left & right: 60 Brushdifferential pairs; middle: 18 Brush differential pairs plus180 Brush low speed signal contacts)Hybrid Connector that has GigaStak-LG TM <strong>and</strong> DigiStak TMInserts , shown on Testing <strong>Board</strong>sIntroduction/Pkg. Solutions/Brush ContactLRM (Line Replaceable Modules)Staggered/ Hybrids - Fiber Optics/ Options/GEN-X Hi Speed/RF/Power AccessoriesRuggedizedVME 64x/VITA 60, 66High DensityHDB3 HSB3Hi SpeedSt<strong>and</strong>ardBrushHybrids - Signal/Power/ Docking Conn./Coax/Fiber Optics Accessories/Install.Low Mating Force MIL-DTL-55302Rack & PanelBrushRuggedizedInsert for RF orPower contactsLMD/LMS<strong>Rectangular</strong><strong>Interconnects</strong>GigaStak LG TMInsertsDigiStak TM InsertsOther<strong>Rectangular</strong><strong>Interconnects</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com31