CORRAX - Uddeholm

CORRAX - Uddeholm

CORRAX - Uddeholm

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

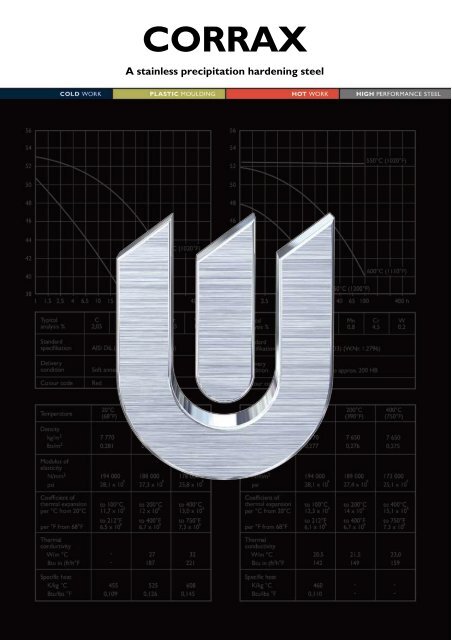

PRELIMINARY BROCHURE<strong>CORRAX</strong>A stainless precipitation hardening steel

<strong>CORRAX</strong>This information is based on our present state of knowledge and isintended to provide general notes on our products and their uses.It should not therefore be construed as a warranty of specificproperties of the products described or a warranty for fitness for aparticular purpose.2

<strong>CORRAX</strong>GeneralCompared with conventional corrosion resistanttool steel, <strong>CORRAX</strong> has the following advantages:• Flexible hardness, 32–50 HRC, achieved by anageing treatment in the temperature range425–600°C (790–1110°F).• Extremely good dimensional stability duringthe ageing• High uniformity of properties also for largedimensions• Very good weldability, no preheating necessary• No hard “white” layer after EDM• Corrosion resistance superior to that ofAISI 420 and W.-Nr. 1.2083.Typical C Si Mn Cr Ni Mo Alanalysis % 0,03 0,3 0,3 12,0 9,2 1,4 1,6Deliverycondition Solution treated to ~34 HRCColourcode Black/greyApplications• Injection moulds for– corrosive plastics– rubber– medical and food industry• Extrusion dies• Plastic processing– screws• Engineering parts.PropertiesPHYSICAL DATAAged to ~46 HRC.Temperature 20°C 200°C 400°C(68°F) (390°F) (750°F)Densitykg/m 3 7 700 – –lbs/in 3 0,28 – –Modulus of elasticityN/mm 2 200 000 190 000 170 000psi 29 x 10 6 28 x 10 6 25 x 10 6Coefficient ofthermal expansionper°C from 20°C – 11,7 x 10 –6 12,3 x 10 –6per°F from 68°F – 6,5 x 10 –6 6,8 x 10 –6Thermal conductivityW/m °C – 18 21Btu in/ft 2 h °F – 125 146MECHANICAL DATATensile strength at room temperature.Solutiontreated Aged to Aged to Aged to~34 HRC ~40 HRC ~46 HRC ~50 HRCYieldstrengthRp0,2N/mm 2 700 1 000 1 400 1 600psi 100 000 150 000 200 000 230 000TensilestrengthRmN/mm21 100 1 200 1 500 1 700psi 160 000 170 000 220 000 250 000Compressive strength at room temperature.Solutiontreated Aged to Aged to Aged to~34 HRC ~40 HRC ~46 HRC ~50 HRCRc0,2N/mm 2 900 1 300 1 600 1800psi 130 000 190 000 230 000 260 000<strong>CORRAX</strong> is a very suitable mould steel for plastic partswith complicated design.3

<strong>CORRAX</strong>TOUGHNESSThe toughness decreases with increasing hardness.The diagram below shows the Charpy Vimpact energy in the short transverse direction of<strong>CORRAX</strong> at different hardnesses.Ageing: 34 HRC delivery condition, 40 HRC:600°C/1112°F 4h, 46 HRC: 575°C/1067°F 2h,50 HRC: 525°C/977°F 2h.ft.lb. Impact energy (J)44 603015402050 HRC0–100 –50 0 50 100 150 200 °CCORROSION RESISTANCE<strong>CORRAX</strong> has a very good corrosion resistance,better than the corrosion resistant standard gradesused for plastic moulding. The corrosion resistanceis the same in all heat treated conditions (exceptafter nitriding).Corrosion resistance6<strong>CORRAX</strong>5432134 HRC Delivery condition1.2083(~52 HRC)1.2316(~30 HRC)46 HRC–150 –50 0 50 100 150 200 250 300 350 400 °FTemperature40 HRC<strong>CORRAX</strong> will withstand attacks from most corrosiveplastics and diluted acids.A mold made of <strong>CORRAX</strong> will also have good resistanceto humid working and storage conditions.<strong>CORRAX</strong> also shows better resistance to stress corrosioncracking than standard hardenable corrosionresistant steel grades.Heat treatment<strong>CORRAX</strong> is delivered in solution treated conditionand can be used in the as-delivered condition.When, however, the steel is to be heat treated to ahigher hardness, the following instructions may behelpful.STRESS RELIEVINGStress relieving can not be performed as for othersteel grades since an increase in temperature resultsin a higher hardness because of ageing effect.AGEING<strong>CORRAX</strong> can be used in as-delivered condition.Higher hardness is obtained by ageing. Suitableageing parameters can be obtained from the figurebelow. Ageing time means the time at the ageingtemperature after the tool is fully heated through.Hardness, HRC52504846444240383634525°C (977°F)0 2 4 6 8 10Ageing time, hAgeing temperature/time525°C/2 h (977°F/2 h)*575°C/2 h (1067°F/2 h)600°C/4 h (1112°F/4 h)Ageing recommendation425°C (797°F)575°C (1067°F)600°C (1112°F)When the ageing time is reached, cool the tool inair to room temperature. Ageing at high temperaturegives a better toughness compared with ageingto the same hardness at a lower temperature.Hardness~50 HRC~46 HRC~40 HRC* Ageing to 50 HRC is only recommended when toughnessis not important (see also PROPERTIES: Toughnesspage 4).If <strong>CORRAX</strong> is used at temperatures higher than200°C (390°F) the solution treated condition (deliverycondition) is not recommended because ageingcan occur during use.4

<strong>CORRAX</strong>SOLUTION TREATMENTIt is possible to solution treat <strong>CORRAX</strong>, if aged, inorder to get back to the delivery condition. Solutiontreatment should be done at 1560°F (850°C),holding time 30 minutes. Cool in air.DIMENSIONAL CHANGEAgeing results in a small and uniform decrease involume. The following shrinkage can be expectedduring ageing.Dimensional change %ShortLongi- Trans- transtudinalversal versalAgeing direction direction direction525°C/2 h (977°F/2 h)~50 HRC –0,07 –0,07 –0,07575°C/2 h (1067°F/3 h)~46 HRC –0,09 –0,09 –0,09600°C/4h (1112°F/4h)~40 HRC –0,14 –0,14 –0,14NITRIDINGNitriding of stainless steels is normally not recommended.Consult with your local <strong>Uddeholm</strong> representative.Cutting datarecommendationsThe cutting data below are to be considered asguiding values which must be adapted to existinglocal conditions. More information can be found inthe <strong>Uddeholm</strong> publication “Cutting data recommendations”.TURNINGTurning with Turningcarbidewith highCutting dataspeed steelparameters Rough turning Fine turning Fine turningCuttingspeed (v c )m/min 90–140 140–190 15f.p.m. 300–465 465–630 50Feed (f)mm/r 0,3–0,6 –0,3 –0,3i.p.r. 0,01–0,024 –0,01 –0,01Depthof cut (a p )mm 2–6 –2 –2inch 0,08–0,24 –0,08 –0,08CarbidedesignationISO P20–P40 P10 –Coated carbide Coated carbideor cermetMILLINGFace- and square shoulder millingMilling withMillingcarbidewith highCutting dataspeed steelparameters Rough milling Fine milling Fine millingCuttingspeed (v c )m/min 80–110 110–160 15f.p.m 265–365 365–535 50Feed (f z )mm/tooth 0,2–0,4 0,1–0,2 0,1inch/tooth 0,008–0,016 0,004–0,008 0,004Depthof cut (a p )mm 2–5 –2 –2inch 0,08–0,20 –0,08 –0,08CarbidedesignationISO P20 P10–P20 –Coated Coatedcarbide carbide orcermet5

<strong>CORRAX</strong>6End millingType of millingCarbideCutting data Solid indexable Highparameters carbide insert speed steelCuttingspeed (v c )m/min 60 80–120 20 1)f.p.m. 200 265–400 66 1)Feed (f z )mm/tooth 0,03–0,20 2) 0,08–0,20 2) 0,05–0,35 2)inch/tooth 0,001–0,008 2) 0,003–0,008 2) 0,002–0,014 2)CarbidedesignationISO K10 P20–P30 –1)For coated HSS end mill v c ~30 m/min. (100 f.p.m.).2)Depending on radial depth of cut and cutter diameter.DRILLINGHigh speed steel twist drillDrill diameter Cutting Feed (f)speed (v c )mm inch m/min f.p.m. mm/r i.p.r.– 5 –3/16 16* 55* 0,08–0,20 0,003–0,0085–10 3/16–3/8 16* 55* 0,20–0,30 0,008–0,01210–15 3/8–5/8 16* 55* 0,30–0,35 0,012–0,01415–20 5/8–3/4 16* 55* 0,35–0,40 0,014–0,0161)For coated HSS drill v c ~20 m/min. (65 f.p.m.).Carbide drillType of drillCutting data Indexable Solid Brazedparameters insert carbide carbide 1)Cuttingspeed (v c )m/min 150–200 70 50f.p.m. 500–265 230 165Feed (f)mm/r 0,03–0,15 2) 0,10–0,25 2) 0,15–0,25 2)i.p.r. 0,0012–0,006 2) 0,004–0,01 2) 0,006–0,01 2)1)Drill with internal cooling channels and brazed carbidetip.2)Depending on drill diameter.GRINDINGA general grinding wheel recommendation isgiven below. More information can be found in the<strong>Uddeholm</strong> publication “Grinding of Tool Steel”.Wheel recommendationSoft annealed HardenedType of grinding condition conditionFace grindingstraight wheel A 46 HV A 46 GVFace grindingsegments A 24 GV A 36 GVCylindrical grinding A 46 LV A 60 JVInternal grinding A 46 JV A 60 IVProfile grinding A 100 LV A 120 JVWhen good surface finish is required a SiC-wheel could bean alternative.EDM<strong>CORRAX</strong> can be EDM’d in the same way asordinary tool steels. The “white layer” will, however,not be as hard and is therefore more easilyremoved.WeldingPreheating is not necessary.When welding on <strong>CORRAX</strong> in delivery condition,intermittant welding is recommended.In order to obtain an even hardness, it is necessaryto carry out a heat treatment after welding. Thetemperature and time are determined by the requiredhardness and the filler material. Normally17–4 PH type material can be used as filler material.For further information, please contact your local<strong>Uddeholm</strong> office.Photo-etching<strong>CORRAX</strong> has a very good corrosion resistance anda special process is thus required for chemicalphoto-etching.Fine patterns with shallow depths