BUILDING ON THE PAST, READY FOR THE FUTURE: - MEMC

BUILDING ON THE PAST, READY FOR THE FUTURE: - MEMC

BUILDING ON THE PAST, READY FOR THE FUTURE: - MEMC

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

66<br />

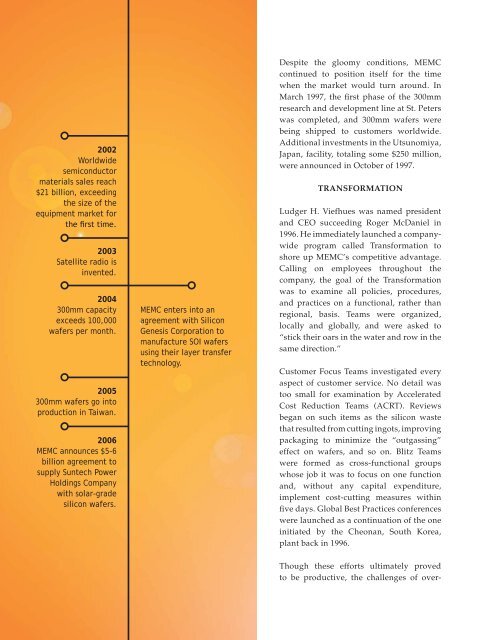

2002<br />

worldwide<br />

semiconductor<br />

materials sales reach<br />

$21 billion, exceeding<br />

the size of the<br />

equipment market for<br />

the first time.<br />

2003<br />

Satellite radio is<br />

invented.<br />

2004<br />

300mm capacity<br />

exceeds 100,000<br />

wafers per month.<br />

2005<br />

300mm wafers go into<br />

production in Taiwan.<br />

2006<br />

<strong>MEMC</strong> announces $5-6<br />

billion agreement to<br />

supply Suntech Power<br />

Holdings Company<br />

with solar-grade<br />

silicon wafers.<br />

<strong>MEMC</strong> enters into an<br />

agreement with Silicon<br />

Genesis Corporation to<br />

manufacture SOI wafers<br />

using their layer transfer<br />

technology.<br />

Despite the gloomy conditions, <strong>MEMC</strong><br />

continued to position itself for the time<br />

when the market would turn around. In<br />

March 1997, the first phase of the 300mm<br />

research and development line at St. Peters<br />

was completed, and 300mm wafers were<br />

being shipped to customers worldwide.<br />

Additional investments in the Utsunomiya,<br />

Japan, facility, totaling some $250 million,<br />

were announced in October of 1997.<br />

transForMatIon<br />

Ludger H. Viefhues was named president<br />

and CEO succeeding Roger McDaniel in<br />

1996. He immediately launched a companywide<br />

program called Transformation to<br />

shore up <strong>MEMC</strong>’s competitive advantage.<br />

Calling on employees throughout the<br />

company, the goal of the Transformation<br />

was to examine all policies, procedures,<br />

and practices on a functional, rather than<br />

regional, basis. Teams were organized,<br />

locally and globally, and were asked to<br />

“stick their oars in the water and row in the<br />

same direction.”<br />

Customer Focus Teams investigated every<br />

aspect of customer service. No detail was<br />

too small for examination by Accelerated<br />

Cost Reduction Teams (ACRT). Reviews<br />

began on such items as the silicon waste<br />

that resulted from cutting ingots, improving<br />

packaging to minimize the “outgassing”<br />

effect on wafers, and so on. Blitz Teams<br />

were formed as cross-functional groups<br />

whose job it was to focus on one function<br />

and, without any capital expenditure,<br />

implement cost-cutting measures within<br />

five days. Global Best Practices conferences<br />

were launched as a continuation of the one<br />

initiated by the Cheonan, South Korea,<br />

plant back in 1996.<br />

Though these efforts ultimately proved<br />

to be productive, the challenges of over-