TGS 203 - Carbon Monoxide Sensor Specifications - Meditronik

TGS 203 - Carbon Monoxide Sensor Specifications - Meditronik

TGS 203 - Carbon Monoxide Sensor Specifications - Meditronik

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

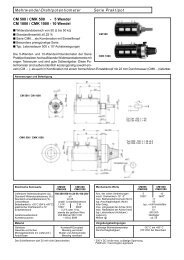

TECHNICAL INFORMATION FOR <strong>TGS</strong><strong>203</strong>4. Reliability4-1 Gas exposure testFigure 15 shows test conditions for short-termexposure of <strong>TGS</strong><strong>203</strong> to various gases. In this test, thesensor was kept energized under standard circuitconditions. <strong>Sensor</strong> resistance in 100ppm of CO␣ wasmeasured prior to the test gas exposure. After theexposure in gases according to the times shown inFigure 15, the sensor was removed from the test gasand energized in normal air. After one hour elapsed,sensor resistance in 100ppm of CO was againmeasured.Exposure to 1000ppm and 3000ppm of test gas (laststep in Figure 15) was not conducted for the followinghighly corrosive gases: hydrogen sulfide (H2S),sulfur dioxide (SO2), and nitrogen dioxide (NO2).Figure 16 shows the test results. The change ratio ofsensor resistance in 100ppm of CO before and afterexposure to the test gas is plotted. Most test gasescaused some decrease in sensor resistance. Especiallythe influence of hydrogen sulfide and sulfur dioxidewere remarkable. The sensor’s ability to recover tooriginal value from gas exposure is coded on Figure16 as follows:1 - quick recovery2 - recovery within one day3 - more than 7 daysTable 1 shows test results on long term gas exposure.<strong>Sensor</strong> resistance in 100ppm of CO was measuredbefore long term gas exposure (Ro) after which thesensors were placed in an enclosed capacity vesselwith a test gas for a designated period. The sensorswere then removed and kept under normalenvironmental conditions for one hour prior tomeasuring their resistance in 100ppm of CO afterexposure to test gas (Rs).As these tests demonstrate, care should be taken tominimize exposure to gases which lower the sensor’ssensitivity.Test gasesGas concentration (ppm)R-22 (freon)NO2SO2H2SH2TolueneEthyl acetateBenzeneIsopropyl alcoholEthanolEthyleneIsobutanePropaneMethane1000010001001055100 10CO20 30 40Gas50 60CO70 80Time (min.)Time ●Figure 15 - Conditions of gas exposure testRs(after)/Rs(before)5 min.0.0 0.2 0.4 0.6 0.8 1.0Figure 16 - Effects of exposure to various gases555332223221111n/an/aRevised 9/99 10/14