Quality Control in Drawings and Specifications

Quality Control in Drawings and Specifications

Quality Control in Drawings and Specifications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

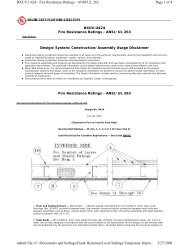

1. Direct vent flues m<strong>in</strong> 2’ from w<strong>in</strong>dows <strong>and</strong> 1’ from ground (from AmericanHeritage Fireplace Co.)2. International Fuel Gas Code, 2003, section 508.3 3: The vent term<strong>in</strong>al of adirect-vent appliance with an <strong>in</strong>put of 10,000 Btu per hour (3 kW) or lessshall be located at least 6 <strong>in</strong>ches (152 mm) from any air open<strong>in</strong>g <strong>in</strong>to abuild<strong>in</strong>g, <strong>and</strong> such an appliance with an <strong>in</strong>put over 10,000 Btu per hour (3kW) but not over 50,000 Btu per hour (14.7 kW) shall be <strong>in</strong>stalled with a 9-<strong>in</strong>ch (230 mm) vent term<strong>in</strong>ation clearance, <strong>and</strong> an appliance with an <strong>in</strong>putover 50,000 Btu/h (14.7 kw) shall have at least a 12-<strong>in</strong>ch (305 mm) ventterm<strong>in</strong>ation clearance. The bottom of the vent term<strong>in</strong>al <strong>and</strong> the air <strong>in</strong>takeshall be located at least 12 <strong>in</strong>ches (305 mm) above grade.Mechanical1. Service heat<strong>in</strong>g boiler <strong>and</strong> or furnace after <strong>in</strong>stallation; change filters.2. Show supply <strong>and</strong> return registers on draw<strong>in</strong>gs3. Make sure that ceil<strong>in</strong>g diffusers are compatible with ceil<strong>in</strong>g material, suchas wood grills on a wood ceil<strong>in</strong>g.Plumb<strong>in</strong>g1. When specify<strong>in</strong>g a whirlpool or bathtub with h<strong>and</strong>-held shower, specifya vacuum breaker <strong>in</strong> the water l<strong>in</strong>es.2. Oak Park requires a 1 ½” deep safety pan or floor dra<strong>in</strong> <strong>in</strong> a room witha 1 ½” threshold <strong>and</strong> waterproof<strong>in</strong>g under floor<strong>in</strong>g material <strong>in</strong> rooms wherewash<strong>in</strong>g mach<strong>in</strong>es <strong>and</strong> hot water heaters are located above basementlevel. Safety pan shall be connected to 1 ½” vertical pipe discharg<strong>in</strong>g<strong>in</strong>directly to a dra<strong>in</strong> at the lowest level of the build<strong>in</strong>g. Vertical stack cannotbe more than 24” away from the safety pan unless the size of the pipe<strong>in</strong>creases. Pip<strong>in</strong>g from the safety pan to the vertical l<strong>in</strong>e should be a teefor vent<strong>in</strong>g the vertical pipe.3. Oak Park requires new basement bathrooms or relocated basementbathrooms to connect to an ejector system.4. Provide battery backup for sump pumps <strong>and</strong> ejectors.5. Oak Park requires basement floor dra<strong>in</strong>s as follows:a. Exist<strong>in</strong>g floor dra<strong>in</strong>s discharge <strong>in</strong>to an exist<strong>in</strong>g or new sump pumpor ejector pump to the sewer, or a taped floor dra<strong>in</strong> with a 48” tallst<strong>and</strong> pipe.b. All new floor dra<strong>in</strong>s connect to an ejector system.6. Provide area dra<strong>in</strong>s for courtyards.7. Provide dra<strong>in</strong>s for all small roofs.8. Always look for plumb<strong>in</strong>g stacks <strong>and</strong> vents to relocate9. Specify that all pipes are parallel with walls.10. Use cast iron dra<strong>in</strong> stack to reduce noise problems.11. Provide gravity loop for hot water stacks.12. Provide temperature control at faucets for commercial toilet rooms.12