Quality Control in Drawings and Specifications

Quality Control in Drawings and Specifications

Quality Control in Drawings and Specifications

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

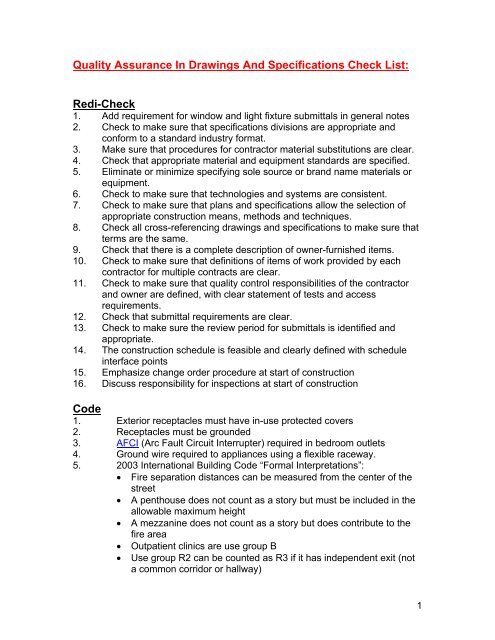

<strong>Quality</strong> Assurance In Draw<strong>in</strong>gs And <strong>Specifications</strong> Check List:Redi-Check1. Add requirement for w<strong>in</strong>dow <strong>and</strong> light fixture submittals <strong>in</strong> general notes2. Check to make sure that specifications divisions are appropriate <strong>and</strong>conform to a st<strong>and</strong>ard <strong>in</strong>dustry format.3. Make sure that procedures for contractor material substitutions are clear.4. Check that appropriate material <strong>and</strong> equipment st<strong>and</strong>ards are specified.5. Elim<strong>in</strong>ate or m<strong>in</strong>imize specify<strong>in</strong>g sole source or br<strong>and</strong> name materials orequipment.6. Check to make sure that technologies <strong>and</strong> systems are consistent.7. Check to make sure that plans <strong>and</strong> specifications allow the selection ofappropriate construction means, methods <strong>and</strong> techniques.8. Check all cross-referenc<strong>in</strong>g draw<strong>in</strong>gs <strong>and</strong> specifications to make sure thatterms are the same.9. Check that there is a complete description of owner-furnished items.10. Check to make sure that def<strong>in</strong>itions of items of work provided by eachcontractor for multiple contracts are clear.11. Check to make sure that quality control responsibilities of the contractor<strong>and</strong> owner are def<strong>in</strong>ed, with clear statement of tests <strong>and</strong> accessrequirements.12. Check that submittal requirements are clear.13. Check to make sure the review period for submittals is identified <strong>and</strong>appropriate.14. The construction schedule is feasible <strong>and</strong> clearly def<strong>in</strong>ed with schedule<strong>in</strong>terface po<strong>in</strong>ts15. Emphasize change order procedure at start of construction16. Discuss responsibility for <strong>in</strong>spections at start of constructionCode1. Exterior receptacles must have <strong>in</strong>-use protected covers2. Receptacles must be grounded3. AFCI (Arc Fault Circuit Interrupter) required <strong>in</strong> bedroom outlets4. Ground wire required to appliances us<strong>in</strong>g a flexible raceway.5. 2003 International Build<strong>in</strong>g Code “Formal Interpretations”: Fire separation distances can be measured from the center of thestreet A penthouse does not count as a story but must be <strong>in</strong>cluded <strong>in</strong> theallowable maximum height A mezzan<strong>in</strong>e does not count as a story but does contribute to thefire areaOutpatient cl<strong>in</strong>ics are use group BUse group R2 can be counted as R3 if it has <strong>in</strong>dependent exit (nota common corridor or hallway)1

Unlimited area build<strong>in</strong>gs cannot have basements Combustible nailers <strong>and</strong> block<strong>in</strong>g are permitted <strong>in</strong> Types 1 <strong>and</strong> 2construction Area <strong>in</strong>crease for open perimeter <strong>and</strong> fire spr<strong>in</strong>klers apply to bothheight <strong>and</strong> area The posted 20 foot fire lane required for perimeter <strong>in</strong>crease doesnot have to be paved but must be fire dept accessible Rated fire dampers cannot be <strong>in</strong>stalled at floor levels <strong>in</strong> lieu of firerated shaft enclosures Unfaced fiberglass <strong>in</strong>sulation can be used as a fireblock<strong>in</strong>g materialfor wall cavities <strong>in</strong> combustible construction only When two exits are required, one cannot pass through a stairwayfor a cont<strong>in</strong>uous corridor beyond the stairway lead<strong>in</strong>g to the secondexit6. Calculate area of build<strong>in</strong>g <strong>and</strong> area of sidewalks for permit costcalculation7. If exterior wall is less than 3’ from property l<strong>in</strong>e, it must be 1 HR rated –5/8” type “X” gypsum board on each side of wall. No penetrations,even conduit, are allowed through this wall.8. Soffits: If soffits are less than 3’ from property l<strong>in</strong>e, bottom of soffit must beclad with 5/8” type “X” gypsum board. Overhangs cannot be less than 24” from property l<strong>in</strong>e. If they are,Head of department may allow fire treatment of roof sheath<strong>in</strong>g <strong>and</strong>wood fascia.9. Rail<strong>in</strong>gs <strong>and</strong> guard rails: Show rail<strong>in</strong>g height along stairs <strong>and</strong> at l<strong>and</strong><strong>in</strong>gs Show stair <strong>and</strong> riser sizes Show spac<strong>in</strong>g of balusters Must have “graspable” h<strong>and</strong>rail on one side of stairs (1 ½” roundrail)10. Residential egress: Front or back door must be 3’ wide to qualify as an egress door Cannot use slid<strong>in</strong>g door for egress Cannot open a door out over a step. Must have 3’ long l<strong>and</strong><strong>in</strong>g at top <strong>and</strong> bottom of stairs11. If you're <strong>in</strong>volved <strong>in</strong> construction or <strong>in</strong>stallation <strong>in</strong> homes or other childoccupiedfacilities built before 1978, you'll need to know about the EPA's new2

Lead: Renovation, Repair <strong>and</strong> Pa<strong>in</strong>t<strong>in</strong>g rule, which will become m<strong>and</strong>atory <strong>in</strong>April 2010. In short, the Lead: Renovation, Repair <strong>and</strong> Pa<strong>in</strong>t<strong>in</strong>g rule requires: An eight-hour tra<strong>in</strong><strong>in</strong>g session New work practices, <strong>in</strong>clud<strong>in</strong>g clean<strong>in</strong>g verification Keep<strong>in</strong>g records for three yearsPlann<strong>in</strong>g1. Check height of w<strong>in</strong>dow sill above floor for readers.2. Locate telephone, cable, <strong>and</strong> network wir<strong>in</strong>g risers <strong>and</strong> jacks <strong>in</strong> all build<strong>in</strong>gs.3. Provide access panels for motors, thermostats, <strong>and</strong> P-traps.4. Provide sound batts between rooms especially around toilet rooms.Site work1. Always note grad<strong>in</strong>g to dra<strong>in</strong> away from build<strong>in</strong>g.2. Note architect to verify top of foot<strong>in</strong>gs <strong>and</strong> foundations prior to pour<strong>in</strong>g.3. Note that all borrow <strong>and</strong> fill to be provided <strong>in</strong> contract.4. Underground water pip<strong>in</strong>g m<strong>in</strong> 3'-6" deep.5. 4" m<strong>in</strong> soil pipe outside build<strong>in</strong>g.6. Use 6" diameter ASTM D3034 SDR green PVC pipe for storm dra<strong>in</strong>s.7. Use s<strong>and</strong> fill around pipes.8. Use rigid perforated PVC with filter fabric for sub-soil dra<strong>in</strong>s.9. Field verify compaction of all soil after excavation.10. Check level at every door at grade.Decks & Porches1. Use sta<strong>in</strong>less steel nails on exterior decks.2. Ease edges of stairs.3. Redwood thickness m<strong>in</strong>. 1 1/4" for spann<strong>in</strong>g 16" joist spac<strong>in</strong>g.Additions & Remodel<strong>in</strong>g1. Must have photographs for rehab jobs <strong>in</strong> draw<strong>in</strong>gs so noth<strong>in</strong>g ismissed.2. Assume that ceil<strong>in</strong>g heights <strong>in</strong> adjacent rooms are slightly out of level.3. Specify floor levelness for rehab; specify that all floors must be filled &leveled.4. Check that all exist<strong>in</strong>g items, <strong>in</strong>clud<strong>in</strong>g hardware shall be stripped ofpa<strong>in</strong>t.3

5. Note on draw<strong>in</strong>gs that all surfaces should be pa<strong>in</strong>ted <strong>in</strong> area ofremodel<strong>in</strong>g.Masonry1. New masonry horizontal jo<strong>in</strong>ts must l<strong>in</strong>e up with exist masonry.2. Expansion jo<strong>in</strong>ts <strong>in</strong> l<strong>in</strong>tels or shelf angles support<strong>in</strong>g masonry wheremasonry expansion jo<strong>in</strong>ts occur.3. Always use hot dipped galvanized wire ties <strong>in</strong> exterior walls.4. Do draw<strong>in</strong>gs <strong>in</strong>dicate the proper location of expansion <strong>and</strong> controljo<strong>in</strong>ts on all of the elevations?5. Do draw<strong>in</strong>gs conta<strong>in</strong> proper details of expansion <strong>and</strong> control jo<strong>in</strong>ts?6. Do draw<strong>in</strong>gs <strong>in</strong>dicate compressible fillers, flexible anchor, etc., tocompensate for various structural movements?7. Has flash<strong>in</strong>g been properly detailed <strong>and</strong> located <strong>in</strong> the appropriateareas?8. Do draw<strong>in</strong>gs <strong>in</strong>dicate the type of flash<strong>in</strong>g to be used?9. Specify the required fire rat<strong>in</strong>g, if so required?10. Are weepholes properly <strong>in</strong>dicated on draw<strong>in</strong>gs?11. Do draw<strong>in</strong>gs <strong>in</strong>dicate the proper number of wall ties as required bycode?12. Do draw<strong>in</strong>gs <strong>in</strong>dicate the proper location of wall ties <strong>and</strong> anchors?13. Do draw<strong>in</strong>gs notate the type of <strong>in</strong>sulation that is to be used?14. Do draw<strong>in</strong>gs <strong>in</strong>dicate a 1" or greater air space, with rigid <strong>in</strong>sulation forthe cavity wall detail?15. Do draw<strong>in</strong>gs <strong>in</strong>dicate locations of all sealants?16. Do draw<strong>in</strong>gs <strong>in</strong>dicate "grade" at a m<strong>in</strong>imum of 2" below foundationbase flash<strong>in</strong>g?17. Are <strong>in</strong>tricate masonry patterns or ornamental details properly workedout on the draw<strong>in</strong>gs?18. Do draw<strong>in</strong>gs <strong>in</strong>dicate a vapor barrier <strong>in</strong> walls hav<strong>in</strong>g an exterior wytheof glazed brick?19. Do draw<strong>in</strong>gs <strong>in</strong>dicate proper ventilation of the cavity when an exteriorwythe of glazed brick is used?20. Do draw<strong>in</strong>gs <strong>in</strong>dicate a sta<strong>in</strong> <strong>and</strong>/or waterproof coat<strong>in</strong>g on exteriorconcrete masonry walls?21. Are all dimensions of masonry based on 4", 8" or 12" <strong>in</strong>crements?22. Do draw<strong>in</strong>gs <strong>in</strong>dicate realistic dimensions <strong>and</strong> tolerances <strong>in</strong> details forplumb<strong>in</strong>g <strong>and</strong> chase walls?23. Did you specify the proper brick type, which is conducive to itsproposed function?24. Did you specify <strong>and</strong> <strong>in</strong>dicate on the draw<strong>in</strong>gs <strong>and</strong> the specifications therequired fire rat<strong>in</strong>g, if so required?25. For economy, did you specify the largest modular size brick (not aquad-sized brick) available?26. Did you specify the proper strength of the masonry unit to be used?4

27. Did you specify all special shapes that might be used?28. Did you specify special cold weather masonry construction <strong>and</strong>protection recommendation when weather conditions are near freez<strong>in</strong>g?29. Did you specify the type of mortar <strong>and</strong> grout that is to be used?30. Did you specify the proper mix<strong>in</strong>g <strong>and</strong> procedure for mortar <strong>and</strong> grout?31. Did you specify properly tooled mortar jo<strong>in</strong>ts?32. Did you specify for all head, bed, <strong>and</strong> collar jo<strong>in</strong>ts to be filled as solidlyas possible?33. Did you specify the proper amount of galvaniz<strong>in</strong>g on all metals used <strong>in</strong>conjunction with masonry wall systems?34. Did you specify that cavity wall ties <strong>and</strong> veneer ties have adequatethickness to fully transfer lateral loads?35. Did you specify that all shelf angles be properly designed to limitdeflection to 1/600, <strong>and</strong> properly shimmed to avoid rotation?36. Did you specify all the types of accessories to be used, such as<strong>in</strong>serts, regrets, etc. <strong>and</strong> by whom they are to be supplied?37. Did you specify that necessary masonry samples be submitted?38. Did you specify that a mock-up masonry panel (with flash<strong>in</strong>g,expansion jo<strong>in</strong>t <strong>and</strong> corner conditions) be built prior to start ofconstruction?39. Did you specify that all cop<strong>in</strong>gs, sills <strong>and</strong> cornices are to be pitched<strong>and</strong> have a drip?40. Did you specify all proper <strong>and</strong> realistic construction tolerances forstructural frames <strong>and</strong> for masonry walls supported on frames?41. In general, do not specify brick masonry for cop<strong>in</strong>gs or low slope sills.42. Do not specify the use of chloride admixtures <strong>in</strong> mortar.43. Do not specify parg<strong>in</strong>g <strong>in</strong> cavity walls.44. Do not specify a vapor barrier <strong>in</strong> a conventional cavity wall.45. Do not specify the use of oil-base or alkyd pa<strong>in</strong>ts on exterior brickmasonry.46. Do not specify plastic tubes to be used as weepholes.W<strong>in</strong>dows1. W<strong>in</strong>dows with sills below 24” require a guard.2. Specify tempered glass <strong>in</strong> bathroom <strong>and</strong> showers <strong>in</strong> notes3. Seal all w<strong>in</strong>dows <strong>and</strong> doors <strong>in</strong>side <strong>and</strong> out.4. Bedroom Egress W<strong>in</strong>dows:a. 1009.2 M<strong>in</strong>imum size: Emergency escape <strong>and</strong> rescue open<strong>in</strong>gsshall have a m<strong>in</strong>imum net clear open<strong>in</strong>g of 5.7 square feet.Exception: The m<strong>in</strong>imum net clear open<strong>in</strong>g for emergency escape<strong>and</strong> rescue open<strong>in</strong>gs on the ground level at grade is 5.0 squarefeet.b. 1009.2.1 M<strong>in</strong>imum dimensions: The m<strong>in</strong>imum net clear open<strong>in</strong>gheight dimension shall be 24 <strong>in</strong>ches. The net clear open<strong>in</strong>g width5

dimension shall be 20 <strong>in</strong>ches. The net clear open<strong>in</strong>g dimensionsshall be the result of normal operation of the open<strong>in</strong>g.c. 1009.3 Maximum height from the floor: Emergency escape <strong>and</strong>rescue open<strong>in</strong>g shall have the bottom of the clear open<strong>in</strong>g notgreater than 44 <strong>in</strong>ches (1118 mm) measured from the floor.5. Basement Egress W<strong>in</strong>dows:a. Sill height of w<strong>in</strong>dow above floor: Not to exceed 44”M<strong>in</strong>imum open<strong>in</strong>g area: ≥ 5.7 sq. ft.M<strong>in</strong>imum open<strong>in</strong>g height ≥ 24”M<strong>in</strong>imum open<strong>in</strong>g width: ≥ 20”b. W<strong>in</strong>dow Wells/Area Wells:Required where w<strong>in</strong>dow open<strong>in</strong>g sill height is below groundelevation.Horizontal dimensions: ≥ 9 sq.ft. (width x projection)Horizontal projection: ≥ 36 “c. Ladders:Required on w<strong>in</strong>dow wells deeper than 44” <strong>and</strong> must bepermanently attached.Ladder may encroach <strong>in</strong>to well up to 6”.Step distance between rungs: ≤ 18”Rungs:12” wide or greater <strong>and</strong> must project a m<strong>in</strong>imum of 3” awayfrom wall but maximum of 6”.d. Grates:Shall be removable without special tools.6. Safety Glaz<strong>in</strong>ga. Safety Glaz<strong>in</strong>g Requirements from IBC 2003:b. 2406.3 Hazardous locations. The follow<strong>in</strong>g shall be consideredspecific hazardous locations requir<strong>in</strong>g safety glaz<strong>in</strong>g materials:c. Glaz<strong>in</strong>g <strong>in</strong> sw<strong>in</strong>g<strong>in</strong>g doors except jalousiesd. Glaz<strong>in</strong>g <strong>in</strong> fixed <strong>and</strong> slid<strong>in</strong>g panels of slid<strong>in</strong>g door assemblies <strong>and</strong>panels <strong>in</strong> slid<strong>in</strong>g <strong>and</strong> bifold closet door assemblies.e. Glaz<strong>in</strong>g <strong>in</strong> storm doors.f. Glaz<strong>in</strong>g <strong>in</strong> unframed sw<strong>in</strong>g<strong>in</strong>g doors.g. Glaz<strong>in</strong>g <strong>in</strong> doors <strong>and</strong> enclosures for hot tubs, whirlpools, saunas,steam rooms, bathtubs <strong>and</strong> showers. Glaz<strong>in</strong>g <strong>in</strong> any portion of abuild<strong>in</strong>g wall enclos<strong>in</strong>g these compartments where the bottomexposed edge of the glaz<strong>in</strong>g is less than 60 <strong>in</strong>ches above ast<strong>and</strong><strong>in</strong>g surface.h. Glaz<strong>in</strong>g <strong>in</strong> an <strong>in</strong>dividual fixed or operable panel adjacent to a doorwhere the nearest exposed edge of the glaz<strong>in</strong>g is with<strong>in</strong> a 24-<strong>in</strong>charc of either vertical edge of the door <strong>in</strong> a closed position <strong>and</strong>where the bottom exposed edge of the glaz<strong>in</strong>g is less than 60<strong>in</strong>ches above the walk<strong>in</strong>g surface.i. Exceptions:6

i. Panels where there is an <strong>in</strong>terven<strong>in</strong>g wall or other permanentbarrier between the door <strong>and</strong> glaz<strong>in</strong>g.j. Where access through the door is to a closet or storage area 3 feetor less <strong>in</strong> depth.k. Glaz<strong>in</strong>g <strong>in</strong> walls perpendicular to the plane of the door <strong>in</strong> a closedposition, other than the wall towards which the door sw<strong>in</strong>gs whenopened, <strong>in</strong> one- <strong>and</strong> two-family dwell<strong>in</strong>gs or with<strong>in</strong> dwell<strong>in</strong>g units <strong>in</strong>Group R-2.7. Glaz<strong>in</strong>g <strong>in</strong> an <strong>in</strong>dividual fixed or operable panel, other than <strong>in</strong> thoselocations described <strong>in</strong> preced<strong>in</strong>g Items 5 <strong>and</strong> 6, which meets all of thefollow<strong>in</strong>g conditions:i. 7.1. Exposed area of an <strong>in</strong>dividual pane greater than 9square feet;ii. 7.2. Exposed bottom edge less than 18 <strong>in</strong>ches above thefloor;iii. 7.3. Exposed top edge greater than 36 <strong>in</strong>ches above thefloor; <strong>and</strong>iv. 7.4. One or more walk<strong>in</strong>g surface(s) with<strong>in</strong> 36 <strong>in</strong>cheshorizontally of the plane of the glaz<strong>in</strong>g.1. Exception: Safety glaz<strong>in</strong>g for Item 7 is not requiredfor the follow<strong>in</strong>g <strong>in</strong>stallations:v. A protective bar 11/2 <strong>in</strong>ches or more <strong>in</strong> height, capable ofwithst<strong>and</strong><strong>in</strong>g a horizontal load of 50 pounds plf withoutcontact<strong>in</strong>g the glass, is <strong>in</strong>stalled on the accessible sides ofthe glaz<strong>in</strong>g 34 <strong>in</strong>ches to 38 <strong>in</strong>ches above the floor.vi. The outboard pane <strong>in</strong> <strong>in</strong>sulat<strong>in</strong>g glass units or multipleglaz<strong>in</strong>g where the bottom exposed edge of the glass is 25feet or more above any grade, roof, walk<strong>in</strong>g surface or otherhorizontal or sloped (with<strong>in</strong> 45 degrees of horizontal) surfaceadjacent to the glass exterior.8. Glaz<strong>in</strong>g <strong>in</strong> guards <strong>and</strong> rail<strong>in</strong>gs, <strong>in</strong>clud<strong>in</strong>g structural baluster panels <strong>and</strong>nonstructural <strong>in</strong>-fill panels, regardless of area or height above a walk<strong>in</strong>gsurface.9. Glaz<strong>in</strong>g <strong>in</strong> walls <strong>and</strong> fences enclos<strong>in</strong>g <strong>in</strong>door <strong>and</strong> outdoor swimm<strong>in</strong>g pools,hot tubs <strong>and</strong> spas where all of the follow<strong>in</strong>g conditions are present:a. The bottom edge of the glaz<strong>in</strong>g on the pool or spa side is less than60 <strong>in</strong>ches above a walk<strong>in</strong>g surface on the pool or spa side of theglaz<strong>in</strong>g; <strong>and</strong>b. The glaz<strong>in</strong>g is with<strong>in</strong> 60 <strong>in</strong>ches horizontally of the water’s edge of aswimm<strong>in</strong>g pool or spa.10. Glaz<strong>in</strong>g adjacent to stairways, l<strong>and</strong><strong>in</strong>gs <strong>and</strong> ramps with<strong>in</strong> 36 <strong>in</strong>cheshorizontally of a walk<strong>in</strong>g surface; when the exposed surface of the glass isless than 60 <strong>in</strong>ches above the plane of the adjacent walk<strong>in</strong>g surface.7

11. Glaz<strong>in</strong>g adjacent to stairways with<strong>in</strong> 60 <strong>in</strong>ches horizontally of the bottomtread of a stairway <strong>in</strong> any direction when the exposed surface of the glassis less than 60 <strong>in</strong>ches above the nose of the tread.i. Exception: Safety glaz<strong>in</strong>g for Item 10 or 11 is not requiredfor the follow<strong>in</strong>g <strong>in</strong>stallations where:1. The side of a stairway, l<strong>and</strong><strong>in</strong>g or ramp which has aguardrail or h<strong>and</strong>rail, <strong>in</strong>clud<strong>in</strong>g balusters or <strong>in</strong>-fillpanels, comply<strong>in</strong>g with the provisions of Sections1012 <strong>and</strong> 1607.7; <strong>and</strong>2. The plane of the glass is greater than 18 <strong>in</strong>ches fromthe rail<strong>in</strong>g.b. 2406.3.1 Exceptions: The follow<strong>in</strong>g products, materials <strong>and</strong> usesshall not be considered specific hazardous locations:1. Open<strong>in</strong>gs <strong>in</strong> doors through which a 3-<strong>in</strong>ch sphere isunable to pass.2. Decorative glass3. Glaz<strong>in</strong>g materials used as curved glazed panels <strong>in</strong>revolv<strong>in</strong>g doors.4. Commercial refrigerated cab<strong>in</strong>et glazed doors.5. Glass-block panels6. Louvered w<strong>in</strong>dows <strong>and</strong> jalousies7. Mirrors <strong>and</strong> other glass panels mounted or hung on asurface that provides a cont<strong>in</strong>uous back<strong>in</strong>g support.Doors1. Specify dark bronze anodized alum<strong>in</strong>um for thresholds.2. Check to make sure that Baldw<strong>in</strong> hardware fits with<strong>in</strong> door stile.Walls1. Inspection of drywall f<strong>in</strong>ish<strong>in</strong>g - use long straightedge to teststraightness of f<strong>in</strong>ish (can't see quality without straightedge)Floors2. Use dark grout color for floors; use white grout for light wall tile.3. Do not sta<strong>in</strong> maple floor<strong>in</strong>g -- s<strong>and</strong><strong>in</strong>g by h<strong>and</strong> at edges will take sta<strong>in</strong>differently.4. Inspect all wood for floors to make sure it meets quality st<strong>and</strong>ard.5. Beware of us<strong>in</strong>g strip floor<strong>in</strong>g near toe-space heaters - the boards willdry out <strong>and</strong> separate.Stairs1. Use skirt boards on stairs.2. Watch out for stair rail<strong>in</strong>g support.8

Energy & Insulation1. Make sure steel beams are <strong>in</strong>sulated to prevent excessive expansion<strong>and</strong> contraction.2. Foil-faced fiberglass <strong>in</strong>sulation is available from Bone Roof<strong>in</strong>g Supply<strong>in</strong> Chicago (773) 237-9740, <strong>and</strong> ABC Supply, Cicero 222-8222.3. Provide weep holes at bottom of steel tubes or pipe columns subject toweather, temperature changes <strong>and</strong> condensation.Accessibility1. Truncated domes are required at curb ramps under the ADA -temporary suspension expired July 26, 2001.Structure2. Stresses3. Paralam PSL: 45 pcf; 3 ½” 5 ¼” <strong>and</strong> 7” wide x 9 ½” 11 7/8” 14” 16” 18”deep; Fb = 2900 psi; E=2x10 \6 psi4. Microlam LVL: 42 pcf; 1.75” wide; 5 ½” 7 ¼” 9 ¼” 9 ½” 11 ¼” 11 7/8” 14”16” 18” 20” Fb = 2600 psi; E = 1.9 x 10 \6 psi5. Brace tops of all exterior walls.6. Spike sister joists with two 10d nails @ 12" o.c.7. Use 20 gage studs to support cement backer board for ceramic tile.8. Calculate stress on beams <strong>and</strong> slabs for snow drift<strong>in</strong>g.9. Tops of beams must be braced to qualify for compact section F ballowable.10. Concrete stairs must have #4 bars @ 12" o.c. at bottom <strong>and</strong> #4 nos<strong>in</strong>gbars.11. M<strong>in</strong>imum length of shear wall adjacent to garage door is 28"12. Light gage metal thicknesses:13. 54 mil = 16 ga14. 43 mil = 18 ga15. 33 mil = 20 ga16. 18 mil = 25 ga17. Stud designation "362S 137-43" means a metal stud 3.62" deep (35/8") x 1.37" wide <strong>and</strong> 43 mills thick (18 ga), the S is for "stud". From SteelStud Manufacturers Association (SSMA)http://www.ssma.com/ssmatechcatalog.pdfPa<strong>in</strong>t<strong>in</strong>g1. Back prime all trim.2. Call for pa<strong>in</strong>t<strong>in</strong>g of edges of exterior w<strong>in</strong>dow <strong>and</strong> door cas<strong>in</strong>gs to matchface at clapboard sid<strong>in</strong>g.9

3. Pa<strong>in</strong>t project<strong>in</strong>g PVC vent pipes black4. Pa<strong>in</strong>t<strong>in</strong>g general notes:a. Pa<strong>in</strong>t all exposed surfaces, except where the draw<strong>in</strong>gs <strong>in</strong>dicate thata surface or material is not to be pa<strong>in</strong>ted or is to rema<strong>in</strong> natural. Ifthe draw<strong>in</strong>gs do not specifically mention an item or a surface, pa<strong>in</strong>tthe item or surface the same color as similar adjacent materials orsurfaces. Also pa<strong>in</strong>t the follow<strong>in</strong>g items: un<strong>in</strong>sulated metal pip<strong>in</strong>g,un<strong>in</strong>sulated plastic pip<strong>in</strong>g, pipe hangers <strong>and</strong> supports, tanks that donot have factory-applied f<strong>in</strong>al f<strong>in</strong>ishes, visible portions of <strong>in</strong>ternalsurfaces of metal ducts, without l<strong>in</strong>er, beh<strong>in</strong>d air <strong>in</strong>lets <strong>and</strong> outlets,duct, equipment, <strong>and</strong> pipe <strong>in</strong>sulation hav<strong>in</strong>g cotton or canvas<strong>in</strong>sulation cover<strong>in</strong>g or other pa<strong>in</strong>table jacket material, mechanicalequipment that is <strong>in</strong>dicated to have a factory-primed f<strong>in</strong>ish for fieldpa<strong>in</strong>t<strong>in</strong>g, switchgear, panelboards, <strong>and</strong> electrical equipment that is<strong>in</strong>dicated to have a factory-primed f<strong>in</strong>ish for field pa<strong>in</strong>t<strong>in</strong>g, surfacesbeh<strong>in</strong>d movable equipment <strong>and</strong> furniture. Before f<strong>in</strong>al <strong>in</strong>stallation,pa<strong>in</strong>t surfaces beh<strong>in</strong>d permanently fixed equipment or furniture withprime coat only. Pa<strong>in</strong>t front <strong>and</strong> backsides of access panels,removable or h<strong>in</strong>ged covers, <strong>and</strong> similar h<strong>in</strong>ged items to matchexposed surfaces.b. Do not pa<strong>in</strong>t pref<strong>in</strong>ished items such as architectural woodwork <strong>and</strong>casework, acoustical wall panels, metal toilet enclosures, metallockers, unit kitchens, elevator entrance doors <strong>and</strong> frames, elevatorequipment, f<strong>in</strong>ished mechanical <strong>and</strong> electrical equipment, lightfixtures, distribution cab<strong>in</strong>ets; concealed surfaces such as foundationspaces, furred areas, ceil<strong>in</strong>g plenums, utility tunnels, pipe spaces,duct shafts, elevator shafts; f<strong>in</strong>ished metal surfaces such asanodized alum<strong>in</strong>um, sta<strong>in</strong>less steel, chromium plate, copper, bronze<strong>and</strong> brass; <strong>and</strong> operat<strong>in</strong>g parts <strong>and</strong> labels.c. Pa<strong>in</strong>t<strong>in</strong>g Preparation:d. Remove plates, mach<strong>in</strong>ed surfaces, <strong>and</strong> similar items already <strong>in</strong>place that are not to be pa<strong>in</strong>ted. If removal is impractical orimpossible because of size or weight of item, provide surface-appliedprotection before surface preparation <strong>and</strong> pa<strong>in</strong>t<strong>in</strong>g.e. Clean substrates of substances that could impair bond of pa<strong>in</strong>ts,<strong>in</strong>clud<strong>in</strong>g dirt, oil, grease, <strong>and</strong> <strong>in</strong>compatible pa<strong>in</strong>ts <strong>and</strong> encapsulants.Coord<strong>in</strong>ation of shop-applied prime coats with topcoats is critical.Remove <strong>in</strong>compatible primers <strong>and</strong> reprime substrate with compatibleprimers as required to produce pa<strong>in</strong>t systems <strong>in</strong>dicated.f. Concrete Substrates: Remove release agents, cur<strong>in</strong>g compounds,efflorescence, <strong>and</strong> chalk. Do not pa<strong>in</strong>t surfaces if moisture content10

Fireplacesor alkal<strong>in</strong>ity of surfaces to be pa<strong>in</strong>ted exceeds that permitted <strong>in</strong>manufacturer's written <strong>in</strong>structions.g. Clay Masonry Substrates: Remove efflorescence <strong>and</strong> chalk. Do notpa<strong>in</strong>t surfaces if moisture content of surfaces or alkal<strong>in</strong>ity of mortarjo<strong>in</strong>ts to be pa<strong>in</strong>ted exceed that permitted <strong>in</strong> manufacturer's written<strong>in</strong>structions.h. Concrete Masonry Substrates: Remove efflorescence <strong>and</strong> chalk.Do not pa<strong>in</strong>t surfaces if moisture content or alkal<strong>in</strong>ity of surfaces tobe pa<strong>in</strong>ted exceeds that permitted <strong>in</strong> manufacturer's written<strong>in</strong>structions.i. Steel Substrates: Remove rust <strong>and</strong> loose mill scale. Clean us<strong>in</strong>gmethods recommended <strong>in</strong> writ<strong>in</strong>g by pa<strong>in</strong>t manufacturer.Galvanized-metal substrates should not be chromate passivated(commercially known as "bonderized") if primers are field applied. Ifgalvanized metal is chromate passivated, consult manufacturers forappropriate surface preparation <strong>and</strong> primers.j. Galvanized-Metal Substrates: Remove grease <strong>and</strong> oil residue fromgalvanized sheet metal fabricated from coil stock by mechanicalmethods to produce clean, lightly etched surfaces that promoteadhesion of subsequently applied pa<strong>in</strong>ts.k. Alum<strong>in</strong>um Substrates: Remove surface oxidation.l. Wood Substrates: scrape <strong>and</strong> clean knots, <strong>and</strong> apply coat of knotsealer before apply<strong>in</strong>g primer; s<strong>and</strong> surfaces that will be exposed toview, <strong>and</strong> dust off; prime edges, ends, faces, undersides, <strong>and</strong>backsides of wood, after prim<strong>in</strong>g, fill holes <strong>and</strong> imperfections <strong>in</strong> thef<strong>in</strong>ish surfaces with putty or plastic wood filler, s<strong>and</strong> smooth whendried.m. Gypsum Board Substrates: Do not beg<strong>in</strong> pa<strong>in</strong>t application untilf<strong>in</strong>ish<strong>in</strong>g compound is dry <strong>and</strong> s<strong>and</strong>ed smooth.n. Plaster Substrates: Do not beg<strong>in</strong> pa<strong>in</strong>t application until plaster isfully cured <strong>and</strong> dry.o. Cotton or Canvas Insulation Cover<strong>in</strong>g Substrates: Remove dust,dirt, <strong>and</strong> other foreign material that might impair bond of pa<strong>in</strong>ts tosubstrates.11

1. Direct vent flues m<strong>in</strong> 2’ from w<strong>in</strong>dows <strong>and</strong> 1’ from ground (from AmericanHeritage Fireplace Co.)2. International Fuel Gas Code, 2003, section 508.3 3: The vent term<strong>in</strong>al of adirect-vent appliance with an <strong>in</strong>put of 10,000 Btu per hour (3 kW) or lessshall be located at least 6 <strong>in</strong>ches (152 mm) from any air open<strong>in</strong>g <strong>in</strong>to abuild<strong>in</strong>g, <strong>and</strong> such an appliance with an <strong>in</strong>put over 10,000 Btu per hour (3kW) but not over 50,000 Btu per hour (14.7 kW) shall be <strong>in</strong>stalled with a 9-<strong>in</strong>ch (230 mm) vent term<strong>in</strong>ation clearance, <strong>and</strong> an appliance with an <strong>in</strong>putover 50,000 Btu/h (14.7 kw) shall have at least a 12-<strong>in</strong>ch (305 mm) ventterm<strong>in</strong>ation clearance. The bottom of the vent term<strong>in</strong>al <strong>and</strong> the air <strong>in</strong>takeshall be located at least 12 <strong>in</strong>ches (305 mm) above grade.Mechanical1. Service heat<strong>in</strong>g boiler <strong>and</strong> or furnace after <strong>in</strong>stallation; change filters.2. Show supply <strong>and</strong> return registers on draw<strong>in</strong>gs3. Make sure that ceil<strong>in</strong>g diffusers are compatible with ceil<strong>in</strong>g material, suchas wood grills on a wood ceil<strong>in</strong>g.Plumb<strong>in</strong>g1. When specify<strong>in</strong>g a whirlpool or bathtub with h<strong>and</strong>-held shower, specifya vacuum breaker <strong>in</strong> the water l<strong>in</strong>es.2. Oak Park requires a 1 ½” deep safety pan or floor dra<strong>in</strong> <strong>in</strong> a room witha 1 ½” threshold <strong>and</strong> waterproof<strong>in</strong>g under floor<strong>in</strong>g material <strong>in</strong> rooms wherewash<strong>in</strong>g mach<strong>in</strong>es <strong>and</strong> hot water heaters are located above basementlevel. Safety pan shall be connected to 1 ½” vertical pipe discharg<strong>in</strong>g<strong>in</strong>directly to a dra<strong>in</strong> at the lowest level of the build<strong>in</strong>g. Vertical stack cannotbe more than 24” away from the safety pan unless the size of the pipe<strong>in</strong>creases. Pip<strong>in</strong>g from the safety pan to the vertical l<strong>in</strong>e should be a teefor vent<strong>in</strong>g the vertical pipe.3. Oak Park requires new basement bathrooms or relocated basementbathrooms to connect to an ejector system.4. Provide battery backup for sump pumps <strong>and</strong> ejectors.5. Oak Park requires basement floor dra<strong>in</strong>s as follows:a. Exist<strong>in</strong>g floor dra<strong>in</strong>s discharge <strong>in</strong>to an exist<strong>in</strong>g or new sump pumpor ejector pump to the sewer, or a taped floor dra<strong>in</strong> with a 48” tallst<strong>and</strong> pipe.b. All new floor dra<strong>in</strong>s connect to an ejector system.6. Provide area dra<strong>in</strong>s for courtyards.7. Provide dra<strong>in</strong>s for all small roofs.8. Always look for plumb<strong>in</strong>g stacks <strong>and</strong> vents to relocate9. Specify that all pipes are parallel with walls.10. Use cast iron dra<strong>in</strong> stack to reduce noise problems.11. Provide gravity loop for hot water stacks.12. Provide temperature control at faucets for commercial toilet rooms.12

13. Wrap plastic underground gas l<strong>in</strong>es with signal cable to enable it to bedetected.14. Water service <strong>and</strong> meter siz<strong>in</strong>g – follow state m<strong>in</strong>imum sizes <strong>and</strong> showon draw<strong>in</strong>gs.15. Show riser diagram16. M<strong>in</strong>imum 3” pipe to WC – show17. Show that shower is 6’-8” above top of shower bas<strong>in</strong>18. Ceil<strong>in</strong>g height m<strong>in</strong> 6’-8” above toiletElectrical1. Specify steel conduit <strong>in</strong> basement (not alum<strong>in</strong>um EMT)2. Check location of wall switches near a tub – keep far away.3. Use quartz light<strong>in</strong>g for terrace lights for quick on & off.4. Get owner to approve light fixtures <strong>and</strong> get samples prior to specify<strong>in</strong>g.5. M<strong>in</strong>imize outlets on exterior walls.6. Specify basement receptacles 2'-0" AFF if basement walls are to bef<strong>in</strong>ished <strong>in</strong> the future.7. Smoke detectors:a. basement <strong>and</strong> first floor <strong>and</strong> top of all stairsb. hardwired <strong>and</strong> <strong>in</strong>terconnected8. CO detectors:a. Basement <strong>and</strong> near furnacesb. First floorc. With<strong>in</strong> 15 feet of any bedroom9. Electrical panelboards need to be <strong>in</strong>stalled vertically but may be <strong>in</strong>stalledhorizontally if breakers are <strong>in</strong>stalled so that “on” is <strong>in</strong> the up position – thiswould effectively limit you to us<strong>in</strong>g only half of the number of breakers <strong>in</strong> apanel (NEC Sec. 240.33 <strong>and</strong> 240.81)13