BETASEAL⢠58302 - Promaplast

BETASEAL⢠58302 - Promaplast

BETASEAL⢠58302 - Promaplast

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

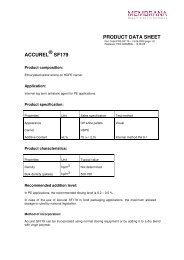

BETASEAL <strong>58302</strong>Urethane AdhesiveDescriptionBETASEAL <strong>58302</strong> is a one component, moisturecuring, high viscosity polyurethane adhesive.BETASEAL <strong>58302</strong> is suitable for stationary glassbonding when used with the appropriate primers. It isresistant to extended outdoor weathering without losingits adhesion and physical characteristics.Application TechniqueBETASEAL <strong>58302</strong> adhesive is applied in bead formwith a pressurized flow gun or other suitable applicationsystem. Can be applied manually or robotically.Demonstrates excellent sag resistance.Safety PrecautionsRefer to Material Safety Data Sheet.StorageBETASEAL <strong>58302</strong> adhesive is a moisture-sensitivematerial and MUST be stored in air-tight, dry containersat temperatures between 15°C (60°F) and 27°C (80°F).Do not store outside.Storage StabilityThe shelf life of this material is 6 months from the dateof manufacture. Regarding elevated temperaturestability, the material is capable of withstanding amaximum temperature of 43°C for up to three days.Urethane adhesives and primers are marked withexpiration dates.Clean-UpIf clean-up is required, the uncured material shall be readilyremovable from production top coats, glass surface, glass innerliners and vinyl top materials with VM&P Naphtha or solvent agreedupon at time of approval with appropriate engineering groupsPackaging<strong>58302</strong> is available in 5 gallon Pails and 55 gallon drums.Physical PropertiesAppearanceSolids content,Minimum, % 96Flash point setaflash,°F°CBlack>109°>43°Viscosity (Flow Rate), initialat 23°C, 50% RH, seconds[0.104” (2.64mm) orifice, 60psi (414 kPa)] 20 - 55Density, g/cm3Tack free time at 23°C,50% RH Maximum, Typicalminutes251.202525Cured PhysicalPropertiesHardness, Shore “A”durometer, average,• After 7 days at 23°C,50%RH 60Elongation at break,Minimum, % > 400Tensile at break, psi (MPa) > 700 (4.8)Performance PropertiesBonding SystemsLap shear• After 3 days at 23°C,50%RH, psi (MPa) > 500 (3.4)Contact your Dow Automotive Sales Representative formore detailed information about this product.DISCLAIMER OF WARRANTYAll statements, technical information and recommendationsherein are based on tests we believe to be reliable. BUT THEACCURACY OR COMPLETENESS THEREOF IS NOTGUARANTEED, AND THE FOLLOWING IS MADE IN LIEUOF ALL WARRANTIES, EXPRESSED OR IMPLIED,INCLUDING THE IMPLIED WARRANTIES OFMERCHANTABILITY AND FITNESS FOR PURPOSE.Seller’s and manufacturer’s only obligation shall be to replacesuch quantity of the product proved to be defective. Beforeusing, user shall determine the suitability of the product for itsintended use, and user assumes all risk and liabilitywhatsoever in connection therein. NEITHER SELLER NORMANUFACTURER SHALL BE LIABLE EITHER INCONTRACT FOR ANY LOSS OR DAMAGE, DIRECT,Trademark of The Dow Chemical CompanyDow Automotive, a business unit of the Dow Chemical Company.All values are typical and not intended for specification use

INCIDENTAL, OR CONSEQUENTIAL, ARISING OUT OFTHE USE AND OR THE INABILITY TO USE THE PRODUCT.No statement or recommendation not contained herein shallhave any force or effect unless in an agreement signed byofficers of seller and manufacturer.Trademark of The Dow Chemical CompanyDow Automotive, a business unit of the Dow Chemical Company.All values are typical and not intended for specification use