Untitled - Materion

Untitled - Materion

Untitled - Materion

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

claddingelectroPlating1milling & sKivingcustom-engineered metal solutionsthe high-performance demands of today’s markets require custom-engineered solutions. We match our leading technologies toyour challenges – delivering a high-performance, cost-effective metal system. As your full-service supplier, we thrive on enhancing your product’sperformance while lowering your total cost.

COPPERC10200C10700C11000C12200C14415C14530C15100C15500C18080OFHCcopperOFScopperETPcopperDHPcopperCuSn 0.15ZHCcopperK8899.95 Cu10 ppm0 max99.9Cu.085 min. Ag99.9Cu99.9Cu.025P99.85Cu.12Sn99.95Cu.013Te.013Sn99.8Cu.15Zr99.75Cu.11Mg.06Ag.06P99Cu.5Cr .2Ag.1Fe .1Ti.05SiDensity 1.323Modulus 217Elect. Cond. 3101Therm. Cond. 4226Therm. Exp. 59.8ASTM 6 B152.323171002249.4B152.322171002249.8B152.32317851969.8B152.32118.5862089.8B747.32317.4952089.8B888.32317.5952089.8B888.32217862009.8B888.32019.5801859.8AnnealedUTS 726-38YS 86-13EL 920-42HV 10 40-7526-386-1320-4240-7526-386-1320-4240-7526-386-1320-4240-7532 nom.11 nom.40 nom.60 nom.34 nom.12 nom.40 nom.60 nom.37-429-2035 nom.55 nom.34-4315-2230-4265 nom.21/4 HardUTSYSELHV34-4226-3913-3370-9534-4226-3913-3370-9534-4226-3913-3370-9534-4226-3913-3370-9536-4628 min.9 min.60-9035-4526-377 min.85-10540-4526-4011-2590 nom.42-5033-4020-2895 nom.1/2 HardUTSYSELHV37-4630-448-3285-10537-4630-448-3285-10537-4630-448-3285-10537-4630-448-3285-10543-5336 min.3 nom.85-11040-5038-485 min.95-12043-5135-483-13105 nom.45-5538-4813-22113 nom.3/4 HardUTSYSELHV41-5039-485-2490-11041-5039-485-2490-11041-5039-485-2490-11041-5039-485-2490-11044-5439-513 min.100-12547-5645-551-7115 nom.48-5845-547-13118 nom.HardUTSYSELHV43-5241-503-1695-11543-5241-503-1695-11543-5241-503-1695-11543-5241-503-1695-11552-6243 min.3 min.105-13047-5743-562 min.108-12853-6251-611-5122 nom.56-6450-606-12126 nom.TM0471-8165 min.8 nom.140-170Extra HardUTSYSELHV47-5646-553-5103-12047-5646-553-5103-12047-5646-553-5103-12047-5646-553-5103-12050-6047-591 min.108-12859-6557-641-3129 nom.63-7258-643-7130 nom.TM0877-8785 min.4 nom.150-180SpringUTSYSELHV50-5848-572-4110-12650-5848-572-4110-12650-5848-572-4110-12650-5848-572-4110-12661-7151 min.2 min.120-14054-6451-631 min.112-13064-7162-701-2126 nom.65-7360-741-5135 nom.TR0875-9072 min.4 nom.160-190Ex. SpringUTSYSELHV52 min.51 min.1-3115 min.52 min.51 min.1-3115 min.52 min.51 min.1-3115 min.52 min.51 min.1-3115 min.58 min.56 min.115 min.68-7563-781-4

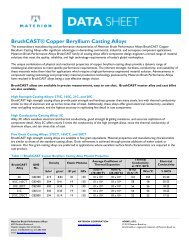

HIGH COPPERBERYLLIUM COPPERC19025C19210C19400C19500C19700C17200C17200C17200C17410C17460C17510NB10998Cu1.0Ni \0.9SnXP1099.85Cu.1Fe.03P97.4Cu2.35Fe.03P97Cu1.5Fe.8Co.6Sn.2P99Cu.6Fe.2P.05MgAlloy 25as rolled98Cu1.9BeAlloy 25age hard 1198Cu1.9BeAlloy 190Mill Hard98Cu1.9BeAlloy 174Mill Hard99Cu0.3Be0.5CoAlloy 60Mill Hard98Cu1.2Ni0.3BeAlloy 3Mill Hard97.8Cu1.8Ni.4BeDensity 1.322Modulus 218.8Elect. Cond. 340Therm. Cond. 4 100Therm. Exp. 59.7ASTM 6 B422.32317.2912019.7.32117.5601509.7B465.32217.3501159.6B465.32117.2801859.6B465.2981915609.9B194.3021922609.7B194.3021917609.7B194.31820501359.8B768.31820501289.8B768.3192045 (HT)1409.8AnnealedUTS 734-49YS 817-32EL 925 min.HV 10 70 nom.40-5020-4015-3580 nom.50-6021-3522-3143-5316 min.20 min.60-7830-5535 min.90-145AT165-195140-1753-15353-413AM100-11070-9516-30210-251A35-5520-4520-4065-1251/4 HardUTSYSELHV47-6953 nom.15-35120-15540-5520-3515 min.95 nom.45-6040-566-2095-12060-7245-795-23112-14575-8860-8020-45121-1851/4 HT175-205150-1853-10353-4241/4 HM110-12080-11015-25230-271HTC75-8550-758-20147-17631/2 HardUTSYSELHVHR0263-7666 nom.9-25135-17047-6044-595 min.105 nom.53-6336-586-15100-12568-7866-763-9140-15553-6336-606-29122-14485-10075-9512-30176-2161/2 HT185-215160-1951-8373-4351/2 HM120-13595-12512-22250-3011/2 HT95-11580-10010 Min.180-2403/4 HardUTSYSELHV52-6260-624 min.115 nom.75-8572-822-5150-16090-1103-153/4 HT115-13595-11511 Min.AT100-13080-10010-25195-275HardUTSYSELHVHR0472-8376 nom.5-14155-18056-6654-663 min.120 nom.60-7053-653-8120-14082-9079-872-355-16560-7053-682-12132-153100-12090-1122-18216-287HT190-220165-2051-6385-445HM135-150110-1359-20285-343HT110-130100-1207 min.210-280HT120-140105-12510 Min.H70-8555-802-10144-176Extra HardUTSYSELHVHR0678-8980 nom.4 min.160-19560-7058-702 min.133 nom.67-7364-722 min.25-14567-7364-712-10144-158SHM150-160125-1409-18309-363HT110-13595-1208-20216-287SpringUTSYSELHV84-9587 nom.175-21064 min.62 min.1 nom.150 nom.70-7667-751 min.130-15088-9785-921-2165-17570-7667-742-8148-164————————XHM155-175135-1704-15317-378————Ex. SpringUTSYSELHV91-10697 nom.190 min.66 min.64 min.73-8070-7997 min.94 min.1-2180 min.73-8070-781 min.153-174————————XHMS175-190150-1803-12325-413————HTR120-150110-1401-5

BrassC21000C22000C23000C24000C26000C26800C42200C42500C42520GildingMetal95 Cu5 ZnCommercialBronze90 Cu10 ZnRed Brass85 Cu15 ZnLow Brass80 Cu20 ZnCartridge Brass70 Cu30 ZnYellow Brass66 Cu34 ZnLubronze90 Cu9 Zn1 SnLubaloy X88 Cu10 Zn2 SnOlin 425288 Cu10 Zn2 Sn.1 Fe, .1 NiDensity 1.320Modulus 217Elect. Cond. 356Therm. Cond. 4135Therm. Exp. 510.0ASTM 6 B36.318174410910.2B36.31617379210.4B36.31316328110.6B36.30816287011.1B36.306152711.3B36.31816317510.2B591.31718286910.2B591.31816307510.2AnnealedUTS 734-40YS 85-15EL 942-48HV 10 50-5736-428-1746-4955-7539-478-1943-4860-8544-5412-2943-5865-9545-6110-3340-6770-11541-6123 nom.50-52 nom.40-5019 nom.45 nom.40-5013-2530-5070-9041/4 HardUTSYSELHV37-4720-4015-4567-9740-5022-4215-4072-10244-5424-4415-3976-11048-5824-4518-3581-11649-5922-4634-5982-11749-5934 nom.40 nom.47-5738 nom.29 nom.87-13049-5920-5424-4790-1351/2 HardUTSYSELHV42-5233-485-2982-10647-5739-525-2093-11851-6140-548-21100-13055-6539-5812-25105-13557-6742-6119-42107-14255-6544 nom.25 nom.54-6550-6017-27115-14057-6951-6613-27120-16058-7347-6820 nom.130-1653/4 HardUTSYSELHV46-5640-522-1793-11752-6244-573-10105-18057-6749-634-12118-14361-7148-656-15124-14964-7455-698-29130-16062-7253 nom.17 nom.62-7264 nom.7 nom.130-16062-7458-7010-21135-17168-8061-7515 nom.150-180HardUTSYSELHV50-5945-572-8102-10457-6650-632-6116-13863-7252-685-9130-15068-7757-734-8140-16171-8167-786-14148-17368-7857 nom.8 nom.67-7963-764-9140-17070-8266-796-13153-19076-9174-8810 nom.175-205Extra HardUTSYSELHV56-6450-632 Max.114-13464-7258-681-3130-15072-8064-763-5146-16678-8766-842-3158-18083-9279-902-5164-18979-8967 nom.4 nom.75-8573-832-7150-18076-8873-854-8165-21088-10385-1026 nom.195-225SpringUTSYSELHV60-6854-662 Max.122-14269-7763-751-2140-16078-8666-883-4156-17685-9375-901-2170-19091-10082-981-2178-20386-9571 nom.2 nom.82-9280-901-5160-19084-9481-922-5175-22095-11092-1084 nom.205-235Ex. SpringUTSYSELHV61-6957-682 Max.124-14472-8069-791 Max.140-16682-9075-882 Min.162-18289-9778-951 Max.174-19495-10486-1021-2184-20990-9975 nom.88 min.86 min.1-3170 min.92mm.87mm.1-3190 min.100-11498-1103 nom.215-245

BronzeC51000C51100C51180C51900C52100C52180C50725C63800C65500C66300C68800Phos.Bronze A94.9 Cu5 Sn.1 PPhos.Bronze 4%95.9 Cu4 Sn, .1P,.1 Ni, .1 FeMod.Phos.Bronze95.5 Cu4.2 Sn.03PPhos.Bronze6%93.9 Cu6 Sn.1 PPhos.Bronze C91.9 Cu8 Sn.1 PMod.Phos.Bronze91.8 Cu8 Sn, .03 P,.1 Ni,1.Fe95.6 Cu2.2 Zn2.0 Sn63895 Cu2.8 Al1.8 Si,.4 CoSiliconBronze A97 Cu3 Si86 Cu9.9 Zn2.2 Sn1.9 Fe68873.5 Cu22.7 Zn3.4 Al.4 CoDensity 1.320Modulus 216Elect. Cond. 3 15Therm. Cond. 4 40Therm. Exp. 5 9.9ASTM 6 B103.3201620489.9B103.3201620509.9.31916153910.0B103.31816133610.1B103.31816133610.1.32216.433879.7.29916.710249.5B422.3081572118B96.3171825629.8B592.29616.8184010.1B592AnnealedUTS 743-58YS 819-31EL 948-62HV 10 70-11540-5516-2845-4967-8748-6316-2850-6570-12053-6723-3560-6780-14077-8745-6727-40562163120 nom.77-8744-6130-401/4 HardUTSYSELHV49-6122-5232-5095-13546-5820-5025-4773-13260-7228-6035-55110-16063-7535-6240-60130-17090-10275-9012-21210 nom.683530140 nom.87-10163-8910-29210 nom.51/2 HardUTSYSELHV58-7347-6816-38130-16555-7042-7012-3197-15869-8460-8022. nom.64-7949-7220-42120-17569-8451-7525-49150-18590-10584-10025 nom.68-8073 nom.11 nom.170 nom.100-11287-1007-13225 nom.784517175 nom.58-7356 nom.20 min.97-11282-1023-15240 nom.3/4 HardUTSYSELHV68-8061-7510-20150-18067-8264-806-15135-17480-9272-9018 nom.74-9064-8014-26160-19580-9570-8518-32175-20597-11288-10520 nom.105-11793-1055-10240 nom. 190 nom.HardUTSYSELHV76-9174-884-11175-20572-8770-832-12148-18085-10077-9712 nom.80-9675-927-16180-21585-10078-9512-30190-220105-12095-11518 nom.81-9385 nom.9 nom.192 nom.114-126102-1153-6250 nom.9458876-9181 nom.17 nom.106-12095-1082-7258 nom.Extra HardUTSYSELHV88-10385-1022-6195-22584-9981-961-6168-19797-11290-1108 nom.92-10888-1063-8200-23597-11292-1076-10210-240108-125100-12012 nom.85-10092 nom.8 nom.206 nom118-130106-1192-510460688-10393 nom.7 nom.113-127102-1152-3266 nom.SpringUTSYSELHV95-11092-1081-3205-23591-10688-1011-5180-209105-11997-1175 nom.99-11695-1102-6210-250105-119100-1133-9225-255115-132105-1258 nom.123-134111-1212-4270 nom.11062495-110100 nom.5 nom.123-133111-1171-2275 nom.Ex. SpringUTSYSELHV100-11498-1101-3215-24596-10892-1041-4187-218110-122102-1203 nom.105mm100mm.1-3110-122105-1162-6235-265120-140110-1303 nom.130 Min.119 Min.1-2100-114104 nom.4 nom.125 min.117 min.1-2280 min.

SteelsS30100S30200S30403S30500S31008S31600S32100S40900S43000G100800K00100301302304L305310 S3163214094301008IronFe 17Cr7NiFe 18Cr9NiFe 19Cr10NiFe 18Cr12NiFe 25Cr20NiFe 17Cr12Ni 2.5MoFe 18Cr10Ni.4TiFe 11CrFe 16CrFe .08CFe .005CDensity 1.285Modulus 228Elect. Cond. 32.5Therm. Cond. 49.4Therm. Exp. 59.5ASTM 6 A666.285282.59.49.5A666.284282.49.49.9A666.29282.49.49.9A240.29282.49.49.9A240.29282.28.29.0A666.29282.39.49.0A240.28292.814.46.1A240.28292.813.86.1A176.283296.7A109.27816AnnealedUTS 7YS 8EL 9HV 10110 Nom.40 Nom.60 Nom.170 Nom.90 Nom.40 Nom.50 Nom.170 Nom.84 Nom.42 Nom.55 Nom.170 Nom.85 Nom.38 Nom.55 Nom.170 Nom.95 Nom.45 Nom.45 Nom.170 Nom.84 Nom.42 Nom.50 Nom.150 Nom.90 Nom.35 Nom.45 Nom.150 Nom.55-6825-4120-3812365-8040-6018-30144-176skin rolled40-5525-4024 Min.125 Max.40-6030-4525 Num.115 Num.1/4 HardUTSYSELHV125 Min.75 Min.25 Min.250 Nom.125 Min.75 Min.25 Min.250 Nom.125 Min.75 Min.25 Min.250 Nom.125 Min.75 Min.25 Min.250 Nom.125 Min.75 Min.25 Min.250 Nom.125 Min.75 Min.25 Min.250 Nom.125 Min.75 Min.25 Min.250 Nom.58252578-9060-783-19172-20545-65--13-27107-13771/2 HardUTSYSELHV150 Min110 Min15 Min.300 Nom.140 Min.110 Min.15 Min.300 Nom.140 Min.110 Min.15 Min.300 Nom.130 Min.110 Min.10 Min.300 Nom.130 Min110 Min15 Min.300 Nom.130 Min110 Min10 Min.300 Nom.130 Min.110 Min.8 Min.300 Nom.75741617290-10076-923-7205-22855-75--4-16125-1703/4 HardUTSYSELHV175 Min135 Min10 Min.350 Nom.165 Min.135 Min.10 Min.350 Nom.160 Min.135 Min.5 Min.350 Nom.150 Min.135 Min.5 Min.350 Nom.150 Min.135 Min.10 Min.350 Nom.150 Min135 Min10 Min.350 Nom.150 Min.135 Min.5 Min.350 Nom.82819.519098-11090-1031-7222-242HardUTSYSELHV185 Min140 Min8 Min390 Nom.175 Min140 Min8 Min390 Nom.170 Min.140 Min.2 Min.390 Nom.170 Min.140 Min.2 Min.390 Nom.1011023222107-115100-1101-2228-24680-100----185 Min.75-8565-80150 Num.maximumstrengthand workhardeningstandardgeneralpurposestablepropertieslow Cstablepropertieslow Clow workhardeninggoodformabilityhigh tempoxidationresistancegoodformabilitymaximumcorrosionresistanceexcellentresistance tooxidation& corrosionferreticeconomicaluse forcorrosion& oxidationresistanceferreticgeneraluse forcorrosion& oxidationresistancebetterformabilityMagnetic No No No No No No No Yes Yes Yes Yes

Aluminum Zinc nickel & nickel AlloysA91100A91145A93003A95052A96061Z13004Z41321N02201N02270N04400N0660099.0 Al99.45 Al98.3Al1.2Mn.1Cu97.2Al2.5Mg.25Cr97.9Al1Mg0.6Si0.3Cu0.2CrPure Zinc99.98 ZnZn Cu TiAlloy99.2 Zn.6 Cu.15 Ti20199.0 Ni.02 Max C27099.98NMonel *40065Ni 35CuInconel *60076 Ni16 Cr8 FeDensity 1.098Modulus 210Elect. Cond. 3 59Therm. Cond. 4 128Therm. Exp. 5 14.1ASTM 6 B209.0977106113013.1.09910.25011213.9B209.09710.1357914.3B209.098104510013.1B2090.2589-13276116.7B690.2599-13266112.7B69.3213018438.0B162.3213023508.6.319263.412.68.8.305311.88.67.6B168AnnealedUTS 7YS 8EL 9HV 10O11-154 Min.15 Min.25 Nom.O8-143 Min.15 Min.20 Nom.O14-195 Min.18 Min.30 Nom.O25-3110 Min.14 Min.40 Nom.O1882540 Nom.10-1830-7525-4521-3215-5050-7550-6512-2830-50120 Max.45-5510-2540-5570-8525-4535-50133 Max.80-10040 Nom.35-55150 Nom.81/4 HardUTSYSELHV60-7545-6617-26120-15050-6520-3435-4885-11275-9540-8020-40133-1601/2 HardUTSYSELHVH1214-1911 Min.4 Min.30 Nom.H1211-169 Min.6 Min.25 Nom.H1217-2312 Min.3 Min.42 Nom.H3231-3823 Min.4 Min.50 Nom.76-9260-848-21140-17060-7032-4430-45108-13080-10060-9014-30157-188100-12560-10010-25235 Nom.3/4 HardUTSYSELHV85-10070-903-8160-19068-8042-5825-37125-15590-11073-1026-20183-209HardUTSYSELHVH1416-2114 Min.–35 Nom.H1412-1710 Min.–30 Nom.H1420-2617 Min.–50 Nom.H3434-4126 Min.–60 Nom.27-4010-4060-9590 Min.80 Min.2 Min.180-22078-9055-7015-28145-175100-12090-1102-15205-234120-15090-1252-15275 Nom.Extra HardUTSYSELHVH1619-2417 Min.–40 NomH1614-1911 Min.–35 NomH1624-3021 Min.–55 NomH3637-4429 Min.–65 NomH1628-36––70 NomSpringUTSYSELHVH1822 Min.20 Min.–50 Nom.H1816 Min.12 Min.–50 Nom.H1827 Min.24 Min.–50 Nom..H3839 Min.32 Min.–50 Nom.T430 Min.16 Min.10 Min.96 Min.85 Min.1 Min.193 Min.120 Min.110 Min.1-10234 Min.145-170120-1602-10320 Nom.Ex. SpringUTSYSELHVH1842 Min.35 Min.–* Monel and Inconel are registered trademarks of Special Metals Corporation.

RefrActory MetalsLow Expansion AlloysR04200R05200R50250R60702K93600K94100K94610ReactorGradeNiobiumNbUnalloyedTantalumTaGrade 1TitaniumTiUnalloyedZirconium99.2 ZrInvar 3664Fe 36NiAlloy 4258Fe 42NiKovar54Fe29Ni17CoDensity 1.310Modulus 215Elect. Cond. 311.5Therm. Cond. 430Therm. Exp. 54.1ASTM 6 B393.6002714343.7B70.1631539.25.1B26144.193.5B5510.292212.15.82.1B753.29321.52.474.56.1F30.302203.5102.9F15AnnealedUTS 718-38YS 810-30EL 920 Min.HV 10 55-9530-4520-4020 Min.90-12035-6025-4524 Min.120 Nom.55-8030-6516 Min.150 Nom.65-8535-7518-3265-8535-7518-3265-8535-7518-321/4 HardUTSYSELHVCW10%48432590CW10%4035120CW10%7016075-90 75-90 75-9091/2 HardUTSYSELHVCW25%55537115CW25%4542125CW25%80180CW25%641885-100 85-100 85-1003/4 HardUTSYSELHVCW50%63622135CW50%5553130CW50%100210CW50%711595-110 95-110 95-110HardUTSYSELHVCW70%70691150CW70%7069150CW70%115230CW70%848100 Min. 100 Min. 100 Min.Extra HardUTSYSELHVSpringUTSYSELHVEx. SpringUTSYSELHV

Precious metal alloYs10material composition density lbs/in 3 coatingtechnologydrY circuitastmspecificationHardness (HK)annealed-springresistivitytypicalapplicationsSoft Gold 99.9 Au 0.698 Plated B-488 40-90 2.4 C, S ,L, RHard Au 99.7 Au 0.633 Plated B-488 130-200 2.9-4.7 C, S ,L, RPalladium 99.8 Pd 0.434 Plated B-679 200-300 10.7 C, S ,L, RPalladium Nickel 80 Pd, 20 Ni 0.405 Plated B-867 250-500 19 C, S, R24kt Gold 99.99 Au 0.698 Clad B-562 40-90 2.4 C, S ,L, R18 kt Gold 75 Au, 25 Ag 0.577 Clad 65-135 C, S, R14 kt Gold 58 Au, 42 Ag 0.516 Clad 70-145 C, S, RWE#1 69 Au, 25 Ag, 6 Pt 0.580 Clad B-522 90-170 15.4 C, S, RPalladium 99.9 Pd 0.434 Clad B-683 80-160 10.7 C, S ,L, RPalladium Nickel 90 Pd, 10 Ni 0.419 Clad 145-265 16* C, S, RPalladium Nickel 80 Pd, 20 Ni 0.405 Clad 180-310 19 C, S, RPalladium Silver 60 Pd, 40 Ag 0.410 Clad B-731 120-210 43 C, S, RPalladium Silver 50 Pd, 50 Ag 0.404 Clad 110-200 C, S, R65 Au, 21 Pd,14 AgDGR-156 Diffused Au, 60Pd, 40 AgWE#1 Capped,60 Pd, 40 Ag0.560 Clad 140-250 47 C, S, R0.439 Clad 140-200 C, S, R0.460 Clad 110-190 C, S, RDGPN Diffused Au, PdNi .5 Clad 150-280 C, S, RPaliney 6 44 Pd, 38 Ag, 16Cu, 1 Pt, 1 NiPaliney 7 35 Pd, 30 Ag, 14Cu, 10 Au, 10 Pt,1 ZnGold Alloys70 Au, 24 Ag,6 Cu70 Au, 20 Ag,10 Cu0.390 Clad B-563 290-370 25.8 C, S, R0.426 Clad B-540 330-400 31.6 C, S, R0.549 Clad 115-190 23 C, S, R0.543 Clad 140-220 31 C, S, R96 Au, 4 Ni 0.667 Clad 110-200 11 C, S, R90 Au, 10 Ni 0.625 Clad 205-280 22 C, S, RPlatinum 99.9 Pt 0.775 Clad B-561 75-140 10.6 RswitcHingSilver 0.379 Plated B-700 40-185 1.7 S, LSilver 99.9 Ag 0.379 Clad B-742 40-90 1.7 S, LSilver Nickel 90 Ag, 10 Ni 0.372 Clad B-693 70-105 2.1 S, RCoin Silver 90 Ag, 10 Cu 0.373 Clad B-617 80-120 2.1 S75 Ag, 24.5 Cu,0.5 Ni0.408 Clad B-780 95-130 2.4 SBT 72 Ag, 28 Cu 0.361 Clad B-628 90-130 2.1 BSilver Tin Oxide 90 Ag, 10 SnO 2 0.357 Clad B-844 100-130 2.3 S, RSilver Cadmium Oxide 90 Ag, 10 CdO 0.368 Clad B781 95-130 2.2 S, RTypical Applications Key: C=Connectors, S=Switches, L=Lead Frames, R=Relays, B=Brazing

This table lists the potential differences for variousmetals in water at 77˚F (25˚C). The order of theseries can change for different electrolytes(for example, different pH, ions in solution).galvanic corrosionelementAnodic end: The corrosion occurs here.standard electrodePotential (volts)Lithium -3.045Potassium -2.920Sodium -2.712Magnesium -2.340Beryllium -1.700Aluminum -1.670Manganese -1.050Zinc -0.762Chromium -0.744Iron, Mild Steel -0440Cadmium -0.402Yellow Brass -0.35050-50 Tin-Lead Solder -0.325Cobalt -0.277Nickel -0.250Tin -0.136Lead -0.126Hydrogen Reference Electrode 0.000Titanium +0.055Copper +0.340Mercury +0.789Silver +0.799Carbon +0.810Platinum +1.200Gold +1.420Graphite +2.250Cathodic end (passive): The corrosion does not occur here.11Note: Stainless steel alloys have not beenincluded in the above table. They cansignificantly change their potential andbecome much more active if exposed tostagnant or poorly aerated water.

SoldersFahrenheitCentigradeDensityComposition(Shaded rows indicate lead-free compositions)Solidus Liquidus Solidus Liquidus (lb/c.in) (g/cc)12SOLDERS205 205 52 Bi, 30 Pb, 18 Sn 96 96 0.346 9.58212 212 35.7 Sn, 35.7 Bi, 28.6 Pb 100 100 0.337 9.33244 244 52 In, 48 Sn 118 118 0.264 7.30244 257 50 In, 50 Sn 118 125 0.264 7.29281 281 58 Bi, 42 Sn 138 138 0.309 8.55281 290 50 Sn, 50 Bi 138 143 0.297 8.22296 296 97 In, 3 Ag 147 147 0.266 7.37315 315 100 In 157 157 0.264 7.31275 333 47 Sn, 40 Pb, 10 Bi, 3 Ag 135 167.2 0.321 8.89338 338 65.5 Sn, 31.5 Bi, 3.0 Zn 170 170 0.290 8.03354 354 62 Sn, 36 Pb, 2 Ag 179 179 0.304 8.41361 361 63 Sn, 37 Pb 183 183 0.301 8.34361 370 60 Pb, 40 Sn 183 188 0.307 8.49361 432 95 Sn, 5 Pb 183 222 0.268 7.42361 376 60 Sn, 40 Pb 183 188 0.307 8.50361 390 80 Sn, 20 Pb 183 199 0.284 7.85361 392 55 Sn, 45 Pb 183 200 0.314 8.68361 401 85 Sn, 15 Pb 183 205 0.278 7.70363 410 50 Pb, 50 In 184 209 0.320 8.86361 414 50 Pb, 50 Sn 183 212 0.320 8.87361 415 90 Sn, 10 Pb 183 213 0.273 7.55430 430 96.5 Sn, 3.5 Ag 221 221 0.266 7.35430 450 96 Sn, 4 Ag 221 232 0.267 7.39430 465 95 Sn, 5 Ag 221 240 0.267 7.39275 439 62 Pb, 25 Sn, 10 Bi, 3 Ag 135 226 0.354 9.80407 439 2 Bi, 1.5 Cu, .2 Ag, 96.3 Sn 208 226 0.267 7.39440 500 95.5 Sn, 4 Cu, 0.5 Ag 226 260 0.267 7.39440 440 95.6 Sn, 4 Cu, 0.4 Ag 227 227 0.266 7.36450 450 100 Sn 232 232 0.263 7.28450 464 95 Sn, 5 Sb 232 240 0.262 7.24355 487 70 Pb, 27 Sn, 3 Ag 179 253 0.342 9.47361 495 70 Pb, 30 Sn 183 257 0.349 9.66520 520 100 Bi 271 271 0.354 9.80529 553 85 Pb, 15 In 277 290 0.380 10.50361 536 80 Pb, 20 Sn 183 280 0.363 10.04361 550 85 Pb, 15 Sn 183 288 0.379 10.48527 576 90 Pb, 10 Sn 275 302 0.379 10.50441 590 97 Sn, 3 Cu 227 310 0.265 7.34590 597 95 Pb, 5 Sn 310 314 0.390 10.80

Brazing AlloysFahrenheitCentigradeDensityCompositionSolidus Liquidus Solidus Liquidus (lb/c.in) (g/cc)BRAZING1125 1145 BAg-1 (45 Ag, 24 Cd, 16 Zn, 15 Cu) 605 620 0.340 9.411160 1175 BAg-1a (50 Ag, 18 Cd, 16.5 Zn, 15.5 Cu) 625 635 0.341 9.451145 1205 BAg-7 (56 Ag, 22 Cu, 17 Zn, 5 Sn) 620 650 0.340 9.411170 1270 BAg-3 (50 Ag, 16 Cd, 15.5 Cu, 15.5 Zn, 3 Ni) 630 690 0.344 9.531125 1295 BAg-2 (35 Ag, 26 Cu, 21 Zn, 18 Cd) 605 700 0.322 9.191220 1305 BAg-24 (50 Ag, 20 Cu, 28 Zn, 2 Ni) 660 705 0.324 8.981240 1325 BAg-9 (65 Ag, 20 Cu, 15 Zn) 671 718 0.347 9.601200 1330 BAg-34 (38 Ag, 32 Cu, 28 Zn, 2 Sn) 650 721 0.327 9.051225 1370 BAg-5 (45 Ag, 30 Cu, 25 Zn) 665 745 0.329 9.111435 1435 BAg-8 (BT) (72 Ag, 28 Cu) 780 780 0.360 9.961742 1742 82 Au, 18 Ni 950 950 0.571 15.811761 1761 99.9 Ag 960 960 0.379 10.50CERAMIC ACTIVE METAL LAMINATES1425 1726 TiLam (88 Ag, 9.5 Cu, 2.5 Ti) 774 959 0.359 9.94131049 1623 TiLam 72 (70 Ag, 27 Cu, 3 Ti) 765 884 0.349 9.67

alloY comPatiBilitYcladding or Plating metal (B)a can be combined with Bvia:aluminumBrazing alloyscarbon steelcoppercopper Becopper Brasscopper Bronzecupro nickelgoldgold alloysironleadBase metal (a)aluminum alloys C -- C C C -- C C C C C CBrazing alloys -- CE C E C E P C E C C E C C E P C E C E C 1carbon steel C 1 C C E C E P C E C C E C E C E P C E C E C 1copper C C C E C E P C E C C E C E C E P C E C E Ccopper Be -- C C E C E P C E C C E C E C E P C E C E C 1copper Brass -- C C C P C C C C C P C C C 1copper Bronze C C C E C E P C E C C E C E C E P C E C E C 1cupro nickel C 1 C C E C E P C E C C E C E C E P C E C E C 1gold alloys -- C C E -- C E -- C E C E C E P C E C E --14iron C 1 C C E C E P C E C C E C E C E P C E C E C 1lead C -- -- C -- C C C C C C Cmolybdenum 2 C 1 -- E E P E -- E E E P -- E --nickel C C C E C E P C E C C E C E E P C E C E Cfe-ni cte alloy C 1 C C E C E P C E C C E C E E P C E C E C 1niobium C 1 C 1 C E C E P C E C 1 C E C E C E P C E C E C 1Palladium alloys C 1 C C E C E P -- -- C E C E C E P C E C E --Platinum C 1 C C E C E P -- -- C E C E C E P C E C E --silver alloy C 1 C E C E P C E C C E C E C E P C E C E Css 300 series C 1 C 1 C E C E P E C 1 C E C E C E P C E C E C 1ss 400 series C 1 C C E C E P C E C C E C E C E P C E C E C 1tantalum C 1 C 1 C 1 E C 1 E C 1 E C 1 C 1 E C 1 E C 1 E C 1 E C E C 1titanium C 1 C C E C E C E C C E C E C E C E C E C 1zinc C -- -- C -- -- -- -- C -- -- C1Rolled tempers only.2Normally requires hot bonding. Plating requires Ni interliner.3SnPb plating only.c = claddinge = electronBeam weldingP = Plating

NickelFe-Ni CTE AlloyNiobiumPalladiumPalladium AlloysPlatinumSilverSilver AlloySolder Alloys 3SS 300 SeriesSS 400 SeriesTantalumTinTitaniumZincC C C C C C C C C C C C C C CC E C E C E C E P C E C E C E P C E C 1 P C 1 E C E C E C 1 P C E C 1C E P C E C E C E P C E C E C E P C E C 1 P C E C E C E C 1 P C E C 1C E P C E C E C E P C E C E C E P C E C P C E C E C E C P C E CC E P C E C E P -- C E C E P C E C 1 P E C E C E C 1 P C E C 1C 1C P C C C P C C C P C C 1 P C1 C C C 1 P C C 1C E P C E C E C E P C E C E C E P C E C 1 P C 1 E C E C E C 1 P C E C 1C E P C E C E C E P C E C E C E P C E C 1 P C E C E C E C 1 P C E C 1C E C E E C E P C E C E C E P C E -- E E -- -- -- --C E P C E C E C E P C E C E C E P C E C 1 P C E C E C E C 1 P C E C 1C -- C C C C C C C -- -- -- C -- C15E E E E P E E E P E P E E E P E CC E P C E C E C E P C E C E C E P C E C 1 P C E C E C E C 1 P C E CC E P C E C E C E P C E C E C E P C E C 1 P C E C E C E C 1 P C E C 1C E C E C E C E C E C E C E C E C 1 C E C E C E C 1 C E C 1C E C E C E C E P C E C E C E P C E -- -- -- -- -- -- --C E -- -- C E P C E C E C E P C E -- -- -- -- -- -- --C E P C E C E C E P C E C E C E P C E C P -- -- C E C P C E CC E P C E C E C E P C E C E C E P C E C 1 P C E C E C E C 1 P C E C 1C E P C E C E C E P C E C E C E P C E C 1 P C E C E C E C 1 P C E C 1C E C E C E C E C E C E C E C E C 1 C E C E C E C 1 C E C 1C E C E C E C E C E C E C E C E C 1 C E C E C E C 1 C E C 1-- -- -- C -- -- C C C -- -- -- C -- C

NOT YOUR AVERAGE HARDNESS VALUES CHARTVickersHardnessKnoopHardnessRockwellHardnessRockwell SuperficialHardnessVickersHardnessKnoopHardnessRockwellHardnessRockwell SuperficialHardnessHV HK B C F 15-T 30-T 15-N HV HK B C F 15-T 30-T 15-N940 920 - 68 - - - 93.2 266 304 - 25.5 - 93.0 83.0 73.5900 895 - 67 - - - 92.9 248 283 100 22.5 - 92.5 81.5 72.0865 870 - 66 - - - 92.5 234 267 98 20.0 - 92.0 80.5 70.5832 846 - 65 - - - 92.2 220 251 96 17.0 - 91.0 79.0 69.0800 822 - 64 - - - 91.8 209 239 94 14.5 - 90.5 77.5 68.0772 799 - 63 - - - 91.4 198 226 92 12.0 - 89.5 76.0 66.5746 776 - 62 - - - 91.1 196 224 94.0 11.4 110.0 90.0 77.5 66.2720 754 - 61 - - - 90.7 194 222 93.5 10.8 109.5 89.8 77.2 65.9697 732 - 60 - - - 90.2 192 219 93.0 10.2 109.2 89.7 77.0 65.6674 710 - 59 - - - 90.8 190 217 92.5 9.6 109.0 89.6 76.6 65.3653 690 - 58 - - - 89.3 188 215 92.0 9.0 108.7 89.5 76.3 65.016633 670 - 57 - - - 88.9 186 212 91.5 8.4 108.5 89.4 76.0 64.7613 650 - 56 - - - 88.3 184 210 91.0 7.8 108.2 89.2 75.7 64.4595 630 - 55 - - - 87.9 182 208 90.5 7.2 108.0 89.1 75.4 64.1577 612 - 54 - - - 87.4 180 205 90.0 6.6 107.5 89.0 75.1 63.8560 594 - 53 - - - 86.9 178 203 89.0 6.0 107.2 88.8 74.7 63.5544 576 - 52 - - - 86.4 176 201 88.5 - 107.0 88.6 74.4 63.2528 558 - 51 - - - 85.9 174 198 88.0 - 106.7 88.5 74.0 62.9513 542 - 50 - - - 85.5 172 196 87.5 - 106.5 88.3 73.6 62.5481 506 - 48 - - - 84.5 170 194 87.0 - 106.2 88.2 73.3 62.0452 476 - 46 - - - 93.5 168 192 86.0 - 106.0 88.0 73.0 61.8427 450 - 44 - - - 82.5 166 190 85.5 - 105.7 87.9 72.5 61.6404 427 - 42 - - - 81.5 164 187 85.0 - 105.5 87.7 72.2 61.4382 436 - 40 - - - 80.5 162 185 84.0 - 105.0 87.6 71.8 -362 413 - 38 - - - 79.5 160 182 83.5 - 104.7 87.4 71.5 -344 392 - 36 - - - 78.5 158 180 83.0 - 104.5 87.2 71.0 -326 372 - 34 - - - 77.5 156 178 82.0 - 104.0 87.0 70.5 -309 353 - 32 - 94.5 85.5 76.5 154 176 81.5 - 103.5 86.8 70.1 -295 337 - 30 - 94.0 85.0 75.5 152 174 80.5 - 103.0 86.6 69.8 -285 325 - 28.5 - 94.0 84.5 75.0 150 172 80.0 - 102.7 86.4 69.5 -Blue: STEELS (non-austenitic) (Ref. ASTM E140-06 Hardness Conversion Chart, Table 1)Black: NICKEL ALLOYS (Ref. ASTM E140-06 Hardness Conversion Chart, Table 2)Red: BRASS (C260) (Ref. ASTM E140-06 Hardness Conversion Chart, Table 3)Green: COPPER (Ref. ASTM E140-06 Hardness Conversion Chart, Table 7)