Soot Deposits and Fires in Exhaust Gas Boiler - Martin's Marine ...

Soot Deposits and Fires in Exhaust Gas Boiler - Martin's Marine ...

Soot Deposits and Fires in Exhaust Gas Boiler - Martin's Marine ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

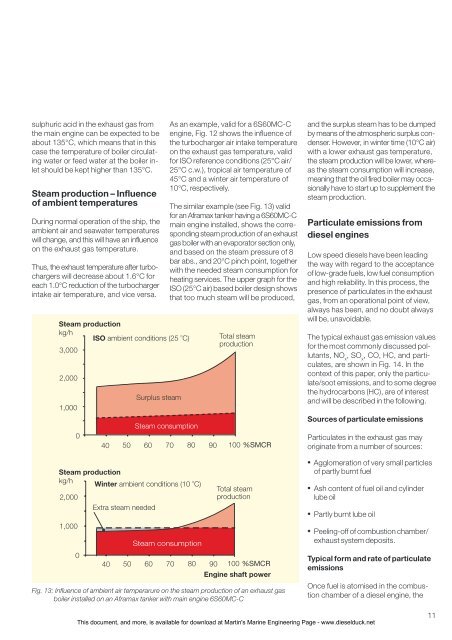

sulphuric acid <strong>in</strong> the exhaust gas fromthe ma<strong>in</strong> eng<strong>in</strong>e can be expected to beabout 135°C, which means that <strong>in</strong> thiscase the temperature of boiler circulat<strong>in</strong>gwater or feed water at the boiler <strong>in</strong>letshould be kept higher than 135°C.Steam production – Influenceof ambient temperaturesDur<strong>in</strong>g normal operation of the ship, theambient air <strong>and</strong> seawater temperatureswill change, <strong>and</strong> this will have an <strong>in</strong>fluenceon the exhaust gas temperature.Thus, the exhaust temperature after turbochargerswill decrease about 1.6°C foreach 1.0°C reduction of the turbocharger<strong>in</strong>take air temperature, <strong>and</strong> vice versa.Steam productionkg/hISO ambient conditions (25 C)3,0002,0001,0001,00002,000040Extra steam needed40Surplus steamSteam consumptionSteam consumptionAs an example, valid for a 6S60MC-Ceng<strong>in</strong>e, Fig. 12 shows the <strong>in</strong>fluence ofthe turbocharger air <strong>in</strong>take temperatureon the exhaust gas temperature, validfor ISO reference conditions (25°C air/25°C c.w.), tropical air temperature of45°C <strong>and</strong> a w<strong>in</strong>ter air temperature of10°C, respectively.The similar example (see Fig. 13) validfor an Aframax tanker hav<strong>in</strong>g a 6S60MC-Cma<strong>in</strong> eng<strong>in</strong>e <strong>in</strong>stalled, shows the correspond<strong>in</strong>gsteam production of an exhaustgas boiler with an evaporator section only,<strong>and</strong> based on the steam pressure of 8bar abs., <strong>and</strong> 20°C p<strong>in</strong>ch po<strong>in</strong>t, togetherwith the needed steam consumption forheat<strong>in</strong>g services. The upper graph for theISO (25°C air) based boiler design showsthat too much steam will be produced,50 60 70 80 90 100 %SMCRSteam productionkg/hW<strong>in</strong>ter ambient conditions (10 C)50 60 70 80 90 100 %SMCREng<strong>in</strong>e shaft powerFig. 13: Influence of ambient air temperarure on the steam production of an exhaust gasboiler <strong>in</strong>stalled on an Aframax tanker with ma<strong>in</strong> eng<strong>in</strong>e 6S60MC-CooTotal steamproductionTotal steamproduction<strong>and</strong> the surplus steam has to be dumpedby means of the atmospheric surplus condenser.However, <strong>in</strong> w<strong>in</strong>ter time (10°C air)with a lower exhaust gas temperature,the steam production will be lower, whereasthe steam consumption will <strong>in</strong>crease,mean<strong>in</strong>g that the oil fired boiler may occasionallyhave to start up to supplement thesteam production.Particulate emissions fromdiesel eng<strong>in</strong>esLow speed diesels have been lead<strong>in</strong>gthe way with regard to the acceptanceof low-grade fuels, low fuel consumption<strong>and</strong> high reliability. In this process, thepresence of particulates <strong>in</strong> the exhaustgas, from an operational po<strong>in</strong>t of view,always has been, <strong>and</strong> no doubt alwayswill be, unavoidable.The typical exhaust gas emission valuesfor the most commonly discussed pollutants,NO x, SO x, CO, HC, <strong>and</strong> particulates,are shown <strong>in</strong> Fig. 14. In thecontext of this paper, only the particulate/sootemissions, <strong>and</strong> to some degreethe hydrocarbons (HC), are of <strong>in</strong>terest<strong>and</strong> will be described <strong>in</strong> the follow<strong>in</strong>g.Sources of particulate emissionsParticulates <strong>in</strong> the exhaust gas mayorig<strong>in</strong>ate from a number of sources:• Agglomeration of very small particlesof partly burnt fuel• Ash content of fuel oil <strong>and</strong> cyl<strong>in</strong>derlube oil• Partly burnt lube oil• Peel<strong>in</strong>g-off of combustion chamber/exhaust system deposits.Typical form <strong>and</strong> rate of particulateemissionsOnce fuel is atomised <strong>in</strong> the combustionchamber of a diesel eng<strong>in</strong>e, theThis document, <strong>and</strong> more, is available for download at Mart<strong>in</strong>'s Mar<strong>in</strong>e Eng<strong>in</strong>eer<strong>in</strong>g Page - www.dieselduck.net11