Dr.Staiger Mohilo Dr.Staiger Mohilo Dr.Staiger Mohilo

Dr.Staiger Mohilo Dr.Staiger Mohilo Dr.Staiger Mohilo

Dr.Staiger Mohilo Dr.Staiger Mohilo Dr.Staiger Mohilo

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

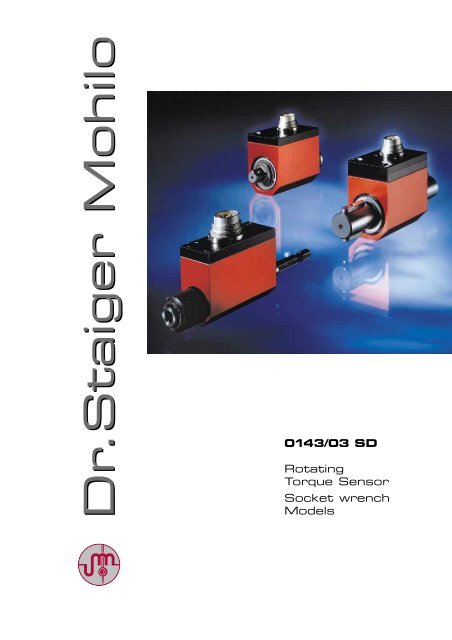

<strong>Dr</strong>.<strong>Staiger</strong> <strong>Mohilo</strong>0143/03 SDRotatingTorque SensorSocket wrenchModels

Torque sensor0143/03 SDIntroductionA reliable measurement of staticaland dynamic torque is requiredin quality control.The larger number of applicationsis in assembly, development andlaboratory all require a robusttransducer.<strong>Dr</strong>. <strong>Staiger</strong> <strong>Mohilo</strong> manufactures abroad range of slip ring transducerfor this extensive field.A range of digital readouts andamplifiers is available for thesetransducers.GeneralDue to three different standardizedshaft ends, the slip ring transducerSD can easily be connected for allimaginable applications.The field of application:from bolting technics to assemblymonitoring, measurement ofefficiency at motors andpumps, bearing friction at gears,friction of gaskets, application inlaboratories, e.g. measurement ofrotation springs, determinationof power demand or the limittorque of drives.Patented hard silver brushes(P 4042270)and self-lubricating slip rings.Special features• Accuracy ± 0,2 % of full scale• Shunt calibration• Bidirectional operation• Robust design• Small and handy• Resistant to high acceleration• Measurement of rotation angleas an option 360 pulses perrevolution0143/03 SDPin connectionsFunction Pin Description Pin Type QA- SupplyA+ SupplyB+ SignalC- SignalD0 VE+ 5 V ± 10%FImpuls I, TTLGImpuls r, TTLH0 VI- SupplyK(Calibration input)ShieldMStrain gage-bridgeSupply 0VSupply +5VOutput 1Output 2GNDTuchel Serie 581; 12-poleFEGMDHCI100% Shunt-Calibration BKAno connection in sensorFunction Pin Description Pin Type Q/R/H- Supply1 -6 VDCTuchel Serie 581; DIN 45322+ Supply2 +6 VDC3Shield3 no connection in sensor 42+ Signal- Signal- Supply4562 mV/V2 mV/V100% Calibration 5Angle sensorOn request available with „Bendix“-plug61

Mechanical designTorque sensor with standardsquare connection Q/QAConnectorM= measuring side• rotating shaft• angle encoder(type QA)*K I GECHMø Lø NDAFBSocket wrench torque sensor (Q)Threads for fixing M4, 6mm deep* for Q type only one thread asidealso QA type 12 NmModel/OrderdesignationRatedtorque(Nm)<strong>Dr</strong>ive A B C D EFHILøNømax. axialload (N)articleno.0143/03 SD 12 Q 12 1/4“ 75 28 52 58 148,551113-150133860143/03 SD 25 Q 25 3/8“ 74,5 38 58 44 19186222517550134050143/03 SD 63 Q 63 3/8“ 74,5 38 58 44 191862225171000134060143/03 SD 160 Q 160 1/2“ 79 38 58 44 1922,562225171800134070143/03 SD 500 Q 500 3/4“ 97 58 76 50 293052540304000134080143/03 SD 1000 Q 1000 1“ 112 73 90 57 36,534,5528,55040600013409Socket wrench torque sensor with angle encoder (QA)Model/OrderdesignationRatedtorque(Nm)<strong>Dr</strong>ive A B C D EFGHIKLøNømax. axialload (N)articleno.0143/03 SD 12 QA 12 1/4“ 75 28 52 58 148,58511-13-15051410143/03 SD 30 QA 30 3/8“ 101 38 58 59 1921,514512352517550133520143/03 SD 63 QA 63 3/8“ 101 38 58 59 1921,5145123525171000133530143/03 SD 160 QA 160 1/2“ 106 38 58 59 1926145123525171800133540143/03 SD 500 QA 500 3/4“ 135 58 76 64 2940305143640304000133550143/03 SD 1000 QA 1000 1“ 177 7390 73 36,5 57,545514455040600013356

Torque sensorwith standard hexagon 1/4“connection accordingDIN 3126 Form E/F, Type HM= measuring side1158Connector• with rotating shaft• quick-change chuck for differentbits for portable drivers(e.g. Philips head, slotted head)MECDFABThreads for fixing M4, 6mm deepModel/OrderdesignationRatedtorque(Nm)Output atrated torquemV/VA B C D EFmax.axialload (N)articleno.0143/03 SD 2 H 2 1,0 101 28 52 58 142820161690143/03 SD 6 H 6 2,0 101 28 52 58 142850161700143/03 SD 12 H 12 2,0 101 28 52 58 142850161710143/03 SD 20 H 20 2,0 101 28 52 58 142815016174Torque sensor with round shaftends and feather keyways(2 x 180°) DIN 6885, type RKIConnectorG• with rotating shaftFDFø 19 g6 (10-100)ø 38 g6 (200–1000N)HMEC= measuring sideABMThreads for fixing M4, 6mm deepModel/OrderdesignationRatedtorque(Nm)Output atrated torquemV/VA B C D EFGHIKmax.axialload (N)articleno.0143/03 SD 10 R 10 2,0 108 38 58 44 19301962253150162000143/03 SD 20 R 20 2,0 108 38 58 44 19301962253550162010143/03 SD 50 R 50 2,0 108 38 58 44 193019622531000162020143/03 SD 100 R 100 2,0 108 38 58 44 193019622531800162030143/03 SD 200 R 200 2,0 182 73 90 57 36,56036,5528,5 90,54000162040143/03 SD 500 R 500 2,0 182 73 90 57 36,56036,5528,5 90,56000162050143/03 SD 1000 R 1000 2,0 182 73 90 57 36,5 60 36,5 5 28,5 90,5 600016206

Technical DataMechanical, electrical specificationsExitation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-15 VDC, ACOutput at rated capacity, up to 10 Nm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 mV/ VOutput at rated capacity, exceeding 10 Nm . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 mV/ VNonlinearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .< ± 0,2 % of full scaleOperating temperature range . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .+5 ...+50 °CTemperature influence on zero . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .< ± 0,15 % / 10 KTemperature influence on sensitivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .< ± 0,15 % / 10 KMechanical overload capacity (working torque) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150 %Max. speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .≤ 3000 rpmAngle measurement (option A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 x 360 pulses, 90° displaced, TTLConnection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6/12-pole TuchelCalibration input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100 % control for torqueHousing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .aluminum, hard eloxadized, redProtection class . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .IP 40Example for order specification(Measuring range 12 Nm, Square drive with angle measurement): . . . . .0143 / 03 SD 12 QA, Art.No.: 5141AccessoriesMating plug, article no. 703 (12-pol.), (QA)Mating plug, article no. 822 (6-pol.), (Q, R, H)Bendix-connector on requestPractical application<strong>Dr</strong>. <strong>Staiger</strong>, <strong>Mohilo</strong>+Co GmbHMaierhofstraße 5D - 73547 LorchTelefon +49 7172•184-0Telefax +49 7172•184-500info@staiger-mohilo.dewww.dr-staiger-mohilo.de<strong>Dr</strong>.<strong>Staiger</strong> <strong>Mohilo</strong>Power tool controlDesign is subject to change without noticeE-07/02-1000 • PARMA & SEILER WERBEAGENTUR GMBH • NEUHAUSEN

Transducer instrumentationTorque-AnalyserType MD 9000, Data sheet 4110Portable torque / force monitorand data collection instrumentDC-AmplifierType DV 3101, Data sheet 4103DC-Amplifierfor 19“ rack mountingSupply and evaluation instrumentType UMV 2000, Date sheet 4600eMeasurement of torque, speed,angel of rotation, force andmechanical powerApplications• Continuous dynamicmonitoring of all torquecontrolled power tools.• Fastener assemblytroubleshooting.• Testing and recalibratingof torque wrenches.• Product quality audits.• Control of nutrunnerequipment (controlled bytorque and/or rotation angle).Special features• Connection of all static ordynamic strain gaugetransducers. Even load cells(traction and compression)can be connected.• Connection of rotational brushless torque transducers acc.to data sheet 0170 and slipring transducers acc. datasheet 0143.• Easy to handle by menuguidance via LCD graphicsdisplay.• Charger is part of delivery.The level ofcharging is indicated.An adapter foroperating on power lineis optionally available.Functions• Power supply• Amplifier• Display• Evaluation• ComperatorFeatures• Simplified operation• 19“rack mounting (10TE)• Compact• Analog circuit• Quick signal rise timeTechnical data• Peak value: 0-10 V• Voltage output: 10 V(Ri = 100 Ohm)• Current output: ±20 mA• Peak or track• High, low and in limitLED status indicatorsDescriptionThe desktop model is designed for115 VAC and 230 VAC input power.All connections are pluggable. Theinstrument is menu-driven and thereforevery easy to configure andprogram, and can quickly be adjustedto the measuring task.Any functions of the device (taring,peak value storage, mean valueoperation, limit setting, measuringduration, pre-and posttrigger, calibration,volume of indications, unitand interface) are simply adjustable.Up to 20 sensor parameter setscan be internally stored in the nonvolatileFlash-memory.ApplicationThe instrument is ideal for applicationsin process measurement techniquesand for the use in researchand laboratory environments.All sensors with strain gauge techniquesand sensors with standardizedvoltage output can directly beconnected. The simple programmingwith the software providesthat the instrument can be used forthe evaluation of torque-/speedmeasurements or torque-/angle ofrotation measurements in industrialenvironments.The applications are manifold:The required power can be easilydetermined by input torque andspeed of an actuated unit. Thisincludes generators, pumpsystems, gear-boxes, engines, driveshafts ect. which determine theefficiency factor when transmissioncomponents or systems are evaluated.This type of analyzing is normallyperformed on couplings, brakes,gear-boxes, engines and turbines.For process control, the instrumentis used to measure and test screwings,or for the verification of thebreakpoint at torque wrenches.Additional use in function controlin assembly procedures, where thetorque is rated as function of theangle rotation. For example the testof seat adjustments is optionallyavailable.