Valtek Severe Service Equipment

Valtek Severe Service Equipment

Valtek Severe Service Equipment

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

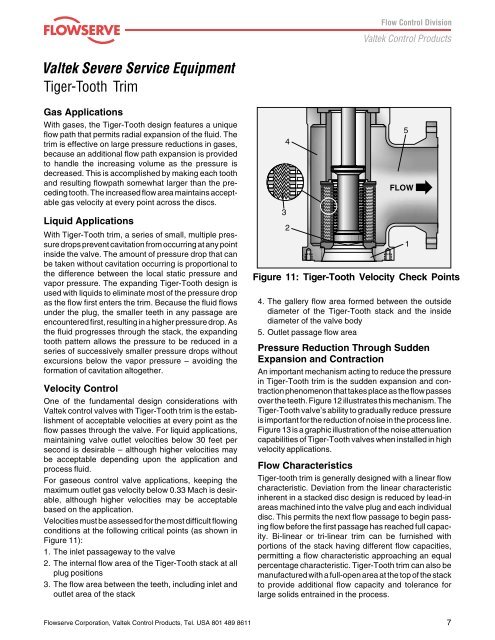

<strong>Valtek</strong> <strong>Severe</strong> <strong>Service</strong> <strong>Equipment</strong>Tiger-Tooth TrimGas ApplicationsWith gases, the Tiger-Tooth design features a uniqueflow path that permits radial expansion of the fluid. Thetrim is effective on large pressure reductions in gases,because an additional flow path expansion is providedto handle the increasing volume as the pressure isdecreased. This is accomplished by making each toothand resulting flowpath somewhat larger than the precedingtooth. The increased flow area maintains acceptablegas velocity at every point across the discs.Liquid ApplicationsWith Tiger-Tooth trim, a series of small, multiple pressuredrops prevent cavitation from occurring at any pointinside the valve. The amount of pressure drop that canbe taken without cavitation occurring is proportional tothe difference between the local static pressure andvapor pressure. The expanding Tiger-Tooth design isused with liquids to eliminate most of the pressure dropas the flow first enters the trim. Because the fluid flowsunder the plug, the smaller teeth in any passage areencountered first, resulting in a higher pressure drop. Asthe fluid progresses through the stack, the expandingtooth pattern allows the pressure to be reduced in aseries of successively smaller pressure drops withoutexcursions below the vapor pressure – avoiding theformation of cavitation altogether.Velocity ControlOne of the fundamental design considerations with<strong>Valtek</strong> control valves with Tiger-Tooth trim is the establishmentof acceptable velocities at every point as theflow passes through the valve. For liquid applications,maintaining valve outlet velocities below 30 feet persecond is desirable – although higher velocities maybe acceptable depending upon the application andprocess fluid.For gaseous control valve applications, keeping themaximum outlet gas velocity below 0.33 Mach is desirable,although higher velocities may be acceptablebased on the application.Velocities must be assessed for the most difficult flowingconditions at the following critical points (as shown inFigure 11):1. The inlet passageway to the valve2. The internal flow area of the Tiger-Tooth stack at allplug positions3. The flow area between the teeth, including inlet andoutlet area of the stack342FLOWFigure 11: Tiger-Tooth Velocity Check Points4. The gallery flow area formed between the outsidediameter of the Tiger-Tooth stack and the insidediameter of the valve body5. Outlet passage flow areaPressure Reduction Through SuddenExpansion and ContractionAn important mechanism acting to reduce the pressurein Tiger-Tooth trim is the sudden expansion and contractionphenomenon that takes place as the flow passesover the teeth. Figure 12 illustrates this mechanism. TheTiger-Tooth valve’s ability to gradually reduce pressureis important for the reduction of noise in the process line.Figure 13 is a graphic illustration of the noise attenuationcapabilities of Tiger-Tooth valves when installed in highvelocity applications.Flow CharacteristicsTiger-tooth trim is generally designed with a linear flowcharacteristic. Deviation from the linear characteristicinherent in a stacked disc design is reduced by lead-inareas machined into the valve plug and each individualdisc. This permits the next flow passage to begin passingflow before the first passage has reached full capacity.Bi-linear or tri-linear trim can be furnished withportions of the stack having different flow capacities,permitting a flow characteristic approaching an equalpercentage characteristic. Tiger-Tooth trim can also bemanufactured with a full-open area at the top of the stackto provide additional flow capacity and tolerance forlarge solids entrained in the process.51Flowserve Corporation, <strong>Valtek</strong> Control Products, Tel. USA 801 489 86117