Precision rail guides - Waikato Bearings

Precision rail guides - Waikato Bearings

Precision rail guides - Waikato Bearings

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

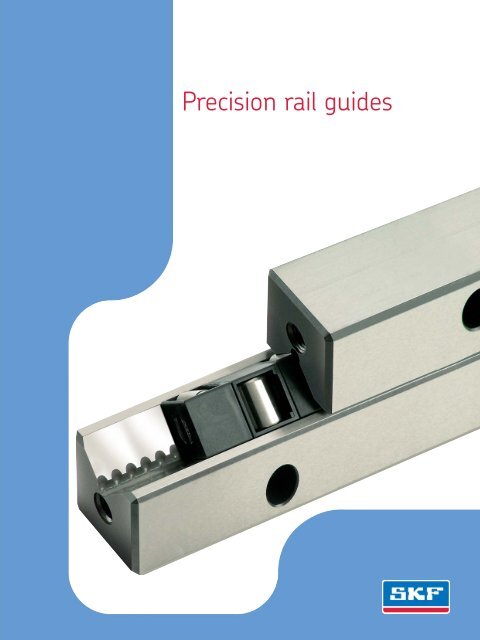

<strong>Precision</strong> <strong>rail</strong> <strong>guides</strong>

ContentGeneral information3 Introduction4 Produkt overview4 Modular Range <strong>rail</strong> <strong>guides</strong>8 Other productsThe SKF ® brand now stands for morethan ever before, and means more toyou as a valued customer.While SKF maintains its leadershipas the hallmark of quality bearingsthroughout the world, new dimensionsin technical advances, product supportand services have evolved SKF intoa truly solutions-oriented supplier,creating greater value for customers.These solutions encompass ways tobring greater productivity to customers,not only with breakthrough applicationspecificproducts, but also throughleading-edge design simulation toolsand consultancy services, plant assetefficiency maintenance programmes,and the industry’s most advancedsupply management techniques.The SKF brand still stands for the verybest in rolling bearings, but it nowstands for much more.SKF – the knowledge engineeringcompanyTechnical data9 <strong>Precision</strong> of <strong>rail</strong> <strong>guides</strong>9 Raceway accuracy9 Dimensional accuracy10 Grading10 Tolerance of distance between attachment holes10 Marking of matches sets11 Accuracy of adjacent components11 Selection of <strong>rail</strong> <strong>guides</strong>SKF precision <strong>rail</strong> <strong>guides</strong> in kit packaging12 Rail <strong>guides</strong> in kit packaging12 Advantages of <strong>rail</strong> guide kits12 LWR <strong>rail</strong> <strong>guides</strong> in kit packaging - table13 LWRE <strong>rail</strong> <strong>guides</strong> in kit packaging - table13 LWRE ACS <strong>rail</strong> <strong>guides</strong> in kit packaging (supplied to order) - tableLWR <strong>rail</strong> <strong>guides</strong>14 LWR <strong>rail</strong> <strong>guides</strong> with crossed roller assemblies14 LWR <strong>rail</strong> <strong>guides</strong> with ball assembly15 Ball and crosses roller assemblies18 Accessories for LWR <strong>rail</strong> <strong>guides</strong>LWRE <strong>rail</strong> <strong>guides</strong>20 LWRE <strong>rail</strong> <strong>guides</strong>21 Crossed roller assemblies21 Special attachment screws22 LWRE 3 - LWRE 9 / LWRE 221124 Accessories for LWRE <strong>rail</strong> <strong>guides</strong>25 LWRE ACS <strong>rail</strong> <strong>guides</strong> with non-slip cage (Anti Creep System)26 Accessories for LWRE ACS <strong>rail</strong> <strong>guides</strong>LWRM/LWRV <strong>rail</strong> <strong>guides</strong>29 LWRM/LWRPV <strong>rail</strong> <strong>guides</strong>30 LWRM/LWRV 6 and LWRM/LWRV 932 Accessories for LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong>LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong>33 LWM/LWV <strong>rail</strong> <strong>guides</strong>34 LWRPM/LWRPV 3 - LWRPM/LWRPV 936 Accessories for LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong>LWM/LWV <strong>rail</strong> <strong>guides</strong>37 LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong>38 LWM/LWV 3015 - LWM/LWV 805040 Accessories for LWM/LWV <strong>rail</strong> <strong>guides</strong>LWJ/LWS flat <strong>rail</strong> <strong>guides</strong>41 LWJ/LWS flat <strong>rail</strong> <strong>guides</strong>LZM miniature slide42 LZM miniature slideStandard slides44 Design and characteristic features45 Technical data46 GCL - Drill hole pattern in top plate47 GCL - Drill hole pattern in base plate2

IntroductionAs the world’s leading rolling bearingmanufacturer, SKF supplies practicallyevery type of bearing for rotationaland linear motion.SKF is therefore in a position tomeet almost any customer requirementboth technically and economically.This catalogue covers the SKFrange of precision <strong>rail</strong> <strong>guides</strong> and accessories.SKF precision <strong>rail</strong> <strong>guides</strong> arehighly accurate products for linearmotion and are therefore ideallysuited for use in a wide variety ofmachine tools, machining centres,handling systems and special machineryas well as measuring and testingequipment.The “Modular Range” has introduceda new concept to the market,ensuring the internal interchangeabilityof all well-known guidance systemsincluding the high capacityLWRE-type <strong>rail</strong> <strong>guides</strong>. This matrixrange of <strong>rail</strong> guide modules permitsthe individual selection of <strong>rail</strong>s androlling elements.SKF precision <strong>rail</strong> <strong>guides</strong> are availablein many different designs, sizesand standard lengths, incorporatingball, roller or needle roller assembliesand slide coating. They are suppliedwith the required accessories for attachmentand sealing.The use of SKF precision <strong>rail</strong> <strong>guides</strong>facilitates the construction ofeconomical, clearance-free linear<strong>guides</strong> of practically any type andlength, according to the buildingblock principle. The characteristics ofthe <strong>guides</strong> include:• a constant, high degree of runningaccuracy• low-friction, stick-slip free operation• high speed of travel• low heat generation• low wear and high reliability• high stiffness• excellent load carrying capacityIf there is a danger of cage-creep(in particular when the guide ismounted vertically), precision <strong>rail</strong><strong>guides</strong> of type LWRE-ACS (Anti-Creep System) are an obvious choice,as they will eliminate this problem.For applications that are characterisedby high accelerations or shortstrokes of high frequency, SKF <strong>rail</strong><strong>guides</strong> with dry sliding coating arerecommended.These <strong>rail</strong> <strong>guides</strong> are also suitablefor machine tool applications wherethe good damping properties of the<strong>guides</strong> are of greater importancethan the lower friction of the rollingelement <strong>rail</strong> <strong>guides</strong>. For those applicationswhere <strong>rail</strong> <strong>guides</strong> are unsuitable,for instance because of theirlimited travel, SKF can supply alternativeforms of linear guidance systems.All fast-selling precision <strong>rail</strong> <strong>guides</strong>are also available in convenientkit packaging. This ensures completedelivery of all single components includingend pieces and screws.If you would like further details,please contact the SKF applicationengineering department. We will bepleased to provide the required informationwithout obligation and atno cost, or to prepare a technicalproposal.This catalogue brings together allthe basic data which we consider tobe of interest. For further specialisedadvice please contact your nearestSKF sales office.3

Product overviewSKF modular range <strong>rail</strong> <strong>guides</strong>LWRPM/PVLWRM/VLWRELWRE ACSLWRwith ball assemblyNon-slip cageof LWRE ACSLWRwith roller assembly4

SKF modular range <strong>rail</strong> <strong>guides</strong>The SKF modular range consists of amatrix range of <strong>rail</strong> guide modulesthat enables individual permutationsof <strong>rail</strong>s and rolling element assemblies.Different requirements for the<strong>guides</strong> do not call for changes in thedesign or mechanical environment.The choice of appropriate <strong>rail</strong> <strong>guides</strong>is determined solely by the mechanicalconditions under which the <strong>guides</strong>ystem is to operate. These operatingrequirements are covered by six differentmodels (Fig. 1) that may bedefined as <strong>rail</strong> <strong>guides</strong> with:• crossed roller assemblies of thestandard LWR series• ball assemblies of the LWRB series• crossed roller assemblies of theoptimised LWRE series• crossed roller assemblies withnon-slip cage to prevent cagecreepof the LWRE ACS series• needle roller assemblies of theLWRM/LWRV series and• slide coating of theLWRPM/LWRPV seriesThe blue shaded areas in the chartindicate the sizes included in the ModularRange. Experience has shownthat some 80 % of applications canbe covered by these (Fig. 2).Contrary to the current lack ofuniformity within the market, thestandard, interchangeable guidancesystems of the Modular Range coveralmost the entire spectrum of <strong>rail</strong>Fig. 2guide applications. The choice of aspecific rolling element or, for extremeconditions, of a slide coating, isdetermined only by the actual operatingconditions (Fig. 5). Generally, any<strong>rail</strong> guide can be operated in the‘clamped’ or ‘floating’ mode. The designof the <strong>rail</strong> <strong>guides</strong> does not imposeany special space requirements.Market situationSKF Modular RangeFig. 1Ax BTypeSize8.5 x 4 12 x 6 18 x 8 22 x 11 25 x 12 31 x 15 44 x 22 58 x 28 71 x 36 83 x 40 110 x 551 2 3 2211 4 6 9 12 15 18 24––X––XXOOOO––XOXXX––––LWRE ACSLWRE ACS––XOO O O – – – ––––––OOOO––––O––OOOO––XX––= Modular Range––––X = available ex-stock in standard lengthsO = available to order– = not available–––5

Increased performance achievablewithout design modificationThe Modular System is based on thewell-proven LWR design which coversa wide range of applications.The new optimised LWRE series offerseither doubled stiffness and aload carrying capacity increased by afactor of five or, alternatively, for agiven load carrying capacity, a 50 %reduction in bearing size comparedwith the standard LWR design (Fig. 3).Fig. 3LWR 12LWRE 6pacity. It thus offers a far better price/performanceratio. Secondly, thereplacement of other <strong>rail</strong> <strong>guides</strong>, includingthose supplied by other manufacturersand already installed, canbe carried out with ease and in a minimumof time.Above all, where the user needs toincrease machine performance, aunit with a higher load rating can befitted. In-situ replacement is madeeasier by the fact that no new attachmentholes or fixing devices arerequired when using <strong>rail</strong> <strong>guides</strong> ofthe Modular Range. An additionaladvantage is the worldwide availabilitythrough distributors, simply byquoting the appropriate cataloguenumber. The internal design of theLWRE series ensures increased operationallife through even distributionof load. This results from the optimisationof the cross-section whichpermits the use of larger rolling elements.The new design leads to asignificant improvement in the roller/racewaycontact performance. Animportant additional benefit is theintroduction of a practically maintenance-freecage made of POM thatmatches the stringent demands forlong operational life of the rollingelements and maintains its dimensionalstability up to +80 °C. The individualrollers are well covered andthe space between the <strong>rail</strong>s is almostfilled, thus providing good protectionagainst contamination. A special characteristicof the LWAKE 3, 6 and 9cages is that they consist of ‘snap-on’elements and can be fitted togetherto the required length (Fig. 4). Conventionalcrossed roller cages havetheir rollers arranged alternatelyevenly spaced, so that only half therollers in a preloaded guide are loadbearingwhile the remainder act asidlers. In the new LWRE cage theseessentially unused rollers can bepartially turned in the direction ofthe load. For this purpose each individualcage segment is designed toFig. 4Optional configurationsof LWAKE 3, 6, and9 cage segmentsStandard crossedroller configurationComplete rangeIn order to further simplify the applicationof Modular Range <strong>rail</strong> <strong>guides</strong>,all <strong>guides</strong> within a given size rangehave the same external dimensionsand thus fit the space requirementsof most commercially available <strong>rail</strong><strong>guides</strong>. This results in a very widechoice in terms of load carrying capacity,stiffness and operating characteristics.From the economical point ofview, the use of the optimised LWREseries offers a double advantage.Firstly (although the initial cost isslightly higher) the range of applicationis extended significantly as regardsstiffness and load carrying cabeturned through 90° about thelongitudinal axis. These are manualadjustments and no special instructionsare required when ordering fromthe catalogue.LWAKE 4 crossed roller cagesconsist of roller segments that areassembled according to the lengthspecified by the customer.6

Fig. 5LWRECrossedrollerLWRCrossed rollerLWRE ACSLWR/LWRBBallLWR/LWRB seriesThis basic series of the ModularRange covers a wide variety of <strong>rail</strong>guide applications for limited travel.Where low friction is essential, ballcage assemblies are recommended.If, on the other hand, high load carryingcapacity is the chief requirement,robust crossed roller assembliesare to be preferred. The LWRseries is manufactured in nine sizesbased on rolling element dimensions.LWRE seriesFor a given load carrying capacity,the dimensions of the LWRE seriesare significantly less than those ofthe corresponding member of theLWR series.Thus, for instance, an LWRE 6 guidewith a cage length of 100 mm has agreater load carrying capacity than astandard LWR 12. The LWR 12 measures58 x 28 mm whereas theLWRE 6 measures only 31 x 15 mm(Fig. 1).LWRPM/LWRPVSlide coatingLWRM/LWRVNeedle rollerLWRE ACS seriesAll <strong>rail</strong>s of the LWRE series are alsoavailable with ACS, a special systemto prevent “cage-creep”. These <strong>rail</strong>sare used where cage-creep occursdue to high acceleration, unevenpreloading or load distribution aswell as jerky running or directiondependentspeeds of travel.LWRM/LWRV seriesThese <strong>guides</strong> are used principallywhere high load carrying capacity iscalled for in combination with highstiffness, for instance on grindingmachines. This series is fitted withneedle roller and cage assembliesconsisting of two rows of needle rollersat right angles to each other.LWRPM/LWRPV seriesWhere extremely short strokes ofhigh frequency occur, this special serieswith slide coating is an essentialalternative to those with rolling elementassemblies. In the case of ballsor rollers subjected to high transverseacceleration, pitting of the tracksmay occur as a result of the unfavourabletribological conditions. Sliding<strong>rail</strong> <strong>guides</strong> are preferred in suchcircumstances.The coating material is based onPTFE and is bonded on to the unhardenedLWRPM <strong>rail</strong> and thenground to the correct dimension.This wear-resistant material combinationis characterised by its stickslip-free,vibration-damping runningproperties, at the same time offeringexcellent stiffness and emergencyrunning properties. These guide <strong>rail</strong>sare largely insensitive to contamination,coolants and lubricants.Materials and precisionThe <strong>rail</strong>s of the Modular Range <strong>guides</strong>are manufactured from tool steel90 MnCrV 8 with a hardness of between58 and 64 HRC. If required bythe application, the <strong>rail</strong>s can also besupplied in special stainless steel, e.g.X 90 CrMoV 18 in all standard dimensions.All rolling elements aremade from carbon chromium steel100 Cr 6 with a hardness of between58 and 64 HRC. The parallelism ofthe raceways is divided into threeclasses. Class P10, with a maximumdeviation of 10 μm per 1 000 mmlength, meets most of the demandsfor normal machinery. Where greaterprecision is required, tolerance classesP5 and P2 are also available.The assortment is complementedby various accessories specially designedfor the Modular Range of <strong>rail</strong><strong>guides</strong>. These include end pieceswith or without wipers as well asspecial attachment screws.7

Technical data<strong>Precision</strong> of <strong>rail</strong> <strong>guides</strong>All SKF precision <strong>rail</strong> <strong>guides</strong>, regardlessof type, are manufactured to thesame tolerances indicated below.Raceway accuracyIn order to meet the different requirementsregarding the precision of linearbearing arrangements, the <strong>rail</strong>sare produced in three different toleranceclasses. These are classifiedaccording to the parallelism betweenthe raceways and the support surfacesA and B (Fig. 6).P10Tolerance class normal. This meetsthe requirements of general engineeringapplications. The deviationfrom parallelism for a 1 000 mmlong <strong>rail</strong> is approximately 10 μm. Seealso adjacent table 1.P5This satisfies the demands normallymade on the running accuracy formachine tool applications. The deviationfrom parallelism for a 1 000 mmlong <strong>rail</strong> is 5 μm maximum. See alsoadjacent table 1.Dimensional accuracySKF precision <strong>rail</strong> <strong>guides</strong> with limitedtravel are produced to the followingtolerances (Figs. 7 and 8):Width A: 0/-0,3mmAbutment heightT = B1 + B2 ± 0,02 mmRail height B: 0/-0,2 mmRail length L: L ≤ 300 ± 0,3L > 300 ± 0,001 · L [mm]Fig. 6For <strong>rail</strong>s composed of two or moresections the tolerance for the totallength is ± 2 mm.SKF precision <strong>rail</strong> <strong>guides</strong> for recirculatingroller assemblies are producedto the following tolerances:Width A: 0/+0,1 mmHeight A: 0/+0,1 mmLength L: L ≤ 300 ± 0,3L > 300 ± 0,001 · L [mm]P2Accuracy for the most exacting demands.Rails made to this toleranceclass should only be used when theassociated components are made toa correspondingly high degree ofprecision. Rails to tolerance class P2will be manufactured by SKF to specialorder. See also table 1.If no mention is made of the requisiteaccuracy on the order, <strong>rail</strong>swith normal P10 tolerances will besupplied.Table 1Permissible deviation in parallelism between reference planes A and BRail lengthTolerance classfrom to P10 P5 P2mm100 2 1 1100 200 3 2 1200 300 4 2 1300 400 5 2 2400 500 6 3 2500 600 6 3 2600 700 7 4 2700 800 8 4 2800 900 8 5 2900 1 000 9 5 21 000 1 200 10 6 31 200 1 400 11 6 31 400 1 600* 12 7 3mm* Rail length > 1 600 mm, please contact SKF9

Grading<strong>Precision</strong> <strong>rail</strong> <strong>guides</strong> with limited travelare generally mounted in pairs. Inorder to obtain the same assemblyheight T (Fig. 7), the <strong>rail</strong>s are gradedand supplied in pairs.This ensures that any two similar<strong>rail</strong> <strong>guides</strong> in a system will have thesame height.If two or more rolling element assembliesare to be mounted immediatelybehind each other in a <strong>rail</strong>guide, the rolling elements must havethe same tolerance grade. On request,graded rolling element assembliescan be supplied.Rails of the same profile for recirculatingroller assemblies, which areto be mounted immediately adjacentto each other or immediately behindeach other should be ordered in gradedcondition. Depending on theirtype, they will be graded in height orin height and width and delivered asa single package.Rail guide sets are always matchedso that it is not necessary to requestthis when ordering.Tolerance of distance between attachmentholesThe maximum deviation in the distancebetween the attachment holesmeasured from centre to centre is± 0,8 ‰ of the <strong>rail</strong> length L for onepiece<strong>rail</strong>s (Fig. 8). Where the <strong>rail</strong>consists of several sections, the toleranceis also ± 0,8 ‰, related to thelength of the longest section. Railshaving tighter tolerances for the distancebetween the holes can be suppliedon request.Marking of matched setsMatched components are markedwith consecutive numbers as indicatedin Fig. 8a.Fig. 7Fig. 8Fig. 8a(=B1+B2)10

Accuracy of adjacent componentsAn important criterion for the correctperformance of a <strong>rail</strong> guide system isthe accuracy of the associated components.The higher the demands foraccuracy of guidance and for smooth,easy operation, the greater the attentionwhich must be paid to theaccuracy of form and position of theassociated components. Generallythe same accuracy requirementsshould be applied to these componentsas to the <strong>rail</strong> <strong>guides</strong> themselves.The adjacent table shows thevalues, for each tolerance class, ofthe surface roughness, perpendicularityand parallelism of the adjacentcomponents.To assure an even load distributionover the roller length, the maximumdifference in height of the supportsfor a <strong>rail</strong> guide should notexceedΔh = 0,1 · B 1whereΔh = maximum height deviation, μmB1 = mean distance between two<strong>rail</strong> <strong>guides</strong>, mmTo obtain good support for the<strong>rail</strong>s on the associated components,the attachment holes should be carefullydeburred (Figs. 9 and 10).Selection of <strong>rail</strong> <strong>guides</strong>When selecting a <strong>rail</strong> guide, thelength of travel, load carrying capacity,requisite life and stiffness are themost decisive factors. Other importantparameters include the requisitespeed of travel, lubrication, operatingtemperatures, ease of movement,environmental influences and certaindesign constraints, for instancewhether “clamped” or “floating” guidanceis required. If further informationis needed, please contact SKF.The selection of the size and lengthof the rolling element assemblies ismainly determined by the requiredFig. 9Fig. 10Accuracy of form of support surfacesCharacteristic Symbol for Permissibledeviation of formCharac- Tolerance Dimensions Tolerance classteristic zoneP10 P5 P2Roughness R a a μm 1,6 0,8 0,2Perpendicularity ⊥ t 1 /t 2 μm/mm 0,3 0,3 0,3Parallelism ⁄⁄ t 3 /T 4 μm depending on theguide length L (mm)3 2 1 2006 4 2 50010 6 3 1 000load carrying capacity, life and stiffness.For light, centrally acting loadsand moderate demands for speed oftravel, it is possible to use practicallyall the types of <strong>guides</strong> listed in thiscatalogue. However, technical andeconomic reasons often dictate thechoice of the most appropriate modelfor a given application.The length of a <strong>rail</strong> guide and ofthe individual <strong>rail</strong>s is mainly determinedby the travel as well as thelength of the rolling element assemblies,which depends on the requisiteload carrying capacity and life.The following relationships serveas guidelines for determining thelength of <strong>rail</strong> <strong>guides</strong> and rolling elementassemblies:For a given stroke:Cage length = stroke, at leastFor a given cage length:Rail length = cage length+ 0,5 x strokeFor a given <strong>rail</strong> length and stroke, thecage length is is obtained from:Cage length = Rail length– 0,5 x stroke11

SKF precision <strong>rail</strong> <strong>guides</strong> in kit packagingRail <strong>guides</strong> in kit packagingKit packaging is a new service offeredby SKF. Each kit consists of afour-piece <strong>rail</strong> guide set, 2 cages and8 end pieces.Advantages of <strong>rail</strong> guide kits• all required components are suppliedin ready-to-mount sets andcan be ordered via one single ordernumber• for enhanced ease of mounting, allparts can now be supplied directlyto the machine on site• cage length easily adjustable *• environmentally compatible packagingthat can be returned free ofcharge and directed to the recyclingprocess• most kits available ex stock• also available with ACS for the effectiveprevention of cage-creepCertified in accordance with ISO14001, SKF Linear Motion and theentire SKF Group attach great importanceto environmental protection.Hence as a matter of course, SKFkit packagings can be returned freeof charge and are directed to the recyclingprocess. This makes themboth a convenient and an environmentally-friendlypackaging solution.LWR <strong>rail</strong> <strong>guides</strong> in kit packagingDesignation Load ratings Stroke Type of <strong>rail</strong> Type of cagedyn. stat. 4 pieces 2 piecesC C 0NLWR 3050 Kit 999 1 120 26 LWR 3050 LWAK 3x7LWR 3075 Kit 1 422 1 760 36 LWR 3075 LWAK 3x11LWR 3100 Kit 1 811 2 400 46 LWR 3100 LWAK 3x15LWR 3125 Kit 2 088 2 880 66 LWR 3125 LWAK 3x18LWR 3150 Kit 2 442 3 520 76 LWR 3150 LWAK 3x22LWR 3175 Kit 2 781 4 160 86 LWR 3175 LWAK 3x26LWR 3200 Kit 3 110 4 800 96 LWR 3200 LWAK 3x30including 8 end pieces LWERA 3LWR 6100 Kit 4 915 5 440 50 LWR 6100 LWAL 6x8LWR 6150 Kit 6 744 8 160 78 LWR 6150 LWAL 6x12LWR 6200 Kit 8 441 10 880 106 LWR 6200 LWAL 6x16LWR 6250 Kit 10 045 13 600 134 LWR 6250 LWAL 6x20LWR 6300 Kit 11 955 17 000 144 LWR 6300 LWAL 6x25LWR 6350 Kit 13 422 19 720 172 LWR 6350 LWAL 6x29LWR 6400 Kit 14 846 22 440 200 LWR 6400 LWAL 6x33including 8 end pieces LWERA 6mm* Note: Do not cut the cage (roller assembly) shorter than 2/3 of the total <strong>rail</strong> length.12

LWR <strong>rail</strong> <strong>guides</strong>LWR <strong>rail</strong> <strong>guides</strong> are well-proven, limited-travellinear <strong>guides</strong> used innumerous applications. They consistof two identical <strong>rail</strong>s between whichcrossed roller assemblies or ball assembliesare inserted, depending onthe respective application.LWR <strong>rail</strong> <strong>guides</strong> with crossed rollerassemblies are robust linear bearingswith high load carrying capacity.Their special characteristicsmake them suitable for a large proportionof linear bearing arrangementswith limited travel.LWR <strong>rail</strong> <strong>guides</strong> with ball assemblycan be used to advantage where loadsare light and/or easy running isrequired.Rail <strong>guides</strong> with a length greaterthan 1 200 mm are supplied insections.Because of the many permutationsavailable, each part of an LWR<strong>rail</strong> guide must be ordered separately,e. g:4 <strong>rail</strong>s LWR 906002 crossed roller assembliesLWAL 9x258 end pieces LWERA 9OrderingTo facilitate the order routine, <strong>rail</strong>guide sets can also be ordered in kitpackaging (see pages 12-13).14

Ball and crossed roller assembliesfor LWR <strong>rail</strong> <strong>guides</strong>Ball assembliesWhere moderate loads are to besupported by a <strong>rail</strong> guide and greaterpriority is given to smooth operationand low friction, the use of ball assembliesis recommended.LWJK ball assemblies are providedwith a plastic ball-retaining cage.These are available for sizes 1 and 2.Crossed roller assembliesWhere greater stiffness is required,crossed roller assemblies are recommended.Various cage types areavailable, depending on the size ofthe rollers.LWAK crossed roller assemblies arefitted as standard for size 3 with aplastic cage to retain the cylindricalrollers.SKF modular rangeThe LWR <strong>rail</strong> <strong>guides</strong> form the basisfor the whole Modular Range system.All <strong>guides</strong> with designations commencingLWR... included in this catalogueare interchangeable with eachother within a given dimension series.All external and attachment dimensionscorrespond with those ofthe LWR series.LWR <strong>rail</strong> <strong>guides</strong> are available in atotal of nine sizes. The “ModularRange” includes sizes 3, 6 and 9which, according to experience, cover80 % of the normal market requirements.To enable prompt deliveryfrom stock, certain standard <strong>rail</strong>lengths have been defined.SKF Modular Range <strong>rail</strong> <strong>guides</strong>are specially highlighted in the tables.For further information, please referto pages 5 to 7.LWAL crossed roller assemblies areavailable in sizes 6 to 12 with aluminiumcages. They comprise retainedrollers.End pieces for LWR <strong>rail</strong> <strong>guides</strong>End pieces prevent the drift of thecage away from the loaded zone.LWERA end pieces fulfil these requirementsin low-load conditions combinedwith horizontal mounting.Attachment screws forLWR <strong>rail</strong> <strong>guides</strong>In particular in the case of long <strong>rail</strong><strong>guides</strong>, heat treatment can lead tothermal expansion which will also influencethe distance between the tapholes. Special attachment screwscompensate for this longitudinal expansion.LWGD special attachment screwscan be used for all <strong>rail</strong>s within theModular Range.15

LWR <strong>rail</strong> <strong>guides</strong>LWR 3 - LWR 12 LWRB 1 + 2Designation Dimensions: System Mounting holes End face holes Available lenghtsA B A 1 D w J J 1 J 2 G G 1 N N 1 J 3 G 2 G 3 L 1)mm 020 030 040 045 050 060LWRB 1 8,5 4 3,9 1,6 10 5 1,8 M2 1,65 3 1,4 1,9 M1,6 2LWRB 2 12 6 5,5 2 15 7,5 2,5 M3 2,55 4,4 2 2,7 M2,5 3• • • •• •••Designation Dimensions: System Mounting holes End face holes Available lenghtsA B A 1 D w J J 1 J 2 G G 1 N N 1 J 3 G 2 G 3 L 1 )mm 050 075 100 125 150 175 200 225 250LWR 3 18 8 8,2 3 25 12,5 3,5 M4 3,3 6 3,2 4 M3 6LWR 6 31 15 13,9 6 50 25 6 M6 5,2 9,5 5,2 7 M5 9LWR 9 44 22 19,7 9 100 50 9 M8 6,8 10,5 6,2 10 M6 9LWR 12 58 28 25,9 12 100 50 12 M10 8,5 13,5 8,2 13 M8 12• • • • • • • º •• º • • ••º1)Sizes LWR 15, 18 and 24 are available on request.16

Ball and crossed roller assemblies End pieces Special attachment screwsLWJKLWERA 1+2LWAKLWERA 3-12LWGDLWALBall and crossed End pieces 1) Specialrollerassembliesattachmentscrews070 075 080 090 100 105 120 135 150 LWJK LWERA LWGDº º º º• • • • º º• •• •Ball and crossed End pieces 1) Specialrollerassembliesattachmentscrews275 300 350 400 450 500 550 600 650 700 800 900 1 000 LWJK LWAL LWERA LWGDº•• • • • • º º º º• • • • • º º ºº º º º º º • º º º º º••••••••••••• SKF Modular Range.Preferred range, prompt delivery• Prompt deliveryº Available to orderExample: 4 LWR 3100 or 4 LWR 902002 LWAK 3 x 17 2 LWAL 9x108 LWERA 3 4 LWERA 917

Accessories for LWR <strong>rail</strong> <strong>guides</strong>Ball and crossed roller assembliesLWJKLWALLWAKFor description and data relatingto rolling element assemblies, see page 15Designation 1) Dimensions Load ratings Appropriatefor 10 rolling elements <strong>rail</strong> guidedynamic staticD w U U 1 t t 1 C C 0mmNLWJK 1,588 1,588 3,5 0,5 2,2 1,0 410 580 LWRB 1LWJK 2 2 5 0,75 3,9 1,5 640 720 LWRB 2LWAK 3 3 7,5 1 5 3,5 1 320 1 600 LWR 3LWAL 6 6 14,8 2,7 9 6 5 850 6 800 LWR 6LWAL 9 9 20 4 14 9,4 17 000 18 300 LWR 9LWAL 12 12 25 5 18 12 30 000 30 500 LWR 1218

End piecesSpecial attachment screwsLWERA 1+2SWwidth across flatsLWERA 3-12LWERB 3–12LWGDLWERB 1+2 LWERB 1 LWERB 2wiperLWERC 3–12with wiperDesignation Dimensions Appropriate Designation Dimensionsattachment SpecialEnd pieces End pieces screw attachmentwith wiper L L 1 screws G1 G2 L4 L5 D d SW 2)mm DIN 963 mmLWERA 1 – 1 – M 1,6 – – – – – – – –LWERB 1 – 0,5 – M 1,6LWERA 2 – 1,5 – M 2,5 – – – – – – – –LWERB 2 – 0,5 – M 2,5LWERA 3 – 2,5 – M 3 LWGD 3 M 3 5 12 3 5 2,3 2,5LWERB 3 – 2 – M 3 DIN 7991– LWERC 3 2 5 M 3LWGD 4 M 3 5 16 3 5 2,3 2,5(für LWRE 4)LWERA 6 – 3 – M 5 LWGD 6 M 5 8 20 5 8 3,9 4LWERB 6 – 3 – M 5 DIN 7991– LWERC 6 3 6 M 5 DIN 7991LWERA 9 – 4 – M 6 LWGD 9 M 6 12 30 6 8,5 4,6 5LWERB 9 – 4 – M 6 DIN 7991– LWERC 9 4 7 M 6 DIN 7991LWERA 12 – 5 – M 8 LWGD 12 M 8 17 40 8 11,3 6,2 6LWERB 12 – 5 – M 8 DIN 7991– LWERC 12 5 8 M 8 DIN 79912)Width across flats of internal hexagon19

LWRE <strong>rail</strong> <strong>guides</strong>LWRE <strong>rail</strong> <strong>guides</strong> are a logical developmentof the proven LWR <strong>rail</strong> <strong>guides</strong>.Within the Modular Range systemthe LWRE <strong>rail</strong> <strong>guides</strong> offer anoutstanding price/performance ratio.Alongside the familiar characteristicsof the LWR series, the newLWRE <strong>rail</strong> <strong>guides</strong> offer the advantagesof a fivefold increase in the loadcarrying capacity and a doublingof the stiffness, achieved through optimisedinternal geometry in conjunctionwith larger roller diameters.LWRE <strong>rail</strong> <strong>guides</strong> offer a greatlyincreased safety margin, thus a verymuch smaller LWRE <strong>rail</strong> guide can beused in a given design space whilemaintaining the same load carryingcapacity as the LWR.The mounting and attachmentdimensions of the LWRE <strong>rail</strong> <strong>guides</strong>conform to those of all the SKF ModularRange <strong>rail</strong> <strong>guides</strong> included inthis catalogue.Rail <strong>guides</strong> of more than1 200 mm in length should be builtup of sections. Because of the manypermutations available, each part ofan LWRE <strong>rail</strong> guide must be orderedseparately, e.g.:4 <strong>rail</strong>s LWRE 62002 crossed roller assembliesLWAKE 6x134 end pieces LWERE 6OrderingTo facilitate the order routine, <strong>rail</strong>guide sets can also be ordered in kitpackaging (see pages 12-13).20

Crossed roller assemblies forLWRE <strong>rail</strong> <strong>guides</strong>LWAKE crossed roller cages consistof individual plastic elements.In LWAKE 3, 6 and 9 cages, theseelements are assembled using a‘snap in’ technique whereby eachelement can be rotated manuallythrough an angle of 90°. Thus theload rating and stiffness can be enhancedby turning the rollers in thedirection of the load.Dimensional stability of the LWA-KE crossed roller assembly is maintainedup to a temperature of +80 °C.The cage retains the rollers and atthe same time almost fills the freespace between the <strong>rail</strong>s, thus providinggood protection against the ingressof dirt.LWAKE 4 cages consist of rollersegments which are fitted togetherto the customer’s specific length requirements.End pieces for LWRE <strong>rail</strong> <strong>guides</strong>End pieces prevent the drift of thecage away from the loaded zone.LWERE end pieces are generallyused for horizontal and vertical applications.All end pieces are supplied withappropriate fixing screws.Special attachment screws forLWRE <strong>rail</strong> <strong>guides</strong>For designations and dimensionsplease refer to the LWR table on page19. The LWGD special attachmentscrews listed in the table may be selectedto suit each size of LWRE <strong>rail</strong>guide.Internal geometry of LWR andLWRE <strong>rail</strong> <strong>guides</strong>Normal LWR <strong>rail</strong> <strong>guides</strong> utilise onlyabout 40 % of the roller length. Dueto the parallel displacement of theload axes, LWR <strong>rail</strong> <strong>guides</strong> are proneto an internal tilting moment on therollers. This can lead to high edgestresses and hence to a reduction ofload carrying capacity. LWRE <strong>rail</strong> <strong>guides</strong>,on the other hand, utilise thewhole roller length. Their internalgeometry is such that no tilting momentcan occur and there are no edgestresses.At the same time the diameter ofthe rollers has been considerably increased(+33 %). These features providethe following advantages:• fivefold increase in load carryingcapacity• 100 % increase in stiffness21

LWRE <strong>rail</strong> <strong>guides</strong>LWRE 3 - LWRE 9 / LWRE 2211Designation Dimensions: Attachment holes End face holes Available lengthsSystemA B A 1 D w J J 1 J 2 G G 1 N N 1 J 3 G 2 G 3 L 1)mm 050 075 100 125 150 175 200LWRE 3 18 8 8,7 4 25 12,5 3,5 M 4 3,3 6 3,2 4 M 3 6LWRE 4 25 12 12 6,5 25 12,5 5 M 4 3,3 6 3,2 5 M 3 6LWRE 6 31 15 15,2 8 50 25 6 M 6 5.2 9,5 5,2 6,75 M 5 9LWRE 9 44 22 21,7 12 100 50 9 M 8 6,8 10,5 6,2 9,75 M 6 9• • • • • • •º• • º •º•Designation Dimensions: Attachment holes End face holes Available lengthsSystemA B A 1 D w J J 1 J 2 G G 1 N N 1 J 3 G 2 G 3 L 1)mm 080 120 160 200LWRE 2211 22 11 10,7 4 40 20 4,5 M 5 4,3 7,5 4,1 6 M 3 6 º º º º1)Other lengths are available on request22

Crossed roller assemblies End pieces Special attachmentscrewsLWAKELWERE 3, 6, 9LWGDLWAKELWERE 4Crossed End pieces Specialrollerattachmentassembliesscrews225 250 275 300 350 400 450 500 550 600 650 700 800 900 1 000 LWAKE LWERE LWGDºº º º •º º º º º º º ºº• • º • º º º º º º•• • • • • º º º ••º•••º••Crossed End pieces Specialrollerattachmentassembliesscrews240 280 320 360 400 LWAKE LWERE LWGDº º º º º• •• SKF Modular RangePreferred range, prompt delivery• Prompt deliveryº To special orderOrdering example: 4 LWRE 904002 LWAKE 9 x 224 LWERE 916 LWGD 923

Accessories for LWRE <strong>rail</strong> <strong>guides</strong>Crossed roller assembliesLWAKE 3, 6, 9LWAKE 4For description and data on crossed roller assemblies, please see page 21Designation Dimension Load ratings Rail guidefor 10 needle rollers designationper rowdynamic staticD w t t 1 t 2 C C 0mmNLWAKE 3 4 6,25 2,65 3,6 6 300 8 500 LWRE 3, LWRE 2211LWAKE 4 6,5 8 4,3 4,3 17 300 20 800 LWRE 4LWAKE 6 8 11 5 6 34 000 39 000 LWRE 6LWAKE 9 12 16 7,35 8,65 78 000 78 000 LWRE 9End piecesSpecial attachment screwswiperLWERE 3, 6, 9 LWEREC 3, 6, 9for designation and dimensionssee page 19LWGDLWERE 4Designation Dimensions Appropriate Railattachmentguidewithout with screw designationwiper wiper L L 1mm DIN 7991LWERE 3 2 M 3 LWRE 3, LWRE 2211LWEREC 3 4 M 3 LWRE 3, LWRE 2211LWERE 4 4 M 3 (DIN 84) LWRE 4LWERE 6 3 M 5 LWRE 6LWEREC 6 5 M 5 LWRE 6LWERE 9 3 M 6 LWRE 9LWEREC 9 6 M 6 LWRE 924

LWRE ACS <strong>rail</strong> <strong>guides</strong> with non-slip cage(Anti Creep System)Many users are familiar with “cagecreep”in conventional precision <strong>rail</strong><strong>guides</strong>. This effect occurs as a resultof high acceleration and uneven preloadingor load distribution. Thanksto a new design conceived by SKF LinearsystemeGmbH, this drift of thecage away from its intended positionis eliminated through a sophisticated“Anti Creep System”, in short ACS.<strong>Precision</strong> <strong>rail</strong> <strong>guides</strong> with ACS increasethe reliability of installationsand lead to extended operating periodsof the linear <strong>guides</strong>. Thus, damagedcages are a thing of the past.“Cage-creep” test resultsAxial displacement [mm]Moreover, the exchange of <strong>guides</strong>and the resultant need for readjustingthe machine or installation areeliminated.LWRE ACS <strong>rail</strong> <strong>guides</strong>are equivalent to LWRE <strong>rail</strong> <strong>guides</strong>,designed for use in non-slip LWAKEcages.The non-slip effect is achievedthrough a patented control gear attachedto the cage which is in meshbetween the LWRE ACS <strong>rail</strong>s duringoperation, thus retaining the cage inits defined position.The external dimensions of LWREACS <strong>rail</strong> <strong>guides</strong> are identical withthose of LWRE <strong>rail</strong> <strong>guides</strong>. The nonslipguide has been integrated in theexisting design. Thus, sizes LWRE 3ACS, LWRE 6 ACS and LWRE 9 ACSfit into the Modular Range system.Sizes LWRE 4 ACS and LWRE 2211ACS are available in addition. Split<strong>rail</strong> <strong>guides</strong>, <strong>rail</strong>s of tolerance class P2or P5 or protruding cages can besupplied upon request.Advantages• ACS eliminates “cage-creep”• Increased accuracy thanks todefined positioning of cage• Easily interchangeable with standardprecision <strong>rail</strong>s• Identical size thanks to integraldesign• Suitable for high acceleration, verticalmounting and uneven loaddistribution• Less downtime and lower maintenancerequirementsDistance travelled [km]Special cage of size 3 with ACSStandard crossed roller cage of size 325

LWRE ACS <strong>rail</strong> <strong>guides</strong> can be designedfor specified or maximum travelof the <strong>rail</strong> guide system. For systemswith specified travel, the length ofthe stroke is quoted after the suffixACS. LWAKE ACS cages must only beoperated over the specified strokelength.A <strong>rail</strong> guide with maximum travelis prepared for the use of ACS overits entire length. This may be requiredfor mounting, maintenance ordismounting purposes. When placingan order, this design is specified bythe suffix ACS, without a stroke, directlyafter the LWRE <strong>rail</strong> guide designation.Fig. 11 ALWRE ACS <strong>rail</strong> <strong>guides</strong> for “maximum travel” strokeOrdering designation forLWRE ACS <strong>rail</strong> <strong>guides</strong>:LWRE ACS <strong>rail</strong> guide for maximumtravel of the <strong>rail</strong> system (see Fig. 11A):LWRE <strong>rail</strong> ACSe.g. LWRE 6200 ACSLWRE ACS <strong>rail</strong> <strong>guides</strong> for specifiedtravel of the <strong>rail</strong> system (see Fig. 11B):LWRE <strong>rail</strong> ACS stroke (mm)e.g. stroke: 100 mm(cage travel: 50 mm)LWRE 6200 ACS 100 mmBecause of the many permutationsavailable, all parts of LWRE ACS<strong>rail</strong> <strong>guides</strong> are usually ordered separately,e.g.:Maximum travel:4 <strong>rail</strong>s2 crossed roller cages8 end piecese.g.:LWRE 6200 ACSLWAKE 6x12 ACS (147,3 mm)LWERE 6(see Fig. 11A)Specified travel:4 <strong>rail</strong>s2 crossed roller cages8 end piecese.g.:LWRE 6200 ACS 100 mmLWAKE 6x12 ACS (147,3 mm)LWERE 6(see Fig. 11B)OrderingTo facilitate the order routine, <strong>rail</strong>guide sets can also be ordered in kitpackaging (see pages 12 – 13).Fig. 11 BLWRE ACS <strong>rail</strong> <strong>guides</strong> for “specified travel” stroke26

Crossed roller assemblies for LWREACS <strong>rail</strong> <strong>guides</strong>Compared to LWAKE cages, LWAKEACS crossed roller cages incorporatean additional control gear located atthe centre of the cage. The load carryingcapacity of LWAKE ACS cages isidentical with that of LWAKE standardcages, provided that they comprisean identical number of rollers.However, it has to be taken into considerationthat, due to their additionalcontrol gear, LWAKE ACS cagesare longer than the correspondingLWAKE cages, even if the number ofrollers is identical. Protruding cagesshould be used only after consultationwith SKF.Ordering designation forLWAKE ACS cages:LWAKE ACS cages should be orderedas follows:LWAKE size x number of rollers ACSFor instance, an LWAKE 6 cage with12 rollers and ACS control gear hasthe designation LWAKE 6x12 ACS(147,3 mm).Design and mounting ofLWRE ACS <strong>rail</strong> <strong>guides</strong>Mounting of LWRE ACS <strong>rail</strong> <strong>guides</strong>proceeds to the same rules asmounting of SKF standard precision<strong>rail</strong>s. In addition, it is essential to observethat the ACS control gear isconstantly kept in mesh between the<strong>rail</strong>s during operation. Furthermore,the cage must never be subjected todirect or indirect external axial loads.The ACS control gear must not bedamaged during mounting, e.g.through the insertion of the ACS cagebetween the <strong>rail</strong>s against an endstop, or tilting or twisting of two adjacent<strong>rail</strong>s.Protection and lubrication ofLWRE ACS <strong>rail</strong> <strong>guides</strong>In order to ensure the impeccableoperation of the Anti Creep System,it should be protected against contaminationand relubricated with moderatequantities of SKF standardgrease. Any “blocking” or “gumming”of the element must be ruled out.End pieces for LWRE ACS<strong>rail</strong> <strong>guides</strong>As a rule, end pieces must not beused as a mechanical stroke limitationof the guidance system, as thiscan result in cage damage. End piecescan be used as a protectionagainst external influences.Special attachment screwsfor LWRE ACS <strong>rail</strong> <strong>guides</strong>For designation and dimensions,please refer to LWR, page 19. Thelisted special attachment screws oftype LWGD can also be used formounting LWRE ACS <strong>rail</strong> <strong>guides</strong>, iftheir respective size is taken intoconsideration.27

Accessories for LWRE ACS <strong>rail</strong> <strong>guides</strong>Crossed roller assembliesLWAKE 3, 6, 9 ACSLWAKE 4 ACSn = number of rollersFor description and data on crossed roller units, please see pages 21, 24 and 27.Designation Dimensions Load ratings Rail guidefor 10 needlerollersdesignationper rowdynamic staticD w t t 3 C C 0mmNLWAKE 3 ACS 4 6,25 9 6 300 8 500 LWRE 3 ACS, LWRE 2211 ACSLWAKE 4 ACS 6,5 8 17 17 300 20 800 LWRE 4 ACSLWAKE 6 ACS 8 11 15,3 34 000 39 000 LWRE 6 ACSLWAKE 9 ACS 12 16 22 78 000 78 000 LWRE 9 ACSEnd piecesSpecial attachment screwsFor designation and dimensionsplease see LWRE, page 24.For designation and dimensionsplease see LWR, page 19.LWGD28

LWRM/LWRV <strong>rail</strong> <strong>guides</strong>LWRM/LWRV <strong>rail</strong> <strong>guides</strong> offer guidancesystems with high load carryingcapacity and maximum stiffness.Needle roller assemblies forLWRM/LWRV <strong>rail</strong> <strong>guides</strong>LWHW needle roller assemblieshave aluminium cages with retainedneedle rollers. They are available forsize 6 and 9 units.When ordering, the appropriatecage length in mm should be statedafter the cage designation, e.g.:LWHW 10x225.End pieces forLWRM/LWRV <strong>rail</strong> <strong>guides</strong>End pieces serve to prevent the driftof the cage away from the loadedzone.LWEARM and LWEARV end piecesfeature a plastic wiper with a sealinglip that keeps the raceways free fromcontamination. All end pieces aresupplied with the appropriate attachmentscrews.The mounting and attachment dimensionsof LWRM/LWRV <strong>rail</strong> <strong>guides</strong>conform to those of all the SKFModular Range <strong>rail</strong> <strong>guides</strong> includedin this catalogue.Because of the many permutationsavailable, each part of anLWRM/LWRV <strong>rail</strong> guide must be orderedseparately, e.g.:2 <strong>rail</strong>s LWRM 904002 <strong>rail</strong>s LWRV 904002 needle roller assembliesLWHW 15x3582 end pieces LWEAM 929

LWRM/LWRV <strong>rail</strong> <strong>guides</strong>LWRM/LWRV 6 and LWRM/LWRV 9LWRMLWRVDesignation 1) Dimensions: Attachment holes End face holesSystemA B A 1 A 2 A 3 D w J J 1 J 2 G G 1 N N 1 J 3 J 4 J 5 J 6 G 2 G 3mmLWRM 6 31 15 16,5 – – 2 50 25 6 M 6 5,2 9,5 5,2 8,5 7 – – M 3 6LWRV 6 31 15 – 17,8 10,8 2 50 25 6 M 6 5,2 9,5 5,2 – – 7 6 M 3 6LWRM 9 44 22 23,1 – – 2 100 50 9 M 8 6,8 10,5 6,2 10 11 – – M 5 8LWRV 9 44 22 – 26,9 16,6 2 100 50 9 M 8 6,8 10,5 6,2 – – 10 6 M 5 81)Sizes LWRM/LWRV 12 and 15 as well as other <strong>rail</strong> lengths are available on request.30

Needle roller assemblies End pieces Special attachment screwwiperLWHWaluminiumLWEARVwith wiperwiperLWGDLWEARMwith wiperAvailable lengths Needle End pieces SpecialrollerattachmentassembliesscrewsL 1)100 150 200 250 300 350 400 500 600 700 800 900 1 000 LWHW LWEARM LWEARV LWGDº º º º º º º º º º••º º º º º º º º º º•-º º º º º º º º º ••º º º º º º º º º •--•-•••••• SKF Modular RangePreferred range, prompt delivery• Prompt deliveryº To special orderOrdering example: 2 LWRM 906002 LWRV 906002 LWHW 15 x 4504 LWEARM 931

LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong>LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong> are linear<strong>guides</strong> for limited travel, fittedwith Turcite-B ®1) slide coating.Based on PTFE, this material isself-lubricating and offers excellentsliding properties.The coating is bonded to the nonhardenedLWRPM <strong>rail</strong> and subsequentlyground to size. The LWRPV<strong>rail</strong> is hardened and ground. In orderto avoid damage to the sliding surfaceof the LWRPM <strong>rail</strong>, the leadingedges of the LWRPV <strong>rail</strong>s are slightlyrounded. Otherwise, the dimensionsof these <strong>rail</strong>s are the same as thoseof the LWRV series.LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong> shouldbe used where <strong>rail</strong> <strong>guides</strong> with rollingelement assemblies are unsuitabledue to external influences.Such applications include thosesubjected to high transverse accelerationthat may cause indentation ofthe rolling elements in the raceways,or where extremely short strokes arerequired. The unfavourable tribologicalconditions produced by such operationwould give rise to race-waypitting in a rolling element <strong>rail</strong> guide.The mounting and attachment dimensionsof the LWRPM/LWRPV <strong>rail</strong><strong>guides</strong> conform to those of all theSKF Modular Range <strong>rail</strong> <strong>guides</strong> includedin this catalogue.LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong> are characterisedby:• stick-slip-free operation• smooth running• good emergency running properties• low wear and high reliability• insensitivity to contamination• excellent vibration damping propertiesWhen ordering, the individual componentsof the <strong>rail</strong> <strong>guides</strong> must bespecified separately, e.g.:2 <strong>rail</strong>s LWRPM 63002 <strong>rail</strong>s LWRPV 63001)Turcite-B ® is a registered trademark ofBusak & Shamban GmbH33

LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong>LWRPM/LWRPV 3 – LWRPM/LWRPV 9LWRPMLWRPVDesignation 1) Dimensions: Attachment holesSystemA B A 1 A 2 A 3 J J 1 J 2 G G 1 N N 1mmLWRPM 3 18 8 9,5 – – 25 12,5 3,5 M 4 3,3 6 3,2LWRPV 3 18 8 – 9,6 6,45 25 12,5 3,5 M 4 3,3 6 3,2LWRPM 6 31 15 16,6 – – 50 25 6 M 6 5,2 9,5 5,2LWRPV 6 31 15 – 17,8 10,8 50 25 6 M 6 5,2 9,5 5,2LWRPM 9 44 22 23,1 – – 100 50 9 M 8 6,8 10,5 6,2LWRPV 9 44 22 – 26,9 16,6 100 50 9 M 8 6,8 10,5 6,21)Sizes LWRPM/LWRPV 12 and LWRPM/LWRPV 15 as well as other <strong>rail</strong> lengths are available on request.34

Slide coatingLWRPM <strong>rail</strong> <strong>guides</strong> are provided witha slide coating bonded to the racewaysand subsequently ground tosize. Separate ordering of the slidecoating is not required.End piecesBecause of their design, <strong>rail</strong> <strong>guides</strong>of these series do not normally requirethe use of end pieces.Special attachment screwsFor designations and dimensions,see page 19.Available lengthsL 1)050 075 100 125 150 175 200 225 250 275 300 350 400 450 500 550 600 650 700 800 900 1 000 LWGDSpecialattachmentscrewsº º º º º º º º º º ºº º º º º º º º º º ºº º º º º º ºº º º º º º ºº º º º º ºº º º º º ºº º º º º º º º ºº º º º º º º º º••••••• SKF Modular RangePreferred range, prompt delivery• Prompt deliveryº To special orderOrdering example: 2 LWRPM 64002 LWRPV 630035

Accessories for LWRPM/LWRPV <strong>rail</strong> <strong>guides</strong>Slide coatingDesignation 1) Dimensions load carrying Railcapacity 2)guidedesignationRail guide H CmmNLWRPM 3 0,7 300/100 mm LWRPV 3LWRPM 6 1,7 700/100 mm LWRPV 6LWRPM 9 1,7 1 200/100 mm LWRPV 91)The slide coating is an integral part of the LWRPM <strong>rail</strong> and does not have to be ordered separately.2)for a surface loading of approx. 1 N/mm 2 (momentary loads of up to 6 N/mm 2 are permissible).End piecesLWRPM/LWRPV <strong>rail</strong> <strong>guides</strong>, by virtue of their design,do not normally require end pieces.For this reason, tapped holes on the end faces are also unnecessary.However, for production reasons,LWRPV <strong>rail</strong> <strong>guides</strong> will in certain cases be supplied with end face holes.LWGDSpecial attachment screwsSee page 19 for designations and dimensions.36

LWM/LWV <strong>rail</strong> <strong>guides</strong>LWM/LWV <strong>rail</strong> <strong>guides</strong> enable the designof linear guidance systems forheavy loads with maximum stiffness.The internal geometry is identicalwith that of the Modular Range <strong>rail</strong>sof the LWRM/LWRV series. As thesame needle roller assembly is used,the load ratings are also the same.The external dimensions of theLWM/ LWV <strong>rail</strong> <strong>guides</strong>, however, differslightly from those of theLWRM/LWRV Modular Range dimensions.Yet LWM/LWV <strong>rail</strong> <strong>guides</strong> find wideapplication especially in machinetools. As standard they are suppliedwith attachment holes of type 15, i.e.through hole with counterbore.If attachment hole type 13 is ordered,corresponding threaded insertsare supplied along with theguide.For new designs the choice ofLWRM/LWRV <strong>rail</strong> <strong>guides</strong> is recommended.These offer the advantageof being interchangeable with other<strong>rail</strong> <strong>guides</strong> of the Modular Range.Needle roller assemblies forLWM/LWV <strong>rail</strong> <strong>guides</strong>LWHW needle roller assembliescomprise an aluminium cage withneedle rollers arranged at right anglesto each other. The needle rollersare retained by the cage.End pieces for LWM/LWV <strong>rail</strong> <strong>guides</strong>End pieces serve to prevent drift ofthe cage away from the loaded zone.LWEAM and LWEAV end pieces havethe addition of a plastic wiper with asealing lip that keeps the racewayfree from dirt.All end pieces are supplied togetherwith attachment screws.Rail <strong>guides</strong> with a length of morethan 1 200 mm should be made upof sections. If, for design reasons,one-piece <strong>rail</strong>s are required, thesecan be supplied to special order.37

LWM/LWV <strong>rail</strong> <strong>guides</strong>LWM/LWV 3015 – LWM/LWV 8050Locktyp 13 Locktyp 13Locktyp 15LWM <strong>rail</strong>Locktyp 15LWV <strong>rail</strong>Designation Dimensions: Attachment holes End face holesSystemsA B A 1 A 2 A 3 D w J 1) J 1min2)J2 G N N 1 N 2 J 3 J 4 J 5 J 6 G 1 G 2mmLWM 3015 30 15 16 – – 2 40 15 5,5 M 4 8,5 4,5 5,25 8 7 – – M 3 6LWV 3015 30 15 – 17,2 10,5 2 40 15 5,5 M 4 8,5 4,5 5,25 – – 7 5,5 M 3 6LWM 4020 40 20 22,3 – – 2 80 15 7,5 M 6 11,5 6,8 7,5 10 11 – – M 5 7LWV 4020 40 20 – 22 13,5 2 80 15 7,5 M 6 11,5 6,8 7,5 – – 10,5 5,5 M 5 7LWM 5025 50 25 28 – – 2 80 20 10 M 6 11,5 6,8 7,5 12 13 – – M 6 8LWV 5025 50 25 – 28 17 2 80 20 10 M 6 11,5 6,8 7,5 – – 13 7 M 6 8LWM 6035 60 35 36 – – 2,5 100 20 11 M 8 15 9 10 14 20 – – M 6 8LWV 6035 60 35 – 36 20 2,5 100 20 11 M 8 15 9 10 – – 18 8 M 6 8LWM 7040 70 40 40 – – 3 100 20 13 M 10 18,5 11 12,5 16 20 – – M 6 8LWV 7040 70 40 – 42 24 3 100 20 13 M 10 18,5 11 12,5 – – 20 10 M 6 8LWM 8050 80 50 45 – – 3,5 100 20 14 M 12 20 13 14 20 30 – – M 6 8LWV 8050 80 50 – 48,5 26 3,5 100 20 14 M 12 20 13 14 – – 25 10 M 6 81)for lengths L < J + 2 · J 1 min , J = 50 mm (except for LWM/LWV 3015)2)J 1 depends upon the <strong>rail</strong> length and is of the same size at each end of the <strong>rail</strong>J 1 = L – ∑ J23)J = 35 mm38

Needle roller assembliesEnd pieceswiperwiperLWHW aluminium LWEAMwith wiperLWEAVwith wiperAvailable lengths 4) Needle roller End piecesassemblies100 150 200 300 400 500 600 700 800 900 1 000 LWHW LWEA LWEAV3)• • • • • º º3)• • • • • º º• • • • • º º º º º º• • • • • º º º º º º• • • • • º º º º º• • • • • º º º º ºº º º º º º º º ºº º º º º º º º ºº º º º º º º º ºº º º º º º º º ººººººººººººººººººº•••••••••••••••ººº•••ººº4)other lengths available on request•ºavailable from stockavailable to orderOrdering example: 2 LWM 40202002 LWV 40202002 LWHW 15x1304 LWEAM 402039

Accessories for LWM/LWV <strong>rail</strong> <strong>guides</strong>Needle roller assembliesLWHV plastics LWHW aluminiumFor description and data on crossed roller assemblies, please see page 37.Designation Dimensions Load ratings Railfor 10 needle rollers guide designationper rowD w L w U t t 1 dynamic staticC C 0mm NLWHW 10 2 4,8 10 3,75 2,7 10 400 25 500 LWM/LWV 3015LWHV 15 2 7,8 15 3,75 2,7 16 300 45 000 LWM/LWV 4020 + 5025LWHW 15* 2 6,8 15 4,5 3,5 14 600 42 500 LWM/LWV 4020 + 5025LWHV 20 2,5 11,8 20 5 3,7 32 000 88 000 LWM/LWV 6035LWHW 20* 2,5 9,8 20 5,5 4,0 26 000 76 550 LWM/LWV 6035LWHW 25* 3 13,8 25 6 4,5 43 100 129 400 LWM/LWV 7040LWHW 30* 3,5 17,8 30 7 5,0 64 500 195 000 LWM/LWV 8050End pieceswiperwiperLWEMLWEAMLWEVDesignation Dimensions Appropriateattachmentwithout with screwswiper wiper L L 1mmLWEAVLWEM 3015 4 M 3 DIN 84LWEV 3015 4 M 3 DIN 84LWEAM 3015 6 M 3 DIN 84LWEAV 3015 6 M 3 DIN 84LWEM 4020 6,3 M 5 DIN 84LWEV 4020 6,3 M 5 DIN 84LWEAM 4020 8,3 M 5 DIN 84LWEAV 4020 8,3 M 5 DIN 84LWEM/LWEV 5025 bis 8050 6,9 M 6 DIN 84LWEAM/LWEAV 5025 bis 8050 8,9 M 6 DIN 84* Higher load ratings are available on request40

LWJ/LWS flat <strong>rail</strong> <strong>guides</strong>LWJ/LWS flat <strong>rail</strong> <strong>guides</strong> are used inconjunction with LWRM/LWRV,LWM/LWV or LWN/LWO <strong>rail</strong> <strong>guides</strong>as non-locating linear <strong>guides</strong>. Theyare incorporated in floating slides.LWJ/LWS flat <strong>rail</strong> <strong>guides</strong> as well asthe appropriate rolling element assembliesand end pieces are availableto order.41

LZM miniature slidesWith the new LZM miniature slideproduct range SKF offers the idealsolution for linear motion applicationsfor short strokes and compactboundary dimensions. The use ofminiature slides has increased inmedical applications, measurementtechnologies and micro mechanics &assembly.The different LZM miniature slidecomponents meet the highest precisionstandards. LZM miniature slidesfeature high running accuracy andsmooth motion.The LZM miniature slides are manufacturedwith all stainless steelcomponents. Optimized hardnessenables long endurance life and highperformance within compact boundarydimensions.The new LZM miniature slides havebeen designed to ensure high systemstiffness and precision guidance.Running accuracies of 2 μm overa stroke of 100 mm are attainabledepending on the particular application.Ease of installation is anotheradvantage of the LZM miniature slides.Unlike cross roller systems using4 <strong>rail</strong>s and cages to be assembled onthe production floor, the LZM slideprovides a complete slide that cansimply be bolted into place withoutthe use of precision devices to setpreload.Every application provides newchallenges for the modern designer.SKF will modify existing designs tomeet your specific technical requirements.Applications:• Pneumatics• Semi conductor manufacturing• Medical• Micro- and electronics assembly• Measurement applications• Fiber opticsAdvantages:• Compact design• High carrying capacity• Very good running accuracy• Smooth running• High stiffness• Easy assemblyTechnical dataStructureFour-point contact with identical load anglesRange Four (4) sizes (7, 9, 12 and 15)Temperature resistance From -20 °C up to +80 °CSpeedUp to 3 m/sAccelerationUp to 80 m/s 2 (preloaded system)Preload class Three (3) preload classes (T0, T1 and T2)T0 = standard, light clearanceT1 = light preload, very slight clearanceT2 = medium preload, no clearanceAccuracy class Two (2) accuracy classes (P1 and P5)P1 = highP5 = standard, for most applicationsLubrication Slides are pre-lubricated with “Paraliq P460”Material specificationsCarriage & <strong>rail</strong> Steel 1.4034Balls Steel 1.4034End piecePlasticCagePlastic42

LZM miniature slideM cM aM bType W W 2 W 3 L 2 M 1 x depth d3 x d2 x h H H 1 M 2 FmmLZM HS 7 17 12 7 8 M2 x 2,5 2,5 x 4,5 x 2,5 8 2,35 M3 15LZM HS 9 20 15 9 13 M3 x 3 3,5 x 6,0 x 3,5 10 3,55 M4 20LZM HS 12 27 20 12 15 M3 x 3,5 3,5 x 6,0 x 4,5 13 4,7 M4 25LZM HS 15 32 25 15 20 M3 x 4 3,5 x 6,0 x 4,5 16 6 M4 40Type L L 4 E L 1 max. stroke Number of holes C C 0 Ma/Mb Mccarriage <strong>rail</strong>mm - N NmLZM HS 7 26 29 5,5 5 24 6 2 700 1 100 3,5 634 37 9,5 5 34 8 2 900 1 400 5,5 750 53 10 5 50 12 3 1 100 2 000 12 1066 69 10,5 5 66 16 4 1 400 2 700 21 14LZM HS 9 32 35 8 9,5 28 4 2 1 200 1 800 7 1242 45 11 8 40 6 2 1 400 2 100 11 1555 58 7,5 8 54 8 3 1 900 3 400 18 1981 84 10,5 8 78 12 4 2 500 4 900 43 2994 97 7 8 92 14 5 2 700 5 500 57 33LZM HS 12 37 40 6 11 32 4 2 2 200 3 300 11 2151 54 13 10,5 47 6 2 2 600 4 300 22 2866 69 8 10,5 62 8 3 3 000 5 300 36 3696 99 10,5 10,5 95 12 4 3 800 7 200 76 52126 129 13 10,5 122 16 6 4 700 9 700 131 68LZM HS 15 52 56 6 12,5 50 4 2 2 800 3 900 25 4285 89 22,5 12,5 80 8 2 4 600 7 800 73 70105 109 12,5 12,5 102 10 3 5 100 9 100 106 84165 169 22,5 12,5 162 16 4 7 300 15 000 264 131Miniatur slide unit Standard Size Length (L)Order example: LZM HS 9 - 3243

Standard slidesDesign and characteristic featuresGeneralThe range of slides shown in this catalogueis standardised in terms ofdesign, sizes and type of bearing. Slidesdiffering from those included here,in design and drill hole patterncan only be produced economically inlarge batches.GCL standard slidesSlide top and base of blackened steelor GG25 (cast iron) depending onsize.These slides are provided withstandard patterns of mounting holes.The slide top carries tapped holesand the base plate counterbored holesto DIN 74 Form K for cylindricalscrews to DIN 912. Both the upperand lower surfaces of the slides areground. The surface of the side oppositeto the set screws is groundparallel to the slide axis and can thereforebe used as a reference face.Internal stops serve as stroke limits.The slides are fitted with SKF precision<strong>rail</strong> <strong>guides</strong> type LWR with crossroller cage assemblies type LWAK(plastic) for GCL 3 or type LWAL (aluminium)for GCL 6. The mountingorientation is optional.44

Technical dataTolerancesSlide straightness:height Tzside TyGCL and RM standard slidesStroke [mm]Tolerance (P10) 25 50 100 200 300 400 500μmStraightness: height Tz 2 2 3 3 4 4 5Straightness: side Ty 2 2 2 3 3 4 4Specific featuresThe standard slides are fitted withlimited-stroke <strong>rail</strong> <strong>guides</strong>, with crossroller units.Permissible speed and accelerationThe <strong>rail</strong> <strong>guides</strong> can run at speeds upto 2 m/s and accelerations up to10 m/s 2 are acceptable.PreloadPreload is applied by set screws fittedalong one side of the slide top. Thestandard slides are preloaded toapproximately 10 % of the static loadrating.MaterialsGCL Standard slides• slide top and base: blackened steelor GG25 (cast iron), depending onsizeFor all slides• guide <strong>rail</strong>s: tool steel 90MnCrV9(1.2842) hardened• rolling elements: carbon chromiumsteel 100Cr6 (1.3505) hardened• cage: plastic PA12 or aluminium,depending on sizePermissible operating temperature–30 °C to +80 °CFrictionThe slides are free from stickslip.With normal light lubrication theyhave a coefficient of friction of between0,003 and 0,005.LubricationRail <strong>guides</strong> of standard slides arelightly greased on assembly with SKFLGMT2 grease, a multi-purposelithium based grease which alsoserves as protection against corrosion.It can be used in all standardapplications.45

Standard slidesGCL - Drill hole pattern in top plateDesignationsDimensionsStrokeB H L S B 1 B 2 B 3 D w G G 1 H 1 H 2 H 3 H 4 J J 1 J 2–0,2 ±0,1–0,4mmGCL 3050 60 28 55 30 28 46 10 3 M4 M4 9 18,5 10 8 – 27,5 25GCL 3075 80 45 1x25GCL 3100 105 60 2x25GCL 3125 130 75 3x25GCL 3150 155 90 4x25GCL 3175 180 105 5x25GCL 3200 205 130 6x25GCL 6100 100 45 110 60 45 76 14 6 M6 M5 13 31 15,5 15 – 55 50GCL 6150 160 95 1x50GCL 6200 210 130 2x50GCL 6250 260 165 3x50GCL 6300 310 200 4x50GCL 6400 410 280 6x5046

Standard slidesGCL - Drill hole pattern in base plateLoad carryingcapacityJ 3 J 4 J 5 J 6 J 7 J 8 J 9 J 10 Fig N N 1 T C eff C 0Mass5,5 1x25 15 39 17 25 10 40 1 4,5 8 4,6 1 030 480 0,5710,5 2x25 1 1 535 800 0,8015,5 3x25 1 1 883 1 040 1,020,5 4x25 1 2 322 1 360 1,325,5 5x25 3 2 636 1 600 1,530,5 6x25 3 3 038 1 920 1,730,5 7x25 4 3 234 2 080 2,016 1x50 30 64 26 50 10 60 1 6,6 11 6,8 5 150 2 380 3,123,5 2x50 1 7 327 3 740 4,531 3x50 3 8 844 4 760 5,938,5 4x50 3 10 759 6 120 7,246 5x50 3 12 134 7 140 8,656 7x50 4 15 186 9 520 11,447

Notes48

Notes49

Notes50

Notes51

Linear guidingsContactsLinear motion from SKFwww.linearmotion.skf.comBeneluxSKF Multitec Benelux B.V.NederlandTel +31 030 6029 029Fax +31 030 6029 028België & LuxembourgTel +32 25 024 270Fax +32 25 027 336E-mail multitec_benelux@skf.comBrasilSKF do Brasil LtdaTel +55 11 461 991 114Fax +55 11 461 991 99E-mail marketing.skf@skf.com.brCanadaSKF Canada LimitedTel +1 416 299 1220Fax +1 416 299 6548E-mail www.marketing@skf.caDanmarkSKF MultitecTel +45 65 92 77 77Fax +45 65 92 74 77E-mail customerservice.multitec@skf.comDeutschland & ÖsterreichSKF Linearsysteme GmbHTel +49 9721 657 232/233Fax +49 9721 657 111E-mail lin.sales@skf.comEspaña & PortugalSKF Productos Industriales S.A.Tel +34 93 377 99 07/-77Fax +34 93 474 2039/-2156E-mail prod.ind@skf.comFranceSKF EquipementsTel +33 1 30 12 73 00Fax +33 1 30 12 69 09E-mail equipements.france@skf.comItaliaSKF Multitec S.p.A.Tel +39 011 22 49 01Fax +39 011 22 49 233E-mail multitec.italy@skf.comMexicoSKF de México S.A. de C.VTel +52 222 229 4900Fax +52 222 229 4908Web www.skf.com.mxNorgeSKF MultitecTel +47 22 90 50 00Fax +47 22 30 28 14E-mail customerservice.multitec@skf.comSchweizSKF LM&PTTel +41 44 825 81 81Fax +41 44 825 82 82E-mail skf.schweiz@skf.comSuomiSKF MultitecTel +358 9 615 00 850Fax +358 9 615 00 851E-mail multitec.nordic@skf.comSverigeSKF MultitecTel +46 42 253 500Fax +46 42 253 545E-mail customerservice.multitec@skf.comU.K.SKF (UK) Ltd.Tel +44 1582 496 735Fax +44 1582 496 574E-mail a&mc.uk@skf.comUSASKF Motion TechnologiesTel +1 610 861 4800Toll free +1 800 541 3624Fax +1 610 861 3716 4811E-mail motiontech.usa@skf.comOther countriesFax +49 972 657 118E-mail guidings@skf.comRepresented by:SKF is a registered trademark of the SKF Group.© SKF Group 2006 2006The contents of this publication are the copyright of the publisher and may not be reproduced (even extracts) unless prior written permission is granted.Every care has been taken to ensure the accuracy of the information contained in this publication but no liability can be accepted for any loss or damagewhether direct, indirect or consequential arising out of the use of the information contained herein.Publication 4183EN - 0609BPublication 0000EN 0601APrinted in GermanyPrinted in Sweden