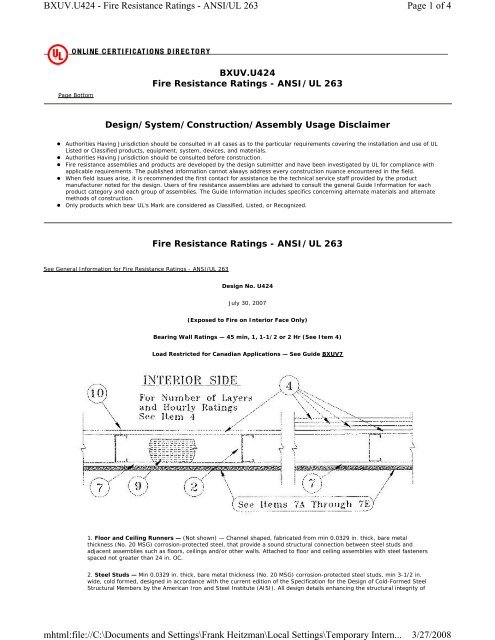

an example of a U.L. tested wall assembly fire rating

an example of a U.L. tested wall assembly fire rating

an example of a U.L. tested wall assembly fire rating

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

BXUV.U424 - Fire Resist<strong>an</strong>ce Ratings - ANSI/UL 263mhtml:file://C:\Documents <strong>an</strong>d Settings\Fr<strong>an</strong>k Heitzm<strong>an</strong>\Local Settings\Temporary Intern...Page 3 <strong>of</strong> 43/27/2008metal <strong>wall</strong> ties attached to each stud with steel screws, not more th<strong>an</strong> each sixth course <strong>of</strong> brick.B. Cementitious Backer Units* — 1/2 or 5/8 in. thick p<strong>an</strong>els, attached to steel studs overgypsum sheathing with 1-5/8 in. long, Type S-12, corrosion resist<strong>an</strong>t, wafer-head steel screws,spaced 8 in. OC. Studs spaced a max <strong>of</strong> 16 in. OC. Joints covered with glass fiber mesh tape.UNITED STATES GYPSUM CO — Durock Exterior Cement Board or Durock Br<strong>an</strong>d Cement Board.C. Foamed Plastic* — Aged exp<strong>an</strong>ded polystyrene (EPS) board per ASTM C578, with a nomdensity not less th<strong>an</strong> 1 pcf, R-value 3.8 min per in. with a flame spread <strong>of</strong> less th<strong>an</strong> 25 <strong>an</strong>d a smokedeveloped <strong>of</strong> less th<strong>an</strong> 450, adhered to the gypsum sheathing (Item 7) or to the cementitiousbacker units (Item 7B) with USG Exterior Insulation Board Adhesvie. See Foamed Plastic (BRYX<strong>an</strong>d/or CCVW) Categories for names <strong>of</strong> Classified comp<strong>an</strong>ies.D. Wall <strong>an</strong>d Partition Facings <strong>an</strong>d Accessories* — Min 3/32 in. thick, applied over the gypsumsheathing (Item 7) or the cementitious backer units (Item 7B) or the insulation board (Item 7C), toembed <strong>an</strong> open-weave fiberglass mesh (mesh weighing not less th<strong>an</strong> 4.5 oz per sq yd, treated foralkaline resist<strong>an</strong>ce). Instructions provided with the product shall be consulted regarding limitationson the use <strong>of</strong> the product.UNITED STATES GYPSUM CO — USG Exterior BasecoatE. Wall <strong>an</strong>d Partition Facings <strong>an</strong>d Accessories* — Min 1/16 in. thick, applied over basecoat(Item 7D). Instructions provided with the product shall be consulted regarding limitations on theuse <strong>of</strong> the product.UNITED STATES GYPSUM CO — USG Exterior Textured Finish or USG Exterior Stone Finish8. Furring Ch<strong>an</strong>nels — (Optional, not shown, for single or double layer systems) — Resilient furring ch<strong>an</strong>nels fabricatedfrom min 25 MSG corrosion-protected steel, spaced vertically a max <strong>of</strong> 24 in. OC. Fl<strong>an</strong>ge portion attached to eachintersecting stud with 1/2 in. long Type S-12 steel screws. Not for use with Type FRX gypsum p<strong>an</strong>els.9. Batts <strong>an</strong>d Bl<strong>an</strong>kets* — (Optional, not shown) — Placed in stud cavities, <strong>an</strong>y glass fiber or mineral wool insulationbearing the UL Classification Marking as to Surface Burning Characteristics <strong>an</strong>d/or Fire Resist<strong>an</strong>ce. See Batts <strong>an</strong>dBl<strong>an</strong>kets (BKNV <strong>an</strong>d/or BZJZ) Categories for names <strong>of</strong> Classified comp<strong>an</strong>ies.10. Joint Tape <strong>an</strong>d Compound — Vinyl or casein, dry or premixed joint compound applied in two coats to joints <strong>an</strong>dscrew heads <strong>of</strong> interior face layer. Paper tape, nom 2 in. wide, embedded in first layer <strong>of</strong> compound over all joints <strong>of</strong>interior face layer. Paper tape <strong>an</strong>d joint compound may be omitted when gypsum boards are supplied with square edges.11. Caulking <strong>an</strong>d Seal<strong>an</strong>ts* — (Optional, not shown) — A bead <strong>of</strong> acoustical seal<strong>an</strong>t applied around the partitionperimeter on interior side for sound control.UNITED STATES GYPSUM CO — Type AS12. Lead Batten Strips — (Not Shown, For use with Item 4A) - Lead batten strips, min 1-1/2 in. wide, max 10 ft long witha max thickness <strong>of</strong> 0.125 in. Strips placed on the interior face <strong>of</strong> studs <strong>an</strong>d attached from the exterior face <strong>of</strong> the stud withtwo 1 in. long Type S-12 p<strong>an</strong> head steel screws, one at the top <strong>of</strong> the strip <strong>an</strong>d one at the bottom <strong>of</strong> the strip. Lead battenstrips to have a purity <strong>of</strong> 99.9% meeting the Federal specification QQ-L-201f, Grade "C". Lead batten strips required behindvertical joints <strong>of</strong> lead backed gypsum <strong>wall</strong>board (Item 4A) <strong>an</strong>d optional at remaining stud locations. Required behindvertical joints.13. Lead Discs or Tabs — (Not Shown, For use with Item 4A) - Used in lieu <strong>of</strong> or in addition to the lead batten strips(Item 12) or optional at other locations - Max 3/4 in. diam by max 0.125 in. thick lead discs compression fitted or adheredover steel screw heads or max 1/2 in. by 1-1/4 in. by max 0.125 in. thick lead tabs placed on gypsum boards (Item 4A)underneath screw locations prior to the installation <strong>of</strong> the screws. Lead discs or tabs to have a purity <strong>of</strong> 99.9% meeting theFederal specification QQ-L-201f, Grade "C".*Bearing the UL Classification MarkLast Updated on 2007-07-30Questions? Notice <strong>of</strong> Disclaimer Page TopCopyright © 2008 Underwriters Laboratories Inc. ®The appear<strong>an</strong>ce <strong>of</strong> a comp<strong>an</strong>y's name or product in this database does not in itself assure that products so identified have been m<strong>an</strong>ufactured

BXUV.U424 - Fire Resist<strong>an</strong>ce Ratings - ANSI/UL 263mhtml:file://C:\Documents <strong>an</strong>d Settings\Fr<strong>an</strong>k Heitzm<strong>an</strong>\Local Settings\Temporary Intern...Page 4 <strong>of</strong> 43/27/2008under UL's Follow-Up Service. Only those products bearing the UL Mark should be considered to be Listed <strong>an</strong>d covered under UL's Follow-UpService. Always look for the Mark on the product.UL permits the reproduction <strong>of</strong> the material contained in the Online Certification Directory subject to the following conditions: 1. The GuideInformation, Designs <strong>an</strong>d/or Listings (files) must be presented in their entirety <strong>an</strong>d in a non-misleading m<strong>an</strong>ner, without <strong>an</strong>y m<strong>an</strong>ipulation <strong>of</strong> thedata (or drawings). 2. The statement "Reprinted from the Online Certifications Directory with permission from Underwriters Laboratories Inc." mustappear adjacent to the extracted material. In addition, the reprinted material must include a copyright notice in the following format: "Copyright ©2008 Underwriters Laboratories Inc.®"