safety data sheet - North West Sealants

safety data sheet - North West Sealants

safety data sheet - North West Sealants

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

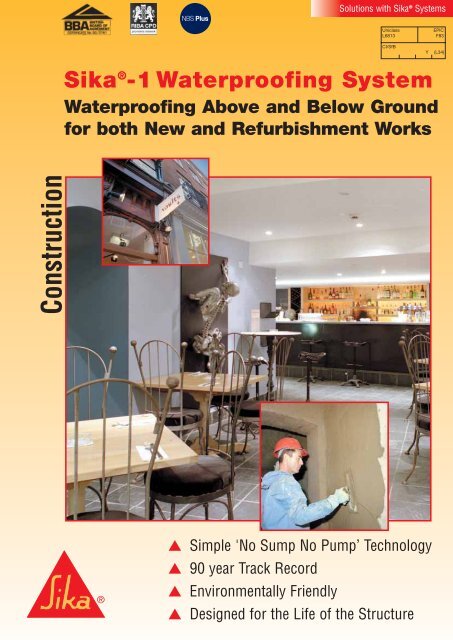

Solutions with Sika ® SystemsUniclassL6813EPICF83Sika ® -1 Waterproofing SystemWaterproofing Above and Below Groundfor both New and Refurbishment WorksCI/SfBY(L34)Construction▲ Simple 'No Sump No Pump’ Technology▲ 90 year Track Record▲ Environmentally Friendly▲ Designed for the Life of the Structure

The Components of Sika ® -1 WaterThe Sika ® -1 Waterproofing System can be designed to“keep water in” or to “keep water out”.With rising groundwater in many areas, coupled with the ever increasingcommercial need to optimise land usage by creating and re-creating habitablebasement areas, there is a need for effective and durable waterproofing in bothnew and refurbishment works.Similarly, with ever stricter controls on water quality, many existing structures,for the retention of potable water or for the protection of ground water fromeffluents, will need upgrading.Applied internally or externally, the cementitious Sika ® -1 WaterproofingSystem has provided the answers for over 90 years. Using neither sumps orpumps the Sika ® -1 Waterproofing System forms an integral part of thestructure to which it is applied, and is designed to last the lifetime of that structure.▲ Keeping Water Out▲ Basements▲ Underground Car Parks▲ Metro Stations and Subways▲ Utility Vaults▲ Marine Structures▲ TunnelsSika ® -1 Mortar TechnologyDense impervious mortar is produced by minimisingcapillaries and using pore blocking techniques.▲ Keeping Water In▲ Reservoirs▲ Water Tanks▲ Waste Water Treatment Plants▲ Secondary Containment Bunds▲ Swimming Pools▲ Sewers and Pipelines2▲ Keeping Water In ▲ Keeping Water Out ▲ Keeping Water In

proofing SystemThe Sika ® -1 Waterproofing Systemconsists of a specialist liquid admixture andpre-bagged quality controlled mortars.Sika ® -1 mortars consist of kiln driedpre-batched precision graded aggregates andcements, in 3 easily identifiable grades withsimple colour striping to ensure site qualitycontrol.Sika ® -1 admixture is a colloidal silicate liquid,diluted and incorporated into the mortar mixproducing a complete waterproofing system.Durability“Under normal conditions of use, theSika ® -1 Structural WaterproofingSystem will provide an effective barrier to thetransmission of liquid water for the life of thebuilding to which it is applied”.As quoted in British Board of Agrément Certificate. Number00/3761 Section 15.Jointing TechnologyConstruction joints and movement jointsmust be sealed using theSikaDur ® -Combiflex ® SystemPenetrationsPipe entries, service ducts etc must be sealedincorporating SikaSwell ® hydrophillic profilesand Sikaflex ® <strong>Sealants</strong>3 coats ofSika ® -1WaterproofingSystemSikaDur ® -Combiflex ®Jointing Systemat floor/walljunctionKeeping Water Out ▲ Keeping Water In ▲ Keeping Water Out3

Sika ® -1 Waterproofing SystemNote: Full installation guide and detailing <strong>sheet</strong>s for Sika ® -1 Waterproofing System are available on request1. All materials must be stored inclean dry conditions2. Suitably qualified and experiencedcontractors should be used.3. All surfaces must be thoroughlymechanically prepared.7. Immediately prior to installation ofSika ® -1 Waterproofing System,saturate the surface with clean water.8. The first wall coat of Sika ® -1Spritz Mortar is "cast" vigorouslyonto the wall at 6mm thickness.9. The 2nd and 3rd wall coats ofSika ® -1 Render and FinishingMortar are trowel applied to aminimum 6mm per coat.13. A Sika ® -1 Bonding CoatMortar is brush applied as a slurryto the prepared floors.14. The 2nd and 3rd coats of Sika ® -1Screed Mortar are applied to thefloor by trowel and lapped onto wallfinishes.15. All service entries must be filled withSika ® -1 Waterproofing Systemand sealed using high performancesealants Sikaflex ® -11FC+,SikaSwell ® or SikaDur ® -Combiflex ® System.4▲ Keeping Water In ▲ Keeping Water Out ▲ Keeping Water In

Application Guide4. All joints should be protected bySikaDur ® -Combiflex ® Systemincorporated within the render.5. Sika ® -1 Waterproofing admixtureshould be diluted 1:10 with freshclean water to make up a gaugingsolution.6. Sika ® -1 pre batched Mortars mustbe mixed in forced action mixers usingSika ® -1 gauging solution.10.Keying between trowelled mortars isachieved by application of splattercoats of Sika ® -1 Spritz Mortar.11.Dry joints in wall finishes should belapped by a minimum of 100mm.Similarly wall finishes should belapped onto floors.12. If no SikaDur ® -Combiflex ®System joint is used at floor/wallinterface, a Sika ® -1 RenderMortar corner fillet must be included.16. Fixings must be secured usingSikaDur ® -31, Sika Powerfix ®resin adhesives, or Sikaflex ® -11FC+ polyurethane adhesivesealants.Do Not Drill into system17. Final plaster finishes suitable fordecoration can be produced withSikaMur ® Finish.18. For additional demands such asmechanical and chemical resistance,or crack bridging etc; use compatibleSikaGard ® or Sikafloor ® coatings.Keeping Water Out ▲ Keeping Water In ▲ Keeping Water Out5

The Requirements for Waterproofing Basements(BS 8102 - 1990). Code of Practice for Protectionof Structures Against Water from the GroundGrade1Grade2Typical Structure &RequirementsBasic utility.Basement Car Parks.Plant rooms (excludingelectrical equipment).BS 8102:Grade 1: Slight seepage anddamp patches are tolerable.Residential and CommercialBasementsWorkshops, plant rooms and retailstorage where a drier environmentis required.BS 8102:Grade 2: No water penetrationbut moisture vapour tolerable.Sika ® Solutions- Sika ® -1 Waterproofing System- SikaDur ® -Combiflex ® System- Sika ® -1 Waterproofing System- SikaDur ® -Combiflex ® SystemGrade3Ventilated residential and workingareas including offices, restaurantsand leisure facilities.BS 8102:Grade 3: A dry environment isrequired and water penetration isintolerable.- Sika ® -1 Waterproofing System- SikaDur ® -Combiflex ® SystemGrade4Use for archives, storage ofsensitive material, i.e. computerrooms.BS 8102:Grade 4: A totally dry environment.Vapour impermeable.- Sika ® -1 Waterproofing System- SikaDur ® -Combiflex ® System- Sika ® EpoCem ® Systems- SikaDur ® Liquid Damp-ProofMembrane- SikaGard ® Coatings6Additional performancerequirements▲ Hygenic and easy to clean▲ Approved for contact withdrinking water▲ Crack bridging▲ Chemically resistant▲ De-icing salt resistant▲ Waste water resistantSika ® Solutions- Sika ® -1 Waterproofing System andjoint sealing systems as Grade 3and 4 above.Plus:- Sika ® EpoCem ® Systems- SikaTop ® cementitious renderdependent on the specific requirements.- SikaGard ® coatings▲ Keeping Water In ▲ Keeping Water Out ▲ Keeping Water In

Sika ® Vapour Barrier Systems▲ Impermeable Moisture Barriers▲ Solvent Free▲ Fast Track Construction▲ Unique Sika ® Epocem ® TechnologyWhere total vapour impermeability is demanded in addition to structural waterproofingas part of a Grade 4 system under BS 8102, this can be achieved by using a Sika ®Vapour Barrier System.Sika ® Vapour Barrier Systems comprise SikaGard ® -720 EpoCem ® for wallsand Sikafloor ® -81 EpoCem ® for floors sealed with solvent free SikaGard ® andSikafloor ® epoxy resin coatings.SikaGard ® and Sikafloor ® EpoCem ® provide a temporary moisture and vapourbarrier allowing the application of the appropriate SikaGard ® / Sikafloor ® solventfree epoxy resin coating to produce a permanent and moisture vapour resistant finish.Similarly, this system can be used on new concrete structures where residual moisturelevels are too high for the installation of finishes.Alternatively, SikaDur ® Liquid Damp-Proof Membrane can be installedwhere there is no current anticipated water pressure to help achieve a Grade 4installation under BS 8102 – please contact Sika for full technical advice.Excess moisturevapour absorbedby free cement inSikafloor ® ®-81 EpoCemSikaGard ® /SikaDur ®Sikafloor ® coatingKeeping Water Out ▲ Keeping Water In ▲ Keeping Water Out 7

Sika ® -1 Waterproofing System Case StudiesDeptford Town HallLondonProblems▲ Now part of Goldsmiths College, the Old Town Hall atDeptford has a basement constructed from brickworkwhich provided an ideal area for conversion into anational archive for the storage and study of historicfabrics.▲As with many 19th Century basements, over the years,the original waterproofing had become ineffective withevidence of damp and water ingress causing severedeterioration to the building fabric.Requirements▲ Complete internal waterproofing system.▲ Proven ‘last the lifetime of the building’ systemto protect valuable artefacts.▲ Totally controlled environment to Grade 4 use inaccordance with BS 8102.▲ Smooth plaster finish ready to accept decoration.Sika ® Solutions▲ All exposed brickwork repaired, re-pointed and bushhammered to provide a rough surface.▲ Existing concrete floor mechanically cleaned.▲ SikaDur ® -Combiflex ® System to all potentialmovement joints.▲ Sika ® -1 three layer waterproofing system to floors andwalls.▲ 2 coats of SikaDur ® Liquid Damp ProofMembrane to provide vapour barrier.▲ Finished surface provided by SikaMur ® Dry andSikaMur ® Finish renovating plasters.▲ All materials installed to provide Grade 4 of BS 81028▲ Keeping Water In ▲ Keeping Water Out ▲ Keeping Water In

Sika ® -1 Waterproofing System Case StudiesWellington ArchWar MemorialLondonBuilt in 1928 to commemoratethe Battle of WaterlooRefurbishment Project completed 2000Problem▲ Previously used for storage by Park Rangers fromthe nearby Hyde Park the memorial had been leftunoccupied for years allowing water penetrationinto the basement and subsequent deterioration ofthe internal building fabric.Requirements▲ As part of a full scale renovation for the millenniumby English Heritage, the leaking basement was to beconverted to a clean, dry visitor centre.▲ Provide a permanently dry underground structurefor commercial use, including offices and toilets.In accordance with Grade 3 BS 8102.▲ To ensure water tight connections betweennew suspended floor slabs and existing walls▲ Maintain the historic character of this listedstructure.Sika ® Solutions▲ Full mechanical preparation of all barrelvaulted basements▲ Sika ® -1 three layer waterproofing systemto floor and walls▲ Installation of SikaDur ® -Combiflex ® Systemat wall to floor connections.▲ Sikaflex ® -11FC+ fast curing one partpolyurethane elastic sealant adhesive forfixing skirtings and architraves.▲ All materials installed to provide Grade 3 of BS 8102.Keeping Water Out ▲ Keeping Water In ▲ Keeping Water Out 9

Sika ® -1 Waterproofing System Case StudiesThe VaultsTrinity StreetCambridgeRefurbishment Project completed 2000Problem▲ Availability of quality commercial properties inthis University City are at a premium andoptimum use of all floor space is crucial.This often involves using existing basementsfor a wide variety of uses.▲ The original solid brick masonry walls had noform of external waterproofing, relying solelyon the interlocking brickwork.Requirements▲ To convert a damp, dreary brick vaulted basementinto a light airy Café Bar▲ Complete internal waterproof system▲ To accept ceramic floor tiles▲ Suitable for internal decorative finish▲ Last the lifetime of the building▲ Provide Grade 3 use in accordance with BS 8102.Sika ® Solutions▲ All existing lime wash coatings mechanicallyremoved and existing brickwork mortar jointsraked out and re-pointed.▲ Exposed brickwork bush hammered to providea rough textured surface.▲ Sika ® -1 three layer waterproofing systemto floor and walls, suitable to accept final finishes.▲ Completed systems provided waterproofing in accordanceGrade 3 of BS 8102.10▲ Keeping Water In ▲ Keeping Water Out ▲ Keeping Water In

Other Sika ®Damp-Proofing SolutionsSika ® Damp-Proofing Slurry▲ Pre-bagged polymer modified cementmortar slurry▲ Simple, just add water, technology▲ Brush, trowel or spray application▲ Two layer application to provide permanentdamp-proof finish▲ Acts as a waterproof lining for ponds, tanks,pools etc.Sika ® Inertol 49W Thick(Sika ® Liquid Asphaltic Compound)▲▲▲One pack phenol-free coating complying with BS3416 Type IIWaterproof treatment to foundation walls, andgeneral concrete / steel structures above andbelow groundProvides a DPM for ground floorsSikaMur ® Ventilating PlasterSystem▲ Internal and external re-plastering of masonry walls▲ Prevents migration of soluble salts following flooddamage or DPC injection▲ Limestone based - ideal for Heritage works▲ Fine finish plaster to produce a smooth surfacefor decorationKeeping Water Out ▲ Keeping Water In ▲ Keeping Water Out 11

Additional Sika ® Technologies and SolutionsSika ® WaterstoppingSystemsRange of quick settingliquid additives for leaksealing and rapidplugging.SikaBond ®Permanently elasticpolyurethane bondingsystems for solidwood and parquet flooring.Sikaflex ®Range of one componentpolyurethane basedconstruction joint sealantswith classifications to ISO11600 selection criteriaSikafloor ®Range of highperformance flooringsystems for the mostdemanding industrial andcommercial installationsSikaTack ® PanelSystemElastic bonding of façadecladding. Suitable for mostpressure ventilated curtainwalling. No visible mechanicalfixings and suitable foraluminium or timberframework. Elastic bondingallows for load transmissionand avoids stress fatigue atscrew fixingsSika ® Membran SystemHighly elastic vapour barriersystem for use in glasscurtain walling or infillwindows.Polyurethane elastic adhesivesallow re-positioning ofmembrane.Internal and external gradesfor insulated cavities.ConstructionThe information, and, in particular, the recommendations relating to the application and end-use of Sika products, are given in goodfaith based on Sika’s current knowledge and experience of the products when properly stored, handled and applied under normalconditions. In practice, the differences in materials, substrates and actual site conditions are such that no warranty in respect ofmerchantability or of fitness for a particular purpose, nor any liability arising out of any legal relationship whatsoever, can be inferredeither from this information, or from any written recommendations, or from any other advice offered. The proprietary rights of thirdparties must be observed. All orders are accepted subject to our current terms of sale and delivery. Users should always refer tothe most recent issue of the Technical Data Sheet for the product concerned, copies of which will be supplied on request.Sika LimitedSika Ireland LimitedISO 14001Watchmead, Welwyn Garden City,Herts, AL7 1BQFax: 01707 329129Telephone: 01707 394444e-mail: sales@uk.sika.comUnit 3 Ballymun Industrial Estate,Dublin 11, IrelandFax: (01) 8620707Telephone: (01) 8620709e-mail: info@sika.ieISO 9001WP.12.06.3K