Suchak, NJ, Jethani, KR, Joshi, JB

Suchak, NJ, Jethani, KR, Joshi, JB

Suchak, NJ, Jethani, KR, Joshi, JB

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

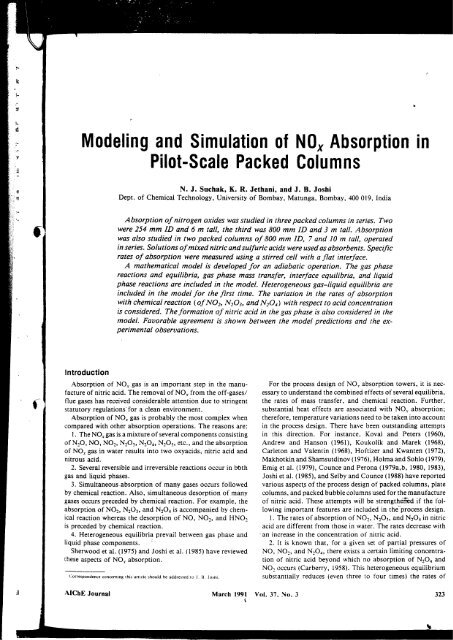

!-Ie:t-":sl,dModeling and Simulation of NOx Absorption inPilot-Scale Packed ColumnsN. J. <strong>Suchak</strong>, K. R. <strong>Jethani</strong>, and J. B. <strong>Joshi</strong>Dept. of Chemical Technology, University of Bombay, Matunga, Bombay, 400019, IndiafAbsorption of nitrogen oxides was studied in three packed columns in series. Twowere 254 mm ID and 6 m tall, the third was 800 mm ID and 3 m tall. Absorptionwasalsostudied in two packed columns of 800 mm ID, 7 and 10 m tall, operatedin series. Solutions of mixed nitric and sulfuric acids were used as absorbents. Specificrates of absorption were measured using a stirred cell with a flat interface.A mathematical model is developed for an adiabatic operation. The gas phasereactions and equilibria, gas phase mass transfer, interface equilibria, and liquidphase reactions are included in the model. Heterogeneous gas-liquid equilibria areincluded in the model for the first time. The variation in the rates of absorptionwith chemical reaction (of NOb N203, and N204) with respect to acid concentrationis considered. The formation of nitric acid in the gas phase is also considered in themodel. Favorable agreement is shown between the model predictions and the experimentalobservations.JfIntroductionAbsorption of NOx gas is an important step in the manufactureof nitric acid. The removal of NO. from the off-gases/ essary to understand the combined effects of several equilibria,For the process design of NO< absorption towers, it is nec-flue gases has received considerable attention due to stringent the rates of mass transfer, and chemical reaction. Further,statutory regulations' for a clean environment.substantial heat effects are associated with NO. absorption;Absorption of NOx gas is probably the most complex when therefore, temperature variations need to be taken into accountcompared with other absorption operations. The reasons are: in the process design, There have been outstanding attemptsI. The NOx gas is a mixture of several components consisting in this direction. For instance, Koval and Peters (1960),of N20, NO, N02, N20J, N204, N20s, etc., and the absorption Andrew and Hanson (1961), Koukolik and Marek (1968),of NO. gas in water results into two oxyacids, nitric acid and Carleton and Valentin (1968), Hoftizer and Kwanten (1972),nitrous acid.Makhotkin and Shamsutdinov (1976), Holma and Sohlo (1979),2. Several reversible and irreversible reactions occur in bbth Emig et al. (1979), Counce and Perona (1979a,b, 1980, 1983),gas and liquid phases.<strong>Joshi</strong> et al. (1985), and Selby and Counce (1988) have reported3. Simultaneous absorption of many gases occurs followed various aspect,s of the process design of packed columns, plateby chemical reaction. Also, simultaneous desorption of many columns, and packed bubble columns used for the manufacturegases occurs preceded by chemical reaction. For example, the of nitric acid, These attempts will be strengthened if the followingimportant features are included in the-'process design.absorption of N02, N203' and N204 is accompanied by chemicalreaction whereas the desorption of NO, N02, and HN02 I. The rates of absorption of N02, N203' and N204 in nitricis preceded by chemical reaction.acid are different from those in water. The rates decrease with.4. Heterogeneous equilibria prevail between gas phase and an increase in the concentration of nitric acid.liquid phase components.2. It is known that, for a given set of partial pressures ofSherwood et al. (1975) and <strong>Joshi</strong> et al. (1985) have reviewed NO, N02, and N204' there exists a certain limiting concentrationof nitric acid beyond which no absorption of N204 andthese aspects of NO. absorption.N02 occurs (Carberry, 1958). This heterogeneous equilibriumCorrespondence concerning this arllde should be addressed to j. B. Jo~hi.substantially reduces (even three !O four times) the rates ofAIChE Journal March 1991\Vol. 37, :"10.3 323

_c.'.'..-,;..-

NOPNO2NO + 02-2N02- PN022N02 ~ N20,,-PN 0-2 4NQ..-N02 ~ N203-PN 0-- 2 3HNO'+T'H,O3HN023N02 + H20 ~ 2HN03- PNHO+ NO3HN03 T HN021NOi'NOit-H20 ~ 2HNOt-PHHO2P~N02iPH 0IBULKGASIIGASFILMII LlOUID FILM IIBULKLIQUIDIFigure 1. Mechanism of NOx absorption into water.P~203.K3=(PNO) (PN02)2(PHN02 )K4=. . .(PNO) (PN02) (PH20).(14)(15)N204(/) + H20(/) - HN02(/) + HN03(/)(21)HN02 in bulk in the liquid phase is considered to be decomposingto form nitric acid:3HN02(/) - HN03(/) + 2NO(/) + H20(/) (22)HN03 and H20 are at their saturation concentrations at theo~erface. The vapor pressure of H20 or HN03 over aqueoussulfuric acid solution is a function of temperature and nitricacid concentration:p~20=f [T, conc(HN03)](16)PHN03= f[T, cone (HN03)] (17)P~ Hx=where x denotes the component.compiled by <strong>Joshi</strong> et al. (1985).[A *]x(18)The values of Hx have beenLiquid Phase Reactions. Nitrogen oxides when absorbedin aqueous sulfuric acid solution, form nitrous and nitric acid.The followi~g reactions occur in the liquid phase:Mass Transfer with Chemical Reaction in the LiquidFilm. The concentration profiles for different species in theliquid film are given in Figure 1. It has been illustrated by<strong>Joshi</strong> et al. (1985) that the absorption ofN02, NP3, and N204is accompanied by chemical reaction within the liquid film.However, absorption of NOx is also limited by nitric acidconcentration in the liquid phase bulk and the partial pressureof NO at the interface. Carberry (1958) made a plot of maximumattainable concentration of nitric acid as a function ofparameter K6 defined asP~oK6 = (p b ) 3/2N204An empirical equation (Matasa and Tonca, 1973) obtainedfrom various plots is of the form:(23)2N02(l) + H20(/) - HN03(/) + HN02(l)(19) InKH = 2.188 X 107 12.58 - 4.571 X 104 11.424W(24)N203(/) + H20(/) - 2HN02(l)(20) whereAIChE JournalMarch 1991 Vol. 37, No.3 325

1-~~,~",""","",'i"'t:",,,.~.,_,:,.,~ ,,

,'''""'. ""'.' ',y"'''"'i.,~~~{''.',:'',''.'':\''',.,.'",.,:"',,,,('\i:"'"",?",:o.o',".~,!:~i;',~:".,.".-'t:tdYNO' S [ FP NO)~= -c O 2 PU2l'''i(" Ec,-RaNO.c,+RaN20,.C,+ 0.5 (RaHN02.C - RaHNO"C>J(36)ReactionsTable 2. Heatsof ReactionStd. Heat ofReaction (25°C)kJ x 10"dYI"b. Balance for total reactive nitrogenS. 'dh = - c [ - RaNO.C T RaI'02'C+ 2RaN20,.C + 2RaN204.C... RaHNO,.C + RaHN02,dc. Water-vapor balancedYH,o'~= -cSd. Oxygen balancedYo,[RaH20.C+ 1!2RaHNo,.c+ 1!2RaHNo2.d1 Sdh .= -2 C[kJ (p~O)2 (P02) Ed(37)ReaClions2NO + 02(Ri - 2N02",'"2N02(,,-N~04(g)NO,g) + N02tg)- N20J(g)3N02(g) + H~Otg)-2HN03(g) + NOtg)NO,,) + N02(g) + H~O(g)-2 HN02tg)Iin GaS Phaset.H, = - 5.7per kmol NO oxidizedt.H, = -5.72per kmol N~O" formedt.H,,=-3.99per kmol N~O) formedtJi6= - 1.77per kmol HNO, formedt.H-= -2.05per kmol HN02 formed(38) ReaClions in the Liquid PhaseEq. 020 per kmol NO, absorbed t.H,= -5.36Eq. 021 per kmol N~O" absorbed t.H9= - 5.03Eq. 022 per kmol N~O, absorbedt:..HIO=-3.99Eq. 023 per kmol HNO, decomposed t.H1, + 2.39Eq. 024 per kmol HNO, absorbed t.H'1 = - 3.92(39)Eq. 025 per kmol of HN02 absorbed t.H12 = - 4.14Component balance in liquid phasee. Balance for nitric aciddX HNO,S~ = - L[4!3RaN204.L + 2/3RaN203.L + RaHNO"C+ 2/3RaN02.L + 1/3RaHNo2.L1(40)T=~ mOC~(41)where T is the temperature change across the differential element.Further details pertaining to the heat balance are givenin appendix D.Equations 36-40 are coupled linear differential equations. Tootal mass balance is established across the differentia) heighton solving these equations simultaneously.Estimation of Design Parameters. Mahajani and <strong>Joshi</strong>(1990) have developed general design procedures and derivedrational correlations for hydrodynamics and mass transfercharacteristics in packed columns. The design parameters includegas- and liquid-side mass transfer coefficients and ef-. fective interfacial area. In addition, we need to know the valuesor "ffusivity and solubility. Details are given in appendix C.upecific rates of absorption of N204 were measured experimentallyto estimate H(kD)l/2 values. This is discussed in alater section.Heat Balance. Oxidation of NO, formation of N203 andN204 in the gas phase, absorption of N02, N203' N204' andthe liquid phase reactions are exothermic. The decompositionof HN02, however, is endothermic. Because of these reactions,significant heat changes occur. The values of physicochemicalparameters such as reaction rate constants, equilibrium constants,solubilities, vapor pressures, and diffusivities dependupon temperature. Heat, liberated because of various reactionsin the gas and liquid phases, has been included in Table 2. Itwill be assumed that the heat liberated is taken up by the liquidphase and the interface is always saturated with water vapor.Further, it was ~ssumed that at any point in the column, thegas and liquid phase temperatures are the same.If QT is the total heat change per unit time in the differentialelement, then the temperature change under adiabatic conditionsis given by:AIChE Journal March 1991Methodof SolutionThe method of solution involved the following five steps.1. Estimation of gas phase compositionEquations A9-All, appendix A, form a set of four simultaneousalgebraic equations. The four unknowns are the mollmol inerts of NO, N02, H20, and total moles in the gas phase.Equations were solved numerically by the Newton-Raphsonmatrix method for nonlinear equations.2. Estimation of interface compositionFor the estimation of interface composition, we need to solvetwenty-one equations simultaneously, Eqs. 6-18, 23, and 26-32. The intricate algebraic reductions of these twenty-one equationsinto two polynomial equations, Eqs. Al and A2, hasobviated the need for a scaling algorithm. The variables selected-theinterfacial partial pressures of NO and N02-arealways present in greater magnitude than other componentsof NOx' These two equations were numerically solved by theNewton-Raphson and Gauss-Jordan method. The main objectivebehind using this composite technique, which was algebraicand analytical in nature, was to achieve a single positivefinite solution with minimum numerical iterations. Substitutingthese values in Eqs. 13-15, 23, and 26-28 results in theinterfacial and limiting partial pressure values of N204' N203,and HN02.Vol. 37, No.3 327

3. Estimation of H;JkD)~/2valuesAbsorption of NOz, NzO), and NZ04 in water has beenextensively studied in the literature. <strong>Joshi</strong> et al. (1985) havecritically reviewed the previous work. Kameoka and Pigford(1977) have shown that the rates of absorption of NZ04 inwater and aqueous sulfuric acid solution are practically thesame. They carried out experiments with 0.09 NHzS04 solutions.At higher concentrations of sulfuric acid, the rates arelikely to decrease. Further, in the present work the absorbentis a mixture of sulfuric and nitric acids at different concentrations.The kinetics of absorption of NO, in mixed acidsolutions has not been studied in the past. Therefore, it wasthought desirable to undertake a systematic investigation. Thedetails are given later.4. Solutions of ordinary differential equationsEquations 36-40 are five coupled ordinary differential equations.Further, they constitute a boundary value problem. Theflow rate and composition of the incoming gas phase are known.Similarly, the flow rate and concentration of incoming mixedacid (at the top of the column) are known. The equations weresolved simultaneously by the fourth-ordermethod. To start the integration procedure, the concentrationRunge-Kuttaof oUtgoing nitric acid (at the bottom of the column) wasassumed. Integration was carried out up to the top of thecolumn. A comparison was made between the calculated andthe actual concentration of nitric acid. For convergence, theguess value at the bottom of the column was varied using themethod of interval halving.5. Solution of heat balance equationsFrom steps 1-4 the concentrations of all the species areknown at the inlet and exit of a differential height. The ratesof chemical reaction and mass transfer are also known. Assumingthat all the sensible heat is taken up by the liquid phase,the change in temperature across the differential height wasestimated. For this purpose Eqs. DI-D27, appendix D, wereused.Discussion of the ModelIn the mathematical model developed in this work, four newfeatures have been included:I. The reduction in the rates of absorption of :--JOz, :--JzO) ,and :--J.O.!with respect to HNO) concentration was includedby seJ;cting appropriate values of H(kD)'/z in Eqs. 29, 30,and 31. The values of H(kD)lIzfor the case of absorption inWater have been summarized by <strong>Joshi</strong> et al. (1985). The variationof [H( kD)I'ZJNz04 with respect to HNO) concentrationhas been reported by Lefers and Van der Berg (1982). Thesame variation was assumed in the case of NOz and NzO)absorption.2. The heterogeneous equilibria between gas and liquid phasespecies have been included through Eqs. 23-28.3. Complete heat balance has been established.4. Provision was made for the formation of HNO) in thegas phase, Eq. 5.Some results will now 5e given to demonstrate the relativeimportance of these features.328March 1991908070.:; 60z...o~ 50o>%...a:.... '0z...ua: 30...Q.20101. MODEL EXCLUDING HETEROGENEOUSEQUILIBRIA AND RATE DEPENOENCEON HNO, CONCENTRATION2. MODEL EXCLUDING HETEROGENEOUSEQUiliBRIA AND INCLUDING RATEDEPENDENCE ON HNO,CONCENTRATION3. MODEL INCLUDING HETEROGENEOUSEQUlll BRIA AND RATE DEPENDENCEON HNO, CONCENTRATION-- 1-=':-":---: : --- ---- 2-.. .............",,',3o o 10 15 20 25 30 35'0WEIGHT PERCENT,NITRIC ACIDFigure 3. Effect of nitric acid concentration on e;of NOx absorption.NOx flow rate = 0.99 x IO-'kmol/sInerts flow rate=2.15x 1O-4kmol/sLiquid inlet temperatureLiquid superficiaJ velocity == 303 K-Air flow rate 7 mm/s5.1 X 10-4 kmol/s'Uu Air flow rate= 0.0 kmol/sFigure 3 shows the relative importance of the rate depences on the :--JHO) concentration and the heterogeneous elibria. In one set of experiments (solid lines) air was addeNOr gas, whereas in the second set (broken lines) air wasadded. In both of the sets the rate dependence on HNO) ,centration has a small effect on the extent of NOr remoHowever, the heterogeneous equilibria markedly influencerates of absorption. First of all, the heterogeneous equililsuccessfully predict the maximum attainableHNO) for a given gas phase NO, composition concentratiorand temperat(for instance, 54% in set I and 39070in set 2). If this featis not included, then it can be seen from Figure 3 thatextent of NO, removal does not depend appreciably on HNconcentration.The role of heterogeneousequilibria with respect to Ncomposition is shown in Figure 4. It can be seen that the extcof NOr removal strongly depends upon HNO)The effect of energy balance is shown in Figure concentratio 5. It canseen that the rise in temperature, as expected, reduces the exteof absorption. Therefore, the extent of NO; removal in tJisothermal case is higher than in the adiabatic case. It is obviolthat the difference in these two cases will depend upon tttemperllture difference across the column.The formation of HNO) in the gas phase was found to tsubstantial when NO~ partial pressure and temperature afhigh. It was found that the gas phase HNO, formation caVol. 37, No.3'550AIChE Journa

Ii.\ I-ll I80IIU,5!ntld.ui..10:tJI'noal.h~contribute up to 20070to the overall rate of absorption whenNO" IN" is 0.1 and at 30°C. The contriburion was found toincrease with an increase in temperature.The effect of temperature on the extent of NO" removal isshown in Figure 6. At low HNO) concentrations, NO< removalis practically independent of temperature. However, at highHNO) concentrations an optimum temperature was observed.At low temperatures, NO oxidation and the formation of N204are favored. However, the value of absorption parameterH(kD)I/2 increases with an increase in temperature. The combinedeffect of the above two factors results in an optimumtemperature. It may be emphasized that the relative importanceof the above two factors depends upon HNO) concentrationand column height.The effect of air flow rate on the extent of NO< removal isshown in Figure 7. It can be seen thatNO" absorption ismaximum when the air flow rme is 4 x 10-4 kmol/s. An increasein the air flow rate increases the oxygen partial pressure,whereas it decreases the gas phase residence time for NO ox-'laof.re.rehe0,0,:TIt:'11,Je:Jt~e~\~Iete~::60..oZII. '0o....~o>%UIex: 207o o 0'2Figure 4.0,'N0',/ tt"Effect of nitric acid concentration on extentof NOx absorption.Packed column dia. ; 0.6 m, hI. ;1.0 mPacking; 38 mm Intalox saddlesLiquid superficial veloc. ; 6 mm/sGas superficial veloc. ; 0.1 m/skaO; 1.25 x 10-' kmol/mJ's'(kN/m')kLa; 1.5x 10-"5-10';125 m'/mJLiquid inlet temp. ; 298 KTotal press.; 101.33 kN/m'NO, gas partial press.; 10 kN/m'Case I. Model predictions excluding heterogeneous equilibria andrate dependence on nitric acid concentrationCase 2. Model predictions excluding heterogeneous equilibria andincluding rate dependence on nitric acid concentrationCase 3. Model predictions including heterogeneous equilibria andrate dependence on HNOJ concentrationLine No. Case HNO, Outlet Conc.. wI. 07.1 Any2 2 153 2 304 2 455 156 307 450-6 0-8,.0idation. These two opposite factors result in an optimum flowrate. <strong>Joshi</strong> et al. (1985) have discussed this subject in detail.Experimental Work and DiscussionMeasurement of specific rates of absorptionFor the estimation of rates of absorption, it is desirable toknow the values of diffusivity, rate constant, and orders withrespect to different species. The measurement of these indiovidual parameters is extremely difficult. Fortunately, the ratesof absorption can be determined if we know the value of thecombined parameter Hx(kD)V2 as described by Eqs. 29, 30,and 31.Experiments for determining Hx(kD)V2 values for N02 andN204 in water and mixed solutions of nitric and sulfuric acidswere conducted in a stirred cell of 95 mm ID. Temperaturewas maintained by using a constant-temperature bath. Theexperimental setup is shown in Figure 8.A gas stream constituting 19-20% NOt was obtained as aproduct gas from the pilot plant for producing oxalic acid.The gas stream was at 65°C and contained water vapor. Thestream was passed through a condenser where the outlet tem-::'0080..0Z 60II.0-' ~'0UIa:0.5 ,.0HEIGHT IN METERS,2 3,,.5 2.0Figure 5. Effect of isothermal/adiabatic operation onextent of NOx absorption.Packed column;dia. 0,6 mPacking; 38 mm Intalox saddlesLiquid superficial veloc.; 4 mm/sGas superficial veloc. ; 0, I m/ skaO;4.9x 1O-4kmol/mJ's.(kN/m')kLa;2.36x IO-"s-I0';154 m'/mJLiquid temp. 323 K at 0 m hI.;Total press. ;709.0 kN/m'NO, gas partial press.; 77 kN/m'NO'/N';0,5Line No. HNO, Cone" WI. 070 Case. 123456101030305050IsothermalAdiabaticIsothermalAdiabatic1sothermalAdiabatic-" AIChE Journal March 1991Vol. 37, :'110.3 329

,..,o:..~._~'~'i:;.;;;..:;~~,-,.;4..",~ .~,~::.,,;n,~70;::60>Caz 50I>.aIC 90a z 80'0 'I. I>.a 70....I~60a%IU 500::50 'I.-4NO. FLOW =1.10 kmol/sCOl FLOW =2'15.U)4kmol(sNO"/NO~ = 2.5INLET HNO, CONCENTRATION =0 'I, wt/wtINLET TEMPERATURE = 303 KSUPERFICIAL LIQUID VELOCITY =7 mm Is205 10 5015 20 25 30 35 '0 '5TEMPERATURE, "cFigure 6.Effect of temperature and nitric acid concen.tration on extent of NO" absorption.Packed column ilia. = 0.6 m, hI. = 0.5 mPacking = 38 mm Intalox saddlesLiquid superficial veloc. = 6 mm/sGas superficial veloc. =0.1 m/skaD= 1.25 x 1O-3kmollm3.s.(kN/m2) for NOkLa= 1.5 x 1O-2.s-1a~125 m2/m3Total press. =303.33 kN/m'NO, gas partial press.= 33 kN/m2NO'/N" = 0.05O2 partial press. = 10"10excessH20 partial press. = satUratedperature was controlled to equal the desired temperature inthe stirred cell. The gas stream leaving the condenser wassaturated with water vapor. It was analyzed for divalent andtetravalent nitrogen oxides. Over 96070of NOx was in the form5510o o 2 12, 6 8 10AIR FLOW RATE IN k malls. 104Figure 7. Effect of air flow rate on extent of NO" alsorptionof NOz. The gas stream was introduced to the stirred Cfthrough a rotameter. The flow rate was adjusted'in such a w,that the extent of absorption was less than 10070.This elirnnated the uncertainty regarding gas phase backmixing becauthe extreme plug flow and back mixed behaviors will differ tlrates of absorption by about 5070. We assumed completebackmixed behavior.In all the experiments, the absorbent quantity was 120 rnand absorption was carried out for 300 s. During this peri,there was no appreciable change in the absorbent quantibecause of either evaporation or condensation,WATER IN0~TOWATER EJECTORG)TTCDoSTrRRED CELL 95 mm DIAMETERCONSTANT TEMPERATURE BATHG) TEMPERATURE TRANSMETER(CONTACT THERMOMETER)CDTEMPERATURE CONTROLLERo HEATING PADo ROTAMETERG) WATER JET EJECTORCD2-4-- GAS STREAM FROM PROCESS20 'f, NO. (96 'f, NO.)CDFigure 8. Experimental setup in stirred cell.330Mardh 1991Vol. 37. ~(). 3 AIChE Jour'''''-.,,--,...-,'~" ;'.,«"-"'~:

Itab.cellway:imiause~theetelymL-fioeintity-'-..The effect of stirrer speed was investigated in the range of0.167 to 1.33 rls. The liquid surface was flat, without anyvortex. It was observed that the specific rate of absorption wasindependent of the stirrer speed when the speed exceeded 0.67rls. This also indicates that there is no effect of gas- and liquidsidemass transfer coefficients (kG and kd when the speedexceeds 0.67 rls. It also indicates complete homogeneity ofthe liquid phase. Since the absorption operation was found tobe independent of kL, it means that absorption does not conformto the instantaneous reaction regime. All the above evidenceindicates that the absorption operation falls in a fastpseudo mth-order reaction regime.Water, 40070sulfuric acid, and mixed acid solutions containingnitric acid and 40% sulfuric acid were used as absorbents.A few experiments were also conducted to evaluate theeffect of temperature on the values of the absorption parameterHx(kD)~2.Tetravalent nitrogen oxides (NO!) constituted more than96070of the NOx gas used in the experiments. Under theseconditions the partial pressure of divalent nitrogen oxidestpNo and PN20J)was negligible. It was expected that the valuesof [H312(2/3 kD)1I2]N02 and [H(kD)II2]N204 in H2S04 wouldbe lower than those in water due to the presence of electrolyte.It was assumed that[HJ/2 (2/3kD) 1/2]N02.water H(kD) 1I2]N204.water[H3/2 (2/3kD) 1I2]N02.H2S04 [H (kD) 1I2]N204.H2S04The specific rate of formation of HNOJ by the absorptionof NOx gas is given by the following equation:RHNOJ = 4/3RNZ04 + 2/3RN02= 4/3 [H( kD) 1I2]N204.H2S04 PN204(42)+2/3 [H3/2(2/3kD)1I2]N02,H2S04 (PN02)J/2 (43)The interfacial partial pressures of N02 and N204 are relatedby Eq. 13. The following equation is obtained by substitutingEqs. 13 and 42 in Eq. 43:iRHNOJ=4/3 [H(kD) I'''' '"]NZ04.HZS04(K2(PNOZ)"2 [H3/2 (2/3kD)1/2]NO"water..,I 312-+3 [H ( kD ) 112 (PNO»]N204.water,The value of [H(kD) li2]NZ04.HZS04was obtained from Eq.44 by using the experimental values of the specific rate offormation of HNOJ.The value of [H(kD) 1/2]N204for water was found to be7,6x 10-6 kmol/m2.s.(kNlm2) at 30.C. This value is in agreementwith those reported in the literature (Sherwood et aI.,1975; <strong>Joshi</strong> et aI., 1985). The values of H(kD)I/2 for NZ04 atvarious acid concentrations are given in Table 3. It can be seenthat the value decreases with an increase in the concentrationof nitric acid. Further, [H(kD)1/2]NZ04 was found to increasewith an increase in temperature. It was thought desirable todevelop a correlation for [H(kD)II2]NZ04 in the range of tem-(44)Table 3. Experimental Values of [H(kDl/2]N204 for 40%Sulfuric AcidNitric Acidwt.O,1o0.05.010.015.020.0Temp..C4020070 NOx= 19Temp. 30.CSulfuric acid cone., 40 wt. 0,10[H(kD) 112)N204'.[kmol/m3. s(kN/m2») x 1062.952.602.291.120.60Nitric acid, 0.0 wt. 0,10Sulfuric acid, 40 wt. 0,10[H(kD) I12)N204'[kmol/m2. s(kN/m2») X 1063.32.8[H(kD)II2]N,O.' 30'C for water=7.6x 10-6 kmol/m'.s(kN/m')perature and concentration covered in this work. The followingcorrelations were found to hold.For mixed acid solutions:[H(kD) 1I2]N204 = 3.66 x 1O-5e-6263.7IRT (I - 1.616 X 10-2 W:"-1.267x 1O-3W~) (45)For water and nitric acid (Lefers and Van der Berg, 1982):[H( kD) 1/Z]N204 = IO[-3.215 -IA2~ Wi( I - WII.8JJe-I.285.JIT(46)[H(kD) 1/2]'1204values in the presence of 40% sulfuric acidwere found to be much lower than those found in water. Thisis because the activity of water decreases in the presence ofsulfuric acid. The values of [H(kD) 1/2]given by Eqs. 45 and46 were used for the estimation of K6 values for mixed acids.The equivalent nitric acid concentration was estimated on thebasis of the same [H(kD) 1/2] values. Table 4 gives the valuesfor nitric acid concentration equivalent to mixed acid concentration.These values were used for determining K6 from Eq.25.The values of [H(kD) 1/2]N20Jand [HJ/2(2/3 kD) 1'2]'102wereassumed to vary (with respect to concentration of acids andtem?erature) in an identical manner to that of [H(kD) 1/2]'1204'Table 4. Nitric Acid Concentration EquivalenCto MixedAcid ConcentrationWt. 0,10HNO,.in 400,10H2S045101520[H(kD) 1/2]'1,04at 30'C -2.70x 10-62.168xlO-1i1.44 x 1O-1iO.519x 10-6Equiv. wt. 0,10HNO, in Water36.3638.5541.9347.97~aliAIChE Journal March 1991Vol. 37, :"-10. 3 331

.~,~~ '......,..~" -'Table 5. Details of ExperimentalSetupColumn 1 Column 2 Column 3Diameter 0.254 m 0.254 m 0.8 mPacked height 4.8 m 4.8 m 1.5 mTotal height 6.0 m 6.0 m 3.0 mPacking type Pall ring Pall ring Intalox saddleSize 16 mm 16mm 25 mmMaterial SS 316 SS 316 CeramicNo. support plates 2 2 ILiquid distributor 1 1 IPlate heat exchanger 2.5 m2 2.5 m2 NonePumpCapacity, m3/hr 3 3 9Head. m water 18 18 22.5Material Polypro- Polypro. SS 316pylene pyleneExperimentalConditionsVL 5-6 mm/s 5-6 mm/s 5-6 mm/sHN03 cone., wt. 070 10.5 5.6 3PL, kg/m3 1,350 1,350 1,350Va, m/s 0.2-0.3 0.2-0.25 0.2-0.25070NOx at inlet 20-23 8-12 3-6Absorption of NDx in a series of packed columnsExperiments were conducted in three continuous, countercurrentlyoperated packed columns in series. Details pertainingto column dimensions and internals are given in Table 5. Thefirst two columns were 0.254 m ID and 6 m tall. The thirdcolumn was 0.8 mID. and 3 m tall. The experimental setupis shown in Figure 9.These three columns were used for the recovery of NOx gasesgenerated in the manufacture of oxalic acid. The prqcess consistsof oxidation of monosaccharides using mixed acid (40 wt.11/0sulfuric acid and 14-15 wt. 11/0nitric acid). The oxidationreactions are as follows (Kirk and Othmer, 1981):(a) C6H1206 + 12HNOJ-3CzHz04'+ 9 NOz(b) 4C6H1206 + 18HNOJ + 3HzO-12CzHz04'+ 9NzO(c) C6H 1206 + 6HNOJ - 3CzHz04(d) C6H1Z06+ 12HNOJ-6COz+2HzO + 31'1z0 + 3NO. 2HzO + 6NO2HzO12HzO+6NO+6NOzThese reactions were carried out in two stirred-tank reactOr~operated in series. The off-gases consist main!y of NOx anecarbon dioxide (some COz is generated due to complete oxi,dation). The volumetric flow rate of this stream was measurecusing a precalibrated orifice meter. To this stream, a measurecquantity of air was continuously added. The gaseous mixtUfiwas passed through a column that provided sufficient residencitime (<strong>Joshi</strong> et aI., 1985) for 9511/0conversion of divalent t(tetravalent nitrogen oxides. The oxidized stream formed thgaseous feed for column 1. Some NOx absorption occurred ilcolumn 1 and the remaining gases entered column 2 and subsequently column 3.The liquid product from the reactors consisted of sulfuriacid (40 wt. 11/0),product oxalic acid (11-12 wt. 11/0),and urreacted nitric acid (0.5 wt. 11/0).Oxalic acid was separated bcooling crystallization. The mother liquor was used for threcovery of NO, gases and entered the liquid circulation 100of column 3. The average composition of the liquid phase fccolumn 3 is given in Table 5. The overflow from the colum3 stOrage tank was added to the circulation loop of column:and overflow of the column 2 stOrage tank was added to ttcirculation loop of column 1. The overflow of column 1 w:C.1C2C3CP1CP 2CP3R1R2R3= COLUMN1= COLUMN 2= COLUMN 3=CENTRIFUGAL PUMP 1CENTRIFUGAL PUMP 2=CENTRIFUGAL PUMP 3== ROTAMETER 1= ROTAMETER 2= ROTAMETER 3NOX,AIRPHE 1 = PLATE HEAT EXCHANGER 1PHE 2 = PLATE HEAT EXCHANGER 2R3SP 1 =SAMPLE POINT 1SP 2 =SAMPLE POINT 2SP 3 =SAMPLE POINT 3@)CP1 CP 2 CP3Figure 9. Three.column absorption system.332 Mar~h 1991Vol. 37, No.3cUChEJoUi'........\.

Table (I. Comparison between Model Predictions andExperimental ObservationsVENT---Total gas flow =:.] x 10- 4 kmol/sNO, flow =1.78 x 10-4 kmollsNO'IN" =0.72Air flow =4.] 7 X 10-4 kmolls-_.~_.~._~.~--~-------Column] Column 2 Column 3ActUal Removal of No" GJoSimulation 52.27 12.9 4.85Experiment 59.5 12.3 4.9ActUal NO'IN' at OutletSimulation 0.63 0.655 0.688Experiment 0.565 0.629 0.70Equilibrium Removal ofNO" GJoSimulation 54.1 13.2 5.1Average Conc. GJoNitric acid 11.25 6.05 3.1Sulfuric acid 40.25 41.0 41.5Pressure Atm. Atm. Atm.Liquid Temp.. .CAt inlet 31 31 31At our letSimulation 3:.3 31.7 32Experiment 36.0 32.0 32OILHZS04recycled \0 the reactors after adjusting acid concentration (byadding concentrated nitric and sulfuric acids). The liquid phasein all three columns was circulated \0 get a sufficiently goodflow rate for wening of the packings. In each recycle srream,the plate heat exchanger was incorporated to maintain thetemperature within :I::I 0c.The composition of the gas and the temperarure were measuredat the inlets and outlets of the columns. The liquid phaseconcentrations and flow rates were also measured. Liquid phaseconcentration was measured by fixing the acid mixture in anexcess quantity of sodium hydroxide. The concentrations ofsodium nitrate and sodium sulfate were measured using an ionchromatograph. Calibration charts were constructed by usingstandard samples of NaN03 and Na2S04' The liquid phaseDiameterPacked heightTotal heightPacking typeSizeMaterialNo. support platesLiquid distribuwrPlate heat exchangerPumpCapacity, m3/hHead, m of waterMaterialVLHN03 cone., wI. OJoPL, kg/m3VG, mlsOJoNO, at inletTable 7. Details of ExperimentalExperimentalSetupColumn 1 Column 20.80 m6.0m7.0 mIntalox saddle37 mmCeramic2I15.0 m21525SS 316Conditions5-6 mmls6.01,3500.14140.80 m6.0 m10.0 mIntalox saddle37 mmCeramic2INone1525SS 3165-6 mmls2.51,3500.147AIChE Journal March 1991@yCP1@yFigure 10. Two-column absorption system.Ct, C2, columnsCP I, CP2, centrifugal pumpsR I, R2, rmametersPHE, plate heat exchangerSPI, SP2, sample pointsflow rate was measured by using a precalibrated rotameter.Details pertaining to the superficial gas velocity, superficialliquid velocity, temperature of operation, and the concentrationsof various species are given Table 5. The percentageremoval of NOx in all the columns is summarized in Table 6.For the purpose of comparison, the results of model predictionsare also given in Table 6. A favorable comparison (within I5OJofor column I and within 5% for columns 2 and 3) can be seenbetween the predicted and experimental values of conversionwith respect to NOx' The predicted temperarure of the columnI outlet is somewhat higher than the measured temperature.This was because the column was not insulated and the heatlosses were not included in the model.Experiments were also carried out in two 0.8 m ID packedcolumns operated in series. The flow sheet is given in Figure10. The qualitative description of the process is the same asthat for Figure 9. The details of the equipment are given inTable 7. A comparison between model predictions and experimentalobservations is given in Table 8. It can be seen thatthe agreement is within 5%. It may be emphasized that theinlet values of NO. IN. are markedly different for the firstcolumns in Tables 6 and 8, and even then the agreement isgood.Vol. 37, No.3 333CP2

"._j,,"'t.I...~J.' . /.'" .- ._-9080~ 70'"u"'"Q.. 60zo...~ 50oVICD... '0 oẓ..COLUMN DIAMETER = 1.Z5mSUPERFICIAL LIQUID VELOCITY = 6 mm/sNo.NO" / AT THE BOTTOM = 0,333PERCENTAGE NO. AT THE INLET = Z,o30AVERAGE TEMPERATURE = 33.CI-z UJTOTAL PRESSURE ~ 101 '33 kN / ml- XUJZO TOTAL GAS FLOW RATE = 2."9s",o3kmo~./SFLOW RATE OF NO, = 6 '10' kmol.IsFLOW RATE OF AIR = ,.81.x'0') kmol~/ s10o o 3, 5 6HEIGHT FROM THE BOTTOM, mFigure 11. Effect of column height on the extent of NOxabsorption.The extent of NOx absorption increases with an increase inthe packed height, Figure II. It can be seen from Figure IIthat the rate of NO, absorption is high in the bottom region.However, the rate becomes very low when the packed heightexceeds about -+m. At the bottom, the partial pressures ofNO:! and N:P. are high compared with the equilibrium partialpressures for a given nitric acid concentration, Eqs. 23-28.Therefore, the rate of NO, absorption, Eqs. 29-32, is high atthe bottom. As the height increases, the driving force continuouslydecreases. Above a certain height-say 4 m in FigureII-the overall absorption operation is controlled by the oxidationof NO in the gas phase. Therefore. for large packedColumn I Column 2Actual Removal of NOn %Simulation 55.9 21.9Experiment 56.3 20.7Actual NO" /N" at outletSimulation 0.318 0.239Experiment 0.331 0.226Equilib. Removal of :"'10" 070Simulation 58 23.3Average cone., 070:O;itricacid 6.0 2.5Sulfuric acid 42.0 43.0Pressure Atm. Atm.Liquid Temp., °CAt Inlet 31 31At outletSimulation 37.3 31.7Experiment 36.0 32.0334Table 8. Comparison between Model Predictions andExperimental ObservationsTotal gas flow=2.5x 10-3 kmol/sNO, flow=3.5 x 10-4 kmollsNO"/N" =0.107Air flow = 1.74 x 10-3 kmolls8Total77.877.081.3~March 1991Table 9. Extent of NOx Removalin 250 mm ID Colum7.1 X 10-4 kmolTotal flow rate of gas phase1.78 x 10-4 kmcFlow rate of NO,(U2NO" IN" ratio at boltom4.l7x 10-4 km(Flow rate of airColumn details are given in Table 5Superficial liquid velocity 6 mm/sMixed acid concentration is given in Table 6Removal of NO. at I m height. "10Simulation39.2Experimental 41.7Extent of removal at 4.8 m height is given in Ta':>le 6'Column I, Table 5heights, the extent of NO, removal is controlled by hegeneous equilibrium. Thus, Tables 6 and 8 show a compabetween predictions and experimental observations wherlerogeneous equilibrium was practically established.In order to check the validity of the mass transferEqs. 29-32, the extent of NOx removal was measured i250 mm ID column (column 1 in Table 5). The gas and Isamples were withdrawn at a distance of 1 m from the btand at the top of the column. The results are given in9. In 1 m packed height, heterogeneous equilibrium condare not established and the rate of mass transfer is th(trolling step. The agreement between the model prediand experimental observations can be seen to be withinIt may be noted that in all five packed columns studthis work, most of the liquid phase was recycled, as sheFigures 9 and IQ. As a result, the HNO:! concentrationliquid phase attains a constant composition. as reportCounce and Perona (1983). This was indeed found to tin the present set of experiments. Therefore, the contrib[0 the extent 0of HNO:! formation and decompositionabsorption were not considered in the present model.ConclusionsA mathematical model has been developed in whicnew features have been included. These are:I. Variations in the rates of absorption of NO,. :'-.I,N:!04 with respect [0 concentration of nitric acid2. Heterogeneous equilibria between NO. :'-.1,0], :'-.I:nitric acid concentration3. Formation of nitric acid in the gas phase4. Complete energy balanceThe new model is capable of incorporating the effects Cimum permissible concemration of nitric acid on Nsorption.Specific rates of absorption of N:!OJ in water and mixsolutions of sulfuric and nitric acids were measured in 8cell with tlat interface. The observed rares of absor~water were found to agree with the published literalmixed acid solutions. the specific rates of absorptiefound to decrease with an increase in the nitric acidtration. The following correlation was found to holtrange of 0-20 wr.1)10HNO, in 40 wr. 070sulfuric acid18-19 kN/m:! panial pressure of tetravalent nitrogen[H(kD)i :!IN,()4=3.66x lO 'eV III. 37."III. J263.-Hr(l-1.616x 10-[,267 X II.\IChE

In'is. )L' 5)i 5Absorption of NOx gases was carried out in 254 mm and800 mm ID packed columns. A favorable agreement was observedbetween the model predictions and experimental observations.[era-~isan,het-ares,1 the:quid[[Om~able. tionscontions51770.ed inmmnthe1i by:truetions\0,iour.~nd.and(acidtrred!~ :n~, In\ere::a\~iab-t;entihetd at~es:t\ = pressure drop in packed columnQ, = heat changes due to formation of N20] in bulk gas,kcaJ/ sQ2 = heat changes due to formation of N20, in bulk gas,kcal/ sQ] = heat changes due to formation of HNO] in bulk gas,kcal/sQ,= heat changes due l0 formation of HN02 in bulk gas,kcal/ sQ,= heat changes due to oxidation of NO in bulk gas,kcal/ sQ6 = heat changes due to water evaporation in bulk gas,kcal/ sQc total heat changes in gas phase, kcal/sQL= toral heat changes in liquid phase, kcallsQr = total heat change, kcal/sAIChE Journal March 1991(R= universal gas constant, (m3. kN/m2)/(kmol. K)Rax L = rate of absorption of component x, kmoll(m3s)Rax:o = rate of gas phase mass transfer of component x,'kmoll(m3s)ReL = Reynolds number for liquids = exponent, Eq. 55S = cross-sectional area of column, m2Seo = Schmidt number for gasT = temperature, Kt!.T = temperature difference, KVL = superficial liquid velocity, m/sVo = superficial gas velocity, m/sW wt. frac. HN03 in aqueous nitric acid solutionW N = wt. O?o HN03 in mixed acidXx kmol x ions per kmol water(X).= component X at exit of differential volume(X)f= component X formed in differential volume(X); component X at inlet of differential volume(X)o= component X oxidized in differential volume(X)v= component X vaporized in differential volumeX(g) =component X in gas phaseX(/) component X in aqueous phaseY T = total moles gas per mol inertYx = mol gaseous component x per mol inert( Yx). = Yx at exit of differential height( Yx); = Yx at inlet of differential heightYN. = kmol reactive nitrogen per kmol inertsYNO. = kmol divalent nitrogen per kmol inertsYHo. 2 = kmol water in form of oxyacids and free water in gasphase per kmol inertsZ = coefficient, Eq. 55Greek lettersSubscriptsex = coefficient, Eq. C3{3 = exponent of superficial liquid velocity, Eq. C3'Y= exponent of nominal packing diameter, Eq. C3." = coefficiem, Eq. C9PL = density of liquid, kg/m3Po = density of gas, kg/m3/Joo = viscosity of gas/JoL viscosity of liquid/Jow viscosity oi water€ = voidageEO= fractional gas holdupEL= fractional liquid holdupES = fractional solid holdupa = absorptione = exit conditionf= formationG. (g) =gas phaseI = inlet conditionL, (/)= liquid phaseT = totalv = vaporx = x in NO,LiteratureCited-Andrew, S. P. S.. and D. Hanson, "The Dynamics' of Nitrous GasAbsorption," Chem. Eng. Sci., 14, 105 (1961).Carberry, J., "Some Remarks on Chemical Equilibrium and Kineticsin the Nitrogen Dioxide-Water System," Chem. Eng. Scl.. 9, 189- (1958).Carleton. A. J.. and F. H. Valentin, Proc. 4th Eur. Symp. Chem.Reaction Eng. (suppl. Chem. Eng. Scl.), Pergamon. Oxford, 361(1968).Carra, G., and R. L. Pigford, Ind. Eng. Chem. Fundam.. 22, 329(1983 ).Vol, 37, ~o, 3 335

.""":'-".~'"-';::., , ,~.;.,.,...~,."",.~.Counce, R. M., and J. J. Perona, "Gas-Liquid Interfacial Area ofa Sieve Plate with Down Comers and 0.6070 Perforations," Ind.Eng. Chern. Proc. Des. Develop., 18,562 (l979a).Counce, R. M., and 1. J. Perona, "Gaseous Nitrogen Oxide Absorptionin a Sieve Plate Column," Ind. Eng. Chern. Fundarn., 18,400 (l979b)..Counce, R. M., and J. 1. Perona, "A Mathematical Model for NitrogenOxide Absorption in a Sieve Plate Column," Ind. Eng. Chern.Proc. Des. Develop., 19, 426 (1980).Counce, R. M., and 1. J. Perona, "Scrubbing of Gaseous NitrogenOxides in Packed Towers," AIChE J., 29,26 (1983).Danckwerts, P. V., Gas-Liquid Reactions, McGraw-HilI, New York(1970).Emig, G., K. Wohlfahrt, and U.. Hoffmann, "Absorption with SimultaneousComplex Reactions in Both Phases, Demonstrated bythe Modeling and Calculation of Counter-Current Flow Columnsfor the Production of Nitric Acid," Cornput. Chern. Eng., 3, 143(1979).Holma, H., and J. Sohlo, "A Mathematical Model for an AbsorptionTower of Nitrogen Oxides in Nitric Acid Production," Cornput.Chern. Eng., 3, 135 (1979).Hoftizer, P. J., and F. J. G. Kwanten, "Absorption of Nitrous Gases,"G. Honhabel, Gas Purification Processes for Air Pollution Control,Butterworths, London (1972).<strong>Joshi</strong>, 1. B., V. V. Mahajani, and V. A. Juvekar, "Absorption ofNO, Gases," Chern. Eng. Cornrnun., 33, I (1985).Kameoka, V., and R. L. Pigford, "Absorption of Nitrogen Dioxideinto Water, Sulfuric Acid, Sodium Hydroxide, and Alkaline SodiumSulfite Aqueous Solutions," Ind. Eng. Chern. Fundarn., 16, 163(1977) .Kirk and Othmer, Encyclopedia of Chernical Technology, 3rd ed.,Wiley, New York, 16,623 (1981).Koukolik, M., and J. Marek, Proc. 4th Eur. Syrnp. Chern. React.Eng. (sup pI. Chern. Eng. Sci.), Pergamon, Oxford, 347 (1968).Koval, E. J., and M. S. Peters, "Reaction of Aqueous Nitrogen Dioxide,"Ind. Eng. Chern., 52, 1011 (1960).Lefers, J. B., and P. J. Van der Berg, "Absorption of N02/N204 intoDiluted and Concentrated Nitric Acid," Chern. Eng. J., 23, 211(1982).Mahajani, V. V., "Figuring Packed-Tower Diameter," Chern. Eng.,Sept. 20, 132 (1982).Mahajani, V. V., and J. B. <strong>Joshi</strong>, "Mass Transfer in Packed Column:A Quick Look," (in preparation, 1990).\lakhotkin, A. F., and A. M. Shamsutdinov, Khirn. Khirn. Tekhnol.,19(9),1411 (1976).Matasa, C., and E. Tonca, Basi!: Nitrogen Cornpounds, ChemicalPub. Co., New York (1973).Niranjan. K., V. G. Pangarkar, and J. B. <strong>Joshi</strong>. "Estimate TowerPressure Drop;" Chern. Eng., June 27,67 (1983).Onda. K.. E. Sada. T. Kobayashi, S. Kita, and K. Ita, "Salting OutParameters of Gas Solubility in Aqueous Salt Solutions," J. Chern.Eng. Japan, 3. 18 (1970).Sada. E., H. Kumazawa. N. Hayakawa, I. Kudo, and T. Kondo."Absorption of NO in Aqueous Solutions or KMnO,," Chern. Eng.Sci., 32. 1171 (1977).Sherwood, T. K., R. L. Pigford, and C. R. Wilke. .Vfass Transfer,\1cGraw-Hill. New York (1975).Selby, G. W., and R. \1. Counce, "Aqueous Scrubbing' of DiluteNitrogen( 1988).Oxide Gas Mixtures," Ind. Eng. Chern. Res., 27. 1917Appendix A. Estimation of Partial Pressures ofVarious Gaseous Components on the Basis ofGas Phase EquilibriaThe total number of moles in the gas per mole of inert isobtained by adding ratios of all gaseous species to mole '01'inert.whereYNZ04 = Kz( YNOZ)zPTIYT uYN °=K]YNOYNO, PTIYTZ ] -YHNOZ= (K4YNOYNOzYHZOPTIYT)1/Z (lI/ZKs( YNOZ)3yHzO PTYHN03- - [ Y NO YTJIn computing gas phase equilibria, we assume that thenno formation or removal of reactive nitrogen. Hence Ytotal reactive nitrogen per mole of inert, is expressed as:YN' = YNO + YNOZ + 2( YNZ04)+ 2 ( YNZ03) + Y HN03 + Y HNOZwhereas the extent of oxidation at any moment is expresin the form of YNO', moles of divalent nitrogen per moleinert:YNO' = YNO + YNZ03 + 0.5(YHNOZ) - 0.5 ( YHN03)(,YHZO' is moles of water in the form of oxyacids andwater vapor per mole of inert. It is expressed as:YHZO" = YHZO + 0.5 ( YHN03) + 0.5( YHNOZ)u(f(iIEquations A2 to A5 express YNZ04,YNZ03,YHNO~' and YHin terms of YNO, YNO" YH,o, and YT. When these are subtuted in Eqs. AI, A6, A7: and A8. four equations in YY'IO" YH,o, and YT are obtained. They are:yj.- YT( Y'IO + Y"o~ -+-YH:o + Yo: + 1)- YV~ {[K,Pr( Y'IO~)3 YH~O'Y'lO]li~ + (K.jPT Y:-ooY"oz YH~o-[K,PTY"o~Y"o...K:PT (Y'IO~)~]=OYT( Y,,* - Y'IO- Y"o:) - Y~~ I (K.jPT Y'IOY'Io:YH:o)L:+ [KSPT( YNO/ YH~oIY'lo]1 : I - 2PT[K~( Y"o~):- K] YNo YNo:] = 0 (PYT( YNO* - YNO) -1/2 Y~~ [(K.jPTY'IOY';!.O~YH~O)I/Z3I!2- [KSPT( YNOZ) YHZOi ' Y'\Io]] - K]PT YNO YNoz = 0 (AYT( YH~O" - YHZO) - 1/2 Y~~ I (K4PTYNO Y"o~ YHZO)I/Z3 i/2+ [K,PT (Y'\I0z) YH~oIYNo] = 0 (A(,YT= Y"o+ Y'Io~+ Y'I~().j+ Y'I~(),+ YHNO]336-r YHNO, + Y H,O + Y(h -r I- - -(AI)\March 1991For known molar concentrations of inerts, oxygen, tNO~. and NO" to (N") ratio, equilibrium partial pressureall the gaseous species in the bulk gas can be estimatedVol. 37. No. J AIChE JOUi~,

(A2)solving Eqs. A9-A12 simultaneously for Yr, YNO' YN02' andYH o. Compositions of HN03, HN02, N203' and N204 areobtzained from equilibria relations, Eqs. A2-A5.(A3) Appendix B. Simplification of Eqs. 6-15, 23,26-35(A4) The following two equations are obtained by substitutingEqs. 6-15, 23, and 26-35 into Eqs. 34 and 35:(A5)A I [PN02 - A2 (p{.;o) 1/3]312 + A3 (p{.;oZ)2 - A4 (p~O)2I3]8s = - A989=3A7810= -AIO8ll = - (k~)N02PRi02 - (k~)HN02PHNO/2812=As- (kG~)N203PRi203 - 2(kG~)N204PRi204~re ISY~*,(A6)~ssedIe of(A7)free.(A8).flNO)bsti-Y"Q,,.j: :::\9)where+ As[P~~oz - Az (p{.;O)4/3] + A7[ (PNO) 112(p~OZ).2/3.. .- AS(PNO) ] + A9(PNO) (PNOZ)+AlO(PNO) (PNOZ) IIZAI = I~ (HNOZ)3/Z[(2/3Az=I/K~/ZK6113kD)NOZ]1/2)/3A3 = (2K2 ~ HNZ04 [(kD)N20/12) 13A4= I/(Kz K~/3)As= (K3 ~HNZOJ [(Dk)NZO/I2J/3A7 = (K4pkzo)As = 1/ (K~I2K~/3)IIZKL'!.HHNO/6I/ZA9 = - K3 (kG~)NZOJAIO= - (K4 pkzo)112 (kG'!.)HNO/2All = -(kG'!.)NO112.IIZ+ A I iPNO + A 12 = 0 (Bl)A,z= (kG~)NOP~O+ (kG'!.)HNO:PHNO/2+(kG~)N20~Ri203andB [P i B ( i ) 1/3 ] 3/2 IB B [ (II NOZ - 2 PNO + JPN02 + ~ PN02 )2- S PNO + 6 PN02 + 7 NOPN02 - 2 PNOB ( i ) 213 ] B ( i ) 2B [P I i B ( i ) 4/3 ]B [( i I ) 1/2 B ( I ) 213 ] B ( I) ( i )+ 9 PNOPN02 - 12 PNO + S PNO PN02Appendix C. Estimation of Design Parametersand Physical PropertiesThe column diameter was estimated on the basis of floodingcalculations. The correlation (Mahajani, 1982) used to determineflooding conditions is:whereIn Y = - 3.3861- 1.0814 In X - 0.1273 (In X)2 (CI)(O*)2p J1.~.1-Y=PL PGX =~: ~:r/2Packing factor P was calculated from the equation,P=Z(dp)-S(C2)The correlation employed for computing the effective interfacialarea (<strong>Joshi</strong> et aI., 1985) in packed column is'!.Ct VL(3(dp)r,E'(C3)Values for Ct, (3, and 'Yfor different pac kings are as in TableAI. Mahajani and <strong>Joshi</strong> (1990) have developed correlationsfor gas-side and liquid-side mass transfer coefficients basedon turbulence intensity. They have shown that the followingcorrelation for the gas-side mass transfer coefficient holds forall the packings.\10)+ B ( i i )10 PN02PNO 1/2 T B 0' II = (B2)Ill)\12)'oral~ ofj bywhereBI=3AIB2 = A2B) = (kG~ON02B,=3A)B

'""",".',.'.' " """,~h"'~'.,..' . ~Table AI. Values of Constants in Eqs. CI-CllPac kings f m n=-y a {3 Z s"X 10-2Raschig rings 3.76 4.53 -1.015 0.5dp 8.0 0.403 27,800 1.533 2.1Pall rings 2.17 3.96 -1.07 O.ldp 28.4 0.5 843 0.913 4.4Intalox saddles 2.03 6.74 1.337 2.7- 1.0 0.25dp 19.6 0.478 7,091where the Reynolds number is given byReL=dp VL PLILL E(C7)The specific surface area is calculated from the packingdiameter asap=m(dp)n(C8)Values of m and n for different packings are given in TableAI.Liquid-side mass transfer coefficient kL has been estimatedfrom the following correlation:(kd/Dd=1/ReL( ) 0.5P:~L(C9)Values of coefficient 1/are listed in Table AI.Pressure drop in the packed column was estimated by thefollowing correlation (Niranjan et a!., 1983)f( G* )2a p(M'/h) = [6 PC(E-Ed](ClO)Oiffusivities of gases vary with temperatUre and pressure.For this purpose, the following correction was used.Dx=DdS'C(T/298.2)L75(101.33/ ?T) (CII)The solubility of HNOJ and HNOc in water is 2,090 and0.484 kmol/mJ. (kN/mz), respectively (<strong>Joshi</strong> et a!., 1985). Thesolubility of NO in water is given by the following equation:roglo (101.33 x H"o) = - 1,463.32IT + 2.178 (CI2)The solubility of NO and HNOc in the presence of electrolyteslike HzSO~ and HNOJ was estimated by using the fullowingequation;where10glO(He/Hw) = -f.K,l (CI3)Hw=solubility in water, kmol/mJ.(kN/mC)Hel = solubility in electrolyte solution, kmol/mJ. (kN I mC)K,=salting-out parameter = i- +i- +i.i- and i- are contributions of carions and anions of the electrolyte,respectively, to the salting-out parameter and i"is thecontribution of the solute gas. Oanckwerts (1970) and Oneet a!. (1970) have reported the values of salting-out parametefor various cations, anions, and gases. The value of ig for Ngas was reported by Sada et al. (1977). The value of ig f(HNO) was estimated from the vapor press un: of HNO) OVnitric acid. The value of ig for HN02 was assumed to be t1same as that of HNO).AppendixD. Heat ChangesGas phase heat changesContribution to the heat changes from the gas phase are d\to the following steps.I. The rate of formation of N20) from NO and N02 in tldifferential element is given by:(NzO)j= (NZO)e - (NZO)i + (NZO)a (0(NzO)j= G ( Y"zo),e - Y"Z0Jol) + Ra"ZO).LSdhThe rate of heat generation due to NzO) formation is:Q, = (NzOJ)j ilii4 (02. The rate of formation of NZ04 from N02 in the diff(ential element is given by;(N204)j= (N204)h - (N204)i + (N204)a (0(N204)j= G( Y"204.e- YN204.i) + Ra"204.LSdhThe rate of heat generation due to N20~ formation is:Q2 = (N204)j ilii) (I:3. The rate of formation of HNO) in the differential elem(is given by:(HNO)j= (HNOJ)e - (HNO)i + (HNO)a ([(HNO)j=G( YHNO).e- YHN0Jol)+ RaHNO).cSdh ([-The rate of heat liberated due to HNOJ formation is;Q) =(HNOJ)j ilii6 ([4. The rate of formation of HN02 in the differential elem(is given by:(HN02)r= (HN02)e -(HN02)i + (HNOzJa (0(0(0338 March 1991 Vol. 37. :"/0.3(AIChEJourr

~ 2:)(HN02)f= G( YHN02.e- YHN02.;) + RaHN02.LSdh (Dll)The rate of heat liberated due to HN02 formation is:Q6 = (H20)u Lw(DI8)The total heat change in the gas phase is given by:Jnda:etersrNO, forovere theQ4= (HN02)fMl7 (DI2)5. The rate of heat liberated due to the oxidation of NO isestimated from the knowledge of the rate of NO oxidation. Itmay be noted that NO is used in the N203 and HN02 formationand it is liberated during HN03 formation.The mass balance for NO across the differential element isgiven by:NO,o = (NO'i- NO,e) - N203,fQG=QI +Q2+Q3+Q4+QS+ Q6 (D 19)Heat changes due to absorption with chemicalreactionIn the absence of information on heats of dissolution ofgases the information on heats of formation of reactants andproducts was used to compute the heats of reactions.Reactions under consideration for the heat balance are:(1) 2 N02(g) + H20(/) - HN03(/) + HN02(/) (020)~ duen the- 112 HN02,f+ 112 HN03,f (DB)= G( YNO,i- YNO,e- YN203.e+ YN203,i-112 YHN02.e+ 112 YHN02,i+ 112 YHN03,e-l12 YHN03,;)- (RaN203.L + 112 RaHN02.L - 112 RaHN03,G) S dh) (DI4). (01) The rate of heat generation due to NO oxidation is given by:(02) Qs = (NO)o Mil (D 15)1D3)Heat changes due to water evaporationThe rate of water evaporation in the differential elementwas obtained by material balance:iffer~ (H20)u= (H20'e- H20,,)+ 1/2 HN03,f+ 1/2 HN02,f (DI6)(04)(H20)u=G (YH2o,e-YH2o,i+1I2 YHNO),e-1I2 YHNO).i(2) N204(g) + H20(/) - HN03(/) + HN02(l)(3) N203(g) + H20(/) -2 HN02(l)(4) 3 HN02(l)-HN03(l)+2 NO(g)+H20(/)(5) HN03(g)-HN03(/)(D2I)(022)(D23)(6) HN02(g)-HN02(/)(D24)(025)Heats of reaction are summarized in Table 2.Heat liberated due to absorption with chemical reaction inthe liquid phase is expressed as:QL = (RaNo2,LMls + RaN204,LMl9 + RaN203,LMlIO+ RaHNO),GMlII + RaHNo2,LMlI2Total heat change in the differentialof all the heat changes.+ RaNo,LMlI3) S dh (D26)volume is the summationID5)+ 1/2 YHN02,e-1I2 YHN02,;) + (112 RaHNO),G+ 11;2 RaHt>i02.dS dh (DI7)Qr= QG -+ QL (D27)Jfanuscripr received June 12, 1990, and rel'isian received ,Vot', 27, 1990,(D6)l1enr{Oi)(08)ID9)":::nentDIO)--"al -\IChE Journal March 1991Vol. 37, No.3 339