Product Information Zytel® FR7025V0F NC010 - Promaplast

Product Information Zytel® FR7025V0F NC010 - Promaplast

Product Information Zytel® FR7025V0F NC010 - Promaplast

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

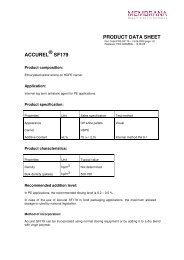

<strong>Product</strong> <strong>Information</strong>DuPont Zytel ®nylon resinZytel ® <strong>FR7025V0F</strong> <strong>NC010</strong>Zytel ® <strong>FR7025V0F</strong> <strong>NC010</strong> is a flame retardant polyamide 66 resin for injection molding. It does not containelemental phosphorous, halogens or heavy metals.Property Test Method UnitsValueDAMIdentificationResin Identification ISO 1043 PA66-FR(30)Part Marking Code ISO 11469 >PA66-FR(30)

<strong>Product</strong> <strong>Information</strong>Zytel ® <strong>FR7025V0F</strong> <strong>NC010</strong>Property Test Method UnitsValueDAMFlammabilityFlammability Classification IEC 60695-11-100.75mm V-01.5mm V-03.0mm V-0Flammability ClassificationUL940.75mm V-01.5mm V-03.0mm V-0Glow Wire Flammability Index IEC 60695-2-12 °C1.5mm 9603.0mm 960Glow Wire Ignition Temperature IEC 60695-2-13 °C1.5mm 7753.0mm 775High Current Arc Ignition Resistance UL 746A PLC0.75mm 01.5mm 03.0mm 0High Voltage Arc Tracking Rate UL 746A PLC0.75mm 01.5mm 03.0mm 0Hot Wire Ignition UL 746A PLC0.75mm 31.5mm 33.0mm 1Contact DuPont for Material Safety Data Sheet, general guides and/or additional information about ventilation, handling, purging, drying, etcISO Mechanical properties measured at 4.0mm, ISO Electrical properties measured at 2.0mm, and all ASTM properties measured at 3.2mm.Test temperatures are 23°C unless otherwise stated.The DuPont Oval Logo, DuPont, The miracles of science and Zytel® are trademarks or registered trademarks of DuPont Company. Copyright© 2011110329/110330The information provided in this data sheet corresponds to our knowledge on the subject at the date of its publication. This information may be subject to revision as newknowledge and experience becomes available. The data provided fall within the normal range of product properties and relate only to the specific material designated; thesedata may not be valid for such material used in combination with any other materials, additives or pigments or in any process, unless expressly indicated otherwise.The data provided should not be used to establish specification limits or used alone as the basis of design; they are not intended to substitute for any testing you mayneed to conduct to determine for yourself the suitability of a specific material for your particular purposes. Since DuPont cannot anticipate all variationsin actual end-use conditions DuPont makes no warranties and assumes no liability in connection with any use of this information. Nothing in this publicationis to be considered as a license to operate under or a recommendation to infringe any patent rights. DuPont advises you to seek independent counsel for a freedom to practiceopinion on the intended application or end-use of our products. CAUTION: This product is not permitted to be sold for use in medical applicationsinvolving any implantation in the human body or where contact with internal body fluids or tissues will equal or exceed 24 hours. For applications involvincontact of less than 24 hours, see “DuPont Medical Caution Statement", H-50102 and contact your DuPont sales representative.plastics.dupont.com2 / 3

<strong>Product</strong> <strong>Information</strong>Zytel ® <strong>FR7025V0F</strong> <strong>NC010</strong>Property Test Method UnitsValueDAMTemperature IndexRTI, Electrical UL 746B °C0.75mm 1301.5mm 1303.0mm 130RTI, Impact UL 746B °C0.75mm 751.5mm 753.0mm 75RTI, Strength UL 746B °C0.75mm 851.5mm 853.0mm 85OtherDensity ISO 1183 kg/m 3 (g/cm 3 ) 1160 (1.16)Water Absorption ISO 62, Similar to %Immersion 24h 1.8Molding Shrinkage ISO 294-4 %Normal, 2.0mm 1.0Parallel, 2.0mm 0.9ProcessingMelt Temperature Range °C (°F) 270-290 (520-555)Melt Temperature Optimum °C (°F) 280 (535)Mold Temperature Range °C (°F) 50-90 (120-190)Mold Temperature Optimum °C (°F) 70 (160)Drying Time, Dehumidified Dryer h 2-4Drying Temperature °C (°F) 80 (175)Processing Moisture Content %