SCHATZ®-ANALYSE - SCHATZ USA Inc

SCHATZ®-ANALYSE - SCHATZ USA Inc

SCHATZ®-ANALYSE - SCHATZ USA Inc

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

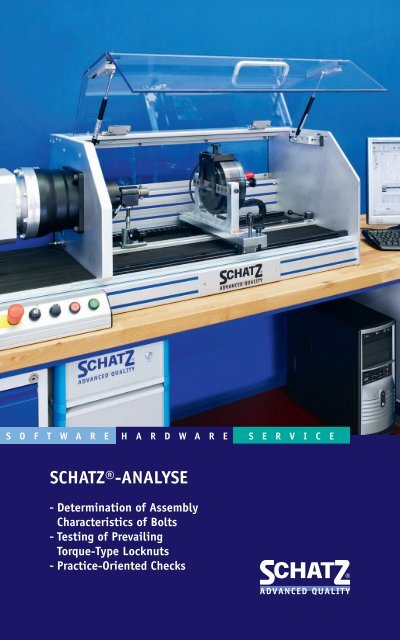

<strong>SCHATZ</strong>®-<strong>ANALYSE</strong>This laboratory system enables fast, accurate analyses of fastener components. Quantities such as torque,preload force and rotation angle, along with other parameters such as screw elongation or temperature andeven video recording, are measured and evaluated during the assembly process.This laboratory system can be used to test fastener components for compliance with standards or underpractical conditions for use in assembly processes. The system can be configured to match your specificapplication scenarios.Torque / angle transducersThe shaft of the torque/angle transducer is fitted with straingauges, and the sensor signals and supply voltage are coupledvia extremely low-wear slip rings. An incremental encoder discwith 360 apertures is also fitted to the transducer shaft. Itpasses through a dual optical barrier sensor. The angle-pulsesignal conditioning stage supplies two phase-offset signals thatcorrespond to the direction of rotation.Measuring ranges from 0.2 Nm to 35 kNm are available.Preload force / thread friction torque transducerThe sensor heads of the preload force transducer and thethread friction torque transducer are fitted with strain gaugesconnected to a full Wheatstone bridge. The thread frictiontorque transducer is braced against the preload force transducerusing an axial bearing, which allows the thread friction torqueto be measured independently. The housing enables the use ofattachments and perforated plates that allow screws and nuts ofvarious sizes to be tested as desired.Measuring ranges from 5 kN to 5000 kN are available.www.schatz.agwww.schatz-usa.com

7Connect the fastenerA series of tests can be performed quicklyand efficiently. Simply connect the fastenerand start the system.When each test is completed, changeto a different fastener and run thenext test.Start the systemThe system begins the defined testsequence at the push of a button. Thedrive can be operated at different speedsduring the test sequence.

The measured values and recordedcurves are displayed on the screen forevaluation. Measurement sets and calculatedassembly parameters are evaluatedstatistically and displayed in tables. Thisenables conformance with standards andspecifications to be judged at a glance.Measurement curves provide productdesigners with valuable information onthe behavior of fastener componentsduring the assembly process. Frictioncoefficient diagrams show the relationshipbetween torque and tension andallow the friction conditions to be seenat a glance.A report wizard helps you generateprinted test reports. Tables and charts can be shown on the document in any desiredform. The document layout and logos are adapted to standard document formats. Thismeans that the documents can be customized for each company and each customer.The testXpert® software also supports direct document transfer by e-mail, so theinformation is available where it‘s needed as quickly as possible.

Special solutions for your specificapplication scenariosThe <strong>SCHATZ</strong>®-<strong>ANALYSE</strong> laboratory system is manufactured andconfigured to suit your specific application scenario.Testing tiny fastenercomponentsIn combination with suitable transducers,the vertical test stand can beused to test extremely small fastenercomponents. With this configuration,the laboratory system can be usedto test the performance of specialscrews and nuts used in the aerospaceindustry.Testing under practicalconditionsFastener assembly systems takendirectly from production can becontrolled using <strong>SCHATZ</strong>®-<strong>ANALYSE</strong> torealistically simulate actual productionconditions. Two-stage tighteningprocesses and high tightening speedscorresponding to actual practice can beused to analyze stick-slip effects andaltered friction characteristics.www.schatz.agwww.schatz-usa.com

11Laboratory system withmanipulatorUsing the manipulator, the fastenertool spindle can be brought up to theoriginal fastener in order to performtests on the completed component.The spindle holder can be rotated andpivoted to enable testing in any installedposition. The manipulator can withstandspindle torques up to 2,000 Nm.Thermal characteristicsof coatingsThe heat chamber can be used to checkwhether the friction characteristics ofthe fastener components change whenthey are heated, with the result that theprevailing-torque property is lost andthe fastener components can loosen dueto temperature effects, despite correctassembly.