Download (PDF) - Metrohm

Download (PDF) - Metrohm

Download (PDF) - Metrohm

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

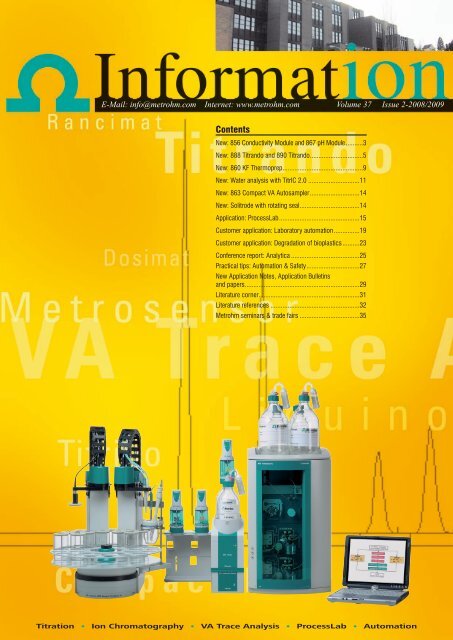

E-Mail: info@metrohm.com Internet: www.metrohm.com Volume 37 Issue 2-2008/2009<br />

Contents<br />

New: 856 Conductivity Module and 867 pH Module ..........3<br />

New: 888 Titrando and 890 Titrando ...............................5<br />

New: 860 KF Thermoprep ...............................................9<br />

New: Water analysis with TitrIC 2.0 ..............................11<br />

New: 863 Compact VA Autosampler .............................14<br />

New: Solitrode with rotating seal ...................................14<br />

Application: ProcessLab ...............................................15<br />

Customer application: Laboratory automation ...............19<br />

Customer application: Degradation of bioplastics ..........23<br />

Conference report: Analytica ........................................25<br />

Practical tips: Automation & Safety ...............................27<br />

New Application Notes, Application Bulletins<br />

and papers ...................................................................29<br />

Literature corner ...........................................................31<br />

Literature references ....................................................32<br />

<strong>Metrohm</strong> seminars & trade fairs ...................................35<br />

Titration • Ion Chromatography • VA Trace Analysis • ProcessLab • Automation

Editorial<br />

Imprint<br />

<strong>Metrohm</strong> Information is a customer<br />

magazine from <strong>Metrohm</strong> Ltd. and is<br />

published in English and German.<br />

Please contact us if you wish to receive<br />

your own copy regularly.<br />

Published by: <strong>Metrohm</strong> Ltd.,<br />

CH-9101 Herisau,<br />

Switzerland<br />

Phone +41 71 353 85 85<br />

Fax +41 71 353 89 01<br />

info@metrohm.com<br />

www.metrohm.com<br />

Editor: Dr. Benedikt Galliker<br />

bg@metrohm.com<br />

Printed by: <strong>Metrohm</strong> Ltd.<br />

Internet: www.metrohm.info<br />

ISSN 1424-0904<br />

Dear Readers,<br />

Globalization – this catchword also applies to <strong>Metrohm</strong>. However, for us it is not<br />

associated with its usual negative attributes. Exactly the opposite is the case:<br />

<strong>Metrohm</strong> draws strength from its global complexity. What does «global» mean<br />

for <strong>Metrohm</strong>? Today <strong>Metrohm</strong> is represented in 40 countries by daughter companies.<br />

Exclusive agencies care for our customers in about 40 further countries. In<br />

each country – no matter whether it is looked after by a daughter company or by<br />

an agency – maintaining highest standards is of outmost importance for us. This<br />

means:<br />

• Providing comprehensive advice about applications<br />

• Short delivery times for all instruments<br />

• Direct availability of accessories and spare parts<br />

• Well-trained service technicians who can provide rapid and reliable on-site help<br />

• The same high standards worldwide – a great bonus for all our customers, and<br />

particularly for those who are global operators themselves<br />

Switzerland is a hospitable country. Every year we welcome <strong>Metrohm</strong> employees<br />

from all over the world to courses and seminars at our <strong>Metrohm</strong> headquarters.<br />

Our Product Managers inform them about the latest news, applications and instruments<br />

in the world of ion analysis. It happens quite often that all the continents are<br />

represented in Herisau at the same time. Courses aimed at further education and<br />

training are also regularly held all over the world. In our regional Support Centers,<br />

which are located in Brazil, South Africa, Singapore and the United Arab Emirates,<br />

employees from the region gather for training. For the instructors from the Swiss<br />

Headquarters, this is a great opportunity of not only getting across the correct<br />

chemistry and analytics, but also of getting to know the different cultures. Obviously,<br />

this method of passing on know-how is not a one-way street. Our employees<br />

listen with great attention – not just on their trips – and in this way can bring back<br />

to Switzerland wishes, suggestions and trends from the various countries. Such<br />

information helps us to develop the right instruments and applications for the exciting,<br />

colorful global market – both today and in future.<br />

A further globalization aspect: today, when most companies have their storerooms<br />

on trucks on the freeways or on planes in the air (keyword just-in-time production),<br />

<strong>Metrohm</strong>’s behavior may appear to be very conservative. <strong>Metrohm</strong> still has instruments<br />

and accessories in its storerooms – both in Switzerland and very close to<br />

you in your local <strong>Metrohm</strong> agency. This means that we can meet your requirements<br />

within a very short time and do not have to ship our products round the world by<br />

express courier. Sending large amounts in a single shipment, as <strong>Metrohm</strong> does, is<br />

not just more economical but also more ecological.<br />

Let‘s return from the global world of ion analysis to this issue of <strong>Metrohm</strong> Information.<br />

Here are some of the highlights: we present you a highly modern analytical<br />

robot system used in fertilizer production in Belgium. You will learn about the<br />

degradation of bioplastics that is investigated at the University of Stuttgart. We are<br />

also seizing this opportunity of introducing you to a further new and interesting<br />

ProcessLab atline application. And last but not least, you can take a first look at the<br />

latest analytical instruments from <strong>Metrohm</strong>.<br />

I wish you much pleasure in reading this issue of <strong>Metrohm</strong> Information.<br />

Yours sincerely,<br />

Dr. Kai Henning Viehweger<br />

Vice President<br />

Division Manager Sales and Marketing<br />

2 <strong>Metrohm</strong> Information Issue 2-2008/2009

New instruments for pH, ion or conductivity measurements<br />

856 Conductivity Module and 867 pH Module<br />

The 856 Conductivity Module is <strong>Metrohm</strong>’s new conductivity meter. Thanks to the<br />

five-ring measuring technique, the new conductivity cells have an extremely wide<br />

linearity range.<br />

The new 867 pH Module is used for pH and ion measurements. Conventional potentiometric<br />

sensors can be used as well as «iTrodes», the new intelligent electrodes<br />

from <strong>Metrohm</strong>.<br />

The 856 Conductivity Module and 867 pH Module can be used in many ways:<br />

– For extending a Titrando by an additional measuring input for pH, ion or conductivity<br />

measurement (tiamo from version 2.0)<br />

– As an integrated, software-controlled pH, ion or conductometer in combination<br />

with PC Control (from version 5.0)<br />

– As a stand-alone pH, ion or conductometer in combination with the 840 Touch<br />

Control (software version 5.0)<br />

– As a completely automated pH, ion or conductometer in combination with the<br />

814 USB Sample Processor or 815 Robotic USB Sample Processor XL.<br />

No matter for which applications the two modules are used – you can be sure that<br />

your measurements comply with the requirements of FDA Standard 21 CFR Part 11.<br />

The two USB and four MSB connections1 provide the modules with flexibility, offer<br />

plug-and-play functionality and allow to connect numerous instruments:<br />

– Printer, sample changer, barcode reader, etc.<br />

– Up to four stirrers and dosing devices for adding auxiliary solutions or for carrying<br />

out standard additions fully automatically<br />

Thanks to the galvanically separated measuring inputs, both instruments can be<br />

used simultaneously for pH and conductivity measurements in the same beaker.<br />

__________________________<br />

1 MSB = <strong>Metrohm</strong> Serial Bus<br />

New: 856 Conductivity Module and 867 pH Module<br />

The new 856 Conductivity Module and 867 pH Module<br />

can be operated either with the 840 Touch Control (left)<br />

or via PC Control (right).<br />

In combination with a Titrando, the new 856 Conductivity<br />

Module allows to carry out pH and conductivity measurements<br />

simultaneously in the same sample vessel.<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 3

New: 856 Conductivity Module and 867 pH Module<br />

The new five-ring conductivity measuring cell (article<br />

number 6.0915.100) offers many advantages and is<br />

easy to handle.<br />

With the pH Module and a Dosino, available as an option,<br />

concentrations can also be determined using the standard<br />

addition method.<br />

The iUnitrode with Pt 1000 temperature sensor is an intelligent<br />

pH glass electrode for universal use that has a<br />

very low alkali error. An 854 iConnect measuring amplifier<br />

is used to connect the iUnitrode to the 867 pH<br />

Module.<br />

856 Conductivity Module and the new five-ring conductivity<br />

measuring cells<br />

The new five-ring conductivity measuring cells for the 856 Conductivity Module<br />

come with a built-in Pt 1000 temperature sensor. They offer a wide linear measuring<br />

range, i.e. the cell constant remains constant and does not need to be determined<br />

again even if the measuring range varies widely. Complicated platinization is<br />

also not required for this type of measuring cells. With their very small immersion<br />

depth for a five-ring measuring cell (see Table) and a diameter of only 12 mm these<br />

cells are also very handy! Thanks to the removable cap, the conductivity measuring<br />

cells are very easy to clean. They are available in two versions.<br />

Technical specifications of the five-ring conductivity measuring cells<br />

6.0915.100 6.0915.130<br />

Shaft length 125 mm 142 mm<br />

Shaft diameter 12 mm 12 mm<br />

Minimal immersion depth 34 mm 50 mm<br />

Cell constant 0.7 cm -1 1 cm -1<br />

Ideal measuring range<br />

(with one calibration)<br />

0.005…20 mS/cm 0.005…100 mS/cm<br />

Temperature range 0…70 °C 0…70 °C<br />

The classical conductivity measuring cells with a banana plug, for example<br />

6.0914.040 for very low conductivities (below 5 μS/cm), can also be connected<br />

by using an optional adapter box.<br />

867 pH Module<br />

As the 867 pH Module is equipped with both a conventional and an intelligent measuring<br />

input, it can be used for pH, potential, ion and temperature measurements with<br />

both conventional and intelligent potentiometric sensors.<br />

If you have any doubts about the condition of your pH electrode, the built-in electrode<br />

test quickly provides certainty. In addition, tips are also given about how to<br />

remedy any faults.<br />

Ion measurements with ion-selective electrodes (ISE) can be made either by direct<br />

measurement or by standard addition with an optional Dosino or 805 Dosimat.<br />

iTrodes, the intelligent <strong>Metrohm</strong> sensors<br />

The memory chip built into the iTrode stores important data such as the article and<br />

serial number of the sensor, calibration data and calibration history, time in use and<br />

calibration interval. All sensor data is read out automatically when the iTrode is connected<br />

to the 867 pH Module. This means that mix-ups, typing errors or expired<br />

calibration intervals are eliminated.<br />

4 <strong>Metrohm</strong> Information Issue 2-2008/2009

Enter the Titrando world<br />

The new 888/890 Titrandos: intelligent and easy to use<br />

The advantages of the new 888/890 Titrandos at a glance:<br />

• Touch Control with large color display<br />

• PC Control or tiamoTM titration software for operation via PC<br />

• Intuitive operation<br />

• Intelligent Exchange Units<br />

• iTrodes – intelligent electrodes for the 888 Titrando<br />

• Potentiometric titration with the 888 Titrando<br />

• Karl Fischer titration with the 890 Titrando<br />

• 847 USB Lab Link for Intranet and Internet<br />

• Complies with FDA 21 CFR Part 11<br />

<strong>Metrohm</strong> has extended the well-proven Titrando family by two new titrators. The<br />

888 Titrando for potentiometric titration and the 890 Titrando for Karl Fischer titration<br />

have been designed for routine applications in titration laboratories and are intended<br />

for customers who place the highest demands on operating comfort, data<br />

management, automation and the traceability of analytical results. The outstanding<br />

property of the new Titrandos is their user-friendliness, which is based on sophisticated<br />

technology with the intelligent iTrode sensors and Exchange Units 1 .<br />

Operation of the Titrandos is either by Touch Control with touch-sensitive screen<br />

(stand-alone titrator) or via a computer with PC Control or tiamo software.<br />

Both the 888 Titrando and the 890 Titrando are equipped with a USB port and allow<br />

connection of a balance, printer, PC, PC keyboard, barcode reader and/or 847<br />

USB Lab Link as well as a sample changer. The titrators can be optimally adapted to<br />

meet customer-specific requirements by connecting further dosing elements.<br />

Comprehensive GLP functions are a matter of course as is compliance with FDA<br />

21 CFR Part 11.<br />

__________________________<br />

1 Intelligent Exchange Units can be used with the 888 and 890 Titrando; the iTrodes only with the 888<br />

Titrando.<br />

New: 888 Titrando and 890 Titrando<br />

The new members of the Titrando family have everything<br />

you need. The 888 Titrando (on the left) is perfect<br />

for potentiometric titrations in routine use. The 890<br />

Titrando (on the right) performs KF titration at the highest<br />

level.<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 5

New: 888 Titrando and 890 Titrando<br />

In the <strong>Metrohm</strong> range of electrodes you will find the<br />

iTrodes, intelligent electrodes allowing you to utilize the<br />

full potential of your new 888 Titrando. The combined<br />

iUnitrode pH glass electrode is one of these electrodes.<br />

The 888 Titrando: perfect for potentiometric titrations<br />

The 888 Titrando is the new potentiometric titration system for routine analysis.<br />

The instrument is equipped with a high-resolution, galvanically separated measuring<br />

input for conventional and intelligent electrodes (iTrodes) as well as an<br />

intelligent Exchange Unit. Optionally, numerous additional dosing elements such<br />

as 805 Dosimats or 800 Dosinos can be connected to the four MSB (<strong>Metrohm</strong><br />

Serial Bus) connections. The 888 Titrando is ideal for dynamic (DET) and monotonic<br />

(MET) equivalence-point titrations as well as for titrations to a predefined<br />

endpoint (SET).<br />

The complete packages we offer allow immediate start up: together with the 888<br />

Titrando you will receive an intelligent Exchange Unit (20 mL), an «Ecotrode plus»<br />

combined pH glass electrode, a magnetic stirrer, all the necessary cable connections<br />

and tubing together with either the 840 Touch Control or the titration software<br />

tiamo light.<br />

The 890 Titrando: KF titrations at the highest level<br />

The 890 Titrando is the new titrator for volumetric Karl Fischer water determinations.<br />

The sophisticated control algorithm and the improved volume resolution of<br />

the intelligent Exchange Unit guarantee results of the highest precision. Great value<br />

has been placed on simple and intuitive user guidance. Icons show whether the titration<br />

cell contents are still being conditioned or whether you can already start the<br />

water determination.<br />

The electrode test and the «Safety stop» parameter prevent the cell from overflowing<br />

during conditioning, i.e. if the electrode is accidentally connected incorrectly or<br />

if the titration cell is very moist, conditioning will be terminated after a preset time<br />

or after the addition of a predefined KF reagent volume. This new feature increases<br />

working safety in the laboratory.<br />

The 890 Titrando also has four MSB connections and a USB connection.<br />

Together with the 890 Titrando you will also receive all the hardware and software<br />

that you require for your Karl Fischer titrations: an intelligent Exchange Unit (10<br />

mL), a double Pt-wire electrode, an 803 Ti Stand, all the necessary cable connections<br />

and tubing together with either the 840 Touch Control or the titration software<br />

tiamo light.<br />

Time-saving KF titrations with the 803 Ti Stand<br />

Save time with the 803 Ti Stand! It is used for stirring and for replacing<br />

the used working medium by simply pressing a button. The built-in membrane<br />

pump aspirates the spent solution and adds fresh working medium<br />

without the cell having to be opened. This reduces the conditioning time<br />

enormously.<br />

The iTrodes – not stupid at all!<br />

Intelligence creates transparency<br />

The electrode is the most important component of each titration system. The<br />

iTrodes represent our new intelligent electrode generation. They guarantee the complete<br />

traceability of the result to each component involved in the analysis.<br />

The digital passport – no more errors<br />

The chip built into the electrode head stores important sensor data such as article<br />

and serial number, calibration data, calibration history and time in use. All sensor<br />

data is read in automatically when the sensor is connected to the 888 Titrando. This<br />

prevents editing errors. The electrode is identified automatically. If the electrode<br />

6 <strong>Metrohm</strong> Information Issue 2-2008/2009

does not match that defined in the method, the user will be informed. This means<br />

that the use of an incorrect electrode is prevented.<br />

Saving the calibration data – outliers don’t have a chance<br />

Monitoring functions permit the exclusion of electrodes whose calibration data is<br />

outside the limits or whose calibration has expired. If the sensor is to be used with<br />

different instruments or if an inexperienced user is to be prevented from calibrating<br />

the electrode, the electrode can be calibrated under defined conditions and<br />

then connected to the particular instrument with the calibration data stored in the<br />

memory chip.<br />

Certified dosing elements with brains<br />

The <strong>Metrohm</strong> Exchange Units set new standards with respect to operating safety.<br />

Each Exchange Unit is equipped with a data chip from which the Titrando<br />

automatically reads off all the data that is required for an error-free titration, i.e.<br />

type of reagent, titer, last titer determination, expiry date and much more. The<br />

Titrando compares this data with that of the selected method and carries out a<br />

plausibility test. If a negative result is obtained an error message appears in clear<br />

text.<br />

Additionally, each Exchange Unit is provided with its serial and cylinder numbers<br />

and supplied with an individual certificate. The Titrando checks the predefined<br />

intervals for determining the titer of the titrant. This ensures that work is always<br />

carried out with the correct titer.<br />

Simple operation<br />

Profit from our vast experience in the titration sector! We have ensured that your<br />

work with our potentiometric and Karl Fischer titrators is as easy as possible – even<br />

if you are new to that field. This is guaranteed by the intuitive and simple operation<br />

of the instruments, standard user methods for a range of applications and a clever<br />

help function that is available to you at any time. There is no need to tediously work<br />

through numerous menus! It is possible to quickly adapt all the parameters and<br />

standard user methods to meet your particular requirements. User dialogs can also<br />

be customized to suit the needs of the particular user. This user-friendly concept<br />

allows you to work efficiently – you only have to select the predefined method and<br />

can then start immediately.<br />

All the methods that have been created for <strong>Metrohm</strong> Titrinos can be automatically<br />

converted into Titrando methods using a PC. The Titrando itself, the memory card<br />

or the PC with its numerous additional possibilities is available for storing your<br />

methods, sample data and results.<br />

Automation made easy<br />

An increasing number of samples, time-consuming sample preparation and unattended<br />

overnight operation quickly justify the use of sample changers. The 888 and<br />

890 Titrandos have the necessary intelligence to control sample changers. Whether<br />

small or large sample capacities, one or two processing stations, measuring out the<br />

sample, sample preparation, liquid handling, rinsing and calibrating the electrodes<br />

– the 814 USB Sample Processor and 815 Robotic USB Sample Processor XL offer<br />

a high degree of automation for low investment costs. Sensational: just connect the<br />

sample changer to the USB interface of the Titrando and the world of automation<br />

already opens up to you.<br />

Convince yourself of the many advantages of our new 888/890 Titrandos for<br />

routine analysis and for users who are new to the Titrando world. Contact your<br />

local <strong>Metrohm</strong> agency today for advice and to arrange an instrument demonstration!<br />

New: 888 Titrando and 890 Titrando<br />

The intelligent <strong>Metrohm</strong> Exchange Units make a considerable<br />

contribution to the error-free performance of<br />

your titrations. These Exchange Units, which are available<br />

with buret volumes of 1, 5, 10, 20 and 50 mL, can<br />

conveniently be used with reagent bottles from various<br />

manufacturers.<br />

The use of sample changers, for example the 814 USB<br />

Sample Processor, helps you to manage even large numbers<br />

of samples.<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 7

New: 888 Titrando and 890 Titrando<br />

888 Titrando and 890 Titrando: an overview<br />

Intelligent dosing elements for titration<br />

Additional dosing elements (for dosing only)<br />

888 Titrando 890 Titrando<br />

One built-in Dosimat for<br />

Exchange Unit<br />

Three 805 Dosimats with<br />

Exchange Unit<br />

Three 800 Dosinos with<br />

Dosing Unit<br />

Intelligent Exchange Unit with built-in data chip Yes<br />

Steps per cylinder content (Exchange Unit) 20 000<br />

One built-in Dosimat for<br />

Exchange Unit<br />

Three 805 Dosimats with<br />

Exchange Unit<br />

Three 800 Dosinos with<br />

Dosing Unit<br />

Measuring interface for pH, U/mV, T/°C 1 –<br />

Intelligent electrodes iTrodes 1 –<br />

Measuring input for polarizable electrodes 1<br />

Operation, dialog Touch Control, PC Control or tiamo<br />

Stirrer, titration stand<br />

801 Stirrer (magnetic stirrer) or 802 Stirrer (rod stirrer)<br />

with 804 Ti Stand or 803 Ti Stand (KF)<br />

Stirrer and intelligent dosing element connections Four MSB connections (<strong>Metrohm</strong> Serial Bus, daisy chain)<br />

Sample changer connections One sample changer via USB<br />

Connection of balance, printer, PC, PC keyboard, barcode<br />

reader and/or Lab Link<br />

Via two USB slave ports, RS-232/USB Box (option)<br />

Temperature sensor Pt 1000 or NTC –<br />

Differential amplifier Option –<br />

Real-time display on Touch Control or PC monitor Yes<br />

DET Dynamic equivalence point titration Yes –<br />

MET Monotonic equivalence point titration Yes –<br />

SET Titration to preset endpoints with<br />

automatic conditioning<br />

KFT Volumetric Karl Fischer titration with automatic<br />

conditioning<br />

Yes –<br />

– Yes<br />

MEAS Measuring mode for pH, U/mV, T/°C, I pol, U pol Yes –<br />

CAL Calibration with automatic buffer recognition Yes –<br />

Additional titration curve evaluation for fixed endpoints,<br />

pK values (HNP)<br />

Yes –<br />

Comprehensive GLP functions; complies with FDA 21 CFR Part 11 Yes<br />

8 <strong>Metrohm</strong> Information Issue 2-2008/2009

Sample preparation: easy, safe and precise<br />

The new 860 KF Thermoprep<br />

The 860 KF Thermoprep is the new <strong>Metrohm</strong> instrument for thermal sample preparation<br />

in Karl Fischer titration (KF titration/KFT). It can be combined with a large<br />

number of KF titrators and KF coulometers for volumetric or coulometric water determinations.<br />

Stumbling blocks in sample preparation and determination<br />

Many substances, such as plastics or salts, release their water either very slowly<br />

or only at high temperatures. This means that they cannot be analyzed by direct<br />

volumetric or coulometric KF titration.<br />

Certain samples are either sparingly soluble or not soluble at all in alcohols and<br />

therefore in Karl Fischer reagents containing alcohols. In order to bring such substances<br />

into solution, it is necessary to use harmful solubility promoters (such as<br />

chloroform, xylene …) or, alternatively, to perform complicated sample preparation<br />

steps.<br />

If you place the sample directly in the titration vessel you risk contaminating the<br />

vessel. As a result, the titration vessel has to be cleaned more often and the reagents<br />

then also need to be replaced. This costs time and, because of the increased<br />

reagent consumption, also money. In addition, various substances present in the<br />

sample can undergo side-reactions with the KF reagents used and produce incorrect<br />

results.<br />

Be on the safe side with thermal sample preparation<br />

All the above problems can be avoided with the new 860 KF Thermoprep made by<br />

<strong>Metrohm</strong>. The sample is heated in a hermetically sealed vessel. The moisture released<br />

by the sample is transferred by a stream of dry carrier gas to the titration<br />

cell and determined there by Karl Fischer titration. Depending on the amount of water<br />

present, either a volumetric or coulometric titration is carried out. The sample<br />

itself does not enter the titration cell and therefore does not come into contact with<br />

the reagents used. This means that interfering side-reactions and matrix effects are<br />

excluded.<br />

What benefits does the 860 KF Thermoprep offer you?<br />

The most important benefits of the 860 KF Thermoprep are:<br />

• Easy operation<br />

• Safe procedure<br />

• Precise results<br />

New: 860 KF Thermoprep<br />

The preparation of difficult samples for water analysis<br />

according to Karl Fischer can be performed easily with<br />

the new 860 KF Thermoprep. As an example, a setup<br />

with an 841 Titrando is shown.<br />

Always be on the safe side by using the 860 KF Thermoprep<br />

for sample preparation in KF titrimetry (at right). It<br />

can be optimally combined with Titrandos for KF titration<br />

or KF coulometers (at left: 756 KF Coulometer).<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 9

New: 860 KF Thermoprep<br />

Thanks to the operating unit with its well laid-out menu,<br />

working with the 860 KF Thermoprep is very easy.<br />

1. Switch on the 860 KF Thermoprep<br />

and select the temperature.<br />

2. Place an empty conditioning vial<br />

in the oven and pierce it with the<br />

needle.<br />

3. Switch on the pump, adjust<br />

the gas flow and start the titrator<br />

(conditioning).<br />

4. Weigh out the<br />

sample into a<br />

sample vial.<br />

5. Hermetically seal<br />

the sample vial<br />

with a septum using<br />

the crimping<br />

tongs.<br />

Easy operation<br />

Well laid-out menu guidance makes working with the 860 KF Thermoprep a pleasure.<br />

All parameters can be set to your requirements by just pressing a few keys.<br />

The sample preparation is also as easy as can be imagined. All you have to do is<br />

weigh out your sample into the sample vial and then seal it hermetically.<br />

Safe procedure<br />

The extraordinarily stable and well thought-out construction of the 860 KF Thermoprep<br />

prevents the needle from being lowered beside the septum. You always hit the<br />

septum – with certainty.<br />

Often the use of toxic solubility promoters can be avoided by using the oven method<br />

– harmful solvent vapors are a thing of the past.<br />

Precise results<br />

As the analytical conditions are identical for all samples, the results are reproducible<br />

and precise. The headspace vials are hermetically sealed by a PTFE septum<br />

and thus guarantee a constant water content, even after the vials have been standing<br />

around for some time.<br />

The heated transfer tubing prevents the condensation of water vapor and ensures<br />

that all the moisture enters the titration cell for determination.<br />

The sample remains in the sample vessel and does not undergo any side-reactions<br />

with the KF reagents.<br />

The analysis – step by step<br />

You will obtain your results in just a few steps:<br />

6. Wait until the preset temperature<br />

has been reached and «Conditioning<br />

OK» appears.<br />

7. Start the titration<br />

at the titrator and<br />

carry out the following<br />

steps 8, 9<br />

and 10 within six<br />

seconds.<br />

8. Remove the conditioning vial from<br />

the oven using the crimping tongs.<br />

Caution: hot!<br />

9. Insert the sample<br />

vial into the oven<br />

of the 860 KF<br />

Thermoprep.<br />

10. Pierce the septum<br />

with the needle<br />

and then wait until<br />

the titration has<br />

finished.<br />

11. When the titration<br />

has finished, remove<br />

the sample<br />

vial from the oven<br />

using the crimping<br />

tongs.<br />

Caution: hot!<br />

Karl Fischer titration with <strong>Metrohm</strong> and the new 860 KF Thermoprep is easy, safe and<br />

precise. Convince yourself at your local <strong>Metrohm</strong> agency!<br />

10 <strong>Metrohm</strong> Information Issue 2-2008/2009

Titration, ion chromatography and direct measurements<br />

Fully automated drinking water analysis with TitrIC 2.0<br />

Until recently, drinking water analysis was time-consuming, complicated and required<br />

a lot of manual work. Not anymore! <strong>Metrohm</strong>‘s TitrIC stands for the fully<br />

automated analysis of drinking water using titration, ion chromatography and direct<br />

measurements (pH, conductivity and temperature). All the ionic components are<br />

determined reliably, rapidly and reproducibly.<br />

The samples only have to be placed on the sample rack. TitrIC then takes control<br />

and works irrespective of daytime or nighttime and even at weekends. Intelligent<br />

control and proven technology guarantee reliable analyses. TitrIC works fully automatically;<br />

up to 100 samples can be conveniently determined without requiring any<br />

manual intervention. The results are stored in the internal database and can also be<br />

shown in the form of a well-laid-out report. The high degree of automation reduces<br />

costs and increases the precision of the measurements. TitrIC can be conveniently<br />

controlled by the TitrIC 2.0 software, which is a combination of the well-proven<br />

tiamo and MagIC Net software packages.<br />

The low space requirements of TitrIC are well worth mentioning. Synergies between<br />

titration, direct measurement and ion chromatography from <strong>Metrohm</strong> come into<br />

play here. All the methods use the same liquid handling units and a common sample<br />

changer. This helps to save both costs and space. TitrIC is based on the most<br />

up-to-date and highly reliable analytical instruments and utilizes the vast know-how<br />

and experience gathered by <strong>Metrohm</strong>, the market leader for ion analysis. The investment<br />

payback time is very short.<br />

Parameters that can be determined with TitrIC<br />

Anion IC with TitrIC<br />

• Fluoride<br />

• Chloride<br />

• Bromide<br />

• Nitrite<br />

• Nitrate<br />

• Phosphate<br />

• Sulfate<br />

• …<br />

Cation IC with TitrIC<br />

• Lithium<br />

• Sodium<br />

• Ammonium<br />

• Potassium<br />

• Calcium<br />

• Magnesium<br />

• …<br />

Direct measurements with TitrIC<br />

• pH<br />

• Temperature<br />

• Conductivity<br />

Titrations with TitrIC<br />

• p value (titration to pH = 8.2)<br />

• m value (titration to pH = 4.3)<br />

• Calcium<br />

• Magnesium<br />

Calculations with TitrIC<br />

• Molar concentration of all cations<br />

• Molar concentration of all anions<br />

• Ionic balance<br />

TitrIC is extremely flexible and can therefore be optimally adapted to suit a wide<br />

range of analytical tasks. The application determines which parameters are of interest.<br />

Different methods and procedures can be freely combined with one another.<br />

New: TitrIC 2.0<br />

The informative TitrIC report shows all the results at a<br />

glance.<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 11

New: TitrIC 2.0<br />

This flow chart gives an example of a drinking water<br />

analysis procedure with TitrIC 5. A sequence of direct<br />

measurements and titrations runs in parallel to the analysis<br />

of the drinking water by ion chromatography; this<br />

saves a lot of time. The sequence proceeds fully automatically.<br />

The system consists of the 856 Conductivity Module, four<br />

800 Dosinos, 802 Stirrer (propeller stirrer), 809 Titrando,<br />

815 Robotic USB Sample Processor XL and 881 Compact<br />

IC pro with sequential suppression.<br />

The system consists of the 856 Conductivity Module,<br />

three 800 Dosinos, 802 Stirrer (propeller stirrer), 855<br />

Robotic Titrosampler, one 881 Compact IC pro without<br />

suppression and one 881 Compact IC pro with sequential<br />

suppression.<br />

Anions<br />

F – , Cl – , NO 2 – , Br – ,<br />

NO 3 – , HPO4 2 – , SO4 2 –<br />

Apart from water analysis, TitrIC is also to be recommended for other applications, for<br />

example in the fields of food analysis and the electroplating or pharmaceutical industries.<br />

There are four basic versions of TitrIC<br />

• TitrIC 4 – the basic system<br />

855 Robotic Titrosampler<br />

28...100 Samples / 75...200 mL<br />

Conductivity<br />

Te m perature<br />

pH value<br />

Titration K A 8.2 (p value)<br />

Titration K A 4.3 (m value)<br />

TitrIC<br />

Database, report<br />

Fully automated system for the direct measurement of temperature, conductivity<br />

and pH, the titrimetric determination of p value, m value, calcium and magnesium<br />

as well as the determination of anions by ion chromatography.<br />

• TitrIC 5 – for complete anion and cation analysis<br />

Cations<br />

Li + , Na + , NH 4 + , K + ,<br />

Mg 2+ , Ca 2+<br />

Fully automated system for the direct measurement of temperature, conductivity<br />

and pH, the titrimetric determination of p value and m value as well as the determination<br />

by ion chromatography of cations (including calcium and magnesium) and<br />

anions.<br />

12 <strong>Metrohm</strong> Information Issue 2-2008/2009

• TitrIC 6 – the professional solution with sealed sample vessels<br />

Fully automated system for the direct measurement of temperature, conductivity<br />

and pH, the titrimetric determination of p value and m value as well as the determination<br />

by ion chromatography of cations (including calcium and magnesium) and<br />

anions. The sample changer is equipped with the DisCover function for automatically<br />

removing the sample vessel covers.<br />

• TitrIC 7 – the solution for samples containing particles<br />

Fully automated system for the direct measurement of temperature, conductivity<br />

and pH, the titrimetric determination of p value and m value as well as the determination<br />

by ion chromatography of cations (including calcium and magnesium) and<br />

anions. Particle-containing samples have their particles removed by <strong>Metrohm</strong> Inline<br />

Ultrafiltration before the ion chromatographic analysis.<br />

Depending on the ecological system, it may take centuries for rainwater to become<br />

drinking water. In contrast, with TitrIC you only need a few moments to find out<br />

about the species contained in drinking water.<br />

New: TitrIC 2.0<br />

The system consists of the 856 Conductivity Module,<br />

three 800 Dosinos, 802 Stirrer (propeller stirrer), 809<br />

Titrando, 815 Robotic USB Sample Processor XL, one<br />

850 Professional IC for anions (sequential suppression)<br />

and cations.<br />

The system consists of the 856 Conductivity Module,<br />

two 800 Dosinos, 802 Stirrer (propeller stirrer), 855 Robotic<br />

Titrosampler, one 850 Professional IC for anions<br />

with Sample Prep 2, one 872 Extension Module IC Pump<br />

and an additional iDetector for cation analysis.<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 13

New: 863 Compact VA Autosampler / Rotating seal for Solitrode<br />

Economic automation for voltammetric trace analysis<br />

863 Compact VA Autosampler<br />

The 863 Compact VA Autosampler saves time and money<br />

– and the reproducibility of the results of your VA<br />

analyses will improve remarkably!<br />

The 843 Pump Station empties and rinses the measuring<br />

vessel and in this way ensures the complete automation<br />

of voltammetric trace analysis.<br />

Comfortable pH measurement<br />

The 863 Compact VA Autosampler is the ideal sample changer for the easy automation<br />

of VA systems. In combination with the 797 VA Computrace, automation in<br />

voltammetric trace analysis is now available at a favorable price while occupying<br />

very little space. In this way, small series of similar samples can be determined with<br />

high accuracy.<br />

The sample rack of the 863 Compact VA Autosampler accommodates up to 18<br />

samples that can be analyzed fully automatically in a single run. The peristaltic<br />

pump built into the sample changer transfers the sample solution from the sample<br />

vessel to the measuring vessel of the 797 VA Computrace. All the auxiliary solutions<br />

that are necessary for the voltammetric determination are added by Dosinos<br />

during the measuring procedure. The two pumps of the connected 843 Pump Station<br />

empty and rinse the measuring vessel after each determination.<br />

The 863 Compact VA Autosampler has two preprogrammed methods that can simply<br />

be selected via the built-in keyboard. A large LCD display provides up-to-date<br />

information on the status of the sample changer.<br />

Existing manually operated 797 VA Computrace systems can easily be extended<br />

with the 863 Compact VA Autosampler and the 843 Pump Station.<br />

Advantages of the 863 Compact VA Autosampler<br />

• Economic automation of voltammetric trace analysis<br />

• Compact design<br />

• Can be used to extend existing 797 VA Computrace systems<br />

• Two different method templates<br />

• Built-in peristaltic pump<br />

• 18 sample positions<br />

New: Solitrode now equipped with rotating seal<br />

With the <strong>Metrohm</strong> MVA-3 VA Automation Package you can start work immediately.<br />

It consists of 797 VA Computrace, 863 Compact VA Autosampler, 843 Pump Station<br />

and 800 Dosino with Dosing Unit, among other things. The 863 Compact VA<br />

Autosampler is also available separately. We offer the 843 Pump Station in two versions,<br />

namely with membrane pumps or with peristaltic pumps.<br />

Let the sample changer carry out repetitive activities. In this way you can save both<br />

your resources and valuable time. The automated system analyzes your samples<br />

with outstanding reproducibility!<br />

The 6.0220.100 Solitrode is a robust and reliable pH electrode. With its break-proof<br />

plastic shaft, it is ideal for routine use in the laboratory.<br />

As a new feature, the Solitrode has now been equipped with a very convenient<br />

system for sealing and unsealing the electrolyte refill opening. The opening is now<br />

made accessible by turning the plastic ring counterclockwise and sealed by turning<br />

it clockwise.<br />

14 <strong>Metrohm</strong> Information Issue 2-2008/2009

Bath analysis with ProcessLab<br />

Monitoring pickling baths in the steel industry<br />

Scale and rust as steel surface contaminants<br />

Steel is one of the most important starting materials for innumerable products. The<br />

world‘s yearly steel production exceeds 1.3 billion tonnes (1). For some time now,<br />

demand has exceeded production, which has led to massive price increases for<br />

steel. As a result, new production capacities are being set up and existing plants<br />

extended at high investment costs. In order to increase the yield while keeping the<br />

quality constant and costs low, each individual step in the production process must<br />

be adequately monitored and controlled. An extremely important part of the process<br />

is pickling the steel, in which impurities resulting from previous production<br />

steps, for example the scale 1 produced during rolling, or any rust already present,<br />

are removed and the surface prepared for subsequent process steps. At the same<br />

time, interfering annealing colors are removed, the surface being passivated by<br />

the formation of a protective layer and in this way protected against further corrosion.<br />

Only after the pickling process can steel be formed or its surface treated and,<br />

for example, used for the production of automobile or metal construction components.<br />

Removal of impurities by using pickling baths<br />

The pickling baths used are made up of diluted acids, for example hydrochloric or<br />

sulfuric acid, or are mixtures of acids such as HNO 3 / HF or H 2SO 4 / H 3PO 4 / HF.<br />

Accelerants and other auxiliary agents are often added to these mixtures to optimize<br />

and speed up the process. While pickling removes impurities, the acids used<br />

also attack the steel surface and partially dissolve it. This is why it is important that<br />

process-relevant parameters such as dwell time, bath temperature and bath composition<br />

are controlled and maintained as accurately as possible. This is the only<br />

way in which a pickling bath can be operated economically and, above all, in a way<br />

that protects both the environment and resources. Physical parameters such as<br />

dwell time and bath temperature are easy to monitor, whereas the analysis of bath<br />

constituents is usually more complicated and must be carried out in an analytical<br />

laboratory.<br />

Analyzing pickling baths with ProcessLab<br />

Steel production is a continuous process that also takes place at night and during<br />

weekends. Qualified laboratory personnel are often not available twenty-four hours<br />

a day; this can make uninterrupted analytical process control difficult. This is where<br />

the <strong>Metrohm</strong> ProcessLab system for bath analysis opens up completely new possibilities.<br />

The easy-to-use ProcessLab analysis system is installed directly in the<br />

process area. The only thing that a process worker has to do is bring a bath sample<br />

to the ProcessLab and start the system by pressing a single button. ProcessLab<br />

analyzes the sample completely automatically. Important process information is<br />

available only a few minutes later. This enables on-site process analysis around the<br />

clock and results in much more direct and precise process control.<br />

Controlling the important process parameters<br />

Each pickling bath consists of numerous constituents and additives, not all of which<br />

are equally relevant to the process. Four of these analytical parameters have a considerable<br />

influence on the steel pickling process: the amounts of free and total acid<br />

and the iron(II) and iron(III) concentrations. The analyses of these parameters is<br />

described in detail below and in <strong>Metrohm</strong> Application Bulletin 295 (2).<br />

__________________________<br />

1 Scale is iron(II, III) oxide that forms on the surface of iron or steel when steel is formed or treated at<br />

high temperatures.<br />

Surface-treated steel products<br />

Application: ProcessLab<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 15

Application: ProcessLab<br />

ProcessLab analysis system with analysis module and<br />

TFT operating unit with touch-screen.<br />

The free acid (FA) is a measure of the acid still available for pickling. It is determined<br />

by potentiometric titration with an NaOH solution to pH 4.2. It is given as the<br />

equivalent of an acid present in the bath; in a hydrochloric acid pickling bath, the<br />

NaOH consumption corresponds to the free acid in g HCl per liter. During the pickling<br />

process in a hydrochloric acid pickling bath, the free acid reacts with the metals<br />

to form metal chlorides, which means that the free acid concentration decreases<br />

and the bath must be topped up by the addition of concentrated hydrochloric acid.<br />

The total acid (TA) corresponds to the total amount of free acid plus the amount of<br />

reacted acid. The total acid is determined by titrating with NaOH to pH 8.6. The total<br />

consumption of NaOH then corresponds to the total acid equivalent.<br />

The Fe(II) and Fe(III) contents in a pickling bath are important process control<br />

parameters. They are a measure of the oxidizing power of the pickling bath and<br />

therefore have a considerable influence on the pickling time and the quality of the<br />

product. Moreover, if the iron contents are too low or too high, pickling becomes<br />

ineffective. Fe(II) is frequently determined by titration with potassium permanganate.<br />

Unfortunately, KMnO4 has the disadvantage that interfering chlorine and chlorine<br />

dioxide are formed in the presence of hydrochloric acid. Another disadvantage<br />

is the unstable titer of potassium permanganate solutions. Thus, KMnO4 is not really<br />

suitable for routine process analysis. In contrast, cerium(IV) is highly suitable;<br />

it is also a strong oxidizing agent and reacts with Fe(II) according to the following<br />

equation:<br />

Fe 2+ + Ce 4+ � Fe 3+ + Ce 3+<br />

In this reaction, no interfering intermediate products are formed even in the presence<br />

of large amounts of chloride and the determination is quantitative. As cerium(IV)<br />

solutions have a very stable titer they are ideal for the determination of Fe(II) in pickling<br />

baths. The endpoint of the redox titration is detected by means of an ordinary<br />

platinum redox electrode.<br />

In addition to the absolute concentrations of Fe(II) and Fe(III), the ratio of the Fe(II)<br />

to Fe(III) concentration is also important for an effective pickling process. It should<br />

always lie within a certain range. Auxiliary agents such as hydrogen peroxide or nitrites<br />

oxidize Fe(II) to Fe(III) and therefore alter the ratio of these two components.<br />

Optimal pickling results can only be achieved when the pickling bath has a high oxidizing<br />

power with an optimal ratio between Fe(II) and Fe(III).<br />

An overview of the <strong>Metrohm</strong> analysis system<br />

The ProcessLab system presented here determines fully automatically those<br />

parameters that are important for the smooth running of a pickling bath: free acid<br />

and total acid as well as the Fe(II) and Fe(III) concentrations. The system is installed<br />

16 <strong>Metrohm</strong> Information Issue 2-2008/2009

in the vicinity of the process to be monitored and allows the rapid on-site analysis<br />

of various pickling baths. A ProcessLab analysis system always consists of one<br />

or several analytical modules adapted to the particular application and a TFT<br />

operating unit. With the built-in touch-screen (option) operation becomes even simpler<br />

and more comfortable.<br />

Both the operating unit and the analysis module are contained in a robust, splashwater-protected<br />

housing and are ideally suitable for use under rough production<br />

plant conditions.<br />

The analysis module of the system described here is also of modular construction.<br />

A titration vessel with magnetic stirrer, variable and automatic sample metering<br />

using a sample loop and an 800 Dosino as well as two 800 Dosinos for the exact<br />

addition of the two titrants Ce(SO4) 2 and NaOH are contained in one housing.<br />

The peristaltic pumps are used for the automatic addition of reagents and auxiliary<br />

agents and for rinsing the titration vessel.<br />

The user only has to take a sample from the bath and bring it to the system. The<br />

analysis sequence for the automatic determination of all four parameters is started<br />

by pressing a single button. The sample is metered automatically, transferred to the<br />

titration vessel and the concentrations of the analytes determined by titration. All the<br />

necessary process information is available within only a few minutes, without the<br />

bath samples having to be taken to the laboratory for analysis.<br />

Determining the free and total acid<br />

2 mL sample is metered fully automatically, treated with 20 mL potassium fluoride<br />

solution (c(KF) = 3 mol/L) to mask the iron, demineralized water is added and the<br />

solution then titrated with NaOH solution to pH 4.2. The NaOH consumption corresponds<br />

to the amount of free acid in the bath. A further aliquot of the sample is<br />

titrated with NaOH solution to pH 8.6; in this case the total amount of NaOH consumed<br />

corresponds to the total acid concentration in the bath.<br />

Determining the Fe(II) and Fe(III) concentrations<br />

Demineralized water is placed in the titration vessel and a sample aliquot of 2 mL is<br />

added to it automatically. Using a Pt electrode, titration is performed with cerium(IV)<br />

sulfate solution (c(Ce(SO 4) 2) = 0.1 mol/L) to the first endpoint. The Ce(IV) consumption<br />

corresponds to the Fe(II) concentration in the pickling bath.<br />

• EP<br />

The Fe(III) concentration is then calculated from the free and total acid content taking<br />

into account the cerimetrically determined Fe(II) concentration.<br />

Application: ProcessLab<br />

Analysis module equipped with Dosinos, peristaltic<br />

pumps and a titration vessel for automatic pickling bath<br />

analysis.<br />

Typical titration curve for the redox-potentiometric Fe(II)<br />

determination by titration with cerium(IV) sulfate.<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 17

Application: ProcessLab<br />

The advantages of the ProcessLab system<br />

A single analysis system determines all the relevant bath parameters and collects<br />

important process information. The results are available at any time for the subsequent<br />

traceability of the process and for making audits easier. The system can<br />

also transmit status signals, for example if a predefined limit is infringed or if a<br />

fault occurs in the system. Information about the bath content can also be easily<br />

transmitted in the form of an analog 4...20 mA signal. The simple process integration<br />

is clearly one of the many advantages of the ProcessLab system; information<br />

is immediately available to the personnel in the operations center or the process<br />

monitoring system. Therefore it is possible to react directly to variations and, if<br />

necessary, to take countermeasures. If a variation does occur, the correct amount<br />

of fresh acid or auxiliary agent to be added can be calculated with the aid of the<br />

included «tiamo for ProcessLab» software; it is even possible to do the addition<br />

fully automatically. Thanks to the rapid availability of the analytical data, the pickling<br />

process can be carried out under optimal conditions. On the one hand, this improves<br />

the quality of the end product, on the other hand, there results a longer operating<br />

period for the pickling bath with simultaneous reduction of its running costs<br />

(reduced usage of chemicals). As a result of the cost savings due to more efficient<br />

bath control and higher-quality end products, a ProcessLab system normally has a<br />

pay-back time of less than three years.<br />

Summary<br />

The quality of the end product is considerably influenced by how well and reproducibly<br />

the individual process steps are carried out. The <strong>Metrohm</strong> ProcessLab<br />

system described here is used for fully automatic on-site analysis of all the relevant<br />

process parameters of a steel pickling bath. This means that all the analytical<br />

data is available directly after sampling. The amount of bath additives to be<br />

added can be calculated automatically and, if required, also added automatically.<br />

The system offers numerous possibilities for process integration, guaranteeing<br />

the relevant information is quickly available wherever it is required.<br />

Thanks to ProcessLab, pickling baths can be used more economically and ecologically<br />

and operating and disposal costs are considerably reduced. This also makes<br />

a particular contribution to protecting both resources and the environment.<br />

References<br />

(1) International Iron and Steel Institute (IISI), data for 2007, www.worldsteel.org<br />

(2) <strong>Metrohm</strong> Application Bulletin AB 295: Determination of Fe2+ , Fe3+ , total and free<br />

acid in an etching bath (steel industry), <strong>Metrohm</strong> AG, Switzerland<br />

Further reading<br />

Monograph: Practical titration – training manual for titrimetric volumetric analysis,<br />

2005, 164 pages, <strong>Metrohm</strong> AG, Switzerland<br />

Prozessbegleitende Analytik in der Galvanotechnik, T. W. Jelinek, 1999, 440 pages,<br />

Eugen G. Leuze Verlag, Saulgau<br />

18 <strong>Metrohm</strong> Information Issue 2-2008/2009

Background information about Nucomat<br />

The Belgian company Nucomat1 , enjoys an excellent reputation in the system integration<br />

sector and as a manufacturer of customer-specific solutions for laboratory automation.<br />

The core competency of Nucomat lies in the conversion of manual laboratory<br />

methods into automated systems. Robotics and automation are frequently associated<br />

with mass production and a large number of constantly repeated steps carried out as<br />

quickly as possible. As can be seen from the text below, laboratory automation requires<br />

a different approach often involving other criteria.<br />

Nucomat builds turnkey units using a building block system made up of autonomous<br />

work stations linked to a sophisticated control and monitoring system. Nucomat can<br />

also incorporate instruments from other manufacturers in its systems in order to solve<br />

specific customer problems.<br />

Nucomat installed various automated systems all over the world for research applications<br />

in the fields of life sciences, biotechnology, food technology, body care and<br />

cosmetics. Other systems are used for environmental analysis, the analysis of ore<br />

samples, quality assurance/quality control and petrochemical applications.<br />

Nucomat systems are used for applications such as:<br />

– Automated determination of copper in ore samples from open-pit mines. The<br />

system complies with stipulated operating rules and has a built-in quality control<br />

system. It is in continuous use 24 hours per day, 7 days per week.<br />

– Automated sample preparation for heavy metal determination in liquid samples<br />

using ICP-AES.<br />

– Automated preparation of plutonium reference materials.<br />

– Recording and observing bacterial growth using measurements for determining<br />

the oxygen consumption in the development of new food preservatives.<br />

– Sample preparation of viscous liquids while monitoring pH and viscosity.<br />

– Cryotube serum aliquotation for clinical studies.<br />

– Automated screening with a high sample throughput for drug development.<br />

– Automated filtration for radioligand binding assays.<br />

An overview of the Nucomat system for the analysis of fertilizers<br />

The automated Wetchem system for the analysis of fertilizer samples has recently<br />

been developed by Nucomat in close cooperation with <strong>Metrohm</strong> (see Fig. 1). The<br />

system allows multi-species determination (about 10 different species) and also<br />

carries out the complete sample preparation procedure, which is particularly worth<br />

mentioning. Sample preparation for wet-chemistry instrumental analysis methods<br />

still remains tedious and labor-intensive even in modern laboratories if it has to be<br />

carried out manually.<br />

Outstanding features of the system are, amongst others:<br />

– Sampling and sample preparation of liquid and solid samples<br />

– Several reagent addition possibilities<br />

– Classical «hotplate» digestion<br />

– Making up the sample to a given volume by weighing (making to mass)<br />

Customer application: Automated system for fertilizer analysis<br />

Automated Wetchem system for fertilizer analysis<br />

__________________________<br />

1 Further information on the Belgian company Nucomat, which was founded in 1988, can be found on<br />

the internet under www.nucomat.be.<br />

Fig. 1: One of Nucomat’s product lines is the automated<br />

«Wetchem system» for the analysis of liquid chemicals.<br />

System characteristics can be described briefly as «untreated<br />

sample in, validated result out», as well as the<br />

possibility of carrying out several analysis methods.<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 19

Customer application: Automated system for fertilizer analysis<br />

Fig. 2: The twin systems, each consisting of two 861<br />

Advanced Compact ICs for the analysis of anions and<br />

cations, respectively.<br />

Fig. 3: Computer image of the module with the <strong>Metrohm</strong><br />

ion chromatographs.<br />

Fig. 4: The Nucomat robotic system for transporting<br />

samples and containers. The illustration shows details<br />

of the robot head with the gripper arm mounted eccentrically<br />

on the spindle axis.<br />

Fig. 5: As the transport robot is mounted above the working<br />

area, even Erlenmeyer flasks under the fume hood<br />

(center of illustration) can easily be accessed.<br />

– Checking the instrument calibration by control measurements<br />

– Integrated quality control<br />

– Automatic system restart after power failure<br />

– Closed-loop labware utilization (e.g. glass beakers) with built-in washing station<br />

– Ion chromatography and titration as analysis methods<br />

– Sample preparation for ICP-AES spectroscopy<br />

– LIMS compatibility<br />

Ion chromatography system<br />

The Nucomat system described below uses 861 Advanced Compact IC ion<br />

chromatographs from <strong>Metrohm</strong>. In order to ensure as good a protection against<br />

breakdown as possible, two twin systems have been installed, each with a<br />

separate ion chromatograph for the analysis of anions and cations (see Fig. 2<br />

and 3).<br />

Robot with gripper arm<br />

The main robot for sample and flask transport has four degrees of freedom. The<br />

robot head has a gripper arm (Fig. 4). Movements are based on a Cartesian coordinate<br />

system, with the belt-driven robot head moving in the X-Y plane and covering<br />

a maximum area of 2 x 2 meters. Movement along the Z axis (enabling 40 cm<br />

vertical reach) is performed by a spindle axis. The spindle can be rotated through<br />

360 degrees for optimal use of the whole available working space. The pneumatic<br />

gripper is mounted eccentrically on the spindle axis. All the labware inside the fume<br />

hood can be accessed without any problems (Fig. 5).<br />

The spatial position of the gripper arm is calculated on the basis of the dimensions<br />

given in the construction plans and of the index signals from the incremental sensor<br />

of the robot. No additional teaching is required for directing the robot head to<br />

any coordinates.<br />

After installation or maintenance work (for example on the drive motor, incremental<br />

sensor/encoder or drive belt), the offset of the robot head needs to be determined.<br />

Therefore a calibration bracket is mounted permanently on the support frame.<br />

Robot encoder index pulses are then referenced against the calibration bracket<br />

for proper alignment; no teach-in programming is necessary.<br />

Analytical procedure<br />

The Wetchem system analyzes liquids, suspensions, solid fertilizer granules or already<br />

ground powder samples. After scanning the barcode, the user only has to<br />

place the samples on the upper conveyor belt.<br />

The barcode information is linked to a LIMS configuration file containing samplespecific<br />

parameters: amount of sample, acid to be added, stirring time, digestion<br />

temperature, final volume, analytical determination method and the corresponding<br />

measuring parameters.<br />

Several working solutions can be prepared from one stock solution. In principle,<br />

each stock solution remains within the reach of the gripper arm until the preparation<br />

of the working solutions derived from it has been concluded.<br />

By pressing a button, the user can cause the robot to reject a working solution at<br />

any time if it does not satisfy the sample preparation quality requirements. The robot<br />

then automatically prepares a new working solution from the corresponding<br />

stock solution.<br />

Wide-neck 250 mL glass Erlenmeyer flasks are suitable for most sample preparation<br />

steps and determinations (Fig. 6). In contrast, PTFE flasks are used for the determination<br />

of boron, as digestion in glass vessels would result in contamination of<br />

the sample and therefore lead to incorrect results for this element.<br />

20 <strong>Metrohm</strong> Information Issue 2-2008/2009

After the analysis, the used sample flasks are cleaned with hot water in a washing<br />

station and are used again.<br />

Stock solutions that are no longer required, excess working solutions, calibration<br />

solutions and samples ready for analysis by ICP-AES are transferred to the lower<br />

conveyer belt by the robot for further processing or disposal.<br />

The ion chromatographs are controlled by the Metrodata IC Net software, which<br />

also records the measuring data. The analysis results obtained from this measuring<br />

data are stored in the internal database and simultaneously exported as ASCII-files<br />

in order to be read into the LIMS.<br />

Calibration and verification of the ion chromatographs<br />

Calibration and control solutions for ion chromatography are simply placed on the<br />

upper conveyor belt. The robot transfers these calibration solutions directly to the<br />

ion chromatographs and starts instrument calibration via the IC Net software. The<br />

operating personnel must ensure that all the necessary calibration solutions are<br />

available when required. A control solution is then used for the verification of the<br />

IC. The analysis result for the control solution is compared with the expected value.<br />

Depending on the result of this comparison, a control character is set to either enable<br />

the ion chromatographs for the analyses or to block them.<br />

The operator can insert additional control solutions in order to verify the instrument<br />

performance and to evaluate the accuracy of the analysis as required by the<br />

laboratory’s quality control procedures.<br />

Instrument calibration is carried out at the same time as sample preparation.<br />

Sampler for liquids and solids<br />

The dosing station sampler obtains all the relevant information necessary for preparing<br />

the solutions from the Wetchem control software. The robot provides the<br />

sampler with the necessary Erlenmeyer flasks for the stock and working solutions.<br />

The sampler disposes of several hundred magnetic stirrer bars.<br />

As soon as everything is ready, the preparation of the solutions can begin. The sequence<br />

consists of determining the tare of the Erlenmeyer flask, providing it with a<br />

magnetic stirrer bar, adding the sample, dosing in all the necessary reagents and<br />

transmitting the measured weights for each of these items.<br />

The program is aborted as soon a serious error is detected during the preparation<br />

of the solutions. The user can terminate the preparation of a sample solution by<br />

pressing a button. The affected Erlenmeyer flask is then removed immediately and<br />

a new solution is prepared.<br />

Integrated quality control<br />

The accuracy of the balance is automatically checked at predefined intervals by the<br />

Wetchem system using a reference weight (Erlenmeyer flask). Each individual step<br />

in preparing the solutions, e.g. the addition of a certain volume of acid, is checked<br />

against the measured values from the balance. All measured values are permanently<br />

stored.<br />

If the result of a control measurement differs too much from the reference value,<br />

then the availability of the particular analytical instrument is set to inactive by the<br />

system control (after confirmation by the operating personnel). In such a case, the<br />

remaining samples to be analyzed are diverted to a different, active analytical instrument<br />

or parked until the analytical instrument is activated again.<br />

The Wetchem software<br />

The Wetchem application program is based on Nucomat’s «Robin» software<br />

architecture, an event-controlled command-line interpreter with SQL server<br />

database.<br />

Customer application: Automated system for fertilizer analysis<br />

Fig. 6: View of the rear panels of the ion chromatographs<br />

and the labware of the Wetchem system (mainly wideneck<br />

Erlenmeyer flasks) that are necessary for fully<br />

automatic sample preparation.<br />

<strong>Metrohm</strong> Information Issue 2-2008/2009 21

Customer application: Automated system for fertilizer analysis<br />

Fig. 7: This illustration shows a chromatogram obtained<br />

with a fertilizer sample by ion chromatography,<br />

in which the nitrate, phosphate and sulfate anions are<br />

determined.<br />

Ammonium<br />

Potassium<br />

Nitrate<br />

Phosphate<br />

Magnesium<br />

Calcium<br />

Sulfate<br />

Strontium<br />

Fig. 8: Cations such as ammonium, potassium, magnesium,<br />

calcium and strontium can also be determined in the<br />

fertilizer sample by ion chromatography.<br />

Fig. 9: This illustration shows the IC Net interface with<br />

ion chromatograms of cationic standards used for a calibration.<br />

If problems occur, the IC Net software is ideal<br />

for troubleshooting.<br />

If a calibration point is clearly off the calibration curve<br />

(i.e. the measurement is incorrect), then the corresponding<br />

calibration solution can simply be analyzed again in<br />

order to complete the calibration. A control solution must<br />

first be measured before the ion chromatograph can be<br />

activated for the analysis.<br />

The system allows the generation of various user profiles in order, for example,<br />

to give only the system administrator the right to alter important parameters. All<br />

alterations to the system configuration are permanently recorded and archived to<br />

ensure traceability. The same applies for each sample presented to the system after<br />

scanning, all movements of the robot, all weights and all messages from the<br />

dosing station.<br />

If the connection to the LIMS computer should be briefly interrupted, then the<br />

Wetchem system can still continue to work; data matching takes place when the<br />

connection is reestablished.<br />

<strong>Metrohm</strong>’s compact ion chromatographs<br />

An 861 Advanced Compact IC <strong>Metrohm</strong> ion chromatograph consists of:<br />

– An Eluent Organizer<br />

– A serial dual-piston pump showing extremely low pulsation with a flow range of<br />

0.2 to 2.5 mL/min<br />

– An injection valve allowing manual or automatic sample injection that can<br />

optionally be equipped with an «internal loop» with a volume of only 0.25 μL<br />

– A completely metal-free flow path with all components made of PEEK or PTFE<br />

– A separation column<br />

– The <strong>Metrohm</strong> Suppressor Module MSM II for chemical suppression that is responsible<br />

for the extremely low noise level of only 0.2 nS/cm<br />

– A conductivity detector with four different measuring ranges: 0...50, 250, 1000<br />

and 5000 μS/cm<br />

– The <strong>Metrohm</strong> data acquisition and control software IC Net that is also used for<br />

the determination of anions, cations and carboxylic acids<br />

The sample to be injected is first pumped through an inline filter by a two-channel<br />

peristaltic pump (this prevents clogging of the separation column) and then enters<br />

the injection valve of the ion chromatograph. After the injection the valve is switched<br />

so that the filter can be rinsed with an acidified solution in reverse flow. The unit with<br />

the peristaltic pump is located directly beneath the ion chromatographs.<br />

Applications and results<br />

In addition to the <strong>Metrohm</strong> ion chromatographs, a titrator is also incorporated in the<br />

Wetchem system. In this way, the system described above can be used to determine<br />

the following species and parameters:<br />

+ K2O, P2O5, total nitrogen content, nitrogen as ammonium (NH4 ), nitrogen as<br />

– 2 – nitrate (NO3 ), CaO, MgO, strontium, sulfate (SO4 ), chloride (all these substances<br />

by ion chromatography; Fig. 7 and 8); pH (using a pH electrode), free acid (titration<br />

with NaOH solution and a pH electrode) as well as B, Al, Fe, Cu, Zn, Cr, Ni, Cd, Mn<br />

(manual determination using an ICP-AES instrument).<br />

The <strong>Metrohm</strong> IC Net software runs as a background process on the Wetchem computer.<br />

In normal operation, the operating personnel do not have to bother with IC<br />

Net. However, should a problem occur with the ion chromatographic analysis, the<br />

IC Net software is an extremely useful diagnostic tool that is available at any time<br />

(Fig. 9).<br />

We would like to thank Prof. Chantal Block, Prof. Carlo Vandecasteele and<br />

Noel Van de Steene (CEO Nucomat) for writing this text and providing us with<br />

the measurement data and illustrations.<br />

22 <strong>Metrohm</strong> Information Issue 2-2008/2009

Enzymatic degradation of bioplastics<br />

Basic information about bioplastics<br />

Biogas and biodiesel have been well known to the general public for several years.<br />

But what are bioplastics and how are they formed?<br />

For many million years, bacteria have been using carbon compounds as storage<br />

substances. Among other things, microorganisms require nitrogen and phosphorus<br />

for growth and cell division. If one of these two elements is missing, cell division<br />

stops. At the same time, the cells switch their internal program to «storage»<br />

by taking up carbon, mainly from sugars, fatty acids and other compounds. This<br />

carbon is then stored inside the cells in the form of granula1 that are made up of<br />

poly(3-hydroxyalkanoate) (PHA), a group of polyesters of which poly(3-hydroxybutyric<br />

acid) (PHB) is particularly widespread (Fig. 1). As soon as the bacteria have<br />

everything they require for cell division again, the stored carbon is consumed.<br />

PHA compounds (Fig. 2) have material properties that very closely resemble those<br />

of conventional plastics such as PET. Additionally, they are biodegradable (Fig. 3)<br />

and can be obtained from self-regenerating raw materials. Other types of bioplastics<br />

have been developed as well, for example on the basis of corn starch or polylactic<br />

acid (PLA). Up to now, PHA products have only been used for test purposes:<br />

PHA isolation and processing is still much more expensive than the manufacturing<br />

of plastics from crude.<br />

Depolymerization studies at the University of Stuttgart<br />

In Prof. Dr. Jendrossek’s workgroup in the Institute for Microbiology at the University<br />

of Stuttgart, the focus of interest is the degradation of the polymer in the<br />

cell itself (depolymerization [1]). It is chiefly the enzymes (so-called PHA depolymerases)<br />