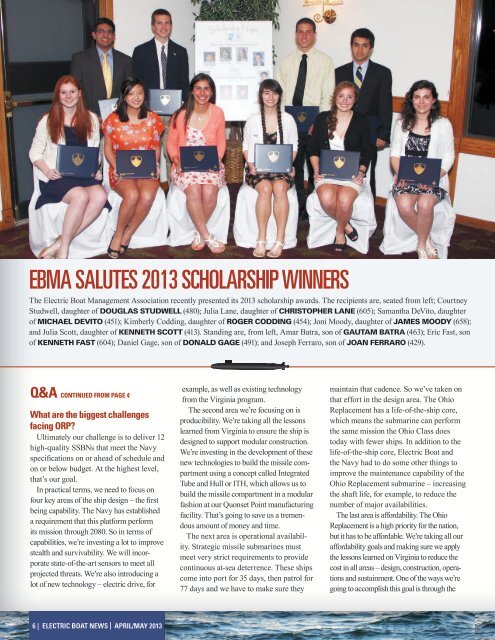

<strong>EB</strong>MA SALUTES <strong>2013</strong> SCHOLARSHIP WINNERSThe <strong>Electric</strong> <strong>Boat</strong> Management Association recently presented its <strong>2013</strong> scholarship awards. The recipients are, seated from left; CourtneyStudwell, daughter of DOUGLAS STUDWELL (480); Julia Lane, daughter of CHRISTOPHER LANE (605); Samantha DeVito, daughterof MICHAEL DEVITO (451); Kimberly Codding, daughter of ROGER CODDING (454); Joni Moody, daughter of JAMES MOODY (658);and Julia Scott, daughter of KENNETH SCOTT (413). Standing are, from left, Amar Batra, son of GAUTAM BATRA (463); Eric Fast, sonof KENNETH FAST (604); Daniel Gage, son of DONALD GAGE (491); and Joseph Ferraro, son of JOAN FERRARO (429).Q&A CONTINUED FROM PAGE 4What are the biggest challengesfacing ORP?Ultimately our challenge is to deliver 12high-quality SSBNs that meet the Navyspecifications on or ahead of schedule andon or below budget. At the highest level,that’s our goal.In practical terms, we need to focus onfour key areas of the ship design – the firstbeing capability. The Navy has establisheda requirement that this platform performits mission through 2080. So in terms ofcapabilities, we’re investing a lot to improvestealth and survivability. We will incorporatestate-of-the-art sensors to meet allprojected threats. We’re also introducing alot of new technology – electric drive, forexample, as well as existing technologyfrom the Virginia program.The second area we’re focusing on isproducibility. We’re taking all the lessonslearned from Virginia to ensure the ship isdesigned to support modular construction.We’re investing in the development of thesenew technologies to build the missile compartmentusing a concept called IntegratedTube and Hull or ITH, which allows us tobuild the missile compartment in a modularfashion at our Quonset Point manufacturingfacility. That’s going to save us a tremendousamount of money and time.The next area is operational availability.Strategic missile submarines mustmeet very strict requirements to providecontinuous at-sea deterrence. These shipscome into port for 35 days, then patrol for77 days and we have to make sure theymaintain that cadence. So we’ve taken onthat effort in the design area. The OhioReplacement has a life-of-the-ship core,which means the submarine can performthe same mission the Ohio Class doestoday with fewer ships. In addition to thelife-of-the-ship core, <strong>Electric</strong> <strong>Boat</strong> andthe Navy had to do some other things toimprove the maintenance capability of theOhio Replacement submarine – increasingthe shaft life, for example, to reduce thenumber of major availabilities.The last area is affordability. The OhioReplacement is a high priority for the nation,but it has to be affordable. We’re taking all ouraffordability goals and making sure we applythe lessons learned on Virginia to reduce thecost in all areas – design, construction, operationsand sustainment. One of the ways we’regoing to accomplish this goal is through the6 | ELECTRIC BOAT NEWS | APRIL/MAY <strong>2013</strong>

development and introduction ofthe new IPDE tools and processes.There’s a tremendous amount ofwork going on to reduce the costof design and provide the shipyardwith a highly producible designthat gives them the informationrequired to build the submarine inthe most effective way.What kind of workforcedevelopment will berequired to meet thesechallenges?We’re in a very interestingtime. The workforce demographicsprovide us with somegreat opportunities as well assome challenges. If you lookat the Engineering and Designworkforce, we’ve got a groupof very senior people who’vebeen through several designprograms. We also have aneven larger number of relativelynew folks who have not beenthrough a full program yet. Soour challenge is this: how dowe transfer the knowledge ofthose with extensive submarinedesign experience to the newerengineers and designers. Bythe same token, we have anopportunity to benefit fromour newer employees and thefamiliarity they have with potentiallyrelevant technologies.Pete Halvordson, MDA-UAW President Bill Louis andothers are also working veryhard with the results of theVeritas survey to develop waysto make <strong>Electric</strong> <strong>Boat</strong> evenbetter – a better business and abetter place to work.And we’re continuing toexplore how we can take fulladvantage of our New Londonfacility to improve our abilityto collaborate and integrateacross all of the organizationsengaged in the Ohio Replacementdesign.ELECTRIC BOAT PRESIDENT KEVIN POITRAS SHARES A MOMENT WITH FORMER SEN. JOHN WARNER DURINGKEEL-LAYING CEREMONY FOR THE SUBMARINE JOHN WARNER (SSN-785), THE 12TH VIRGINIA-CLASS SHIP.KEEL IS LAID FOR SUBMARINE JOHN WARNERANEWPORT NEWS, VA.keel-laying ceremony for the submarineJohn Warner (SSN-785) was held recentlyat Huntington Ingalls Industries - Newport<strong>News</strong> Shipbuilding.The 12th Virginia-class submarine is named forformer five-term U.S. Senator from Virginia andSecretary of the Navy John Warner.In a time-honored Navy tradition, the initialsof Jeanne Warner, the submarine’s sponsor, werewelded onto a steel plate that will be permanentlyaffixed to the submarine’s hull. The submarine’snamesake also had his initials welded onto theplate.“The Navy and the submarine force arehonored to have Mrs. Warner serve as thesponsor for the future USS John Warner,” saidCapt. David Goggins, Virginia-class programmanager. “The event marks the first major constructionmilestone for the submarine and helpsforge a special bond between Mrs. Warner, hersubmarine, and her crew that will last for yearsto come.”John Warner’s keel laying is the submarine’sfirst major event since it began constructionin March 2010. The submarine is on track tocontinue the Virginia-class program’s trend ofdelivering submarines early to their contractdelivery dates.“John Warner’s keel laying is a special dayfor our Navy, the Commonwealth of Virginiaand our shipbuilding partners,” said Rear Adm.David Johnson, program executive officer forsubmarines. “Building the Virginia Class is ateam effort and the skill and commitment ofthe entire shipbuilding team is evident in thefirst-time quality and operational successes ofthese front-line platforms.”The shipbuilders are working to ensure thesubmarine John Warner will extend the Virginiaprogram’s record for delivery on or ahead ofschedule and at or below target cost.Speaking on behalf of <strong>Electric</strong> <strong>Boat</strong>, PresidentKevin Poitras said, “By sustaining this level ofperformance – and improving on it – the Virginiateam will help ensure a continuing productionrate of two submarines per year.“An example of the team’s commitment tomaintaining Virginia as a model acquisitionprogram occurred less than a month ago, hesaid. “That was when North Dakota, the firstBlock III ship, achieved pressure-hull completeat <strong>Electric</strong> <strong>Boat</strong>’s shipyard. We reached thismilestone two months earlier than any of theprevious Virginia-class submarines.“In the current defense-spending environment,it is imperative that each successive shipof the class embody similar meaningful costand schedule improvements,” said Poitras. “Asshipbuilders, we must renew our promise toour customer and congressional supporters toproduce affordable Virginia-class submarines.By doing this, we will help the fleet attain thesubmarine force levels required to retain underseadominance.”Warner’s keel laying is the first of severalmajor shipbuilding milestones for the Virginiaclassprogram in <strong>2013</strong>. The submarine Minnesota’s(SSN-783) commissioning is scheduledfor Sept. 7 and North Dakota’s (SSN-784) christeningis expected this fall. Delaware (SSN-791)will begin construction Sept. 2.ELECTRIC BOAT NEWS | | APRIL/MAY F<strong>EB</strong>RUARY <strong>2013</strong> 2012 | 7