Steam joint and stationary siphon â for optimum dryer ... - Voith

Steam joint and stationary siphon â for optimum dryer ... - Voith

Steam joint and stationary siphon â for optimum dryer ... - Voith

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

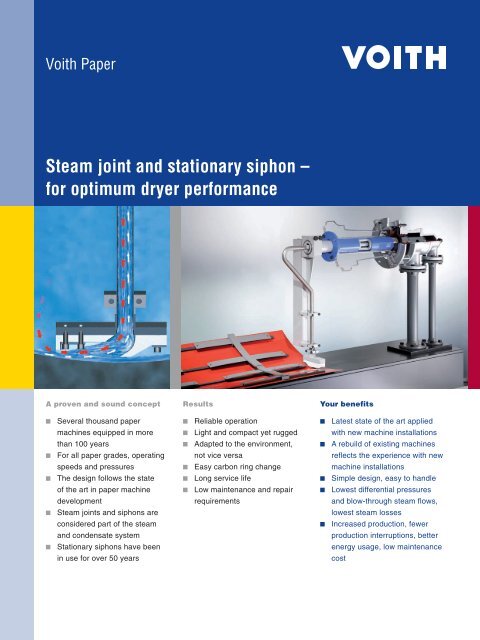

<strong>Voith</strong> Paper<strong>Steam</strong> <strong>joint</strong> <strong>and</strong> <strong>stationary</strong> <strong>siphon</strong> –<strong>for</strong> <strong>optimum</strong> <strong>dryer</strong> per<strong>for</strong>manceA proven <strong>and</strong> sound conceptn Several thous<strong>and</strong> papermachines equipped in morethan 100 yearsn For all paper grades, operatingspeeds <strong>and</strong> pressuresn The design follows the stateof the art in paper machinedevelopmentn <strong>Steam</strong> <strong>joint</strong>s <strong>and</strong> <strong>siphon</strong>s areconsidered part of the steam<strong>and</strong> condensate systemn Stationary <strong>siphon</strong>s have beenin use <strong>for</strong> over 50 yearsResultsn Reliable operationn Light <strong>and</strong> compact yet ruggedn Adapted to the environment,not vice versan Easy carbon ring changen Long service lifen Low maintenance <strong>and</strong> repairrequirementsYour benefitsn Latest state of the art appliedwith new machine installationsn A rebuild of existing machinesreflects the experience with newmachine installationsn Simple design, easy to h<strong>and</strong>len Lowest differential pressures<strong>and</strong> blow-through steam flows,lowest steam lossesn Increased production, fewerproduction interruptions, betterenergy usage, low maintenancecost

<strong>Steam</strong> <strong>joint</strong> <strong>and</strong> <strong>stationary</strong> <strong>siphon</strong> –<strong>for</strong> <strong>optimum</strong> <strong>dryer</strong> per<strong>for</strong>manceThe <strong>stationary</strong> <strong>siphon</strong> is suitable <strong>for</strong> every application as long as thesteam <strong>joint</strong> can be soundly mounted to the bearing or gearbox cover.It is likewise suitable <strong>for</strong> low operating speeds <strong>and</strong> sump condition asit is <strong>for</strong> highest operating speeds <strong>and</strong> rimming condition.In all cases the differential pressure is minimal since it is independentof any centrifugal <strong>for</strong>ces. The <strong>siphon</strong> shoe remains always in thecondensate, flooding of <strong>dryer</strong>s is, there<strong>for</strong>e, not possible.A temperature stable <strong>siphon</strong> support pipe, firmly held inside of thesteam <strong>joint</strong>, keeps the <strong>siphon</strong> shoe at the proper clearance to the<strong>dryer</strong> shell as set when the <strong>dryer</strong> is cold. Optimum effectivenessDifferential pressure <strong>and</strong> blowthroughsteam flow stay constant atapprox. 150 mbar (2.3 psi) <strong>and</strong> 5%<strong>for</strong> all speeds.In comparison to a rotating <strong>siphon</strong>at 1400 m/min (4600 fpm) it isapprox. 800 mbar (12 psi) <strong>and</strong> 30%.Carbon ring sealn The glide ring compensates <strong>for</strong>radial misalignmentn The spherical piston compensatesangular misalignmentn Large carbon wear reserven Status of carbon wear is visible<strong>and</strong> measurablen A mechanical stop preventsmetal-to-metal contactn Spring loading <strong>for</strong> negativeoperating pressures

Carbon ring changen Removal of elbow <strong>and</strong> housingn Replacement of the carbon ringn Re-installation of housing <strong>and</strong>elbown Adjustment of stop pins <strong>for</strong>carbon wearOverhaul of the housingn Insertion into the pistonpush-down devicen Removal of the pistonn Replacement of the seal ringAvailable sizesn <strong>Steam</strong> connections:50 / 65 / 80 / 100 / 125 / 150 mm2“ / 21/2“ / 3“ / 4“ / 5“ / 6“n Condensate connections:32 / 40 / 50 / 65 / 80 mm11/4“ / 11/2“ / 2“ / 21/2“ / 3“n Siphon diameters:16 / 19 / 22 / 26 / 29 / 32 mm.63“ / .75“ / .87“ / 1“ / 1.14“ / 1.26“Insulation sleeveInsulation sleeves protect the <strong>dryer</strong>bearing from heatSpecial designsn <strong>Steam</strong> inlet only, as a rule ondrive siden Condensate outlet only, as arule on tending side.On tending side with extendedpiston length <strong>for</strong> CARB**(Compact Angular RollerBearing) bearings, <strong>for</strong> compensationof <strong>dryer</strong> expansion** SKF TrademarkImportant featuresn Two anchor rods - due to theirlength insensible againsttemperature variations - hold the<strong>siphon</strong> support pipe securely inits position.n The entering steam flows alongthe support pipe on both in- <strong>and</strong>outsides <strong>and</strong> the condensateflows back in a separate pipe.Thus, the support pipe is notinfluenced by temperaturedifferences between steam <strong>and</strong>condensate <strong>and</strong> is, there<strong>for</strong>e,temperature stable.n The <strong>siphon</strong> holder can be madehorizontally adjustable. This canbe advantageous when there isonly unreliable in<strong>for</strong>mationavailable about the location ofthe balancing weights inside ofthe <strong>dryer</strong>.n The <strong>siphon</strong> pipe can bearranged vertically as well asinclined in order to place the<strong>siphon</strong> shoe as close aspossible to the end of the<strong>dryer</strong> shell at a given <strong>dryer</strong>head contour.n The <strong>siphon</strong> shoe is made ofTeflon <strong>and</strong> prevents the <strong>dryer</strong>shell from being damaged,should both get in contact.n A whirl chamber in the <strong>siphon</strong>shoe assures safe condensateremoval at lowest differentialpressures <strong>and</strong> blow-throughsteam flows.

Contact <strong>for</strong> Joints, Siphons<strong>and</strong> Spoilerbars:<strong>Voith</strong> Paper GmbH & Co. KGHeidenheim, GermanyTel. +49 7321 37-3848<strong>Voith</strong> Paper GmbH & Co. KGHeidenheim, GermanyTel. +49 7321 37-2752<strong>Voith</strong> Paper GmbH & Co. KGRavensburg, GermanyTel. +49 751 83-01<strong>Voith</strong> Paper OyVantaa, Finl<strong>and</strong>Tel. +358 10 21844-00<strong>Voith</strong> Paper ABSpanga (Stockholm), SwedenTel. +46 8 62207-40<strong>Voith</strong> Paper ASLier, NorwayTel. +47 3285-9100<strong>Voith</strong> Paper Ltd.Manchester, Great BritainTel. +44 161 643-9273<strong>Voith</strong> Paper SASOrsay, FranceTel. +33 164865-570<strong>Voith</strong> Paper S.A.Tolosa (Guipúzcoa), SpainTel. +34 943 67-3799<strong>Voith</strong> Paper S.r.L.Schio (Vicenza), ItalyTel. +39 0445 690-500<strong>Voith</strong> Paper GmbHSt. Pölten, AustriaTel. +43 2742 806-0<strong>Voith</strong> Paper TechnologyRussia GmbHSt. Petersburg, RussiaTel. +7 812 325-8203<strong>Voith</strong> Paper Inc.Appleton (WI), USATel. +1 920 731-7724<strong>Voith</strong> PaperMáquinas e Equipamentos Ltda.São Paulo (SP), BrazilTel. +55 11 3944-4000<strong>Voith</strong> Paper (China) Co., Ltd.Kunshan, ChinaTel. +86 512 5799 3600<strong>Voith</strong> Paper Co., Ltd.Tokyo, JapanTel. +813 3277-4102<strong>Voith</strong> Paper Technology Ltd.Calcutta, IndiaTel. +91 33 2300-5000PT. <strong>Voith</strong> PaperJakarta, IndonesiaTel. +62 21 7884 5922info.voithpaper@voith.comwww.voithpaper.comvp pmg 3349 en zp/wahl 1500 2008/05