View Full July PDF Issue - Utility Contractor Magazine

View Full July PDF Issue - Utility Contractor Magazine

View Full July PDF Issue - Utility Contractor Magazine

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

2007/2008Buyer's Guide <strong>Issue</strong>Attention NUCA Members: Take this opportunity to list your company for free in the 2007/2008 <strong>Utility</strong> <strong>Contractor</strong> Buyer's Guide.Please fill out this form and submit your FREE listing information today. Be recognized by more than 22,000* industry professionals.If you are not a NUCA member and are interested in joining, please call 800-662-6822or e-mail Shervonne Murphy: shervonne@nuca.com*Publisher’s Own DataGet Listed in the 2007/2008 Buyer’s Guide – It’s FREE for NUCA MembersListing Deadline: August 3, 2007Company____________________________________________________________________________________________________Address_____________________________________________________________________________________________________City __________________________________________________State/Province___________________________________________Zip/Postal Code _________________________________________Country________________________________________________Phone ________________________________________________Fax __________________________________________________E-mail ______________________________________________________________________________________________________Website _______________________________________________Contact _______________________________________________Mail, E-mail or fax both pages of this form to:Benjamin Media, PO Box 190, Peninsula, OH 44264 Attn: Ryan SneltzerPh: 330-467-7588 Fax: 330-468-2289 e-mail: rsneltzer@benjaminmedia.com❒ Logo $175 ❒ Bold/Capitalize your listing $125 ❒ Additional bold caps $75 ❒ Additional listing $75Buy another listing and receive a free logo❒ Accounting Services❒ Aggregate Supplies❒ Air Tools❒ Air/Gas Monitors❒ Attachments❒ Auctioneers/Appraisers❒ Backhoe/Loaders❒ Banking Services❒ Barriers/Rails/Guards❒ Boring Equipment❒ Breathing Apparatus❒ Buckets❒ Cable Pulling Tools❒ Castings/Manholes/Grates❒ Compaction Attachments❒ Compactors❒ Compressors❒ Computers/Software/Supplies❒ Concrete Precast Products❒ Concrete Products❒ Confined Space Equipment❒ <strong>Contractor</strong> Services❒ Conveyors❒ Couplings, Pipe❒ Cranes❒ Cutting Edges/Accessories❒ Detectors, Holiday❒ Directional Drilling Equipment❒ Drills❒ Engineering Services❒ Engines❒ Environmental Services❒ Equipment Leasing/RentalPlease choose from the categories below for your detailed company listing!❒ Equipment Sales❒ Equipment, Internet Brokers❒ Erosion Control Products❒ Excavators❒ Explosives/Demolition Supplies❒ Financial Services❒ Footwear (Safety)❒ Forklift/Loaders❒ Geotextiles/Fabrics❒ Grapples❒ Grinders❒ Grouting, Chemical❒ Grouting, Pressure❒ Hammer/Breaker Attachments❒ Heavy Hauling Equipment❒ Hydraulic Tools❒ Industry Publications❒ Insurance❒ Lasers❒ Leak Detection❒ Legal Services❒ Lighting Equipment❒ Loaders/Dozers❒ Locators, Pipe/Cable❒ Lubricants❒ Magnetic Locating❒ Manhole Rehabilitation❒ Material Suppliers❒ Meters❒ Microtunneling Equipment❒ One Call Systems❒ P-AM Hazardous Water Equipment❒ Pavement Markings❒ Pavers❒ Paving Products❒ P-ER Factoring Services❒ Petroleum Products❒ Pigs❒ Pile Driving Equipment❒ Pipe Cutters❒ Pipe Insulators❒ Pipe Jacking Equipment❒ Pipe Lifting Tongs❒ Pipe Liners❒ Pipe Pullers/Pushers❒ Pipe Stoppers❒ Pipe Testing/Repair Equipment❒ Pipe, Clay❒ Pipe, Concrete❒ Pipe, Corrugated Steel❒ Pipe, Ductile Iron❒ Pipe, Fiberglass❒ Pipe, Plastic❒ Pipe, Steel❒ Pipeline Accessories❒ Pumps, Centrifugal❒ Pumps, Hydrostatic Testing❒ Pumps, Potable Submersible❒ Pumps, Sewer/Slurry❒ Retaining Walls❒ Safety Consulting❒ Safety Equipment❒ Saws/Grinders❒ Scrapers/Graders❒ Sewer & Water Maintenance❒ Sewer Plugs❒ Soil Stabilization fluids❒ Steel Fabricating❒ Steel Sheet Piling❒ Steel Supplies❒ Storm Drainage❒ Surety Bonding❒ Survey Equipment❒ Tampers❒ Teeth❒ Testing Equipment❒ Testing Services❒ Tools❒ Traffic Control Equipment❒ Trailers❒ Training Services❒ Trench Shields/Shoring❒ Trenchers❒ Trenchless Installation Equipment❒ Trenchless Rehabilitation Equipment❒ Trucks❒ Tunnel/Shaft Liner Plate❒ Tunneling Equipment❒ Underground Supports❒ Underground <strong>Utility</strong> Locating❒ Valves/Hydrants❒ Vaults❒ Ventilation Equipment❒ Water Supply Services❒ Wellpointing Services❒ Other

GROUNDBREAKING NEWSIngersoll Rand Explores Alternativesfor Construction-related BusinessesIngersoll-Rand Co. Ltd. announcedon May 15 that it has initiated aprocess to explore strategic alternativesfor its Bobcat and constructionrelatedbusinesses, including the<strong>Utility</strong> Equipment and Attachmentsbusinesses.The company’s alternatives mayinclude an outright sale of the businessesor a spin-off to shareholders.For full-year 2006 these businessescollectively generatedapproximately $2.6 billion in revenues.The company expects toThe Bobcat, <strong>Utility</strong> Equipment and Attachment businesses no longer fit IngersollRand's long-term strategy, according to CEO Herbert L. Henkel.conclude the process in the secondhalf of 2007.“Our Bobcat, <strong>Utility</strong> Equipmentand Attachments businesses representworld-class operations withexceptional people, products andbrands; however, these businesses nolonger fit Ingersoll Rand’s long-termstrategy,” said Herbert L. Henkel,chairman, president and CEO.“The eventual outcomeof our process to explorestrategic alternatives forthese businesses will be thestrategic repositioning ofIngersoll Rand away fromthe capital-intense, heavymachineryprofile of thecompany’s past and towarda true diversified industrialcompany with powerfulgrowth platforms consistingof climate control,industrial and securitybusinesses. These businessesare well positionedto deliver consistentgrowth throughout thebusiness cycle.”Earth Tool UndergoesMajor PersonnelChangesEarth Tool Co. LLC, manufacturerof HammerHead Mole trenchlessproducts, recently announced thepromotion of Payce Reynoldsto CEO and the hiring of formerVermeer Manufacturing Co.employees Jarrett Cowden andBrian Metcalf to the company.Reynolds formerly headed upthe horizontal directional drillingdivision of HammerHead for threeyears and oversaw substantialgrowth in sales of the company’sHDD accessories line of productsthat, along with the HammerHeadMole line of pneumatic piercingtools, are sold exclusivelyby Vermeer’s worldwide dealershipnetwork.New Earth Tool employees include (l-r): Payce Reynolds (CEO), SteveSander, Alan Goodman, Jarrett Cowden and Brian Metcalf.8 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

GROUNDBREAKING NEWSReynolds’ intimate knowledgeof HDD accessories, piercing tooltechnologies and markets willhelp continue to foster thecompany’s long-term relationshipwith Vermeer and its distributionnetwork, which will continueto grow the market for theseproducts. Additionally, Reynoldswill lead the charge in continuingto expand HammerHead’ssuccess in the pipe rehabilitationmarket.Cowden joins HammerHead assenior vice president of sales andmarketing, while Metcalf willassume the responsibilities of vicepresident of international sales andbusiness development. BothCowden and Metcalf have workedfor Vermeer in the past.In addition to Reynolds,Cowden and Metcalf,HammerHead also recently hiredthree more individuals to newpositions within the company.Steve Sander joins HammerHeadas regional sales manager for thenorthwestern territory of NorthAmerica; Alan Goodman has beenpromoted to western businessmanager for western NorthAmerica; and Will LeBlanc hasreturned to HammerHead as southcentral territory manager.HammerHead has also announcedthe resignation of long-timeemployee Jeff Wage.New SubsiteDistributorAnnouncedThe Charles Machine WorksInc., manufacturers of the DitchWitch line of undergroundconstruction equipment, recentlyannounced the addition ofCalifornia’s <strong>Utility</strong> Insight Inc.as an official dealer of thecompany’s Subsite electroniclocating equipment. The Subsiteproduct line is used to locate andidentify underground utilities atconstruction jobsites.Serving northern California andNevada, <strong>Utility</strong> Insight Inc.specializes in the sale and serviceof municipal, utility and plumbingproducts including locators, leakdetectors, marking paint, CCTVvans and trucks, crawlers, pushcameras, push rods and safety andtraffic-control products. For moreinformation about Subsite locatingequipment, call (800) 654-6481 orvisit www.subsite.com.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 9

GROUNDBREAKING NEWSManufacturers Donate Equipment for CleanupEfforts Following Devastating TornadoLeft with huge piles of debris to clear away before rebuilding could begin,equipment manufacturers stepped up to the plate to help the city ofGreensburg, Kan., get back on its feet.On Monday, May 4, residents ofGreensburg, Kan., were devastatedby an F5 tornado that destroyed95 percent of the city and killed10 people. The twister was estimatedto be 1.7 miles in width andtraveled for nearly 22 miles.Left with huge piles of debris toclear away before rebuilding couldbegin, equipment manufacturersJohn Deere, Case ConstructionEquipment, New Holland andKobelco Construction MachineryAmerica all stepped up to the plateto help the city of Greensburg getback on its feet.“The devastation in Greensburgis just immense, and this equipmentwas sorely needed,” saidTom Udland, president ofWichita, Kan.-based MurphyTractor & Equipment Co. Inc., aJohn Deere construction equipmentdealer with locations innearby Wichita, Ulysses, GreatBend, Topeka and Dodge City.“We’re glad to be in a position tohelp our neighbors as they cleanup and begin to rebuild theircommunity.”Murphy Tractor donated a JohnDeere 624J loader equipped with agrapple bucket and an 850J WasteHandler Dozer. The 624J was able tocontribute to the cleanup effort bypicking up splintered wood fromhouses and trees for transfer to thelandfill, where it can be burned tomake room for other debris.The 850J waste handler was put touse moving large loads to a burningpile in a specially built landfill.Murphy Tractor also donated a 655Ccrawler loader to neighboringStafford County, which also suffereddamage from the storm.Case Construction Equipmentcoordinated delivery of two compacttrack loaders and two crawlerdozers to assist Kansas HomelandSecurity in the cleanup efforts.The Case equipment was suppliedthrough Victor L. Phillips, a Casedealer with locations in Wichita,Topeka and Garden City, Kan.,that has been serving Kansas contractorsfor more than 40 years.“The events that brought us hereare tragic, but all of us at Case arepleased to be able to donate theuse of our equipment to assist withthe cleanup effort and help the citizensof Greensburg put thistragedy behind them,” said JamesHasler, vice president of CaseConstruction Equipment Inc.The two Case 450CT CompactTrack Loaders were equipped withbuckets, grapples and forks to handlethe wide variety of materialsthat need to be moved in a cleanupsituation. The Case 750K and 850KNew Holland came through with six Super Boom L190 skid steer loadersand pallet fork attachments, brush grapples and grapple buckets.10 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

GROUNDBREAKING NEWSCrawler Dozers were used to pushdebris and rubble to a central locationfor disposal or to clear land forrebuilding.In addition, Case’s sister companyNew Holland came throughwith six Super Boom L190 skidsteer loaders and pallet forkattachments, brush grapples andgrapple buckets from the company’sWichita plant to the area foruse in clearing and removing tonsof debris and moving emergencysupplies and materials.“Our thoughts are with the residentsof Greensburg and the surroundingarea who are trying torecover from one of the mostsevere tornadoes to hit the state ofKansas in 10 years,” said TerrySheehan, vice president of NewHolland Construction NorthAmerica and president of KobelcoConstruction Machinery America.“We’re proud to help make a differenceand do our part for thecommunity by providing equipmentthat can help in the cleanupand rebuilding efforts in the aftermathof the tornado.”To further assist in the massivecleanup effort under way, NewHolland and its local dealer, WichitaTractor Co., have also offered tosupply the Kansas National Guardwith a W110 wheel loader and,through the company’s joint venturearrangement with KobelcoConstruction Machinery AmericaCo. Ltd., a Kobelco SK210LChydraulic excavator.As of a May 16 newscast on localtelevision station KAKE-TVChannel 10, the equipment hasbeen able to remove more than5,000 loads of debris from the area.However, individuals and groupsstill have the opportunity to assistAmeriCorps with debris removaland other jobs throughout town,subject to approval of Greensburgand its law enforcement officers.Volunteers must call 211 (inKansas) or (888) 413-4327 (outof-state)prior to arrival.Volunteers must be ready to presenta driver’s license and consentto a vehicle search to gain access atany checkpoint. For more information,visit AmeriCorps online atwww.americorps.org.Immigration Bill FailsSenate VoteAlthough advocates of comprehensiveimmigration reform legislationwere encouraging compromisein hopes of passing a billbefore the <strong>July</strong> 4 recess, the legislationwas again pulled from theSenate floor schedule on June 28after a failed vote to end debate,thereby effectively killing the measureindefinitely.The legislation remained on lifesupport through continuingnegotiations among key Senateleaders and President Bush, whopromised an additional $4.4 billionfor immediate border securityactivities.However, after heated debateregarding family reunificationvisas, enhanced enforcement andongoing concerns about a temporaryworker program, Senate leadersfell far short of garnering thesupport needed to bring the bill toa final vote.The bill’s Senate supporters fell14 votes short of the 60 needed tolimit debate and clear the way forfinal passage of the legislation. Thetally was 46 to 53, with three-quartersof Senate Republicans voting toderail the bill.The inability to get the billacross the finish line is a big defeatfor a president grasping for a lastinglegacy in his second term, andhe didn’t mince words when itcame to assigning blame.“Legal immigration is one of thetop concerns of the Americanpeople, and Congress’s failure toact on it is a disappointment,”Bush said after the bill was pulled.“A lot of us worked hard to see ifwe couldn’t find a commonground -- it didn’t work.”NUCA supported certain provisionsof the legislation regarding apath to permanent residency, butopposed others dealing with thetemporary worker program andemployer verification requirements.Therefore we believe thatlast week's action (or inaction)can be viewed as both good andbad news for the industry.After a long, heated debate, Senate leaders fell far short of garneringthe support needed to bring the immigration bill to a final vote.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 11

GROUNDBREAKING NEWSDoosan Finalizes Name TransitionSince the acquisition, Doosan hascommitted itself to providing efficient,durable products to the NorthAmerican market.Doosan Infracore America Corp.recently finalized the two-yearchange to Doosan-only brandedheavy construction and compactequipment. Doosan InfracoreAmerica is the result of the 1998merger of Daewoo Machinery Corp.and Daewoo Equipment Corp. thatformed a new $350 million dollarorganization named Daewoo HeavyIndustries America Corp. In April2005, Doosan Infracore Co. Ltd.became the majority shareholder, andthe name was changed soon after.Since the acquisition, Doosan hascommitted itself to providing efficient,durable products to theNorth American market. It introduced10 Tier-3 DX excavators andfive Tier-3 DL wheel loaders andexpanded its dealer network to betterservice the North Americanmarket. Ranked fourth in the globalmedium and large crawler excavatormarket, Doosan Corp. experiencedrevenue of $14 billion in2006. In North America, there aremore than 70 Doosan dealers withover 130 locations and a NorthAmerican Parts Distribution Centerlocated in Atlanta, Ga.“Doosan Corp. has investedglobally more than $50 millionover the past five years to improvereliability and technology,” saysJohn Vandy, president and COO ofDoosan Infracore America,Construction Equipment Division.“We continue to strive to becomeone of the world’s five largest infrastructuresupport businesses.These additional enhancements toour products and services will helpus achieve our goal.”Doosan has also announced plansto continue to improve its productsand services. According to Vandy,some developments dealers andcustomers can expect from the companyin 2007 include: 17 new models;500 percent growth in sales andservice training support; 100 percentgrowth in field and internaltechnical support; a NorthAmerican Parts Guarantee Program;and new dealer-tested initiatives.MMD EquipmentExpands KomatsuRental OfferingMMD Equipment recentlyexpanded its small rentalhouse sales arrangementwith Komatsu byannouncing the availabilityof two Komatsu backhoeloader models, the KomatsuWB142-5 and WB146-5. Thebackhoe loaders complementMMD’s rental industry offering ofKomatsu compact excavators.“We are very excited that MMDEquipment has the opportunityto market the Komatsu line ofproducts to the rental industry.”said Bob Wright, president ofMMD Equipment. “Now withthe quality Komatsu backhoeloaders, our broad sales networkwill better fulfill the needs ofour rental customers and bolsterKomatsu’s position in therental market.”The Komatsu WB142-5,recently introduced at the ARAshow in February, is being manufacturedin Newberry, S.C., and isdesigned and priced to competein the entry-level backhoe loadermarket. Like its full-featured“big brother” the WB146-5, engineeringand manufacturingincorporate Komatsu’s commitmentto continuous improvementthat result in a backhoeloader which is comfortable, convenient,reliable, productive andeasy to service.MMD Equipment is a leader inoffering quality products to theconstruction, rental and materialhandling industries for more than30 years. Product lines includecompact excavators, backhoeloaders, air compressors, mobilegenerators, dewatering pumps,trash pumps, submersiblepumps, portable generators,wheel loaders, compaction equipment,Parts Power Plus andthe Farrow System.The Komatsu WB142-5 andWB146-5 backhoe loaderswill complement MMD’sexisting rental offering.12 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

GROUNDBREAKING NEWSLeica GeosystemsAnnounces New VP ofConstructionL e i c aGeosystemsAmericasrecentlyannouncedthat ValerieRichardsonRichardsonhas beenappointedto vice presidentof construction for NorthAmerica. Richardson will beresponsible for sales, channel management,service, support, andproduct marketing for all productsand systems designed for the constructionand industry segments,including construction and pavingmachine control; constructionmid-range instruments; exteriorconstruction lasers and levels; andthe interior laser products.Richardson reports directly toBob Williams, president of LeicaGeosystems Inc., Americas region.This new role will also bringRichardson in close collaborationwith the newly-formed HexagonMachine Control and the PrecisionTools Divisions worldwide, as wellas the Geosystems Division whereshe will support sales of mid-rangeinstruments to the constructionsegment.A two-year veteran of LeicaGeosystems, Richardson aptlyproved herself as an effectiveleader in her former position asvice president of strategic marketingand customer support, a positionshe had held since February2005. Prior to joining LeicaGeosystems, Richardson served invarious marketing, sales and channeldevelopment roles at Invensysplc and Siemens Energy &Automation. She has lived andworked abroad, and holds an MBAin Finance from North CentralCollege, as well as an M.A. inindustrial/organizational psychologyand a B.A. in journalism fromDrake University.“Valerie is an effective leader anddelivers quality results,” saidWilliams. “With her diverse businessexperience and skills in many areasrelated to increasing customer-focus,I am confident that she will unify herteam to achieve our business goalsfor the construction and industrymarkets while continuing to improvecustomer satisfaction levels.”<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 13

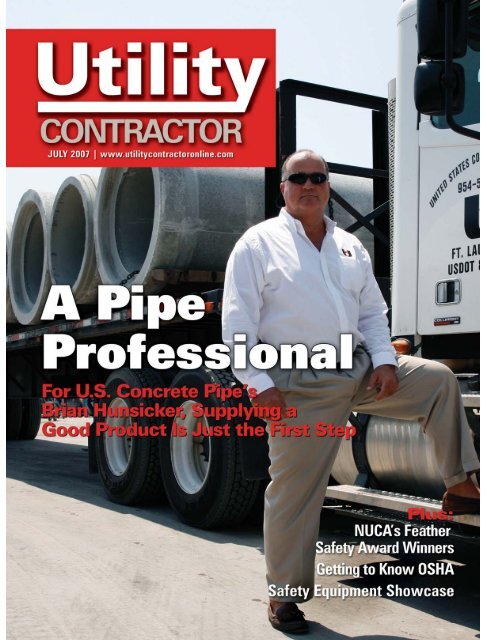

A PipeProfessionalFor U.S. Concrete Pipe’sBrian Hunsicker, Supplying aGood Product is Just the First StepBy Nick ZubkoPlans are important. They are important in life,construction projects, and in a career. Each stepusually needs to be completed before the next canbegin. But there’s a funny thing about plans…they change. And it’s the ones who are able to adapt thatget ahead. Brian Hunsicker knows that as well as anyone.Hunsicker had been around construction his entire life,so when it came time to go to college at the University ofCentral Florida, it only took him a semester to figure outwhere he wanted to end up. He continued working constructionwhile he was in school, earned his degree in civilengineering, and had enough foresight and good advice to14 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007get a background in engineering before jumping back intoconstruction full-time.But after more than 15 years on the construction side ofthe business, Hunsicker’s plans changed too. When Florida’seconomy tanked in the early 1990s, he decided that insteadof waiting for it to get worse, he would change his course.And that’s exactly what he did. Eventually, he accepted a joboffer as a manufacturer’s representative at one of the largestpipe distributors in the United States.“At the time, I fully intended to stay in construction andI had no desire to go into sales, but business had dried up,”explains Hunsicker, who was working for a contractor

Armed with experience, a love of construction and a useful vantagepoint from the other side of the sale, Hunsicker (center) has built a newcareer as one of the most respected pipe reps in the business.named W. Jackson & Sons Construction Co. “That’s whenan opportunity came up to be a manufacturer’s rep forCONTECH [Construction Products]. To be honest, whenI first did it I thought I was making a mistake.”But the risk paid off. Armed with his experience, a loveof construction and a useful vantage point from the otherside of the sale, Hunsicker built a new career as one of themost respected pipe reps in the business. Now vice presidentof sales for the Ft. Lauderdale branch of U.S.Concrete Pipe Co., he has used his talents to benefit therest of the utility construction industry as well, throughhis involvement in the National <strong>Utility</strong> <strong>Contractor</strong>sAssociation (NUCA) as one of its most active associatemembers. In recognition of his continued contributionsto the welfare of the industry, Hunsicker has been namedNUCA’s 2006 “Associate of the Year.”Laying PlansGrowing up, Hunsicker’s father was vice president ofIntercounty Construction of Florida, a constructioncompany owned by Mike Marinelli, who helped foundNUCA back in 1964. He started tagging along with himin the summers and after school when he was nine, butby the time he was 13 his father had passed away.His love of construction persisted, and he went to workfor Webb General Contracting just before his sixteenthbirthday, doing menial labor and driving trucks aroundthe jobsite. Hunsicker immersed himself infootball throughout high school and college,but continued to work construction forIntercounty during summers and Christmasbreaks. After his first semester, he realizedthat his true love was construction andswitched majors (from physical education tocivil engineering).“I loved construction, but I never reallythought of it as a career until I came homefrom my first semester of college,” saysHunsicker. “For some reason, that waswhen I realized that I definitely wanted togo into construction. From then on, everythingfor me gravitated around the constructionindustry.”During his college years, Hunsicker wastutored in calculus by a friend of his namedCraig Smith, who owned Craig A. Smith &Associates Consulting Engineers inPompano Beach, Fla. As Hunsicker consideredhis plans for the future, Smith’s tutelagestretched beyond logarithms and heconvinced Hunsicker to try his hand atengineering first (to get that experienceunder his belt) and then switch to constructionlater.“He said you could always get an engineeringdegree and go into constructionlater. But if you start out in construction, it’stougher to make the change into engineering,”Hunsicker recalls. “So three days aftergraduation, I started working for Craig A. Smith andAssociates Consulting Engineers. They did everything …utility work, land development, water and sewer plantconstruction and highway work. I started out as a fieldengineer and then moved up to design. Eventually Ibecame director of construction services, where I handledall types of the construction contracts.”He spent eight years at Craig A. Smith & Associates,gaining valuable experience in construction inspection,design and construction management from the owner’spoint of view. But Hunsicker knew that engineering wasnot part of his long-term plan. So when a customer of hisnamed W. Jackson & Sons Construction Co. made himan offer, he was ready to take the next step.“W. Jackson & Sons was probably the contractor on40 to 50 percent of the jobs I was already working on.And being director of construction services, I dealt withtheir vice president a lot,” recalls Hunsicker. “We got totalking once and he invited me to come work for him,since they didn’t have an engineer on staff. I alwaysknew the engineering was strictly a stepping stone forme. So it was a natural next step.”He started working as a project manager for W.Jackson & Sons in 1988, where he was able to experiencethe entire scope of development as a contractor.His responsibilities ranged from business development,client relations, estimating, contract award, permit<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 15

tance as a flexible product. As he maturedin the sales side of the business, he movedon from CONTECH and joinedCSR/Rinker Material Hydro Conduit in1999 as a sales engineer and then rosethrough the ranks to promotional engineerand then sales/general manager.“With Rinker, my duties went from salesand promotional work within theengineering community to securing a rigidspecification and illustrating both theinherent strength benefits of a rigid productand the installation-dependentstrength of a flexible product,” heexplains. “Then taking over as generalmanager, I oversaw the operation of threeSouth Florida manufacturing facilitiesthen as sales manager over the same area.”Eventually, Hunsicker landed at U.S.Concrete Pipe Co., a national clay andconcrete pipe manufacturer with locationsin Ohio, Maryland, Michigan,Pennsylvania and Florida. The company’sFlorida division, which wasEventually, Hunsicker took his experience to the Florida branch ofpurchased by the Mancini family inU.S. Concrete Pipe Co., a national clay and concrete pipe manufacturer.1983, has grown immensely over theacquisition, project management, dispute resolution andeventually to completion.“At Jackson, I went from design and overseeing constructionto bidding, estimating, managing, changeorders, claims and project completion... I was able to getinvolved in everything,” Hunsicker explains. “The wayJackson worked, you did your estimating and if you got ajob you were its project manager. So it was a really good,well-rounded experience.”last 24 years. When the Mancinis took it over, they wereproducing 20,000 tons per year from two manual handtamp machines. Today, the facility produces in excess of150,000 tons per year with manufacturing capabilitiesfrom 12- to 96-in. round pipe and fittings.“The cool thing about all of these places [CONTECH,CSR/Rinker and U.S. Concrete Pipe] is that they all prettymuch do the same type of work. CONTECH was aflexible product, whereas CSR/Rinker and U.S. Concreteare both rigid products. But the business is basically theA Seller’s MarketThe next step in Hunsicker’s career was not part of hisplan. In the early 1990s, Florida’s economy and constructionmarket had started to plummet. By 1993, contractorsleft and right were going belly up and W. Jackson & Sonswas fighting to stay competitive. Instead of watching theeconomy continue to get worse, Hunsicker started consideringa sales engineer position at CONTECH that hadbeen on the table for a couple of years. Later that year, hefinally accepted.“It took a while to get used to the sales side of things,but once I did, I realized I was really meant for it,” notesHunsicker. “Sales was great and I loved it, because I hadthe opportunity to have input with both the contractorsand the engineers. It allowed me to stay active and focusedin both fields. And here, you’re basically selling a productthat someone needs. You’re not trying to talk someoneinto buying something they don’t need. I like this kind ofsales. It’s a commodity, but it’s a necessary commodity.”In addition to selling a wide array of products,Hunsicker was responsible for promotional work withinthe engineering communities to get a specification accep-same,” explains Hunsicker. “My background has reallyhelped me, both because of my experience in constructionand the contacts I had. Basically, I was selling topeople who have worked side-by-side with me andcompeted against me. Or, I was selling specs to the engineers,who knew I was a design engineer too. It has givenme the empathy with the contractors to be more customer-serviceoriented, plus a little better credibility withthe engineers.”Today, the most difficult challenge facing his companyand fellow reinforced concrete pipe (RCP) manufacturersis the emergence of cheaper alternative products.To improve market share and stay competitive,Hunsicker says manufacturers need to improve the efficiencyof the product, cut costs and stay vigilant in promotingRCP’s benefits.“We need to make the engineers who are specifyingand the contractors who are installing a product aware ofthe benefits of RCP,” says Hunsicker. “RCP is a rigidproduct that is virtually installation error proof due to itsinherent strength and is usually capable of handling theprojects load requirements separate from the soil enve-16 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

lope. Flexible products have little or no inherentstrength and acquire the majority of its strength from thesoil envelope, which makes installation very critical.”Mutual BenefitsDuring his early years as an engineer and then as a contractor,Hunsicker began to realize the benefits of a participatingin local associations. He joined the Underground<strong>Contractor</strong>s of South Florida (UCA of South Florida) as anengineer with Craig A. Smith & Associates in the early1980s and he is now on the board of directors. He alsobecame a member of the Underground <strong>Utility</strong> <strong>Contractor</strong>sof Florida (UUCF), which is made up of the seven NUCAchapters throughout the state. Hunsicker represents theUCA as a board member.His first experience with NUCA didn’t happen until hewas with W. Jackson in 1993, when Hunsicker attendedthe association’s annual <strong>Utility</strong> Construction EXPO innearby Orlando. He met a bunch of NUCA members,including Scott Johnson of Johnson-Davis Inc., who convincedhim to come out to Washington D.C. for NUCA’sSpring Board and Committee Meetings & WashingtonSummit.Johnson introduced Hunsicker to some other members,including Spunky Thaxton and Walter Gainer. Eventually,they asked if they got Hunsicker nominated to the board,would he be active? He said he would. So, Hunsicker wasnominated as an associate director the following year atthe 1995 EXPO in San Diego. He joined the PAC andGovernment Relation Committees soon after, and startedattending annual conventions, spring fly-ins and fallboard meetings.“The conventions were always fun, but when I actuallystarting going to all of the committee meetings is when Ireally started to enjoy the participation,” says Hunsicker.“To this day, one of my favorite experiences is the congressionalfly-in during NUCA’s Washington Summit.That’s where you really see the effect and influence NUCA,along with the local chapters, has on congressman andsenators. Our Executive Director, Jen Mancini, is fantasticat what she does and represents us well.”According to Hunsicker, Mancini has had the chapterset up with as many as 16 appointments in one day withtheir legislators. She starts making contact with representativesmonths before the trip and is on the phonewith aides literally minutes before the group sees them.“It’s executive directors like Jen who make these tripssuccessful and make us contractors and associates moreeffective,” says Hunsicker. “The other part of the equationis the NUCA staff. Over the years I have seen theleadership that Bill Hillman, Linda Holtz, Eben Wymanand George Kennedy have shown and more recently themembership efforts of Heather Caldwell and the rest ofthe staff. It’s obvious why this organization is successful.”Over the last 10 years, Hunsicker has continued to beactively involved in NUCA’s board of directors and theGovernment Relations and PAC Committees. But whenNUCA formed its Associates Council, Hunsicker took aWhen NUCA formed its Associates Council, Hunsickerimmediately wanted to get involved and served as itssecond chairman in 2003-2004.special interest and immediately wanted to get involved.He even served as its second chairman in 2003-2004.“The council really gave the associates more of a voicein the association, rather than functioning mainly as asupport network,” says Hunsicker. “When it was formed,we got a seat on the executive committee (which we didn’thave) and we had input. Today, that is one of the manybenefits of NUCA — both associate and contractor membersare equally as important. In other organizations, theassociate members are just the ones buying the drinks. Butit’s not like that in NUCA. The associate members are rightthere with the contractors and we’re fighting the same battlesas they are. I think that the ones who don’t take advantageof that are really missing the boat. They should bethere side by side, fighting in the trenches.”On being recognized as NUCA’s “Associate of the Year”this year, Hunsicker says he was both shocked andhonored when notified last October. What made theaward even more special was to get it the same year hisfriend, Cheryl Yoder, received NUCA’s “Ditchdigger of theYear” — not to mention following John Deere’s RogerMohr, who was last year’s recipient.“Roger [Mohr] is truly an inspiration for all associatesabout what it means to put your personal and companyreputation on the line to promote the industry. Some ofthe things he has done are incredible,” Hunsicker says.“To be honored like this, especially being just a localguy, is really something special. You see these peoplewho have the national support, but we’re just one locationserving south Florida. It shows that anyone canmake a difference. Because as much as Roger does, he’sstill just one person, pursuing important issues, lobbying,working for membership. Now other associates canlook at this and say: If Hunsicker can get this with onelocation, then why not me?”Nick Zubko is associate editor of <strong>Utility</strong> <strong>Contractor</strong>.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 17

On the Safe SideNUCA’s 2006William H. FeatherSafety Award WinnersBy Nick ZubkoAny time people are added to an equation, acertain level of human error becomesinevitable. That’s why pencils have erasers,right? In reality, the outcome of that error canvary greatly depending on the situation. It’s not so badwhen a plumber finishes your new bathroom and thefaucet on your sink flushes the toilet (actually, that onemight be pretty funny). On the other hand, if youraccountant puts one decimal point in the wrong place,it could end up costing you a pretty penny.Simply because of the nature of the business and thesheer risk involved in nearly every project, the stakes inutility construction are even higher. Jobsites are larger,more complicated and increasingly difficult to control.One slipup can result not only in financial devastation,but also in a serious or even fatal injury. That’s whysafety is such a critical part of any successful utilitycontractor’s business plan.The National <strong>Utility</strong> <strong>Contractor</strong>s Association (NUCA)has been recognizing companies for their efforts on thesafety front for almost 30 years, establishing the WilliamH. Feather Safety Awards back in 1978. Named for thefounding chairman of NUCA’s safety committee and apioneer in safety awareness, the awards were created torecognize a commitment to safety demonstrated by a lowfrequency of injuries, explicit safety statements andinnovative and sophisticated company programs.Initially bestowed on a single individual or company,the award was later expanded to include contractormembers that had the best safety records. The winnersare chosen on the basis of information in seven categoriesestablished according to total man-hours worked. NUCApresented the winners of the 2006 Feather Awards at itsFourth National Awards Dinner, which was held May 16in Arlington, Va., during its 2007 Spring Board andCommittee Meetings & Washington Summit.18 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

Overall WinnerJ.F. Wilkerson Contracting Co. Inc.Morrisville, N.C.When Joe Wilkerson started J.F. WilkersonContracting Co. back in 1969, the importance of safetywas far from what it is today. Back then, Wilkerson wasa young contractor whose main goal was to get the jobdone quickly and cost-effectively. Safety, he admits, tooka back seat. Things changed in a big way, however, whenin the early 1970s the Raleigh News & Observerpublished a list of contractors it deemed as the “20 worstoffenders” in regard to safe operating practices.J.F. Wilkerson Contracting made the list.“We were not a safe company in the early years, butseeing our name on that list was a real eye-opener.It was a turning point in my career,” Wilkerson recalls.“For safety to work in any company, the managementhas to be the first to buy into it. And back then, I didn’t.We were small enough that we hardly had any accidentsand no one got hurt, but we started putting a programinto place and we have never looked back. Wedidn’t have all the trench box manufacturers that wehave today, so we just made our own.”Ever since, Wilkerson has worked to convey theimportance of safety to everyone else in the company aswell. Through frequent reminders of safety fundamentals,those practices have in time become a way of life forthe company. Safety meetings are held weekly and beforecrew members can step foot on a new jobsite, everyoneis taken through an intense day of training, focusing onspecial things to look out for onsite, understanding thetrenches and any issues with confined space entry.“You just can’t call everyone into a meeting once ortwice a year to go over all the rules and expecteveryone to observe them. It doesn’twork that way,” says Wilkerson. “Therehas to be constant reinforcement. Atone point, we went back and realizedthat a majority of our injuries were bypeople who had been with the companyonly a very short period of time.Taking steps to train and monitor thosepeople more closely was one of the bigthings that really helped us improve.”The company’s efforts showed up onNUCA’s radar for the first time in1990, when J.F. Wilkerson won its firstFeather Award, again taking theoverall spot. Continuing to strive forimprovement, the company has had awritten safety program in place for thelast 10 years and frequently promotessafety in the construction industry bytraining subcontractors in OSHA 10,Subpart P and HazCom free of charge.It has also provided industry trainingand worked with schools to provideequipment for elementary school kidsto see, attended job fairs and train other contractor’semployees.“When we first started using trench boxes, there wasa perception that you couldn’t be productive,” saysWilkerson. “But after using those safety devices for awhile, you realize that it doesn’t hurt production at all —you can actually improve it. It’s human nature to fightchange. So you will always have resistance, but you justhave to explain how necessary it is and when they buyinto that, they will incorporate it into the work.”Another way J.F. Wilkerson combats resistance is byrewarding employees for a job done safely. Accordingto Wilkerson, the compact provides monetary rewardsto their employee’s 401K plan at the end of a safe year.For every dollar that an employee puts into the 401K,Wilkerson adds $1.50. And those rewards are made alittle bit easier as a result, as J.F. Wilkerson’s experiencemodifier has dropped from a pinnacle of 1.8down around a 0.8. This has made a significant differencein insurance premiums, not to mention greatlyimproving its image as a safe contractor.“Before a company can be safe, top management hasto believe that a job can be both safe and productive,”says Wilkerson. “And you have to bid jobs highenough to allow them to be completed safely. I see somany young contractors who get the work too cheaply,and the only thing they can do is cut corners to survive.It’s difficult to convey the importance of safety tothe young guys today. No one thinks it will happen tothem. And many of them have never seen an accident,never had to sit down in a courtroom with OSHA andthey simply don’t know the ramifications. If you continuewith unsafe practices, eventually someone isgoing to get injured.”According to Joe Wilkerson, J.F. Wilkerson Contracting Co.’s founder andpresident, for a contractor to be truly safe, its top management has tobelieve that a job can be both safe and productive.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 19

For Western Summit, a good safety record reflects the quality of management,supervision and workforce. Above, Mark Latham, the company’s corporatesafety director, speaks to a crew about jobsite safety.1,000,000-Plus HoursWestern Summit Constructors Inc.DenverWestern Summit Constructors Inc. has established areputation as a leader in the water and wastewater industries,performing high level work for more than 25 years.A critical part of the Western Summit’s success has beenan established safety and health policy — one so effectivethat it earned the company the overall Feather Awardwinner for both 2001 and 2005, and its continuedprogress is being recognized again this year.Part of the company’s success on the safety front hasbeen credited to its implementation of a People-BasedSafety (PBS) program on all of its jobsites. The programencourages craft people to conduct safety observationsand identify the level of safety being carried out inthe field. Information is entered into a database thatallows tracking to take place, enabling management todevelop leading indicators that identify areasof concern where the company can then concentrateits efforts.“We have continued to put a lot of effort into our peoplebasedsafety and we’re starting to see some results,” saysMark Latham, Western Summit’s corporate safety director.“It’s really the start of a longer journey, but it is definitelygetting our field people involved in safety. More and moreof our people are out in the field as observers, looking forsafe and at-risk behaviors.”Western Summit has increased training efforts on jobsafety assessment and hazard assessment, involving moreand more members if its crew.In addition, the company’s large numberof Spanish-speaking workers hasalso been addressed, hiring its firstbilingual safety trainer more than twoyears ago, and hiring a second justlast year.Western Summit believes safetyshould not be sacrificed for production,but rather considered an integralpart of quality control, cost reductionand job efficiency. While the ultimatesuccess of a safety and health programdepends upon the full cooperation ofeach individual employee, Lathamsays it is management’s responsibilityto see that safety and health rules andprocedures are adequate and enforcedand to see that effective training andeducational programs are employedto the greatest advantage.“You need to have the support fromthe top; there has to be that vision andleadership with clear expectations,”says Latham. “But there is no one-sizefits-allsafety program. Even withinour own company, different jobsiteshave to be approached differently.Some jobs are larger than others and have a dedicatedtraining trailer. On the smaller jobs, you’re training out ofthe back of a pickup.”According to Latham, every one of Western Summit’ssupervisors is aware of safety performance demonstratedby the employees under his or her supervision. A goodsafety record not only reflects the quality of management,supervision and workforce, but also serves to promotebusiness and thereby contributes to the continuinggrowth and success of the company.“Being recognized is kind of a validation from yourpeers that you are heading in the right direction,” saysLatham. “Until you get to zeroes, you know you still havework to do. And then when you get to zeroes, it takeseven more effort to stay there. But [receiving theseawards] is definitely a form of validation that what wehave in place is working.”500,001-1,000,000 HoursAlex E. Paris Contracting Co. Inc.Atlasburgh, Pa.Founded in 1928, Alex E. Paris Contracting Co. is afull service heavy construction firm with an equipmentdivision and an industrial service division. The companyprovides almost any type of construction or industrialservices needed and employs more than 200 people.Today, the company's safety program represents a continuumof loss control measures ranging from preplanning/sitedetermination to implementation, follow-upand improvement activities.20 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

“Our health and safety policyinfluences all work activities, fromthe selection of people, equipmentand materials, to the way work isdone and how we design and completeour projects,” says Bill Santa,the company's safety coordinator.“And we continue to improve in thearea of safety with the belief thatsafety and accident prevention are tobe managed like any other functionof the organization.”According to Santa, the elementwith the most significant impact onthe success of the company's safetyprogram has been its team approach.All employees receive regular trainingto support the safety programand are encouraged to participate insafety and loss prevention efforts, inorder to take full advantage of theirknowledge of how improvementscan be made.In addition to maintaining anactive safety committee that representsall operational functions, AlexE. Paris Contracting relies on activemeasurements of its safety performanceto determine if the program isPlanning is the key to making health and safety efforts work, according to Bill Santa,safety coordinator for Alex E. Paris Contracting. That means setting objectives,identifying hazards, assessing risks and implementing standards of performance.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 21

successful. The safety program is regularlyinspected and audited to ensure that standardsare being implemented and managementcontrols are working.“Planning is the key to ensuring thatour health and safety efforts reallywork,” Santa says. “That means settingobjectives, identifying hazards, assessingrisks, implementing standards of performanceand developing a positive culture.We continue to monitor our safetyprogram to ensure that it supports ourproductivity and quality goals. In yearspast, the two goals were consideredmutually exclusive. We now integratesafety production and quality to supportour operational goals.”At Alex E. Paris Contracting, priority isgiven to areas where the risks are thegreatest. Management looks closely atserious events and those with potential forserious harm. The utility construction industry has inthe past relied on a reactive approach, says Santa, but forthe industry to excel, proactive metrics need to be monitoredbefore things go wrong.“Most traditional safety programs have operated on thebelief that hindsight is 20/20 — investigating after thingsgo wrong; our company has moved beyond the reactionarymode and for the industry to progress, a similarapproach is essential,” he adds. “You need to ensure thatinformation from proactive and reactive monitoring isused to identify situations that create risks, and do somethingabout them.”200,001-500,000 HoursSundance Mechanical & <strong>Utility</strong> Corp.Albuquerque, N.M.Founded by Mike Mechenbrier in 1979, SundanceMechanical & <strong>Utility</strong> Corp. specializes in water line,sewer line and storm sewer installations, in additionto concrete curbing and gutter and asphalt paving.Over the years, a key the company’s safety programhas been its Supervisors Safety AccountabilityProgram, which transfers the responsibility for workersafety to the workers supervisor.While Sundance’s management has always been theguide for safety, its record improved dramatically whenthe supervisors were made accountable for each memberof their crews more than 12 years ago. Ever since, eachmember of the Sundance team has accepted safety as anintegral part of the business. According to Ed Burroughs,safety accountability is simply being responsible for whatyou do. And supervisors need to identify what theyexpect their people to accomplish.“Our goal is to not have any accidents while makinga profit,” says Burroughs. “If you are serious, you keepscore. A group that does not measure what it producesis not effective. Accountability requires precise data onAt Sundance, each supervisor’s Christmas bonus is enriched or reducedbased on their safety performance. Company president Ed Burroughs saysthat just the stigma of being below average can be a great motivator.what you have or have not done. Proper use of consequences(rewards, applause, praise and incentives) isthe fuel of accountability. Without consequences,accountability is without substance.”Sundance’s supervisor safety accountability programmeasures seven items; six are definitive items as follows:employee orientation, tool box talks, safety meetingsattended, timely notice of loss, accident investigationand accident or incident rate. These are all “yes orno” items (either it was done or it wasn’t) that are gradedas a percentage of optimum.The seventh item is safety attitude. Sundanceemployees grade their supervisor by answering eightquestions on the usefulness and sincerity of hissafety efforts. The results are tabulated and a percentagegrade is computed for each supervisor and an averageis computed of the total scores.At an annual supervisor’s safety lunch in December,the results of the last year are presented and eachsupervisor receives a detailed graphic tabulation oftheir scores. Each supervisor’s Christmas bonus isenriched 3 percent for each point he is abovethe average, or reduced by the amount he is belowthe average.According to Burroughs, the amount of penalty orenrichment is not great, but the stigma of being belowaverage is a great motivator — especially in a groupsetting.“Prior to starting the accountability program, ourexperience modifier was 1.85 and its insurance premiumfor workers compensation was around$400,000 every year,” he explains. “The safety programhas reduced that modifier to 0.77 and theinsurance premium to $100,000 a year. As a result ofthis our safety program is credited as saving$300,000 a year for Sundance. There is no better reasonfor having a safety program.”22 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

100,001-200,000 HoursDeKalb Pipeline Co. Inc.Conyers, Ga.Since creating its safety program 14 years ago, DeKalbPipeline Co. has been a safety-oriented company, continuallystriving for excellence in this area of the business.The effort showed, as DeKalb has been fortunate not tohave had any jobsite accidents over the last nine years.As a result, the company has been the recipient of aFeather Award several times over, including categoryspots in 1998, 2001, 2003 and 2005, and the overallwinner in 2002 and 2004. But according to companypresident James King, DeKalb’s safety program has continuedto improve and maintain an accident-free workenvironment.“We have made it a top priority to send our employeesto refresher safety courses,” says King. “The element wefeel has had the most impact is our ability to keep ouremployees trained. Training is one of the most valuablebenefits you can offer your employees. It not only showsthat safety is important to you as a manager, but also thatyou have genuine concern for the employee.”For DeKalb, it is imperative to make safety training asaccessible and as easy as possible. The company’s localassociation, the Georgia <strong>Utility</strong> <strong>Contractor</strong>s Assocation,offers jobsite safety classes that make the process easierfor both employer and employee. In recent years, part ofits challenge has been training Spanish-speakingemployees in their native language. DeKalb looks toOver the last nine years, DeKalb has received a FeatherAward an impressive seven times (including twice asoverall winner). Even so, company president James Kingsays there is always work to be done on the safety front.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 23

GUCA for this, because the associationoffers a variety of classes in Spanish.According to King, the perception ofsafety was perceived as a hindrance inthe past — and to some degree, it stillmight be thought of that way. But it haschanged in the last few years. Today, hesays, contractors pay more attention tothe news when they report a jobsite accidentand to their surroundings, lookingfor ways to make them safer. DeKalb isconstantly learning of new dangers thatits workers are exposed to and whenthey come to light, new training and PPE(personal protective equipment) isbrought into the equation.“<strong>Utility</strong> construction is such a highexposure profession,” notes King.“There are so many more things thatwe are aware of now that affectsemployees on a jobsite. In the industryand in our company, there is alwayswork that needs to be done on the safetyfront. It’s hard to stay one step aheadof danger, because it’s where you leastexpect it. You need to make an effort to keep youremployees focused on safety and keep them trained.”50,001-100,000 HoursRaymow Construction Co. Inc.Oldsmar, Fla.As a medium-sized, family-owned site and utility constructioncompany, Raymow Construction Co. Inc. concentratesits operations in the Tampa Bay, Fla., area. Since thecompany was started more than 14 years ago, its objectivehas been to provide the best quality finished product withinthe agreed schedule completion time — at a fair but profitableprice to its customers. Raymow Construction has nothad one lost-time injury.According to company founder and president E. J.“Bud” Bradley, Raymow’s safety record can be attributedto a number of factors. One is a written, actively implementedsafety program that is supported at all levels ofthe company — from the laborers up to the companyowners. In addition, there are biweekly supervisor safetymeetings to review fundamental safety practices andrules, no compromises on the basics, such as hard hat,safety glasses, long pants, shirt sleeves and hard shoes.Outstanding safety performance is rewarded in everyway possible, as is keeping equipment and tools ingood, safe operating condition.Raymow’s ongoing safety program includes firstaid/CPR training for all management (with biweeklyreview); utilization of NUCA’s “Pocket Safety Guide,”bimonthly “Safety News,” weekly e-newsletter for toolboxtalks and biweekly safety meetings and an annualsafety luncheon with individual awards. Raymow screensemployment candidates for competency and does notRaymow’s founder and president Bud Bradley says the company has been safetyorientedfrom the top down since its first day of business — proving that evenwith safety as a first priority, you can be profitable in this industry.allow an individual to perform any task for which he orshe is not qualified. Its management provides on-the-jobtraining routinely and communicates and enforces thebelief that an attitude of a safe workplace is essential —no matter what the job.“This company has been safety-oriented from the topdown since our first day of business, so it has never beenperceived as an inconvenience for those who’ve embracedthe safety attitude on the job,” says Bradley. “Essentially,we implemented the fundamentals on day-one and madehabits out of them. I think we have proven time and timeagain that, even with safety as our first priority, a companycan be profitable in this industry.”0-50,000 HoursA.E. Bragger Construction Co. Inc.Warwick, R.I.A.E. Bragger Construction Co.’s commitment to safetygoes beyond the normal regulatory requirements.The company’s ongoing commitment to keep all of itsemployees and management up to date on current andnew safety regulations has had the most significantimpact on its impressive safety record.Every day before work, the company engages in a“toolbox talk” of relevant subject matter of the day’sprospective work. Once on the job, the foreman andsuperintendent continually monitor the progress whilereviewing safety precautions, so as to ensure a safe worksite.The company’s staff is very cognizant of its safetyrecord, which instills in them a positive work ethic andcomfort level that they can go home every night to theirfamilies. At the end of the year, the company awardsbonuses based on injuries and accidents.24 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

“Our employees are now more cognizantof the jobsite surroundings and the workenvironment — not only for themselves,but their fellow workers as well; we trulynow work as a team,” says VirginiaDiCristofaro, safety director for A.E.Bragger Construction. “Like anything new,it’s challenging for everyone to get used tonew elements of the safety program.Fortunately, we have a great and supportivestaff. That alone makes any changes in newsafety measures much easier to employ.”DiCristofaro explains that Rhode Island’smandatory OSHA 10 Construction SafetyTraining requirement, in addition to apush by OSHA to increase inspections, hasallowed the company to blend those safetymeasures into its own program. Over thelast few years, the company has continuedto engage in more “toolbox talks” and safetytraining programs in an effort to continueto improve every year.“It’s an ongoing process. We believe thatour accident and incident reductions werea direct result of our increased efforts as well asincreasing our productivity and quality of work,” notesDiCristofaro. “And as a smaller company, it was a littleeasier to introduce these programs to our employees,but we still tried to improve communication toA.E. Bragger Construction never stops working to increase safety awareness.Safety director Virginia DiCristofaro says just one accident is too much.make it even easier. I don’t think you can ever stopworking on increasing safety awareness. Just oneaccident is too much.”Nick Zubko is associate editor of <strong>Utility</strong> <strong>Contractor</strong>.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 25

Safety ShowcaseTraffic Vest Harness from NorthSafety ProductsNorth Safety Products, based in Cranston, R.I., is one ofthe leading manufacturers of occupational health and safetyproducts worldwide, offering a full range of quality personalprotection equipment (PPE), including respiratory, hand,protective footwear and clothing, welding, head, first aid,hearing, eye/face, fall protection, lockout/tagout, safety signageand traffic safety apparel and products. When visibilityis needed, North’sTraffic Vest Harness willkeep workers saferwhere the danger offalls and other accidentsmay be present. Madefor fall arrest and workpositioning, the provenFP700/3D nylon, veststyle,sized harnesscombined with a lightweightmesh traffic vestwork together to protectworkers who must beseen to be safe.Online: www.northsafety.comEclipse Arrow Board fromAllmand Bros.The Allmand Eclipse solar flashing arrow boards,available with highly efficient LED lamps and 15- or 20-light configurations, are extremely energy-efficient unitsthat can run unattended for months. The Eclipse uses50-, 75- or 100-watt high-performance, self-regulatingsolar panels that charge heavy-duty, commercial marinedeep-cycle power batteries to deliver quiet, efficient anddependable performance.The solar panels have a 25-year output warranty.Optional solar panels may be added to increase solar chargingof the batteries.Because the Allmandarrow board doesn’tuse an engine, there26 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007is no fueling, oil,critical leveling,noise or fuel spills,and virtually nomaintenance isrequired. The solarpanels remain facingupward whether theunit is in operatingmode or when thearrow board is in astowed position fortravel or storage in order to collect energy and charge batteries.The unit’s sign board lowers for convenient towingand is available with trailer mount or retrofit configurationsin standard 15- or 25-lamp models.A bright red flashing low-voltage warning lightindicates when batteries need recharging and is visible fordrive-by inspections. An on-board circuit monitorensures optimum battery life by shutting down the unitbefore voltage drops to a low level. The Eclipse isequipped with either highly efficient LED lamps oreconomical halogen lamps that can be easily replacedwithout discarding the fixture assembly.With a solar retrofit kit, a gas or diesel-powered arrowboard converts to an efficient, quiet, dependable solarunit. The kit includes everything needed for the user toconvert a trailer to high-efficiency solar power, with thesame warranty, replaceable lamps and electroniccontroller along with a pair of self-regulating highperformancesolar panels. The only difference is therigid solar panel mounting.Both the standard Allmand arrow board and the retrofitkit models include the 2200/SE ALT 15-lamp arrow boardand the 2200/SE APF 25-lamp arrow board. Both modelsare available with standard, inexpensive and replaceablePAR 46 halogen or optional highly efficient LED lamps.Online: www.allmand.comHeavy-Duty Footwear fromCaterpillarCAT Footwear is a partnership between two wellestablishedleaders in their fields – Caterpillar andWolverine. The product line has evolved from basic workboots to a wide range of industrial styles and high levelsof resilience that appeals to a large consumer base.The “Pneumatic” boot by CAT Footwear meets ASTMF2413-05 PR standards through the inclusion of a steel midplatedesigned to prevent objects from puncturing the sole.In addition to being puncture resistant, the Pneumatic featuresa steel toe that meets ASTM F2413-05 I/75 C/75 standardsas providing the highest available strength for impactand compression. The outsoleprovides supreme slip resistance andis rated ASTM F2413-05 I/75 EH;protecting the wearer againstopen circuits up to 600volts in dry conditions.The 6-in. upper ismade of waterproofleatherwith a protecti v erubber toe.Online: www.catfootwear.com

Safety ShowcaseMCR Safety LuminatorMCR Safety’sLuminator seriesof safety vestsprovides highvisibility.Thesevests are ANSI/ISEA 107-2004Class II and ClassIII, Level 2reflective materialcompliant. MCR’sdielectric, meshback Luminatorvest CL2OC is afavorite of utilitycontractors.Additional featuresinclude a 2-in. silverstripe, nylonzipper solid frontclosure, six pocketsand sizing up to 4X.Other popularconstruction, emergencyresponse andutility industrieshigh-visibility vestoptions include Luminator style WCCL2LA. This seriesfeatures Velcro adjustable side straps with reflectivestripes. Construction includes mesh polyester vest with2-in. silver stripe centered over 3-in. orange stripe,Velcro front closure, soft polyester black binding onfluorescent lime background for additional contrast andmaximum visibility.Other cool offerings for hot environments includeour Class III CL3ML, which features two pocketsand Velcro closure on a fluorescent lime mesh frontand back material.Online: www.mcrsafety.comGeneral EquipmentGas-Powered VentilatorGeneral Equipment, a family-owned manufacturer ofearth augers, ventilation blowers, asphalt cutters and surfacepreparation equipment introduces the GP8/GP8Hportable gasoline air ventilation blower.Able to accommodate most confined workspacerequirements, the compact unit is ideal for supplyingfresh air around construction sites; removing toxic andnoxious atmospheres from confined work spaces; aidingin detecting sewer line leaks; and providing fresh air forpersonnel inside tanks and vaults.The GP8 is available with a Briggs & Stratton 3.5-hp,3,600 rpm engine or with a Honda 3.5-hp, 3,600 rpmengine (GP8H model). The blower housing is fabricatedfrom cast aluminum, for superior resistance to externalfield damage. An adjustable governor with manual speedcontrol allows the operator to vary the blower volume asneeded. The GP8 weights just 56 lbs, making it easy totransport around the jobsite.Online: www.generalequip.comSafety First Consulting & SalesSafety First Consulting & Sales has made orderingeasier by setting up packaged sets of personal coolingproducts that work on the evaporative process, enhancingthe body’s own evaporative process to cool itself.These packaged sets are unique and custom-made to eachcustomer’s specifications. With each set included free isan OSHA Quick Card on Prevention of Heat Illness,reformatted, laminated and on a clip, sturdy enough forthe workplace and a laminated ¼ emergency phonenumber list on the same clip.Online: www.safetyfirstconsultingsales.com28 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

GroundRulesUnderstanding HowOSHA Really WorksBy Greg StrudwickWhen many of today’s contractors got their first jobsjust out of high school or college — at least thosewho graduated before 1970 — what we now know asOSHA (the Occupational Safety and HealthAdministration) didn’t even exist. Some contractors doing federalwork were probably aware of provisions in the existingConstruction Safety Act, but it was contract language and therewasn’t any federal enforcement. For the most part, contractorssimply learned that avoiding accidents saved them money.However, many of those same contractors knew and understoodthe benefits of a safe and healthful workplace. One example wasfrom my early days working for Murray Construction, under thetutelage of an aging pipe layer named Eli Brown. Eli never had anyformal training, so his knowledge of working safely came from alifetime of experience and an understanding that personal safetywas his responsibility and his first priority.He told his crew to watch the surroundings, and to listen.Just by listening and concentrating on your environment, he said,the trench itself could give clues as to its stability. Eli learned overa long period of time that using your senses and ability to recognizepotential hazards were part of a normal workplace routineand the key to survival while laying pipe in a trench.But not everyone was like Eli in those days, so a number ofprotections have been developed over the last 30-odd years tohelp contractors keep their workers safe in the trenches. One ofthe most significant changes started when the Occupational Safetyand Health Act was passed in 1970 and OSHA was created. Fromthat point on, it was clear that the utility construction industrywould never be quite the same again.30 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

Standards & ComplianceThe Occupational Safety and Health Act (also knownas the Williams Steiger Act) begins with a simple statement:“To assure safe and healthful working conditionsfor working men and women.” According to OSHA’sSmall Business Handbook the current goal and missionstatement is as follows.“Under the occupational safety and health act of 1970,employers are responsible for providing a safe andhealthful workplace for their employees. OSHA’s role isto ensure the safety and health of America’s workingmen and women by setting and enforcing standards; providingtraining outreach and education; establishingpartnerships; and encouraging continual improvementin workplace safety and health”As OSHA regulations began to appear, it didn’t takelong for contractors to realize the influence these newrules would have on their businesses. Inevitably, thenew rules were greeted with a fair share of resistance.Many contractors were shocked to learn that there werefines issued after their first inspection. Others thoughtthat the first inspection should be for advice. Some simplyfound the new standards confusing.The first standard for excavation and trenching(referred to as OSHA Subpart P) used terms such as“angle of repose” and “banks.” Workers like Eli foundthe terminology confusing, and it became difficult tokeep jobs profitable. So in 1989, OSHA revised the standardto eliminate anyconfusion and makecompliance easier.These are the currentstandards and representminimum requirements.However, sometimescompliance withOSHA standards is notadequate to eliminatethe hazards.OSHA’s trenchingstandard states thatcontractors are touse an adequatelydesigned protectivesystem in any unsafetrench, except whenexcavations are in stablerock or are less than5 ft deep. In addition,the competent personneeds to have examinedthe ground andstate that there is noindication of a potentialcave-in. For example,a trench dug 4-ftdeep in sugar sand (orthat has been blasted) would obviously require either atrench box or an engineered shoring system — withoutquestion.In the past, many contractors have found some of therules to be either inconsistent or simply too difficult tofollow. They ended up throwing up their hands and saying“to heck with OSHA compliance.” Today, these contractorshave been reduced to a small minority. However,they still serve to adversely affect the rest of the contractorswho are working in compliance.There have been similarly frustrating experienceswith the “Right-to-Know” laws and OSHA HazardCommunication (Haz Comm) laws, which were introducedin the 1970s and 1980s. However, contractorssoon realized that despite its apparent complexity, theOSHA rules actually boiled down to just four basicrequirements:1) The program must be in writing2) Employees must be trained about thehazards of the chemicals with which theywill be working3) Material safety data sheets (MSDS) must bereadily available4) Chemicals must have labels and employeesmust understand themOSHA’s Haz Comm rules are found at 1926.59 andrelates back to the 1910.1200 for the full text of thestandard. Recently, OSHA published several questionsIn 1989, OSHA revised the standard for excavation and trenching (referred to asOSHA Subpart P) to eliminate any confusion and make compliance easier. Theseare the current standards and represent minimum requirements.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 31

Over the last 37 years, OSHA and the utility contracting community have workedtogether to exchange ideas and communicate the realities of the industry.about a new approach to Haz Comm called the GloballyHarmonized System (GHS). OSHA is considering makingthe MSDSs uniform so that they can be usedthroughout the world. This new type of MSDS will haveboth text and pictures.OSHA recently stated that a notice of proposed rulemakingfor confined space in construction would bepublished later this year (once published, please takethe time to convey any comments from your localchapter). The Government Relations department of theNational <strong>Utility</strong> <strong>Contractor</strong>s Association (NUCA) willmake sure these comments are submitted to OSHA sothat it understands the needs of the industry.By January of 2008, OSHA has stated it will publish arevised electric power transmission and distributionelectrical protective equipment standard. The currentconstruction standard is more than 30 years old. OSHAhas stated that this revised standard will address fallprotection from aerial lifts for overhead power-linework and protective equipment.Today, there are several ways OSHA changes astandard. A person, an association of employers oremployees, a nationally recognized standards-producingorganization, the National Institute of OccupationalSafety and Health (NIOSH), or an advisory committeemay request that an OSHA rule be added, revised orremoved.An important part of bridging the gap between contractorsand OSHA is the Advisory Committee onConstruction Safety and Health (ACCSH). TheACCSH provides informationto OSHA aboutcurrent needs for newor improved rules.ACCSH recommendsthat the originalexcavation and trenchstandard be replaced in1989 with the currentstandard. ACCSH hasalso recommendedchanges to theconfined space, safetyprogram and cranestandards.NUCA is currently amember of ACCSH;however, even whenNUCA does not hold aseat on this advisorycommittee, its Safetydepartment attendsmeetings, submitspublic comment andparticipates in theworkgroups. Currently,ACCSH has severalwork groups thatreflect current construction industry areas of concern.These groups focus on Diversity/Multilingual, FocusedInspection Initiative, Noise, OSHA Training Institute(OTI), Residential Fall Protection, Rollover Protection,Silica, Training Certification and Trenching.Common GoalsOver the last 37 years, OSHA and the utility contractingcommunity have worked together to exchangeideas and communicate the realities of the industry.An important step in this ongoing process has been thenational alliance between NUCA, OSHA and otherregional and state alliances.For the last two years, the national alliance hasallowed and encouraged NUCA to work with OSHA toprovide expertise to develop training and educationprograms on utility construction, such as the 10-houroutreach program, which emphasizes on trench andexcavation safety. This program can be downloaded freeof charge from the NUCA Web site, but the 10-hourcard can only be signed by a certified OSHA 500instructor.Even with these types of programs in place, consensuscan still be difficult to achieve. It has taken a significantamount of time, effort and cooperation, but employersin the underground utility construction industry havefinally begun to work together with OSHA officialstoward a common goal and focus on the issues thataffect the safety and health of every utility constructionworker in the United States.32 <strong>Utility</strong> <strong>Contractor</strong> | <strong>July</strong> 2007

5 Tips for Your Next OSHA Visit1. Stop working. If a site visit occurs, never continue to workin front of the COSHO (frequently used acronym referringto an OSHA compliance officer). Always ask for their identificationand call the corporate office immediately.2. No onsite documentation. Documents should not be givento compliance officers onsite. The COSHO has the authorityto request certain documents, but your corporate officeshould be allowed to produce them. Also, keep a running listof all documents they have provided.3. Just the facts. Never offer unsolicited information. Just answerthe officer’s questions as accurately as possible. Take pictureswhere they take pictures and never leave their side while theyare making an inspection of your jobsite.4. Keep a record. When the COSHO leaves the site, intervieweveryone he or she talked to and immediately transcribe areport, then forward it to the safety director and/or thepresident of the company.5. Keep a cool head. The COSHO is only doing their job.Treat them the way you would like to be treatedand keep the site as compliant as possible. There aremore citations written for obvious infractions than anythingelse.Both sides have recognized the importanceof working together — regardless of how someindividuals feel about OSHA. Everyone workingin the utility business knows that oneaccident can destroy a company. At the veryleast, it can eliminate a contractor’s ability tobid on certain projects.At times, OSHA’s job is thankless, unpopular,and most certainly difficult. It is also difficult forcontractors. The work environment is more difficultto control than ever, due to more restrictionsand difficult issues relating to overall governmentalcompliance. As work becomes morecompetitive, we have to remember the responsibilitythat Eli assumed with regard to his crewemployees and their families.Safety is a communal responsibility to helpeliminate work-related pain, suffering anddisease. That’s the simple goal. It is extremelydifficult to achieve, but it’s worth every ounceof effort for every contractor and employer inthe United States. People like my friend andmentor, Eli Brown deserve thanks for helpingso many to be around to see their grandchildrenand to prosper in this business.Greg Strudwick is owner and founder of GregStrudwick & Associates, a safety consulting firmbased in Coppell, Texas, and a member of OSHA’sACCSH.<strong>July</strong> 2007 | <strong>Utility</strong> <strong>Contractor</strong> 33