MIL-DTL-26500, Pyle® Connectors - Amphenol Aerospace

MIL-DTL-26500, Pyle® Connectors - Amphenol Aerospace

MIL-DTL-26500, Pyle® Connectors - Amphenol Aerospace

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

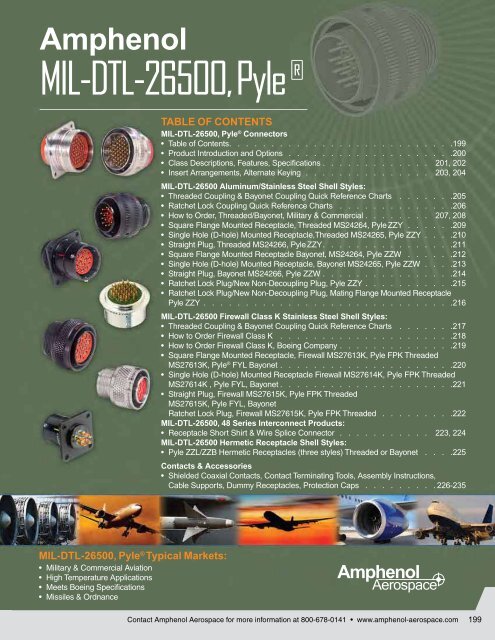

<strong>Amphenol</strong><strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ®TABLE OF CONTENTS<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ® <strong>Connectors</strong>• Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . .199• Product Introduction and Options . . . . . . . . . . . . . . . . . . . . 200• Class Descriptions, Features, Specifications. . . . . . . . . . . . . 201, 202• Insert Arrangements, Alternate Keying. . . . . . . . . . . . . . . . 203, 204<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> Aluminum/Stainless Steel Shell Styles:• Threaded Coupling & Bayonet Coupling Quick Reference Charts . . . . . . . 205• Ratchet Lock Coupling Quick Reference Charts . . . . . . . . . . . . . . 206• How to Order, Threaded/Bayonet, Military & Commercial. . . . . . . . 207, 208• Square Flange Mounted Receptacle, Threaded MS24264, Pyle ZZY . . . . . .209• Single Hole (D-hole) Mounted Receptacle,Threaded MS24265, Pyle ZZY . . . .210• Straight Plug, Threaded MS24266, Pyle ZZY. . . . . . . . . . . . . . . .211• Square Flange Mounted Receptacle Bayonet, MS24264, Pyle ZZW . . . . . .212• Single Hole (D-hole) Mounted Receptacle, Bayonet MS24265, Pyle ZZW. . . . 213• Straight Plug, Bayonet MS24266, Pyle ZZW. . . . . . . . . . . . . . . .214• Ratchet Lock Plug/New Non-Decoupling Plug, Pyle ZZY. . . . . . . . . . .215• Ratchet Lock Plug/New Non-Decoupling Plug, Mating Flange Mounted ReceptaclePyle ZZY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .216<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> Firewall Class K Stainless Steel Shell Styles:• Threaded Coupling & Bayonet Coupling Quick Reference Charts . . . . . . . 217• How to Order Firewall Class K . . . . . . . . . . . . . . . . . . . . . 218• How to Order Firewall Class K, Boeing Company. . . . . . . . . . . . . .219• Square Flange Mounted Receptacle, Firewall MS27613K, Pyle FPK ThreadedMS27613K, Pyle ® FYL Bayonet. . . . . . . . . . . . . . . . . . . . .220• Single Hole (D-hole) Mounted Receptacle Firewall MS27614K, Pyle FPK ThreadedMS27614K , Pyle FYL, Bayonet. . . . . . . . . . . . . . . . . . . . .221• Straight Plug, Firewall MS27615K, Pyle FPK ThreadedMS27615K, Pyle FYL, BayonetRatchet Lock Plug, Firewall MS27615K, Pyle FPK Threaded . . . . . . . . . 222<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, 48 Series Interconnect Products:• Receptacle Short Shirt & Wire Splice Connector . . . . . . . . . . . . 223, 224<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> Hermetic Receptacle Shell Styles:• Pyle ZZL/ZZB Hermetic Receptacles (three styles) Threaded or Bayonet. . . . 225Contacts & Accessories• Shielded Coaxial Contacts, Contact Terminating Tools, Assembly Instructions,Cable Supports, Dummy Receptacles, Protection Caps. . . . . . . . . 226-235<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ® Typical Markets:• Military & Commercial Aviation• High Temperature Applications• Meets Boeing Specifications• Missiles & Ordnance<strong>Amphenol</strong><strong>Aerospace</strong>Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com 199

<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ® <strong>Connectors</strong>Features and Class Descriptions<strong>Amphenol</strong><strong>Aerospace</strong><strong>Amphenol</strong> ® /Pyle <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> <strong>Connectors</strong> are qualified to MilitarySpecification <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, as well as numerous high performancecustomer specifications. These connectors are available in aluminum orstainless steel shells, with bayonet or threaded coupling, and arequalified to meet the specifications of the following <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>classes:<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>ClassesClass R:(EnvironmentalResistant)<strong>Amphenol</strong>/Pyle SeriesClassesHardwareDescriptionFinishA Aluminum Alloy AnodizeClass G M Aluminum Alloy ChromiumClass E R Stainless Steel PassivatedClass K Firewall FPK/FYL Stainless Steel PassivatedClass H HermeticHCCRS/StainlessSteelVariousCrimp ContactsRear-insertable, front-releasable, crimp style contacts are machinedfrom a copper alloy material, plated gold over nickel, and are qualifiedto specification SAE AS39029.Contacts are crimp terminated outside the connector assembly andinserted into the appropriate cavity by means of a hand tool. Socketcontacts utilize a multi-tined construction and feature a “C” spring whichgrips the tines, and insures consistent and repetitive insertion/withdrawal forces. Contact tines are protected by a stainless steelshroud.An optional pencil-clip thermocouple socket design is also offered. Seepage 226 for more information on thermocouple contacts.Alternate KeyingAll <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> Series Connector shells can be furnished withnormal or any of five alternate key positions. (See page 204). Each plugshell has a master key and four alternate keys. The position of thealternate keys in relation to the fixed master key determines the keyidentification. Inserts are bonded to the shell in relation to the masterkey, thus allowing positive protection against mis-mating when differingcircuits exist side by side.Connector SealingThe insert design utilizes a combination of resilient and rigid insulatorsto offer a connector with total sealing capabilities. Bonded interfacesbetween the resilient and rigid dielectric components eliminate air voidsand thus protect the connector from potential degradation due tomoisture and altitude conditions.In Firewall Class K connectors, the resilient insert forms the primarycontact seal and is bonded to a molded ceramic rigid insert. The insertassembly is physically bonded and mechanically retained to the insidesurface of the stainless steel shell, providing a void-less, mono-blockconfiguration impervious to adverse environments.A pressure seal at the connector interface is accomplished through theaid of a coupling device which compresses the front resilient insulationsand thus offers a seal around each contact which prevents the passageof air or moisture through the contact cavity.Back resilient insulators are designed with a triple sealing grip at eachwire hole to offer positive sealing and prevent wicking of moisturethrough the connector without the use of external clamping rings oradapters.In addition, a dynamic “O” ring seal engages the front of the plug shellwhen connectors are mated and offers yet another barrier to moistureand containments.Fluid/Temperature ResistanceThe fluorosilicone compound elastomer, developed by Pyle-National,exceeds all specification requirements and provides excellent resistanceto tear, compression set, fluids, and high temperatures.<strong>Amphenol</strong>/Pyle’s fluorosilicone compound offered in Class R, G, E andK is capable of reliability resisting:- <strong>MIL</strong>-H-5606 hydraulic fluid- <strong>MIL</strong>-L-9236 lubricating oil- <strong>MIL</strong>-L-7808 and <strong>MIL</strong>-L-23699 lubricating oils- <strong>MIL</strong>-J-5624 (JP-5) jet fuel- Glycol- Alkaline cleaning solutions of pH 10 or higher.Test methods are as defined in <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> specification. Alternatecompounds have been developed by Pyle-National to solve uniqueuser requirements not addressed by the specifications.<strong>Connectors</strong> have the capability of resisting high ambient temperaturesup to 200°C (392°F) for long periods of time, thus contributing to anextended connector life. <strong>Connectors</strong> will withstand a combined ambientand internal temperature due to thermal rise of current carryingcapacity of 238°C (469°F).<strong>Amphenol</strong> ® /Pyle ® Firewall, Class K, connectors have the inherent abilityto resist high temperatures up to 460°F (total temperature) for extendedperiods of time and can resist short time exposures (20 minutes) toprevent passage of a direct 2000°F flame.38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PylePrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContactsOptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com201

<strong>Amphenol</strong><strong>Aerospace</strong><strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ®SpecificationsOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIITEST REQUIREMENTS <strong>MIL</strong>ITARY SPECIFICATIONS PYLE CONNECTOR CAPABILITIESAir Leakage (Classes E, G, R & K) 1 cu. inch per hr. max. -55°C (-67°F) ComplyAltitude Immersion(Classes E, G, R & K)Contact Retention(Classes E, G, R & K)Sea level 1 inch of mercury, 3 cycles(IR 5000 megohms hi-pot 1500 volts-submerged)Size 20 contact 20 lbs. min.Size 16 contact 25 lbs. min.Size 12 contact 30 lbs. min.ComplyExceeds specificationsCollet Retention No requirement Without damage to the collet or itsretention means:Size 20 – 75 lbs. min.Size 16 – 140 lbs. minSize 12 – 160 lbs. min.Contact Insertion Force(Classes E, G, R & K)Coupling ForcesFluid Resistance(Classes E, G, R & K)All size contacts 10 lbs. max.Torque required to couple and uncouple mating plugsand receptacles is not to exceed the values listed:Shell size Torque inch lbs.8 10 12 14 16 18 20 22 249 10 14 17 23 26 31 38 4620 hrs. immersion in <strong>MIL</strong>-H-5606 hydraulic fluid and <strong>MIL</strong>-L-9236lubrication oil. Must meet hi-pot.ComplyComply20 hrs. min., fully functional physicallyand electrically after immersion. Nodeteriora tion of resilient material.Ground Resistance (Class G) .250 ohms backshell of plug to rear of receptacle flange. ComplyHigh Potential(Classes E, G, R & K)1500 VRMS mated & unmated at sea level1000 VRMS mated to 110,000 ft. altitudeExceed with ample margin of safety.Insert Retention (Classes E, G, R & K) 75 psi. from either direction for 5 seconds. Exceeds specifications.Insulation Resistance(Classes E, G, R & K)Low Temperature(Classes E, G, R & K)Magnetic Permeability(Classes E, G, R & K)Moisture Resistance(Classes E, G, R & K)21°C (70°F), 5000 megohms between adjacent contacts and anycontact and shell.-55°C (-67°F)Exceeds specifications.Comply2 mu. maximum Comply1000 megohms min. per Mil-std. 202 method 106 ComplyOzone Exposure (Classes E, G, R & K) 0.10 to .015% ozone exposure ComplyPhysical Shock(Classes E, G, R & K)Sand & Dust Exposure(Classes E, G, R & K)Temperature Life(Classes E, G, R & K)Thermal Shock (Mated)(Classes E, G, R & K)Vibration(Classes E, G, R & K)50 G’s, 3 axis, per mil-std-202, method 213, test condition C, wiredto monitor 1 microsecond discontinuity.No requirement.Connector fully functional for 1000 hours at 200°C (392°F)ambi ent internal temperature 238°C (460°F)Cycled five times from -55°C to 260°C, held for 30 minutes at eachtemperature and transferred to the other in 2 minutes or less, withno evidence of damage.<strong>MIL</strong>-Std. 202 method 204 condition “D” at R. T.,-55°C (-67°F) and +200°C (+392°F).Flame Resistance (Class K) Performance requirements of Paragraph 4.5.18Fireproof (Class K of <strong>MIL</strong>-<strong>DTL</strong>-5015D)ComplyMeet <strong>MIL</strong>-E-5272 condition “B”ComplyComplyComply - monitored for a max. of 1micro second discontinuity.Exceeds specifications202Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ®Insert Arrangements<strong>Amphenol</strong><strong>Aerospace</strong>Front Face of Pin Insert or Rear Face of Socket Insert IllustratedContact cavities are identified with a spiral guide lineindicating cavity sequence. The first and last cavities arenumbered and every tenth cavity is bracketed.Symmetrical about center line.Insert Arrangement 08-02 08-03 H 10-02** 10-05 H 10-20 H 12-03 KH 12-12 H 14-03 14-04 KService Rating I I I I I I I I INumber of Contacts 2 3 2 5 2 3 12 2 1 4Contact Size 20 20 20 20 16 16 20 16 12 12ShieldedCoaxial7112123 11211521512113 21212 3Insert Arrangement 14-07 KH 14-12 14-15 KH 16-10 KH 16-24 KH 18-08 KH 18-11 18-14 KHService Rating I I I I I I 1 I1Number of Contacts 7 9 3 15 10 24 8 10 1 14Contact Size 16 20 16 20 16 20 12 16 12 161024118111ShieldedCoaxial1414138999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PylePrintedCircuit BoardEMI FilterTransient311161251281391411Fiber OpticsInsert Arrangement 18-31 KH 20-16 20-25 20-28** 20-39 20-41Service Rating I I I I I INumber of Contacts 31 16 19 6 24 4 37 2 41Contact Size 20 16 20 12 20 12 20 16 20High SpeedContactsOptionsOthers† designates Non-MS Configurations.K designates Firewall Class K inserts.H designates Hermetic inserts.CONTACT LEGEND 20 16 12Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com203

<strong>Amphenol</strong><strong>Aerospace</strong><strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ®Insert Arrangements Alternate KeyingOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIIFront Face of Pin Insert or Rear Face of Socket Insert IllustratedContact cavities are identified with a spiral guide line indicating cavity sequence. The first andlast cavities are numbered and every tenth cavity is bracketed.Symmetrical about centerline.551Insert Arrangement 22-55 KH 24-30† K 24-43** 24-57Service Rating I I I INumber of Contacts 55 30 23 20 55 2Contact Size 20 16 20 16 20 12Insert Arrangement 24-61 28-40† K 28-42† KService Rating I I INumber of Contacts 61 36 4 42Contact Size 20 16 12 16† designates Non-MS Configurations.K designates Firewall Class K inserts.H designates Hermetic inserts.AlternateKeyingPositions ofShellsALTERNATE POLARITYKEYWAYARRANGEMENTS (Shellsizes 12, 14, 16, 18, 20, 22,24, 28) View of front face ofreceptacle shell. Angles arecounter-clock wise from “N”keyway. For plug shell, thekey locations are clock wisewhen viewed from front ofplug.611211Position3019For <strong>Connectors</strong> Size 8 and 101 1For <strong>Connectors</strong> Size12, 14, 16, 18, 20, 22, 24 and 28A B C D A B C DNormal 105° 140° 215° 265° 105° 140° 215° 265°6 102° 132° 248° 320° 18° 149° 192° 259°7 80° 118° 230° 312° 92° 152° 222° 342°8 35° 140° 205° 275° 84° 152° 204° 334°9 64° 155° 234° 304° 24° 135° 199° 240°Y or 10* 25° 115° 220° 270° 98° 152° 268° 338°* Y is used for all Military part number call-outs - aluminum/stainless steel and firewall;10 is used for <strong>Amphenol</strong>/Pyle part number call-outs - aluminum/stainless steel only.(See how to order pages 207, 208 and 218).1Insert Arrangement 22-12 K 22-19 KH 22-27† 22-32Service Rating I I I INumber of Contacts 12 19 27 26 6Contact Size 12 16 16 20 124012714342CONTACT LEGEND 20 16 12BA°°C57Keying Positions°11Master PolarizingKeywayShown is Engaging Face View ofReceptacle Shell with Keyways(Plug Shell Keys would be Opposite)1D°32204Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ®Quick Reference ChartsTHREADED COUPLINGPYLE ZZYMS2426X( )TXXShell Style(Stainless Steel pictured)Square FlangeMountedReceptacleThreadedCouplingSingle Hole(D-Hole)MountedReceptacleThreadedCouplingStraight PlugThreadedCouplingBAYONET COUPLINGPYLE ZZWMS2426X( )BXXBasicPerformance LevelGeneral Purpose,EnvironmentalResistantSuperior Strength,Corrosion Resistanceup to 204°C (399°F)General Purpose,EnvironmentalResistantSuperior Strength,Corrosion Resistanceup to 204°C (399°F)General Purpose,EnvironmentalResistantSuperior Strength,Corrosion Resistanceup to 204°C (399°F)HardwareDescription*Class*<strong>Amphenol</strong><strong>Aerospace</strong>Basic Part Number**Aluminum Military Class R or G MS24264(R or G)XXTXXPyle A or M Series ZZY-(Aor M)X-17XXStainless Steel Military Class E MS24264EXXTXXPyle R SeriesZZY-RX-17XXAluminum Military Class R or G MS24265(R or G)XXTXXPyle A or M SeriesZZY-(Aor M)X-15XXStainless Steel Military Class E MS24265EXXTXXPyle R SeriesZZY-RX-15XXAluminum Military Class R or G MS24266(R or G)XXTXXPyle A or M SeriesZZY-(A or M)X-10XXStainless Steel Military Class E MS24266EXXTXXPyle R SeriesZZY-RX-10XX38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PyleShell Style(Stainless Steel pictured)Square FlangeMountedReceptacleBayonetCouplingSingle Hole(D-Hole)MountedReceptacleBayonetCouplingStraight PlugBayonetCouplingBasicPerformance LevelGeneral Purpose,Environmental ResistantSuperior Strength,Corrosion Resistance upto 204°C (399°F)General Purpose,Environmental ResistantSuperior Strength,Corrosion Resistance upto 204°C (399°F)General Purpose,Environmental ResistantSuperior Strength,Corrosion Resistance upto 204°C (399°F)HardwareDescription*AluminumStainless SteelAluminumStainless SteelAluminumStainless SteelClass*Military Class R or GPyle A or M SeriesMilitary Class EPyle R SeriesMilitary Class R or GPyle A or M SeriesMilitary Class EPyle R SeriesMilitary Class R or GPyle A or M SeriesMilitary Class EPyle R SeriesBasic Part Number**MS24264(R or G)XXBXXZZW-(A or M)X-17XXMS24264EXXTXXZZW-RX-17XXMS24265(R or G)XXBXXZZW-(A or M)X-15XXMS24265EXXTXXZZW-RX-15XXMS24266(R or G)XXBXXZZW-(A or M)X-10XXMS24266EXXTXXZZW-RX-10XXPrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContactsNA designates not available* See how to order, page 207, for further description of hardware classes.** See how to order, page 207, to complete part numbers.OptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com205

<strong>Amphenol</strong><strong>Aerospace</strong><strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ®Quick Reference ChartsOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIIRATCHET LOCK PLUG, BAYONETPYLE ZZYShell Style(Stainless steel only)Ratchet LockPlugNon-DecouplingNNDCPlugNew Non-DecouplingBasicPerformance Level* See how to order, page 207, for further description of hardware classes.** See how to order, page 207, to complete part numbers.Superior Strength, Corrosion Resistanceup to 204°C (399°F)Employs ratchet feature in last 120° ofrotation to eliminate need for safety-wiringSuperior Strength, Corrosion Resistanceup to 204°C (399°F)HardwareDescription*StainlessSteel onlyStainlessSteel onlyRATCHET LOCK PLUG & MATING FLANGE MOUNTED, THREADED RECEPTACLEPYLE ZZYShell Style(Stainless steel pictured)Ratchet LockPlugNon-DecouplingSquare FlangeMountedReceptacleThreaded CouplingBasicPerformance LevelDesigned to meet high vibrationrequirements beyond<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>.Designed to meet high vibrationrequirements beyond<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>.* See how to order, page 208, for further description of hardware classes.** See how to order, page 208, to complete part numbers.HardwareDescription*AluminumClass*Pyle R Series(Commercial only)Pyle R Series(Commercial only)Class*Pyle A SeriesBasic Part Number**ZZY-RX-12XXZZY-RX-13XXPyle Basic Part Number**ZZY (A, D, F, M)X-12 (D, E or F) XXStainless Steel Pyle R Series ZZY-RX-12 (D, E or F)XXAluminum Pyle A Series ZZY (A or F) X-17(D, E or F) XXStainless Steel Pyle R Series ZZY-RX-17 (D, E or F) XX206Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ® – how to orderThreaded/Bayonet Military & Commercial<strong>Amphenol</strong><strong>Aerospace</strong>Easy Steps to build a part number... Military1. 2. 3. 4. 5. 6. 7.Shell StyleServiceClassShellSizeStep 1. Select a Shell StyleMS24264MS24265MS24266CouplingTypeAccessory threads for aluminum and stainless steel hardware differ,and care should be taken in selection of alternate accessoryhardware that will conform to the threads noted in the dimensionaltables within this catalog.InsertArrangementContactTypeAlternateKeyingMS24266 R 22 T 55 P 6DesignatesSquare Flange Mounted ReceptacleSingle D-Hole Mounted ReceptacleStraight PlugStep 2. Select a Service ClassRGEDesignatesAluminum, non-conductive (black anodize finish)Aluminum, conductive (chromium finish)Stainless steel, PassivatedStep 3. Select a Shell Size8 10 12 14 16 18 20 22 24Step 4. Select a Coupling TypeTBZZYZZWDesignatesThreadedBayonetStep 1. Select a Shell StyleStep 5. Select an Insert Arrangementfrom page 203 & 204See page 203 & 204 for Shell Size & InsertArrangements. First number represents Shell Size, secondnumber is the Insert Arrangement.Step 6. Select a Contact TypePSDesignatesPin ContactsSocket ContactsStep 7. Select an AlternateKeying Position of Shell6, 7, 8, 9, Y (N for Normal) See page 204.Easy Steps to build a part number... Pyle Commercial1. 2. 3. 4. 5. 6. 7. 8. 9. 10.Shell Service Contacts/ Shell Shell Insert Contact Alternate Contact Deviations/Style Class Accessories Style Size Arrangement Type Keying Plating SpecialsZZY A C 10 22 55 P 6 D XXXDesignatesThreaded CouplingBayonet CouplingStep 2. Select a Service ClassADFMRDesignatesAluminum, non-conductive (black anodize finish)Aluminum, O.D. CAD/NiAluminum, Clear Cadmium platedAluminum, conductive (chromium finish)Stainless steel, PassivatedStep 3. Select Contacts & AccessoriesNo DigitCDODesignateswith contacts and cable supportwithout cable support, with contactswithout contacts, with cable supportwithout contacts or cable supportStep 4. Select a Shell StyleDesignates10 Straight Plug12 Non-Decoupling Plug(Ratchet Lock)New Non-Decoupling Plug (NNDC) (SS13only)15 Single Hole Mounting Receptacle17 Square Flange ReceptacleStep 5. Select a Shell Size8 10 12 14 16 18 20 22 24 28Step 6. Select an Insert Arrangementfrom page 203 & 204See page 203 & 204 Shell Size & InsertArrangements. First number represents Shell Size,second number is the Insert Arrangement.Step 7. Select a Contact TypePSDesignatesPin ContactsSocket ContactsStep 8. Select anAlternate KeyingPosition of Shell06, 07, 08, 09, 10 (Omit forNormal) See page 204.Step 9. Select aContact PlatingDTDesignatesGoldRhodiumStep10. Deviation/SpecialsConsult <strong>Amphenol</strong> formore information.38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PylePrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContactsOptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com207

<strong>Amphenol</strong><strong>Aerospace</strong><strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ® – How to OrderRatchet Lock Plug, Mating Flange ReceptacleOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II III208<strong>Amphenol</strong> ® /Pyle ® connectors are specifically designed to meet high vibration requirementsabove and beyond the specification require ments of <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>. The plug connectorfeatures a unique non-decoupling device which offers a ratchet mechanism designed toengage as the threaded connectors approach a bottomed condi tion. Connector couplingassembly continues to ratchet for approxi mately 120 degrees until the mated connectorsreach a complete metal-to-metal bottomed condition. The ratchet device maintains theconnectors in a fully coupled condition, thus eliminating the need for safety wiring.Additional features include:• Modified accessory thread to accommodate<strong>MIL</strong>-<strong>DTL</strong>-83723 back shell hardware.• Rear accessory teeth are featured on both the plug and recepta cle shell toassure non-rotation of accessory hardware• Intermateable with all <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> threaded connectors of like insertarrangement and key positionEasy Steps to build a part number... Pyle CommercialZZY1. 2. 3. 4. 5. 6. 7. 8. 9. 10.Shell Service Contacts & Shell Accessory Insert Contact Alternate Contact Deviations/Style Class Accessories Style Style Arrangement Type Keying Plating SpecialsZZY A C 12 D 14 04 P 06 DStep 1. Select a Shell StyleDesignatesThreaded CouplingStep 2. Select a Service ClassADFMRDesignatesAluminum, non-conductive (black anodize finish)Aluminum, O.D. CAD/NiAluminum, Clear Cadmium platedAluminum, conductive (chromium finish)Stainless steel, PassivatedStep 3. Select Contact & AccessoryNo DigitCODesignatesWith contacts and clampWith contactsWithout contactsStep 4. Select a Shell StyleDesignates12 Non-Decoupling Plug, (Ratchet Lock)13 New Non-Decoupling Plug (NNDC) (SS only)17 Square Flange Mounted ReceptacleStep 5. Select Accessory StyleDesignatesRear accessories per <strong>MIL</strong>-<strong>DTL</strong>-83723,D3 Accessory Serrations.Rear accessories per MS 3155E(360° Accessory Serrations)Rear accessories per MS 3155 with EMI BandF(360° Accessory Serrations)Accessory threads for aluminum and stainless steel hardwarediffer, and care should be taken in selection of alternate accessoryhardware that will conform to the threads noted in the dimensionaltables within this catalog.Step 5. Select a Shell Size10 12 14 16 18 20 22 24 28Step 6. Select an Insert Arrangementfrom Page 203 & 204Shell Size & Insert Arrangements are on pages 203& 204. First number represents Shell Size, secondnumber is the Insert Arrangement.Step 7. Select a Contact TypeDesignatesContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.comPSPin ContactsSocket ContactsStep 8. Select anAlternate Keying Position of Shell06, 07, 08, 09, 10 (Omit for Normal) See page 204Step 9. Select aContact PlatingDTDesignatesGold plate per <strong>MIL</strong>-<strong>DTL</strong>-39029Rhodium plate per <strong>MIL</strong>-<strong>DTL</strong>-26636Step 10. Deviations/SpecialsConsult <strong>Amphenol</strong> for more information.

MS24264, Pyle ® ZZY, <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>Square Flange Mounted Receptacle, Threaded<strong>Amphenol</strong><strong>Aerospace</strong>Part #To complete see how toorder pages 207CommercialShell StyleServiceClassContacts &AccessoriesMilitaryShellStyleShellStyleServiceClassShellSizeCouplingTypeInsertArrangementContactTypeAlternateKeyingMS24264 E, R, G XX T XX X XShellSizeInsertArrangementContactTypeAlternateKeyingContactPlatingDeviations/SpecialsZZY X X 17 XX XX X X X XXX38999III II I SJTST.125/.116 SIZES 8 TO 22.154/.145 SIZES 24 & 28(4 HOLES)T S YR THREAD1.375 MAX.1.075 ±.010.718+.010M THREAD.125MAX. PANEL THICKNESS.062 ±.010ZSTAINLESS STEELPyle ZZY-RX-17XX SeriesMS24264EXXTXXMilitary Class E26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease MatrixSTR THREAD1.375 MAX.1.285 ±.010<strong>26500</strong> PyleT S YZALUMINUMPyle ZZY-XX-17XX SeriesMS24264RXXTXXMilitary Class R and GPrintedCircuit Board.125/.116 SIZES 8 TO 22.154/.145 SIZES 24 & 28(4 HOLES).718±.010M THREAD.125MAX. PANEL THICKNESS.062 +.010EMI FilterTransientShellSizeMCable SupportThreadSteelNS-2AAlum.UNEF-2AModifiedAluminum ConnectorWeight (lbs.) maxincluding ContactsPinInsertSocketInsertRCouplingThreadSFlangeWidth ±.005TMountingHole Centers±.005YBackMountMin. HoleZFrontMountMin. Hole08** NA .437-28 .025 .026 .562-24 .812 .594 .606 .44310 .563-36 .562-24 .042 .044 .687-24 .937 .719 .748 .57212 .733-36 .750-20 .061 .062 .875-20 1.031 .812 .913 .76014 .803-36 .812-20 .072 .074 .937-20 1.125 .906 .980 .82216 .930-36 .937-20 .087 .090 1.062-18 1.250 .969 1.107 .94818 1.036-36 1.062-18 .110 .112 1.187-18 1.343 1.062 1.209 1.07220 1.161-36 1.187-18 .130 .134 1.312-18 1.437 1.156 1.325 1.19722 1.286-36 1.312-18 .152 .159 1.437-18 1.562 1.250 1.452 1.32224 1.411-36 1.437-18 .181 .188 1.562-18 1.703 1.375 1.577 1.44828† 1.661-36 NA NA NA 1.812-16 2.000 1.562 1.827 1.700NA designates not available. ** Not available in Stainless Steel. † Not available in Aluminum.All dimensions for reference only.Fiber OpticsHigh SpeedContactsOptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com209

MS24265, Pyle ® (ZZW), <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>Single Hole (D-Hole) Mounted Receptacle, Bayonet<strong>Amphenol</strong><strong>Aerospace</strong>Part #To complete see how toorder pages 207CommercialShell StyleServiceClassContacts &AccessoriesMilitaryShellStyleServiceClassShellSizeCouplingTypeInsertArrangementContactTypeAlternateKeyingMS24265 E or R XX B XX X XShellStyleShellSizeInsertArrangementContactTypeAlternateKeyingContactPlatingDeviations/SpecialsZZW X X 15 XX XX X X X XXX38999III II I SJTS3 PINS 120° APARTTSZ1.375 MAX.1.075 ±.010.771+.010M THREAD.062 MIN./125 MAX.PANEL THICKNESSSTAINLESS STEELPyle ZZW-RX-15XX SeriesMS24265EXXBXXMilitary Class E26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease MatrixShellSizeSMCable SupportThreadSteelNS-2AAlum.UNEF-2AModifiedAluminum ConnectorWeight (lbs.) maxincluding ContactsPinInsertTLock Nut FlatsSSocketInsertFlangeWidth ±.005 Steel Alum.Y DiaMountingHoleZ FlatMountingHoleRecom. min.TorqueJam NutLb. - inches08** NA .437-28 .029 .030 .979 NA .812 .635 .605 3310 .563-36 .562-24 .049 .050 1.104 .937 .937 .760 .730 3612** NA .750-20 .069 .070 1.291 1.125 1.125 .947 .917 5614 .803-36 .812-20 .087 .089 1.391 1.062 1.187 1.010 .980 6516 .930-36 .937-20 .104 .106 1.561 1.187 1.312 1.135 1.105 6918 1.036-36 1.062-18 .131 .133 1.641 1.312 1.437 1.260 1.225 8120 1.161-36 1.187-18 .152 .157 1.766 1.562 NA 1.385 1.350 10022 1.286-36 1.312-18 .181 .187 1.954 1.585 1.687 1.510 1.475 12324 1.411-36 1.437-18 .208 .212 2.079 1.687 1.812 1.635 1.600 13328 NA NA NA NA NA NA NA NA NA NANA designates not available.3 PINS 120° APARTTSD FLATPANELCUT-OUT** Not available in Stainless Steel. All dimensions for reference only.Y1.375 MAX.1.285 ±.010.771+.010M THREAD.062 MIN.125 MAX.PANEL THICKNESSALUMINUMPyle ZZW-XX-15XX SeriesMS24265RXXBXXMilitary Class R<strong>26500</strong> PylePrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContactsOptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com213

<strong>Amphenol</strong><strong>Aerospace</strong>MS24266, Pyle ® (ZZW), <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>Straight Plug, BayonetOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIIPart #To complete see how toorder pages 207CommercialShell StyleServiceClassContacts &AccessoriesShellSizeMilitaryShellStyleShellStyleMCable SupportThreadSteelNS-2AServiceClassShellSizeSSAlum.UNEF-2AModifiedAluminum ConnectorWeight (lbs.) maxincluding ContactsPinInsertS Dia Max.Coupling NutSocketInsert Steel Alum.TShell Dia.+.000–.00508** NA .437-28 .030 .031 NA .762 .42410 .563-36 .562-24 .044 .045 .848 .904 .52612 .733-36 .750-20 .063 .064 1.018 1.076 .69614 .803-36 .812-20 .074 .076 1.087 1.122 .76516 .930-36 .937-20 .091 .094 1.214 1.264 .89218 1.036-36 1.062-18 .110 .112 1.320 1.373 .99820 1.161-36 1.187-18 .133 .136 1.445 1.503 1.12322 1.286-36 1.312-18 .154 .160 1.570 1.623 1.24824 1.411-36 1.437-18 .184 .188 1.695 1.752 1.37328 NA NA NA NA NA NA NANA designates not available. ** Not available in Stainless Steel.All dimensions for reference only.TTCouplingTypeInsertArrangement1.375 MAX.1.375 MAX.1.155±.010ContactTypeAlternateKeyingMS24266 E or R XX B XX X XShellSizeInsertArrangementContactTypeAlternateKeyingContactPlatingDeviations/SpecialsZZW X X 10 XX XX X X X XXXM THREADM THREADSTAINLESS STEELPyle ZZW-RX-10XX SeriesMS24266EXXBXXMilitary Class EALUMINUMPyle ZZW-XX-10XX SeriesMS24266RXXBXXMilitary Class R214Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Pyle ® (ZZY), <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>Ratchet Lock Plug, New Non-Decoupling Plug<strong>Amphenol</strong><strong>Aerospace</strong>Part # To complete see how to order pages 207Shell StyleServiceClassContacts &Accessories*ShellStyleShellSizeInsertArrangementContactTypeAlternateKeyingCommercialContactPlatingDeviations/SpecialsZZY X X 12 XX XX X X X XXXZZY X X 13 XX XX X X X XXX38999III II I SJTR COUPLING THREADST1.375 MAX.1.015 ± 010M THREAD0.032 SAFETY WIRE HOLE(6 LOCATIONS)RATCHET LOCK PLUGSTAINLESS STEEL/ALUMINUMPyle ZZY-XX-12XXSeries26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease MatrixS1NEW NON-DECOUPLINGPLUGSTAINLESS STEELPyle ZZY-RX-13XX Series<strong>26500</strong> PylePrintedCircuit Board1.160 MAXM THREADEMI FilterTransientShellSizeM ThreadCable SupportR ThreadCouplingS DiaCoupling NutS1 DiaCoupling NutTShell Dia.08 .434-36 .562-24 .800 .820 .42410 .563-36 .687-24 .934 .946 .52612 .733-36 .875-20 1.114 1.088 .69614 .803-36 .937-20 1.178 1.191 .76516 .930-36 1.062-18 1.305 1.314 .89218 1.036-36 1.312-18 1.411 1.420 .99820 1.161-36 1.312-18 1.550 1.545 1.12322 1.286-36 1.437-18 1.661 1.670 1.24824 1.411-36 1.562-18 1.786 1.805 1.37328 1.661-36 1.812-16 2.041 2.110 1.623All dimensions for reference only.Fiber OpticsHigh SpeedContactsOptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com215

<strong>Amphenol</strong><strong>Aerospace</strong>Pyle ® ZZY, Ratchet Lock PlugNew Non-Decoupling Plug Mating Sq. FlangeOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II III216Part # To complete see how to order pages 208Shell StyleShellSizeServiceClassSSTTM ThreadCableSupportContacts &Accessories*.125/.116 SIZES 8 TO 22.154/.145 .125/.116 SIZES 24 8 TO & 28 22(4 .154/.145 HOLES) SIZES 24 & 28(4 HOLES)S Dia Max.CouplingNutShellStyleTTSSPlugShellSizeS TS TTShell Dia.+.000–.005RCouplingThread1.375 MAX.1.375 MAX..310 MIN..310 MIN.1.421 MAX.1.421 MAX.SFlange Width±.005S1 DiaCoupling NutReceptacleTMounting HoleCenters ±.005Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.comYBack MountHole (min.)ZFront MountHole (min.)08 NA NA NA NA NA .820 NA NA NA10 .6250-24 .945 .526 .6875-24 .937 .946 .719 .706 .63512 .7500-20 1.165 .696 .8750-20 1.031 1.088 .812 .885 .76014 .8750-20 1.230 .765 .9375-20 1.125 1.191 .906 .947 .88516 1.0000-20 1.353 .892 1.0625-18 1.250 1.314 .969 1.072 1.01018 1.0625-18 1.468 .998 1.1875-18 1.343 1.420 1.062 1.197 1.07220 1.1875-18 1.607 1.123 1.3125-18 1.437 1.545 1.156 1.322 1.19722 1.3125-18 1.733 1.248 1.4375-18 1.562 1.670 1.250 1.447 1.32224 1.4375-18 1.858 1.373 1.5625-18 1.703 1.805 1.375 1.572 1.44828 1.7500-18 2.113 1.623 1.8120-16 2.000 2.110 1.562 1.822 1.760NA designates not available. All dimensions for reference only.YYInsertArrangementR THREADR THREADContactTypeAlternateKeyingM THREADM THREADZZM THREADM THREADCommercialContactPlatingDeviations/SpecialsZZY X X 12 or 13 XX XX X X X XXXS1Size 8-24 1.310 MAXSize 28 1.430 MAXMIN. FULL THREADSize 8-24 .290Size 28 .452M THREADNew Non-Decoupling PlugMatingSerrations per MS3155Stainless Steel/AluminumPyle ZZY- XX-13XXX SeriesRATCHET LOCK PLUGWith <strong>MIL</strong>-<strong>DTL</strong>-83723 AccessorySerrations per MS3155Stainless Steel/AluminumPyle ZZY- XX-12XXX SeriesMATING SQUARE FLANGEMOUNTED, THREADED RECEPTACLEStainless Steel/AluminumPyle ZZY-XX-17XX Series

<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ® – Firewall Class KStainless Steel Threaded and Bayonet<strong>Amphenol</strong><strong>Aerospace</strong>THREADED COUPLING, FIREWALL, PYLE FPK, FPL, FP5K, MS2761X-KXXTXXShell Style(Firewall stainless steel only)BasicPerformance LevelHardwareDescription*Class*Basic Part Number**38999III II I SJTSquare FlangeMountedReceptacleThreaded CouplingSingle Hole (D-Hole)MountedReceptacleThreaded CouplingStraight PlugThreaded CouplingRatchet LockingPlugThreaded CouplingHigh performance.Environmentally sealed.Resists high temperaturesup to 238°C (460°F).High performance.Environmentally sealed.Resists high temperaturesup to 238°C (460°F).High performance.Environmentally sealed.Resists high temperaturesup to 238°C (460°F).High performance.Environmentally sealed.Resists high temperaturesup to 238°C (460°F).Class KFirewallStainless SteelClass KFirewallStainless SteelClass KFirewallStainless SteelClass KFirewallStainless SteelMilitary Class KPyle FPK or FPL orFP5K SeriesMilitary Class KPyle FPK or FPL orFP5K SeriesMilitary Class KPyle FPK or FPLMeets Military Class KPyle FPK or FPL orFP5K SeriesMS27613-KXXTXXFPK-17( ) orFPL-17( ) orFP5K-17( )MS27614-KXXTXXFPK-19( ) orFPL-19( ) orFP5K-19( )MS27615-KXXTXXFPK-11( ) orFPL-11( )Consult <strong>Amphenol</strong>FPK-12( ) orFPL-12( ) orFP5K-12( )26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PylePrintedCircuit BoardBAYONET COUPLING, FIREWALL, PYLE FYL, MS2761X-KXXBXXShell Style(Firewall stainless steel only)Square FlangeMountedReceptacleBayonet CouplingBasicPerformance LevelHigh performance.Environmentally sealed.Resists high temperaturesup to 238°C (460°F).HardwareDescription*Class KFirewallStainless SteelClass*Basic Part Number**Military Class K MS27613-KXXBXXPyle FYL Series FYL-17 ( )EMI FilterTransientFiber OpticsSingle Hole (D-Hole)MountedReceptacleBayonet CouplingHigh performance.Environmentally sealed.Resists high temperaturesup to 238°C (460°F).Class KFirewallStainless SteelMilitary Class KMS27614-KXXBXXPyle FYL Series FYL-19 ( )High SpeedContactsStraight PlugBayonet CouplingHigh performance.Environmentally sealed.Resists high temperaturesup to 238°C (460°F).Class KFirewallStainless SteelMilitary Class KMS27615-KXXBXXPyle FYL Series FYL-11 ( )OptionsOthers* See how to order, page 218, for further description of hardware classes.** See how to order, page 218, to complete part numbers.Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com217

<strong>Amphenol</strong><strong>Aerospace</strong><strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, Pyle ® Firewall, Class KHow to Order - Stainless Steel, Threaded or BayonetOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIIEasy Steps to build a part number... Military1. 2. 3. 4. 5. 6. 7. 8.Shell StyleServiceClassShellSizeStep 1. Select a Shell StyleMS27613MS27614MS27615CouplingTypeInsertArrangementContactTypeAlternateKeyingCableSupportMS27613 K 14 T 7 P 6 DDesignatesSquare Flange ReceptacleSingle Hole Mounting ReceptacleStraight PlugStep 2. Select a Service ClassKDesignatesFirewall - Stainless steel, passivatedStep 3. Select a Shell Size12 14 16 18 22 24 28Step 1. Select a Shell StyleStep 4. Select aCoupling TypeDesignatesT ThreadedB BayonetFor Ratchet Lock Plug and NewNon-Decoupling Consult <strong>Amphenol</strong>Step 5. Select an InsertArrangement on pages203 & 204Shell Size & Insert Arrangements areon pages 203 & 204. First numberrepresents Shell Size, secondnumber is the Insert Arrangement.Easy Steps to build a part number... CommercialFPKFPLFP5KFYLStep 6. Select aContact TypePSDesignatesPin ContactsSocket ContactsStep 7. Select an AlternateKeying Position6, 7, 8, 9, Y (N for Normal) See page 204Step 6. Select aCable SupportDesignatesDPJLong Straight(MS27658)Standard Straight(MS27657)Right Angle (MS27659)1. 2. 3. 4. 5. 6. 7. 8. 9.ConnectorTypeShellStyleShellSizeInsertArrangementContactTypeLess Contact/Contact PlatingAlternateKeyingCableSupportDeviations/SpecialsFPK 11 28 42 S T 06 D XXXDesignates (Firewall, Class K Styles)Threaded coupling, qualified to <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> and BACC63 SeriesThreaded coupling, same as FPK,but used on Lockheed AircraftThreaded Coupling, qualified forGeneral ElectricBayonet Coupling, qualified to <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>Step 2. Select a Shell TypeDesignates11 Straight Plug12 Ratchet Locking Threaded Plug13 Improved Non-Decoupling Plug17 Square Flange Receptacle19 D-Hole Mounting ReceptacleStep 3. Select a Shell Size12 14 16 18 22 24 28Step 4. Select an InsertArrangement on pages203 & 204Shell Size & Insert Arrangements areon page 203 & 204. First numberrepresents Shell Size, secondnumber is the Insert Arrangement.Step 5. Select aContact TypePSDesignatesPin ContactsSocket ContactsStep 6. Select aContact/Contact PlatingDesignatesETDNo ContactsRhodiumGold Contacts(omit for normal)See page 233Step 7. Select an AlternateKeying Position6, 7, 8, 9, Y (N for Normal) See page 204Step 8. Select aCable SupportDesignatesD Long StraightP Standard StraightJ Right Angle(omit for normal)See page 233Step 9. Deviations/SpecailsPlease consult <strong>Amphenol</strong> for moreinformation.218Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, BACC63 Firewall, Class KHow to Order- Boeing Specifications<strong>Amphenol</strong><strong>Aerospace</strong>Easy Steps to build a part number... Per Boeing CompanyBAC1. 2. 3. 4. 5. 6. 7. 8.BoeingAircraftElectricalConnectorShellTypeStep 1. Boeing AircraftShell Size Accessories InsertArrangementContactTypeAlternateKeyingBAC C 63X 14 S T 06 DDesignatesBoeing Aircraft CompanyStep 2. Electrical ConnectorEDesignatesElectrical ConnectorStep 3. Select aShell TypeDesignates63X Plug, Threaded, Fire Barrier63Y Receptacle, Threaded Fire BarrierPlug, Threaded, for use with No. 2063AEWire Fire BarrierReceptacle, Flange Mount, Threaded,Fire Barrier, For use with No. 2063AFWire Fire Barrier.Note: AE & AF require W11 variation on PyleNumber.Step 4. Select a Shell Size12 14 16 18 22 24 28Step 5. AccessoriesCDesignatesTo order with DCable Clamp replace– with Letter CStep 6. Select an InsertArrangement on pages201 & 202Shell Size & Insert Arrangements areon page 201 & 202. First numberrepresents Shell Size, secondnumber is the Insert Arrangement.Step7. Select aContact TypePSDesignatesPin ContactsSocket ContactsStep 8. Select anAlternate KeyingPosition6, 7, 8, 9, Y (N for Normal) See page 20238999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PylePrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContactsOptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com219

Options High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II III<strong>Amphenol</strong><strong>Aerospace</strong>Part #To complete see how toorder pages 218CommercialConnectorTypeShellStyleMilitaryShellStyleShellSizeServiceClassTHREADED COUPLINGClass K Stainless SteelPyle FPK-17XX SeriesMS27613KXXTXXMilitary Class KBAYONET COUPLINGClass K Stainless SteelPyle FYL-17XX SeriesMS27613KXXBXXMilitary Class KMS27613, Pyle ® FPK/FYL, Firewall Class KSquare Flange Mounted Receptacle,Threaded or BayonetShellSizeMCableSupportThreadCouplingTypeRCouplingThreadInsertArrangementST.125/.116 SIZES 8 TO 22.154/.145 SIZES 24 & 28(4 HOLES)STContactTypeSFlangeWidth±.005AlternateKeyingT S YT S Y3 PINS 120˚ APART.125/.116 SIZES 8 TO 22.154/.145 SIZES 24 & 28(4 HOLES)R THREADTMountingHole Centers±.005YBackMountMin. HoleZFrontMountMin. Hole08 NA NA NA NA NA NA10 NA NA NA NA NA NA12** .733-36 .875-20 1.031 .812 .913 .76014 .803-36 .937-20 1.125 .906 .980 .82216 .930-36 1.062-18 1.250 .969 1.107 .94818 1.036-36 1.187-18 1.343 1.062 1.209 1.07220 NA NA NA NA NA NA22 1.286-36 1.437-18 1.562 1.250 1.452 1.32224** 1.411-36 1.562-18 1.703 1.375 1.577 1.42228** 1.661-36 1.812-16 2.000 1.562 1.827 1.700NA designates not available. ** Available in Threaded Coupling only.All dimensions for reference only.CableSupportMS27613 K XX B or T XX X X XShellStyleInsertArrangementContact TypeContactStyleAlternateKeyingCableSupportDeviations/SpecialsFPK or FYL 17 X XX XX X X X XXX1.375 MAX.1.075 ±.010.718+.0101.375 MAX.1.075 ±.010.718±.010M THREAD.125MAX. PANEL THICKNESS.062 ±.010ZM THREAD.125MAX. PANEL THICKNESS.062 +.010Z220Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

MS27614, Pyle ® FPK or FYL, Firewall Class KSingle Hole (D-Hole) Mounted ReceptacleThreaded or BayonetSTSM THREADZPart #*To complete see howto order pages 218CommercialConnectorTypeYShellStyle1.375 MAX.1.075 ±.010.771+.010MilitaryShellStyleServiceClassShellSizeM THREAD.062 MIN/.125 MAX.PANEL THICKNESSCouplingType<strong>Amphenol</strong><strong>Aerospace</strong>InsertArrangementContactTypeAlternateKeyingTHREADED COUPLINGClass K Stainless SteelPyle FPK-19XX SeriesMS27614KXXTXXMilitary Class KCableSupportMS27614 K XX B or T XX X X XShellStyleInsertArrangementContact TypeContactStyleAlternateKeyingCableSupportDeviations/SpecialsFPK or FYL 19 X XX XX X X X XXX38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> Pyle3 PINS 120˚ APARTD FLATPANELCUT-OUT1.375 MAX.1.075 ±.010BAYONET COUPLINGClass K Stainless SteelPyle FYL-19XX SeriesMS27614KXXBXXMilitary Class KPrintedCircuit BoardSShellSizeTSMCableSupportThreadRCouplingThreadSFlangeWidth.771+.010TLock NutFlatsYMountingHole Dia.ZMountingHole FlatRecom. min.TorqueJam Nut08 NA NA NA NA NA NA 3310 NA NA NA NA NA NA 3612** .733-36 .875-20 1.291 1.215 .947 .917 5614 .803-36 .937-20 1.391 1.062 1.010 .980 6516 .930-36 1.062-18 1.516 1.187 1.135 1.105 6918 1.036-36 1.187-18 1.614 1.312 1.260 1.225 8120 NA NA NA NA NA NA 10022** 1.286-36 1.437-18 1.954 1.562 1.510 1.475 12324 NA NA NA NA NA NA 13328 NA NA NA NA NA NA NANA designates not available. ** Available in Threaded Coupling only.All dimensions for reference only.M THREAD.062 MIN./125 MAX.PANEL THICKNESSContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.comEMI FilterTransientFiber OpticsHigh SpeedContactsOptionsOthers221

<strong>Amphenol</strong><strong>Aerospace</strong>MS27615, Pyle ® FPK/PYL Firewall Class KStraight Plug, Threaded or BayonetOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIIPart #To complete see how toorder pages 218CommercialConnectorTypeTHREADED COUPLINGClass K Stainless SteelPyle FPK-11XX SeriesMS27615KXXTXXMilitary Class KShellSizeMS27615, Pyle ® FPK, Firewall Class KRatchet Lock Plug, ThreadedRATCHET LOCK PLUGThreaded CouplingClass K Stainless Steel Pyle FPK-12XX SeriesMS27615KXXSXXMilitary Class KShellSizeShellStyleMCableSupportThreadMCable SupportThreadMilitaryShellStyleRCouplingThreadRCouplingThreadCoupling NutS 1Dia.S 2Dia.SCoupling NutDiaTShell Dia.08 NA NA NA NA NA10 NA NA NA NA NA12 .733-36 .875-20 .984 1.018 .69614 .803-36 .937-20 1.054 1.087 .76516 .930-36 1.062-18 1.181 1.214 .89218 1.036-36 1.187-18 1.287 1.320 .99820 NA NA NA NA NA22 1.286-36 1.437-18 1.537 1.570 1.24824 1.411-36 1.562-18 1.662 1.695 1.37328** 1.661-36 1.812-16 1.912 NA 1.623** Available in Threaded Coupling only.ServiceClassShellSizeCouplingTypeTShell Dia.08 NA NA NA NA10 .563-36 .687-24 .931 .52612 .733-36 .875-20 1.111 .69614 .803-36 .937-20 1.175 .76516 .930-36 1.062-18 1.302 .89218 1.036-36 1.187-18 1.408 .99820 NA NA NA NAInsertArrangement22 1.286-36 1.437-18 1.658 1.24824 1.411-36 1.562-18 1.783 1.37328 1.661-36 1.812-16 2.038 1.6231.250 MAX. 1.250 MAX.WITHOUT WITHOUT1.250 MAX. 1.250 MAX.CABLE CLAMP CABLE CLAMPWITHOUT WITHOUT1.014±.010 1.014±.010CABLE CLAMP CABLE CLAMP 1.014±.010 1.014±.010BAYONET COUPLING Class K Stainless SteelPyle FYL-11XX Series MS27615KXXBXXMilitary Class KS 2S 1TContactTypeTM THREADM THREADM THREAD.035M THREADDIA. .035 DIA.SAFETY WIRE SAFETY HOLES WIRE HOLES.035 DIA. .035 DIA.(6 LOCATIONS) (6 LOCATIONS)SAFETY WIRE SAFETY HOLESWIRE HOLES(6 LOCATIONS) (6 LOCATIONS)S 2AlternateKeyingS 11.375 MAX. 1.375 MAX.TTCableSupportMS27615 K XX B or S XX X X XShellStyleInsertArrangementContact TypeContactStyleAlternateKeyingCableSupportDeviations/SpecialsFPK or FYL 11 or 12 X XX XX X X X XXXS 2NA designates not available.All dimensions for reference only.S 1TTM THREAD M THREADSS 2S 1R COUPLING R COUPLING THREAD THREADT1.375 MAX. 1.375 MAX.TTSM THREADM THREAD1.375 MAX. 1.375 MAX.1.024± .0101.024± .010TM THREADM THREAD0.032 SAFETY 0.032 WIRE SAFETY HOLES WIRE HOLES(6 LOCATIONS) (6 LOCATIONS)222Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> Type – 48 SeriesReceptacle Short Skirt<strong>Amphenol</strong><strong>Aerospace</strong>Receptacle Short Skirt – Aluminum – Bayonet CouplingShorter, lighter, and more economical than the standard <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> connector receptacles,the 48 Series receptacle short skirt comes in two versions: with standard flange andwith reduced flange. Both versions are 1.100” long which is .275” shorter than the length ofthe standard <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> connector.They have molded epoxy fiberglass inserts and can operate continuously up to 125°C(257°F), but otherwise they offer the same environ mental sealing, from the panel out, asstandard <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> connectors. They have bay onet coupling and mate with standard<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> plugs. The hard dielectric inserts, with resilient face seal and molded-ingold plated solder cup pin contacts, are available in insert arrangements shown in thechart below..125DIA. 4 HOLES.116CDIASOLDER CUP, PIN TYPE CONTACTS,GOLD PLATEDHARD DIELECTRIC INSERT WITHMOLDED-IN CONTACTSDDIAEDIA48 Series38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease MatrixBA.067 MAX..728 MAX..870 MAX.1.100 MAX.<strong>26500</strong> PyleAVAILABLE WITH PIN CONTACTS ONLYPrintedCircuit BoardInsertArrangementReceptacle Short Skirt with Standard Flange<strong>Amphenol</strong>Part Number*A±.005B±.005CMax.D+.000–.005EMax.10-5 48-7115-XX .937 .719 .696 .659 .56212-3 48-7116-XX 1.031 .812 .875 .829 .75012-12 48-7117-XX 1.031 .812 .875 .829 .75014-4 48-7118-XX 1.125 .906 .935 .898 .81214-7 48-7119-XX 1.125 .906 .935 .898 .81214-15 48-7120-XX 1.125 .906 .935 .898 .81216-24 48-7121-XX 1.250 .969 1.062 1.025 .93818-8 48-7122-XX 1.343 1.062 1.187 1.131 1.06218-14 48-7123-XX 1.343 1.062 1.187 1.131 1.06218-31 48-7124-XX 1.343 1.062 1.187 1.131 1.06220-25 48-7251-XX 1.437 1.156 1.312 1.256 1.18220-28 48-7175-XX 1.437 1.156 1.312 1.256 1.18222-12 48-7125-XX 1.562 1.250 1.437 1.381 1.31222-19 48-7126-XX 1.562 1.250 1.437 1.381 1.31222-55 48-7127-XX 1.562 1.250 1.437 1.381 1.312InsertArrangementReceptacle Short Skirt with Reduced Flange<strong>Amphenol</strong>Part Number*AMax.B±.005CMax.D+.000–.005EMax.10-5 48-7132-XX .870 .647 .696 .659 .56212-3 48-7133-XX .996 .773 .875 .829 .75012-12 48-7134-XX .996 .773 .875 .829 .750* To complete part number: Replace XX with alternate keying positions(omit for normal position). See page 204.EMI FilterTransientFiber OpticsHigh SpeedContactsOptionsOthersFor more information on other <strong>Amphenol</strong>®/Pyle® 48 Series products consult<strong>Amphenol</strong>, Sidney NYContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com223

<strong>Amphenol</strong><strong>Aerospace</strong><strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> Type – 48 SeriesWire Splice ConnectorOptions High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIISpecial Application Wire Splice ConnectorThe <strong>Amphenol</strong> ® 48 Series Wire Splice Connector is a low cost,space-saving connector design that can be used for variousapplica tions. The push-mating/twist-pull-unmating feature provides asimple solution to many design requirements without sacrificingperformance. This wire splice connector utilizes a metal retention clip fora single size 16 pin and socket contact.Features and benefits include:• Push-mating/twist-pull-unmating• Uses standard M39029/31-229 pin and M39029/32-248socket contacts• Incorporates environmental sealing grommet• Metal collet retention• Uses standard <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> contact removable tools• Low cost• Weight savings design• Space savings design• Color coded connector halves - red or blueRECEPTACLE.300MAX. DIA.PLUG“B”“B”.492 REF. .658 REF.UNLOCKARROWS(2 PLACES)FOR MATING ALIGNMENT.658 REF.1.170 MAX.VIEW “B”– “B”1.170 MAX.ROTATE 45° TO UNLOCK.492 REF.ARROWS (2 PLACES)FOR MATING ALIGNMENT.300MAX. DIA.<strong>Amphenol</strong>48 SeriesPart NumberReceptacle Wire Splice<strong>Amphenol</strong>10- PartNumberColorSize 16 ContactPart Number48-7191 10-804342 Blue Pin ZZL-4016-36LDSocket ZZL-4116-36LD48-7191-1 10-804342-1 Red<strong>Amphenol</strong>48 SeriesPart NumberPlug Wire Splice<strong>Amphenol</strong>10- PartNumberColorSize 16 ContactPart Number48-7190 10-804341 Blue Pin ZZL-4016-36LDSocket ZZL-4116-36LD48-7190-1 10-804341-1 Red224Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Pyle® ZZL/ZZB, <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> TypeHermetic (three styles), Threaded or Bayonet<strong>Amphenol</strong><strong>Aerospace</strong><strong>Amphenol</strong> ® /Pyle ® is an experienced supplier of highly reliable her metic connectors for the aircraftindustry. <strong>Amphenol</strong>’s ZZL and ZZB series of hermetic receptacles are designed to the requirements of<strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>, they are available in stainless steel shells with gold-plated, nickel-iron alloy contacts.Hermetic receptacles are available in shell sizes 8, 10, 12, 14, 16, 18, 22, 24 and 28. The hermeticseries is offered in a variety of receptacle shell styles, which include solder mount, square flange and“D” hole mount. These connectors can be ordered with either eyelet, solder-well or printed circuit tail pincontacts.Consult <strong>Amphenol</strong>, Sidney, NY for more information on hermetic con nectors, and for optionalconnector designs.Easy Steps to build a part number for Hermetic <strong>Connectors</strong>... CommercialZZLZZB1. 2. 3. 4. 5. 6. 7. 8. 9.Series Service Shell Style Shell Insert Contact Alternate Contact VariationsClassSize Arrangement Type Keying PlatingZZY A C T 55 P 6 D H45Step 1. Select a SeriesDesignatesThreaded CouplingBayonet CouplingStep 2. Service ClassHCDesignatesHermetic ClassStep 3. Select a Shell StyleDesignates14 Solder Mount Receptacle15 Single Hole Mounting Receptacle17 Square Flange ReceptacleStep 5. Select a Shell Size8 10 12 14 16 18 22 24 28Step 6. Select anInsert ArrangementSee inserts labeled with an “H” on page 203 & 204Step 7. Select a Contact TypePDesignatesMale Pin Contacts with standardgold plateStep 8. Select anAlternate Keying Position06, 07, 08, 09, 10 (Omit for Normal)See page 204Step 9. Select a Contact PlatingDesignatesE EyeletW SolderwellConsult <strong>Amphenol</strong>, Sidney, NY for ordering information ofprinted circuit tail contacts.Step10. Select aVariationH45H52H56H77H127H146H152H177H181Designates304L Stainless SteelShellTinned Termination TailsSame as standard; goldcontacts304L Stainless SteelShell, Inconel ContactsSame as H125 except304L Stainless SteelShell303 Stainless SteelShell, 100 Micro-inchGold304L Stainless SteelShell with IndividualBeads, Loose Seals303 Stainless SteelShell, Loose SealsTin Plated Contacts38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PylePrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContactsOptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com225

<strong>Amphenol</strong><strong>Aerospace</strong>Contacts and AccessoriesFor <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> <strong>Connectors</strong>Options High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIICrimp Contacts per <strong>MIL</strong>-<strong>DTL</strong>-39029 – Copper Alloy, Gold PlatingContactSizeSpec.NumberPIN CONTACTSBinCodeMS Number<strong>Amphenol</strong>/Pyle No.20 M39029/31 241 MS24254-20P ZZL-4020-36LD*16 M39029/31 229 MS24254-16P ZZL-4016-36LD*12 M39029/31 235 MS24254-12P ZZL-4012-36LD** Add – H139 for Boeing Marking for Pin/Socket, Standard Plating.Add – H148 for Boeing Marking for Pin/Socket, Select Plate.<strong>Amphenol</strong>®/Pyle® Special Application ContactsContactSize201612Copper Alloy, Rhodium plated Contacts†DescriptionCopper Alloy/Rhodium platedCopper Alloy/Rhodium platedCopper Alloy/Rhodium plated<strong>Amphenol</strong>/PylePin No.† Contacts qualified to Boeing BACC47CN/CP.<strong>Amphenol</strong>/PyleSocket No.ZZL-4020-36LT ZZL-4120-36LTZZL-4016-36LT ZZL-4116-36LTZZL-4012-36LT ZZL-4112-36LTPrinted Circuit Board/Wire-Wrap ContactsA variety of different designs are available; please consult<strong>Amphenol</strong>, Sidney, NY for more information.Reel Contacts2000 contacts per reel (gold or rhodium plated) are available.Consult <strong>Amphenol</strong>, Sidney, NY for more information.Sealing PlugsContactSize<strong>Amphenol</strong>/PyleNo.For sealing spare contact holes.Same sealing plug is used in bothplug and receptacle.MS NumberColorCode20 10-405996-20 MS-27488-20 Red16 10-405996-16 MS-27488-16 Blue12  Shielded10-405996-12 MS-27488-12 Yellow# 2 Shielded 10-405996-8 MS27187-4 WhiteContactSize201612ContactSizeSpec.NumberSOCKET CONTACTSBinCodeMS Number<strong>Amphenol</strong>/Pyle No.20 M39029/32 260 MS24255-20S ZZL-4120-36LD*16 M39029/32 248 MS24255-16S ZZL-4116-36LD*12 M39029/32 254 MS24255-12S ZZL-4112-36LD*MaterialAlumelChromelConstantanAlumelChromelConstantanAlumelChromelConstantanSealing GasketsThermocouple Contacts<strong>Amphenol</strong>/PylePin No.ZZL-4020-10RZZL-4020-10PZZL-4020-10NZZL-4016-10RZZL-4016-10PZZL-4016-10NZZL-4012-10RZZL-4012-10PZZL-4012-10N<strong>Amphenol</strong>/Pyle Socket No.Pencil ClipDesign*ZZL-4120-10RZZL-4120-10PZZL-4120-10NZZL-4116-10RZZL-4116-10PZZL-4116-10NZZL-4112-10RZZL-4112-10PZZL-4112-10NSplit TineDesign**ZZY-4120-10RZZY-4120-10PZZY-4120-10NZZY-4116-10RZZY-4116-10PZZY-4116-10NZZY-4112-10PZZY-4112-10PZZY-4112-10NColorCodeGreenWhiteYellowGreenWhiteYellowGreenWhiteYellow* Pencil clip socket design - see page 201 for description.** Split tine socket with napkin ring design - see page 201 for description.For use with square flange mounted receptacles. Provide waterproofingand pressure sealing features.ContactSize<strong>Amphenol</strong>/PyleNo.08 ZZL-6508-10D10 ZZL-6510-10D12 ZZL-6512-10D14 ZZL-6514-10D16 ZZL-6516-10D18 ZZL-6518-10D20 ZZL-6520-10D22 ZZL-6522-10D24 NA226Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Shielded/Coaxial ContactsFor <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> <strong>Connectors</strong><strong>Amphenol</strong><strong>Aerospace</strong>Drawing(See belowand onnext page)Type 1#1 ShieldedType 2#1 ShieldedType 3#1 ShieldedType 4#2 ShieldedType 5#2 ShieldedShieldedContact Part No./Contact Type48-1226-02 Pin48-1227-02 Socket48-1227-50 Socket48-1226-57 Pin48-1227-57 Socket48-1226-51, -54 Pin48-1227-51, -54, -56 Socket48-1226-55 Pin48-1227-55 Socket48-2187-02 Pin48-2188-02 Socket48-2187-50, -51 Pin48-2188-50, -51, -53, -54Socket48-2187-52 Pin48-2188-52 SocketCable Stripping Dim.***+.0156–.0000A B C Tool.2189 .0781 .1094.2189 .0781 .1094.2189 .0313 .1563.2344 .0313 .1563.2189 .1094 .1406.2189 .1094 .1406.3125 .1094 .1406294-268*294-289**294-268*294-289**294-268*294-289**294-268*294-289**294-126**294-243**294-1166**†294-358**294-268*294-1166**†294-358**294-268*294-358**294-268*<strong>Amphenol</strong> Crimp Tools(Center Contact)NestBushing294-1631CrimpSettingOuterFerruleCrimpingTool††Cable Application#3 294-529#22 AWG per <strong>MIL</strong>-C-7078Type II and <strong>MIL</strong>-C-27500-22KING RG-174/U, -188/U#1 294-529 RG-161/U, -179/U, -179A/U, -187/U294-1631 #1 294-528 Raychem 9530A11294-1631 #1 294-528 RG-180/U, -180A/U, -180B/U, -195/U294-1631 #1 294-529 RG-178/U, -178A/U, -178B/U, -196-U294-1014Turret Head294-1014294-1015299-1630294-1014294-1015294-1630294-1015294-1630.030-.040.030.040#3.037-.041294-528* Conforms to <strong>MIL</strong>-C-22520/2 specification. † Same as 294-126, less positioners.** MS3191 tools are inactive for new procurement, but can be used if available. †† Including Hex Die Set*** Refer to illustration on page 228.Shielded Contact Assembly ProcedureStep 1Step 2Step 3Step 4Step 5Slide sealing boot or sleeve and outer ferrule onto cable and strip cable as shown at right.After stripping, slide spacer over center conductor as shown for Type 2 and Type 3.For Type 3 slide spacer under wire braid.Insert stripped center conductor into contact until wire shows through inspection hole and dielectric (Type 1,Type 4 and Type 5) or spacer (Type 2 and Type 3) butts against contact. Fully seat contact in nest bushing ofcrimp tool and crimp in one full stroke. (Follow same crimping procedures except use nest bushing crimpingtool from table above).Slightly flair out ends of wire braid to facilitate insertion of inner ferrule of body assembly.Do not comb braid.Install center contact in body assembly and slide inner ferrule underneath wire braid as shown. Push centercontact until it is locked in place in the body assembly. Pull lightly on cable to make sure that contact issecurely locked in place.Slide outer ferrule over braid and up against body as shown. There should be no slack in the wire braid.Crimp the outer ferrule with proper tool from table above. Then for Type 1, Type 3 and Type 5 slide sealingsleeve toward contact until sleeve touches outer ferrule.#18, 20, 22 AWG per <strong>MIL</strong>-C-7078, Type IIand <strong>MIL</strong>-C-27500-18, -20, -22 KINGExtruded Jacket294-528 RG-180/U, -180A/U, -180B/U, -195/U294-530 RG-59/U and 21-541SEALINGSLEEVEOUTERFERRULEType 1CENTER PINCONTACTCENTER SOCKETCONTACTSOCKET BODYASSEMBLYSEALING CENTER PIN SOCKET BODYSEALING SEALING CENTER CENTER PIN PIN SOCKET SOCKET BODY BODYSEALING SLEEVE CONTACT ASSEMBLYSLEEVE SLEEVECENTERCONTACTPINSOCKETASSEMBLYBODYSLEEVE CONTACT ASSEMBLYPIN BODYASSEMBLYOUTER CENTER SOCKET PIN BODYOUTER OUTER CENTER CENTER SOCKET SOCKETPIN PIN BODY BODYOUTER FERRULESEALING SLEEVE CONTACTASSEMBLYFERRULECENTERCONTACTSOCKETPIN BODYASSEMBLYFERRULE CONTACTASSEMBLYSEALING SLEEVESEALING SEALING SLEEVE SLEEVESEALING SLEEVEOUTER FERRULEOUTER FERRULEOUTER OUTER FERRULEOUTER FERRULE38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PylePrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContactsStep 6Step 7Insert the assembled shielded contact into the connector in the same way as the standard contact usingapplicable insertion tool (see page 28). This completes assembly for Type 1, Type 2, Type 3 and Type 5.To complete assembly for Type 4, push sealing boot into connector grommet until O-ring riser of boot snapsinto place and seals the assembly.OptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com227

<strong>Amphenol</strong><strong>Aerospace</strong>Shielded/Coaxial Contacts, cont.For <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> <strong>Connectors</strong>Options High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIICable StrippingStrip cable jacket, braid and dielectric to the dimensions shown in thetable on page 227. Make all cuts square and sharp, being careful notto nick braid, dielectric, or center conductor when cutting. If conductorends fray, twist them to their normal lay.Shielded Contact Assembly Procedure, cont.OUTERFERRULESPACERA B C(Refer to stripping dimensions in chart on page 227)Type 2 Type 3 Type 4 Type 5OUTER FERRULESPACER BEADSEALINGSLEEVEOUTERFERRULESPACERSEALING SLEEVESEALING SLEEVEOUTER FERRULEOUTER FERRULESEALINGBOOTShielded Contactsafter CrimpingOUTERFERRULESEALING BOOTOUTER FERRULESEALINGSLEEVEOUTERFERRULESEALING SLEEVEOUTER FERRULE228Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Assembly Instructions for <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong><strong>Amphenol</strong><strong>Aerospace</strong>Contact TerminationContacts should be crimped to the wire with MS Standard handcrimping tools or specification automatic crimping machines.When stripping the wire avoid nicking wires or damaging theinsula tion as it is a functional part of the sealing system.ContactSizeWire SizeStripping Length20 20 to 24 .170” – .201”16 16 to 18 .207” – .238”12 12 to 14 .207” – .238”Follow steps 1 – 4, as shown below, for proper contact crimping:38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> Pyle1. Insert stripped wire into contact pocket until itis visible through inspection hole.2. Carefully seat contact in crimp tool positioner.PrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContacts3. Crimp in one full stroke. (The ratchet will notrelease jaws until tool has completed stroke).4. Inspect crimp for wire visibility throughinspec tion hole.OptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com229

<strong>Amphenol</strong><strong>Aerospace</strong>Assembly Instructions for <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong>Options High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIIContact Insertion into the ConnectorThe following steps are recommended for assembly.Contact Removal from the ConnectorNOTE:The Pyle Miniature Connector is designed with a unique sealing principle.Assembly of contacts into the connector must be made with reasonable care toavoid damage to the silicone rubber insert.1. Lubricate wire cavities in back face of insert with a very thin film of DC-200Silicone Oil or equal before inserting contacts.2. Locate contact in insertion tool (as shown in illustration).3. Align contact with hole in rear face of insert. The alignment of insertion toolwith contact must be coaxial with the axis of the connector. When contacthas entered rear seal portion of insert, maintain alignment of contact andtool parallel to, and in line with hole. Insert contact to full depth. Seating of thecontact in the retention collet is audible. The contact insertion force is lessthan five pounds.4. Extract insertion tool, keeping it aligned with hole.A contact is removed from the connector insert with the extraction tool as follows:1. Set the spacer sleeve in the proper position for removal of male or femalecontact.2. Place tool over the contact and insert into front face of cavity. The align mentof removal tool with contact must be coaxial with axis of connector.3. Exert a nominal force axially (from 5 to 10 lbs.) to release retention collet.Spacer sleeve will shoulder at front face of insulation when tool is inserted toproper depth.4. Push extraction plunger to force the contact out of the rear of the insert.5. Grasp contact or wire at rear face of insert and complete the extraction.6. Remove extraction tool axially.7. After using extraction tool the spacer sleeve should be set forward in lastnotch to protect the end of the plunger guide.Panel MountingTwo receptacle shell styles, flange mount and D-hole mount, are available forpanel mounting. See the applicable drawings for mounting hole dimensions. Thesquare flange receptacle, sizes 10 through 22, is fastened to the panel with foursize #4-40 machine screws. The 24 and 28 size shells are fastened with #6-32machine screws.230Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Accessories – Contact Terminating ToolsFor <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> <strong>Connectors</strong><strong>Amphenol</strong><strong>Aerospace</strong>Contact Insertion ToolsContact Removal ToolsContactSize<strong>Amphenol</strong>/Pyle No.Insertion ToolMil. No.ColorCodeInsertion Tool Replacement Tip& Pin<strong>Amphenol</strong>/Pyle No.Mil. No.20 ZZL-R-9510-A-20 <strong>MIL</strong>-I-81969/17-9 Red ZZL-R-9531-A-20 –16 ZZL-R-9510-16 <strong>MIL</strong>-I-81969/17-4 Blue ZZL-R-9531-16 –12 ZZL-R-9510-12 <strong>MIL</strong>-I-81969/17-5 Yellow ZZL-R-9531-12 –ContactSize<strong>Amphenol</strong>/Pyle No.Removal ToolMil. No.ColorCodeRemoval ToolReplacement Tip<strong>Amphenol</strong>/Pyle No.Mil. No.20 ZZL-R-9511-20 MS-24256-R-20 Red ZZL-R-9557-20 –16 ZZL-R-9511-16 MS-24256-R-16 Blue ZZL-R-9557-16 –12 ZZL-R-9511-12 MS-24256-R-12 Yellow ZZL-R-9557-12 –38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PyleContact Crimping ToolsContactSize201612Crimping Tool with Indenters<strong>Amphenol</strong>/Pyle No.TP-201354Mil. No.M22520/1-01(Class 1)Adjustable Turret<strong>Amphenol</strong>/Pyle No.TP-201355Mil. No.M22520/1-02(Class 1)Checking Gage forCrimping Tool<strong>Amphenol</strong>/Pyle No.Mil. No.TP-201356 M22520/3PrintedCircuit BoardEMI FilterTransientFiber OpticsContact TerminationUse table below to determine correct wire stripping length for yourwire sizes. When stripping the wire, avoid nicking wires or damaginginsulation, as it is a functional part of the sealing system.ContactSizeWire SizeStripping Length20 20 to 24 .170” – .201”16 16 to 18 .207” – .238”12 12 to 14 .207” – .238”High SpeedContactsOptionsOthersSee pages 229 and 300 for assembly instructions for proper contacttermination and contact insertion/removal.Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com231

<strong>Amphenol</strong><strong>Aerospace</strong>Accessories – Contact Terminating ToolsFor 48 Series <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> <strong>Connectors</strong>Options High SpeedEMI Filter Printed5015 83723 III 26482 38999OthersFiber OpticsTransient Circuit Board<strong>26500</strong> Pyle Crimp RearContacts Release Matrix Matrix Pyle Matrix 2 SJT I II IIICrimping Tools for Shielded Contacts<strong>Amphenol</strong> Tool 357-100Contact Insertion ToolsContact Removal Tools<strong>Amphenol</strong> Tool 294-529 or294-528Standard Crimping Tool for Power ContactsShieldedContactSizeFor CrimpingCenter ContactBasic Crimp Tool Contact PositionerFor CrimpingOuter FerruleBasic Crimp Tool(Hex dies included)Hex Dimension# 1 Shielded294-1631 294-529 .128 Hex357-100# 2 Shielded 294-1630 294-528 .160 Hex<strong>Amphenol</strong> Part No.ContactSizeBasic Crimp ToolMilitary Part No.Use withTurret Head294-542 M22520/1-01 M22520/1-02ColorCodeWireSize20 Red 20–22–2416 Blue 16–18–2012 Yellow 12–14Contact Size <strong>Amphenol</strong> Part No. Military Part No.20 294-88 MS2456A2016 294-96 MS2456A16#12, # 1 Shielded 294-72 MS24256R12#2 Shielded 294-128 –Contact Size <strong>Amphenol</strong> Part No. Military Part No.20 294-89 MS2456R2016 294-97 MS2456R16#12, # 1 Shielded 294-73 MS2456R12#2 Shielded 294-127 –For more information on other tools availableconsult <strong>Amphenol</strong>, Sidney, NY. NOTE: <strong>Amphenol</strong> and Pyle tools areinterchangeable.232Contact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com

Accessories - Cable SupportsFor <strong>MIL</strong>-<strong>DTL</strong>-<strong>26500</strong> <strong>Connectors</strong><strong>Amphenol</strong><strong>Aerospace</strong>Cable Supports - AluminumShellSizeNon-Conductive,Black Anodize FinishMS. No.Cable Supports - Stainless Steel, StraightLAMAX.DIA.P MAX.ShellSizeMS No.<strong>Amphenol</strong>/PyleNo.Conductive,Chromium FinishMS No.<strong>Amphenol</strong>/PyleNo.AMax.Dia.B±.015XI.D.±.38ThreadUNEF-2BPMax.08 *MS27291-13 *ZZL-R-5308-A *MS27291-701 *ZZL-M-5308 .582 .935 .180 .4375-28 .78510 *MS27291-1 *ZZL-R-5310-A *MS27291-101 *ZZL-M-5310 .731 .935 .270 .5625-24 .91412 MS27291-2 ZZL-R-5312-A *MS27291-201 *ZZL-M-5312 .919 .935 .400 .7500-20 1.02614 MS27291-3 ZZL-R-5314-A *MS27291-301 *ZZL-M-5314 .981 1.170 .460 .8125-20 1.09016 MS27291-4 ZZL-R-5316-A MS27291-401 10-804941-16E 1.106 1.170 .610 .9375-20 1.25018 *MS27291-5 *ZZL-R-5318-A *MS27291-501 *ZZL-M-5318 1.231 1.170 .690 1.0625-18 1.35820 *MS27291-14 *ZZL-R-5320-A *MS27291-801 *ZZL-M-5320 1.356 1.170 .830 1.1875-18 1.49622 *MS27291-6 *ZZL-R-5322-A *MS27291-601 *ZZL-M-5322 1.481 1.170 .940 1.3125-18 1.60424 MS27291-15 ZZL-R-5324-A *MS27291-901 *ZZL-M-5324 1.606 1.170 1.040 1.4375-18 1.740<strong>Amphenol</strong>/Pyle No.Standard Straight Support(L = .781)ADia.MS No.<strong>Amphenol</strong>/Pyle No.ADia.Similar toMS No.Long Straight Support<strong>Amphenol</strong>/Pyle No.ADia.L MaxOverallLengthThread10 NA NA NA NA NA NA NA *FPL-R-5310L NA NA .563-3612 NA NA NA NA NA NA MS27658-12 FPL-R-5312L .435 1.070 .753-3614 MS27657-14 ZZL-R-5314 .230 MS27657-1 FPL-R-5314 .382 MS27658-14 FPL-R-5314L .504 1.170 .803-3616 *MS27657-16 *ZZL-R-5316 .292 *MS27657-2 *FPL-R-5316 .462 MS27658-16 FPL-R-5316L .686 1.270 .930-3618 MS27657-18 ZZL-R-5318 .392 MS27657-3 FPL-R-5318 .556 *MS27658-18 *FPL-R-5318L .794 1.370 1.036-3620 NA NA NA NA NA NA NA *FPL-R-5320L NA NA NA22 MS27657-22 ZZL-R-5322 .516 MS27657-4 FPL-R-5322 .608 MS27658-22 FPL-R-5322L 1.038 1.570 1.286-3624 NA NA NA NA NA NA MS27658-24 FPL-R-5324L 1.162 1.670 1.411-3628 NA NA NA NA NA NA MS27658-28 FPL-R-5328L 1.412 1.870 1.661-36Cable Supports - Stainless Steel, Right AngleLAABXI.D.ShellSizeSimilar toMS No.Cable clamps support cable or wire at the plug orreceptacle and prevent twisting and pulling.Cable Support, Right Angle<strong>Amphenol</strong>/PyleNo.ADia.L MaxOverall LengthThread10 NA *FPL-R-5210 NA NA .563-3612 MS27659-12 FPL-R-5212 .435 1.298 .753-3614 MS27659-14 FPL-R-5214 .504 1.388 .803-3616 *MS27659-16 *FPL-R-5216 .686 1.523 .930-3618 MS27659-18 FPL-R-5218 .794 1.622 1.036-3622 MS27659-22 FPL-R-5222 1.038 1.878 1.286-3624 *MS27659-24 *FPL-R-5224 1.162 2.000 1.411-3628 *MS27659-28 *FPL-R-5228 1.412 2.250 1.661-36*Consult <strong>Amphenol</strong>, Sidney, NY for availability38999III II I SJT26482 83723 III 5015Matrix 2Matrix PyleCrimp RearRelease Matrix<strong>26500</strong> PylePrintedCircuit BoardEMI FilterTransientFiber OpticsHigh SpeedContactsOptionsOthersContact <strong>Amphenol</strong> <strong>Aerospace</strong> for more information at 800-678-0141 • www.amphenol-aerospace.com233