rice husk quasi gasifier stove with side-in steam injector

rice husk quasi gasifier stove with side-in steam injector

rice husk quasi gasifier stove with side-in steam injector

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

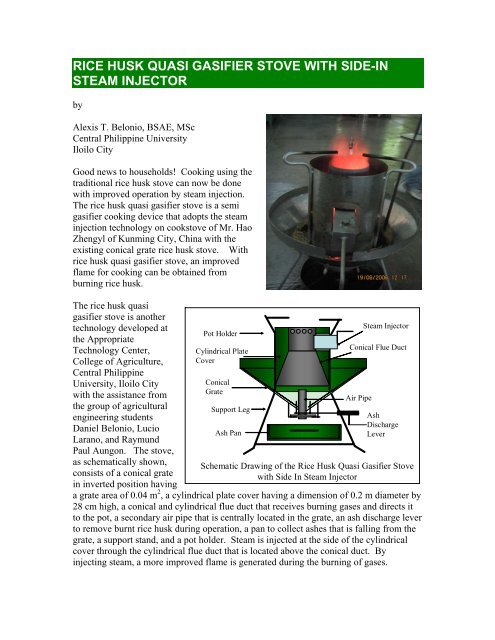

RICE HUSK QUASI GASIFIER STOVE WITH SIDE-INSTEAM INJECTORbyAlexis T. Belonio, BSAE, MScCentral Philipp<strong>in</strong>e UniversityIloilo CityGood news to households! Cook<strong>in</strong>g us<strong>in</strong>g thetraditional <strong>rice</strong> <strong>husk</strong> <strong>stove</strong> can now be done<strong>with</strong> improved operation by <strong>steam</strong> <strong>in</strong>jection.The <strong>rice</strong> <strong>husk</strong> <strong>quasi</strong> <strong>gasifier</strong> <strong>stove</strong> is a semi<strong>gasifier</strong> cook<strong>in</strong>g device that adopts the <strong>steam</strong><strong>in</strong>jection technology on cook<strong>stove</strong> of Mr. HaoZhengyl of Kunm<strong>in</strong>g City, Ch<strong>in</strong>a <strong>with</strong> theexist<strong>in</strong>g conical grate <strong>rice</strong> <strong>husk</strong> <strong>stove</strong>. With<strong>rice</strong> <strong>husk</strong> <strong>quasi</strong> <strong>gasifier</strong> <strong>stove</strong>, an improvedflame for cook<strong>in</strong>g can be obta<strong>in</strong>ed fromburn<strong>in</strong>g <strong>rice</strong> <strong>husk</strong>.The <strong>rice</strong> <strong>husk</strong> <strong>quasi</strong><strong>gasifier</strong> <strong>stove</strong> is anothertechnology developed atthe AppropriateTechnology Center,College of Agriculture,Central Philipp<strong>in</strong>eUniversity, Iloilo City<strong>with</strong> the assistance fromthe group of agriculturaleng<strong>in</strong>eer<strong>in</strong>g studentsDaniel Belonio, LucioLarano, and RaymundPaul Aungon. The <strong>stove</strong>,as schematically shown,consists of a conical grate<strong>in</strong> <strong>in</strong>verted position hav<strong>in</strong>gPot HolderCyl<strong>in</strong>drical PlateCoverConicalGrateSupport LegAsh PanConical Flue DuctAir PipeSteam InjectorAshDischargeLeverSchematic Draw<strong>in</strong>g of the Rice Husk Quasi Gasifier Stove<strong>with</strong> Side In Steam Injectora grate area of 0.04 m 2 , a cyl<strong>in</strong>drical plate cover hav<strong>in</strong>g a dimension of 0.2 m diameter by28 cm high, a conical and cyl<strong>in</strong>drical flue duct that receives burn<strong>in</strong>g gases and directs itto the pot, a secondary air pipe that is centrally located <strong>in</strong> the grate, an ash discharge leverto remove burnt <strong>rice</strong> <strong>husk</strong> dur<strong>in</strong>g operation, a pan to collect ashes that is fall<strong>in</strong>g from thegrate, a support stand, and a pot holder. Steam is <strong>in</strong>jected at the <strong>side</strong> of the cyl<strong>in</strong>dricalcover through the cyl<strong>in</strong>drical flue duct that is located above the conical duct. By<strong>in</strong>ject<strong>in</strong>g <strong>steam</strong>, a more improved flame is generated dur<strong>in</strong>g the burn<strong>in</strong>g of gases.

Performance test<strong>in</strong>g and evaluationshowed that the fuel <strong>in</strong> the <strong>stove</strong> canbe ignited <strong>in</strong> less than a m<strong>in</strong>uteus<strong>in</strong>g 1 to 2 pieces of paper. Itconsumes an average of 2.4 kg of<strong>rice</strong> <strong>husk</strong>s per hour and can boil 2liters of water <strong>with</strong><strong>in</strong> 14 to 18 m<strong>in</strong>.The amount of <strong>steam</strong> used dur<strong>in</strong>goperation averages to 0.46 liter perhour <strong>with</strong> fuel to <strong>steam</strong> ratio of 5.6.The computed burn<strong>in</strong>g rate of the<strong>stove</strong> was 59 kg/hr-m 2 . Thermalefficiency us<strong>in</strong>g boil<strong>in</strong>g andsimmer<strong>in</strong>g tests was determ<strong>in</strong>ed atabout 11 percent. The percentagechar/ash produced after eachoperation is 26 percent. Thecomputed power output of the <strong>stove</strong>is 1 kW. Cook<strong>in</strong>g a kilogram of<strong>rice</strong> <strong>with</strong> 1 liter of water will requirea time of 18 m<strong>in</strong>utes. Us<strong>in</strong>g 2 kg of<strong>rice</strong> <strong>with</strong> 2.9 liters of water will take 28 m<strong>in</strong>utes of cook<strong>in</strong>g.The <strong>stove</strong> is simple and easy to operate. It can becon<strong>side</strong>red as a clean combustion technology fordomestic cook<strong>in</strong>g utiliz<strong>in</strong>g <strong>rice</strong> <strong>husk</strong>s as fuel. Itcan be fabricated us<strong>in</strong>g local materials and skills.The total cost to produce the <strong>stove</strong> (materials, laborplus overhead) is P1,500.00 per unit (1US$ =PHP52).Further development on center <strong>steam</strong> <strong>in</strong>jectionthrough the secondary air pipe and cyl<strong>in</strong>drical platecover are presently undertaken. Any <strong>in</strong>terestedorganization who wishes to adopt the technologymay collaborate <strong>with</strong> the Appropriate TechnologyCenter, Department of Agricultural Eng<strong>in</strong>eer<strong>in</strong>g and Environmental Management,College of Agriculture, Central Philipp<strong>in</strong>e University, Iloilo City, Philipp<strong>in</strong>es. You maycontact through our landl<strong>in</strong>e at 063-033-3291971 loc 1071 or our mobile phone at 063-09167115222.AcknowledgmentI would like to acknowledge the Asia Regional Cook<strong>stove</strong> Program (ARECOP) for giv<strong>in</strong>g me the opportunity to attend the RegionalTra<strong>in</strong><strong>in</strong>g on Biomass Gasification for Thermal Applications <strong>in</strong> Cottage/Small Industries <strong>in</strong> Kunm<strong>in</strong>g City, Ch<strong>in</strong>a. This tra<strong>in</strong><strong>in</strong>g gave alot of <strong>in</strong>sights and avenues where we can <strong>in</strong>novate and develop technology particularly on the use of <strong>rice</strong> <strong>husk</strong>s as fuel.