SC10 4X4 manual - Carrocar

SC10 4X4 manual - Carrocar

SC10 4X4 manual - Carrocar

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

3/11

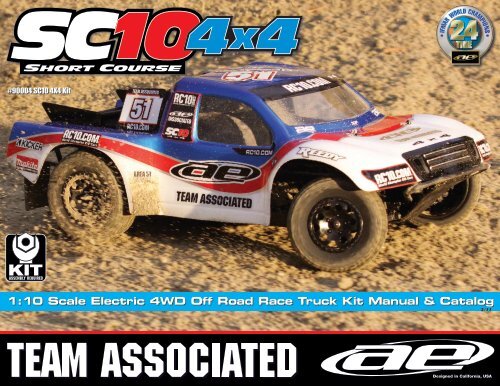

2:: IntroductionThank you for purchasing this Team Associated product. This assembly <strong>manual</strong> contains instructions and tips for building andmaintaining your new <strong>SC10</strong> 4x4. Please take a moment to read through this <strong>manual</strong> to help familiarize yourself with these steps.We are continually changing and improving our designs; therefore, actual parts may appear slightly different than in theillustrations. New parts will be noted on supplementary sheets located in the appropriate parts bags. Check each bag for thesesheets before you start to build.:: KIT FeaturesTeam Associated, the only RC car company with 24 World Championships is proud to present the <strong>SC10</strong> 4x4!Starting with a clean sheet of paper, Team Associated’s Area 51 design engineers have created the ultimate four-wheel drive shortcourseracer, the <strong>SC10</strong> 4x4.Its composite modular chassis design with sealed receiver box and removable ESC tray, combined with innovative features suchas 13mm big bore shocks, a decoupled slipper clutch, and a hybrid belt/gear drive system, make the <strong>SC10</strong> 4x4 unlike any othershort-course truck on the planet. In addition to these unique features, a long list of competition-proven components create anextremely high performance and durable state-of-the-art race truck.It’s not often a new platform is introduced that redefines a class. The engineers of Area 51 seized the opportunity to create the nextlegendary vehicle. Once you build and drive the <strong>SC10</strong> 4x4 for yourself, we think you will agree - this is the 4x4 short course racetruck that you have been waiting for!The <strong>SC10</strong> 4x4 kit is exactly what you have come to expect from Team Associated - one more Championby Design.Features in the <strong>SC10</strong> 4x4 Kit:• Unique dual gearbox drive train coupled together with a 5mm HD belt system with external tension adjustment.• 32 pitch front and rear gearboxes with sealed fluid filled differentials.• Decoupled center slipper clutch allows for front and rear wheel drive to slip independently, resulting in more traction andstability on bumpy track conditions.• CVAs with captured drive pins and heavy duty 6mm alloy axles.• 12mm hex drive KMC replica wheels front and rear with aggressive short course racing tires.• Championship short course racing body (clear), with Team Associated decal sheet.• 13mm blue aluminum big-bore threaded shocks with low friction X-ring seals.• Composite modular tub chassis with Low-CG and Low Polar Moment design.• Enclosed water-resistant receiver box, and removable ESC tray for easy clean up and maintenance.• Ball bearing steering system with adjustable steering stops.• All metric hardware and ball bearings throughout.• Designed for maximum durability and performance.:: Required to complete your <strong>SC10</strong> <strong>4X4</strong> Kit:• R/C 2-channel surface frequency radio system• Battery pack (6 cell NiMh or 2 cell LiPo)• Battery charger (peak detection charger recommended)• Electronic speed control• R/C electric motor (550 sized recommended)• Pinion gear - (32 pitch or 48 pitch) - depending on motor type• Tire Glue• Paint for body• Steering servo * Some servos may require a wire extension!:: Other Helpful Items• Silicone Shock Fluid (Refer to catalog for complete listings)• Body Scissors (AE Part # 1737) • Reamer / Hole Punch • Soldering Iron • Hobby Knife• FT Hex Wrenches (AE Part # 1541) • Needle Nose Pliers • Multi Tool (AE Part #7494) • Wire Cutters• FT Nut Drivers (AE Part #1561) • Calipers or a Precision Ruler • Green Slime shock lube (AE Part # 1105)Associated Electrics, Inc.26021 Commercentre Dr.Lake Forest, CA 92630Customer ServiceTel: 949.544.7500Fax: 949.544.7501http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

3:: Table of Contents1....................Cover2....................Introduction3....................Table of Contents4-7................Servo Install andSteering Assembly8-9...............Differentials Assembly9-11.............Front Gearbox Assembly12-13..........Rear Gearbox Assembly14.................Front Shock Tower Assembly15.................Rear Shock Tower Assembly16-19..........Front Suspension Assembly19-21..........Rear Suspension Assembly21-23.........Shocks Assembly37-38.........Rear Bumper Assembly38-39.........Tire Assembly39-40.........Body Installation41-43.........Tuning Tips44-54.........Catalog55................Contact Info56-57.........Notes68.................Setup Sheet “Blank”59................Setup Sheet “Kit Setup”60................1:1 Hardware “Fold Out61.................Setup Sheet “Blank”62................Back Cover23-26.........Chassis Assembly26-28.........Belt, Belt Tensioners, SpurGear & Covers Assembly29-35.........Electronics Installation36................Front Bumper Assembly:: Notes!This symbols indicates aspecial note or instructionin the <strong>manual</strong>.There is a 1:1 hardware foldout page in the backof the <strong>manual</strong>. To check the size of a part, lineup your hardare with the correct drawing untilyou find the exact size. Each part in the foldouthas a number assigned to it for orderingreplacement parts.Associated Electrics, Inc.26021 Commercentre Dr.Lake Forest, CA 92630Customer ServiceTel: 949.544.7500Fax: 949.544.7501http://www.TeamAssociated.com · http://www.RC10.com · http://twitter.com/Team_Associated · http://bit.ly/AEonFacebook

4:: Servo Install!You will need to have your radio gear, servo,and a charged battery ready to go for theservo installation steps!91004Frontinner bodymount89224M3x16mmshcs91014Frontchassisbrace91002 x43x8x4steeringbearings!Install the servoalignment tool inorder to correctlycenter your servo!91000Servoalignmenttool91001Steeringbellcrankpin91000Steeringbellcranksupport!Servo notincluded!:: Servo Install (cont.)!Loosely installthe #25620shcs91000Servomountx2Left25620 x2M3x10mmshcs892183x8mmwasherx225620 x2M3x10mmshcs!892183x8mmwasherx2Right91000Servomountsliderx225215M3locknut(black)x2!Pinch the Servomounts againstthe servo beforetightening the#25620 screws.

6:: Servo Install (cont.)!Uninstall the servoalignment tool,front body mount,and the steeringbellcrank support!Set parts aside forfuture installation.91003Servohornring91003Servohorn910476mmHD ballstud!There are multipleservo horns includedin your kit.Make sure you installthe correct one foryour brand servo!91000Steeringlink!Flex the servoalignment tool inorder to remove!!A = JRAirtronicsSanwaF = FutabaH = Hitec:: Servo Install (cont.)!Power on your radio, andcenter your servo beforeinstalling the servo horn!89528M3x5.6mmwasher25658M3x6mmshcs

7:: Steering Assembly91001Steeringbellcrankpin91001Steering servosaver cap89216M4 locknut91001Servo saverspring910488mmHD ballstud91000Steeringrack1mm91000Steeringbellcrank91000Servo saverbottom91000Servosaver top91000Servosaverpost91048 x28mmHD ballstud91028 x2Steel hatbushing:: Steering Assembly (cont.)89224M3x16mmshcs89224 x2M3x16mmshcs91004Front innerbody mount

8:: Differential Assembly#6588black grease91007<strong>4X4</strong> geardiff outdriveo-ring91006<strong>4X4</strong> geardiff outdrives91005<strong>4X4</strong> geardiff case#6588black grease91007<strong>4X4</strong> geardiff sun gearwasher91007<strong>4X4</strong> geardiff innero-ring!Build 2outdrivesper diff9115710x16x4bearing91007<strong>4X4</strong> geardiff outdrivewasher:: Differential Assembly (cont.)91007<strong>4X4</strong> geardiff sun gearpin91007<strong>4X4</strong> geardiff sun gear91005<strong>4X4</strong> geardiff case9115710x16x4bearing:: Differential Assembly (cont.)91007<strong>4X4</strong> geardiff sun gearwasher91007<strong>4X4</strong> geardiff sun gearpin91007<strong>4X4</strong> geardiff sun gear#6588black grease91007<strong>4X4</strong> geardiff innero-ring91007<strong>4X4</strong> geardiff outdrivewasher

10:: Front Gearbox Assembly (cont.)!Install the geardiff with thescrew headsfacing as shown!!Note: The idlergear will only slidein one way!91010<strong>4X4</strong> idlergear911565x10x3bearingx2:: Front Gearbox Assembly (cont.)31510M2x4mmbhcs!Note: The M2x4mm bhcscan be removed to inserta tool through the holeto remove the top shaftbearing from the gearcase!:: Front Gearbox Assembly (cont.)91088<strong>4X4</strong> beltcover!The included optional19 tooth clickerpulley is marked witha “O” (overdrive).9630 x3Aluminum 89225ballstud M3x24mmwasher shcs89226M3x26mmshcs91013Front clickerpulley, 20T(no markings)91013Front clickerpulley flange

12:: Rear Gearbox Assembly252386x12x4bearing252386x12x4bearing91015<strong>4X4</strong> reargearbox91015<strong>4X4</strong> reargearbox:: Rear Gearbox Assembly (cont.)91017 x2<strong>4X4</strong> topshaft spacer91016<strong>4X4</strong> topshaft(rear)91011<strong>4X4</strong> idlergear shaft:: Rear Gearbox Assembly (cont.)! !Install the geardiff with thescrew headsfacing as shown!Note: The idlergear will only slidein one way!911565x10x3bearingx291010<strong>4X4</strong> idlergear

13:: Rear Gearbox Assembly (cont.)31510M2x4mmbhcs!Note: The M2x4mm bhcscan be removed to inserta tool through the holeto remove the top shaftbearing from the gearcase!91019Rearchassisbrace:: Rear Gearbox Assembly (cont.)#1596thread lock89226M3x26mmshcs9630 x2Aluminumballstudwasher89225 x2M3x24mmshcs91018<strong>4X4</strong>motorplate91019Rearchassisplate89454 x2M3x12mmshcs

15:: Rear Shock Tower Assembly91024Bodymountsx232191024Rear bodymountbracket25190 x2M3x14mmshcs91022Shockmountsx291023Rearshocktower25217 x2M4 locknutw/flange:: Rear Shock Tower Assembly (cont.)91004Rear innerbody mount!Installshock towerfrom top!25620M3x10mmshcs91021 x2Threadedinserts89454 x4M3x12mmshcs!Note: Make sure thethreaded inserts remainin place when installing theshock tower!:: Rear Shock Tower Assembly (cont.)#1596thread lock91049 x210mmHD ballstuds2 1

16:: Front Suspension Assembly252386x12x4bearing9104910mmHD ballstudRightLeft25215M3locknut(black)!Build leftand rightside!91026Steeringspindle(left, right)#6588black grease91042CVA axle91044CVAcoupler!Build 2CVA’s91040Front CVAbone:: Front Suspension Assembly (cont.)91043CVA pinretainer91044CVA pin!Build 2CVA’s252386x12x4bearing91030Front axlecrush tubex2!91043AxleshimBuild left andright side!(right side shown):: Front Suspension Assembly (cont.)91027Wheelhex pin910488mmHD ballstudLeft91027Wheelhexadapter!Build left andright side!(right side shown)31510M2x4mmbhcs91026Casterblock!Note: #31510 bhcsis to be used as asteering stop.Right!Build leftand rightside!

18:: Front Suspension Assembly (cont.)91029Frontpivotbrace91029Front armmount (A)25620 x2M3x10mmshcs:: Front Suspension Assembly (cont.)! !!Front Camber Link(right side shown)91051 x2HDballcups(Camber)Note the orientationof the ballcups!Build a left andright side!Install ballstudson curved side ofthe ballcup!Front Steering Link(right side shown)(Steering)91051HDballcupsx2Install ballstudson curved side ofthe ballcup!1:134mm91038HD turnbuckles65mmInstall ballstudson curved side ofthe ballcup!1:135.5mm91038HD turnbuckles65mmInstall ballstudson curved side ofthe ballcup!

19PIC :: Front Suspension Assembly (cont.)Orient the notchto the left throughout thecar. It indicates which endhas the left hand threads!!Install an allen wrench(as shown in picture)to lock up the steering,in order to adjust thesteering turnbuckleseasily!:: Rear Suspension Assembly910488mmHD ballstud91041Rear CVAbone91044CVAcoupler#1596thread lock#6588black greaseLeft25215M3 locknut(black)91032Rear hubcarriersRight252386x12x4bearing!Build leftand rightside!!Build 2CVA’s91042CVA axle:: Rear Suspension Assembly (cont.)91033Rear axlecrush tube!Build 2CVA’s91044CVApin!Build 2CVA’s9115512x18x4bearing

20:: Rear Suspension Assembly (cont.)91027Wheelhex pin! !Build left andright side!(right side shown)Build left andright side!(right side shown)91027Wheelhexadapter:: Rear Suspension Assembly (cont.)Left91037 x2Rear hubwheelbaseshimLeft25215M3 locknut(black)89218M3x8mmwasher91031Rear armsRight!Do not91036overtighen!Rear outerEnsure free hinge pinhub movement!Right:: Rear Suspension Assembly (cont.)91034Rear armmount (D)(3+2)91035Inner hingepin25190 x2M3x14mmshcs

21:: Rear Suspension Assembly (cont.)!Rear CamberLink (rightside shown)!Note the orientationof the ballcups!Build a left andright side!91051 x2HDballcupsOrient the notchto the left throughout thecar. It indicates which endhas the left hand threads!Install ballstudson curved side ofthe ballcup!91039HD turnbuckles80mm1:154.3mmInstall ballstudson curved side ofthe ballcup!:: Shocks Assembly#1596thread lock91059M2.5x5x0.5washer910651.2mmpistons91059Shockpistonbhcs91059Shockpistonspacer9105726mm shockshaft (front)!Install the shockcartridge sealtube with thetapered sidepointed to thetop! (see below)ShockfluidShockfluid91054Shockcartridgebody91054Shockcartridgeseal tube91055 x2ShockX-ringsShockfluid9105830mm shockshaft (rear)91054Shockcartridgeseal cap:: Shocks Assembly (cont.)9106026mmshock body(front)91067Springcollar91070Shockboots91070Shockbumper91056Shockpivot ball91056Shockrod end9106130mmshock body(rear)Install through largersized hole on rod end!91107Shocktool(body)91107Shocktool(cap)

22:: Shocks Assembly (cont.)91062Moldedshock cap21332Shocko-ring 31510M2x4mmbhcs!Use a hobbyknife to clearout the bleederhole in eachshock cap!!91063ShockbladderShockfluidShock Fluid (front):30wt #5422Shock Fluid (rear):25wt #5428* Shock Bleeding Steps:1. Fill shock body 3/4 full with silicone fluid2. Pump the shock shaft up and down toremove any air bubbles.3. Wait for the air bubbles to surface,then compress the shock shaft half way.4. Fill the shock within 0.5mm from thetop with silicone shock fluid.5. Gently seat the bladder into the shockcap6. Thread the shock cap onto the shock,excess fluid will exit thru the bleed hole.7. Tighten cap by hand, and pump theshock up and down to check for leaksor air bubbles.8. If the shock is leaking, tighten thecartridge or shock cap and retry.9. If the shock has air bubbles, removethe cap and start at step 2.Note: This setting is known as half rebound.:: Shocks Assembly (cont.)910754.3 Bluefront(short)910792.8 Bluerear(long)Front: 4mmRear: 6mm91067Springcup!Build twofront andtwo rearshocks!:: Shocks Assembly (cont.)FrontShocksInstall89223 x2M3x8mmshcs91068 x2Shock capbushing25612 x2M3 locknutw/flange(black)91069 x2Shock mountpin, steel

23:: Shocks Assembly (cont.)RearShocksInstall89223 x2M3x8mmshcs91068 x2Shock capbushing25612 x2M3 locknutw/flange(black)91069 x2Shock mountpin, steel:: Chassis Assembly91083<strong>4X4</strong>chassis91084Nerfbars!Note:rotate nerf barsinto chassis slots!:: Chassis Assembly (cont.)89454 x4M3x12mmshcs91086Receiverbox89454M3x12mmshcs91085Batterystrap lock

24:: Chassis Assembly (cont.)!Note: Routeservo wirethrough slot inchassis.Then,flex front cliponto chassis!!Note: Route yourservo wirearound the leftside bump!:: Chassis Assembly (cont.)25190 x2M3x14mmshcs89454M3x12mmshcs:: Chassis Assembly (cont.)25191 x2M3x18mmshcs89454 x2M3x12mmshcs25215 x2M3 locknut(black)

25:: Chassis Assembly (cont.)!Note:Install rear cliponto chassis!:: Chassis Assembly (cont.)25190 x2M3x14mmshcs89227M3x28mmshcs25190M3x14mmshcs

26:: Chassis Assembly (cont.)25191 x2M3x18mmshcs25215 x2M3 locknut(black)!Topview!Bottomview:: Belt, Tensioners, Spur Gear, and Covers Assembly91088Rear innerbelt cover25658 x2M3x6mmshcs#1596thread lock91013Belttensionerpulley314024x8mmbearing91158M3x4mmbhcs91091Belttensionercam!Buildtwo!

28:: Belt, Tensioners, Spur Gear, and Covers Assembly (cont.)89528M3x5.6mmwasher31531M3x5mmbhcs!To adjust the belt tensioner, youneed to remove the #91159shcs and the #91091 washer.Loosen the #31531, adjustthe belt tensioner, and reinstallthe #91091 washer and the#91159 shcs.#1596thread lock!!See notes!91159M2.5x5mmshcs91091M2.5x5mmwasher3 4 52191094Spur gear(32P - 62T)(550 motors)91097Spur gear(48P - 93T)(540 motors)9603 x2Slipperpads:: Belt, Tensioners, Spur Gear, and Covers Assembly (cont.)25216M3 locknutw/flange91090Springadapter91090Slipperspring7485V2 slipperhub!Note:Tighten ifclutch slipsexcessivelywhen driving!3.5mm:: Belt, Tensioners, Spur Gear, and Covers Assembly (cont.)91089<strong>4X4</strong> beltcover cap89218 x2M3x8mmwasher31532 x2M3x8mmbhcs91088Center beltcover (inner)91088Front outerbelt cover25620M3x10mmshcs91088Centerbelt cover(outer)89223M3x8mmshcs25201 x2M3x8mmfhcs

29:: Electronics Installation18.5mm!Install the pinion tothe motor shaft sothe end of the pinionsticks out 18.5mmfrom the face of themotor!!!Do not overtightenthe belt cover screws!!Motor, pinion,and setscrewnot included!:: Electronics Installation (cont.)91088Rear outerbelt cover89223 x2M3x8mmshcs89223 x2M3x8mmshcs89528 x2M3x5.6mmsteel washer91089Belt covercap25190 x2M3x14mmshcs:: Electronics Installation (cont.)91152ESC mount!ESC notincluded!6727Servo tape91152ESC mountfoam

30:: Electronics Installation (cont.)91158 x3M3x4mmbhcs!Transpondernot included!91070 x2Shockbumper:: Electronics Installation (cont.)25201 x2M3x8mmfhcs!Use the tabs on theelectronics tray toroute your ESC andtransponder wires!

31:: Electronics Installation (cont.)91087Receiverbox seal91152Receivergrommetplug!Receiver grommetplug can be removedif you use a personaltransponder!:: Electronics Installation (cont.):: Electronics Installation (cont.)6727Servo tape91087! Receiver!box sealReceiver notincluded!(antenna)Install antennawire throughthe hole asshown!

32:: Electronics Installation (cont.)!Trim the antennatube to fit theamount of antennawire that will besticking out of thereceiver box beforeinstallation!:: Electronics Installation (cont.)91087Receiverbox seal89219M3x5mmset screw6338Antennacap6338Antennatube

33:: Electronics Installation (cont.)89223 x2M3x8mmshcs91086Receiverbox lid!The receiver boxlid will have tobe installed at anangle due to thetabs on the backof the lid!:: Electronics Installation (cont.)!91152Side batteryfoamInstall side batteryfoam so it is flushagainst the bottomof the chassis!Batteryfoam

34:: Electronics Installation (cont.)!You can install the battery foamBattery notspacers to either have the batteryincluded!positioned forward, middle, orback, depending on how you wantthe weight to be transferred !!9238 x2Batteryfoamspacers:: Electronics Installation (cont.)91085<strong>4X4</strong> batterystrap

35:: Electronics Installation (cont.)!Twist the battery strapknob to the right to lockthe battery strap intoplace!:: Electronics Installation (cont.)!You can run the batterywires above or below thebelt cover!

36:: Front Bumper Assembly91098Frontbumperbrace25190 x2M3x14mmshcs89224 x2M3x16mmshcs91098Frontbumper:: Front Bumper Assembly (cont.)25190 x3M3x14mmshcs91098Front skidplate89223M3x8mmshcs

37:: Rear Bumper Assembly91099Rearbumper91100Rear skidplate89430Mudflapx289218 x4M3x8mmwasher89223M3x8mmshcs31532 x4M3x8mmbhcs:: Rear Bumper Assembly (cont.)91099 x2Rear bumperbrace (upper)25620 x2M3x10mmshcs25215M3 locknut(black)89227M3x28mmshcs91099Rearbumperpivot91099Rear bumperbrace (lower):: Rear Bumper Assembly (cont.)89224 x4M3x16mmshcs

38:: Rear Bumper Assembly (cont.)89454 x2M3x12mmshcs89224 x2M3x16mmshcs89454M3x12mmshcs:: Wheel and Tire Assembly91101KMC HexWheel(black) 894131/8th moldedtire insert (2)!Note: Clean the rims and tires wherethe two will mount to each other beforeyou glue themtogether. You can clean them witheither rubbing alchohol, or r/celectric motor spray.9809<strong>SC10</strong> Tirew/foaminsertUse CA glue #1597 to glue the tireto the wheel. Glue one side at a time,allowing enough time for the glue to drybefore continuing to the other side.Tip: You can use a rubber band to holdthe tire tight against the wheel whilethe glue is drying.!CA glue is not!included!Build 4!

39:: Wheel and Tire Assembly (cont.)25217 x4M4 locknutw/flange:: BodyBody :Your <strong>SC10</strong> 4x4 kit comes with a clear polycarbonatebody. You will need to prep the bodybefore you can paint it. Wash the inside thoroughlywith warm water and liquid detergent.Dry the body using a clean, soft, lint-free cloth.Use the supplied window masks to cover thewindows from the INSIDE of the body (RC carsget painted from the inside).Using high quality masking tape, apply tape tothe inside of the body tocreate a design. Spray (either rattle can or airbrush)the paint to the inside of the body (prefferablydark colors first, lighter colors last).NOTE: use ONLY paint that isrecommended for use with(polycarbonate) plastics. If you don’t, you candestroy the plastic body!!!!).After painting, cut the body along the trim lines.Remove overspray protectant film. Make sureto drill or use a body reamer to make the holesfor the body mounts, antenna, andnumber plates. Add some stickers, and yourready to race!9837<strong>SC10</strong> 09’clear bodynumber plates(right/left sides)9837<strong>SC10</strong> 09’clear bodyrear fin6222 x10Nylon locknuts4/40/5-406288 x104-40x1/4bhcs

40:: Body (Cont.)9837<strong>SC10</strong> 09’body(clear)!Install screwsoutside thebody asshown!Install nutsinside thebody asshown:: Body (cont.)91160Body clip1.3mmx4:: Final AdjustmentsTips for Beginners:1. Place your car on a block or stand so that all 4 wheels are elevated and free to move. Remove the body.2. Turn the transmitter ON.3. Connect your battery pack and turn the ESC (electronic speed control) power switch ON.4. Turn the steering wheel on the transmitter. If the vehicle does not respond, check your battery connection, ESCplug, and servo plug are all installed correctly. If both systems are powered on, then refer to your transmitter<strong>manual</strong> for help on setting up your radio systems.5. If the steering is working, check that the wheels turn left when you turn the transmitter wheel to the left. If not, thenyou must check the servo reversing switches (see transmitter <strong>manual</strong>).6. Adjust the steering trim setting on the transmitter until the steering rack (page 7) is centered in the car.Then, adjust the steering turnbuckles (page 19) so that both front wheels point straight forward. Use the steeringtrim to fine-tune the centering adjustment once you finish the checklist and start driving your car.7. Now connect the motor to the ESC (refer to ESC instructions for proper installation).8. Set the ESC according to the manufacturer’s instructions. WARNING: Some ESC’s have the motor dis-connectedduring setup and some do not. You risk damaging your brushless system if you do not follow the manufacturer’sinstructions.9. Check that your ESC settings are working by lightly applying the throttle and brake.10. Re-install the body. You are now ready to drive !11. REMEMBER that the transmitter is the first to be turned on and the last to be turned off.Always operate your R/C vehicle in a safe area clear of any vehicles, pedestrians, or animals.

41:: Tuning TipsTips for Beginners:Before making any changes to the standard setup, make sure you can get around the track without crashing. Changesto your vehicle will not be beneficial if you can’t stay on the track. Your goal is consistent laps.Once you can get around the track consistently, start tuning your vehicle. Make only ONE adjustment at a time, testingit before making another change. If the result of your adjustment is a faster lap, mark the change on the included setupsheet (make adddtional copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back tothe previous setup and try another change.When you are satisfied with your vehicle, fill in the setup sheet thoroughly and file it away. Use this as a guide for futuretrack days or conditions.Recommended Motor Gearing:To calculate your <strong>SC10</strong> 4x4 Final Drive Ration (a.k.a. gear ratio), use the following formula:(spur gear # teeth) / (pinion gear # teeth) x 2.57 = Final Drive RatioMotor Gearing ChartMotor4.5 turn, 550 size5.5 turn, 550 size5.5 turn, 540 size6.5 turn, 540 size7.5 turn, 540 sizeGearPitch3232484848Pinion Spur (Final Drive Ratio) : 11213151617626293939313.2812.2615.9414.9414.06<strong>SC10</strong> <strong>4X4</strong> 32 pitchgear chart - 2.57:111121314155813.5512.4211.4710.659.9460 6214.0212.8511.8611.0110.2814.4913.2812.2611.3810.62<strong>SC10</strong> <strong>4X4</strong> 48 pitchgear chart - 2.57:115161718192021228714.9113.9713.1512.4211.7711.1810.6510.169315.9314.9414.0613.2812.5811.9511.3810.86Differential:The <strong>SC10</strong> 4wd heavy duty differentials (a.k.a. “diffs”) are o-ring sealed, and can be filled with silicone fluid.The recommended starting setup is 3000 CST, and normally between 2000-7000 CST differential fluid will work best.For less low-speed steering, try running the front differential thicker than the rear (example, 3000 CST rear, 5000CST in front). The truck will have the best cornering balance with more similar fluids in the front and rear diffs.Slipper Clutch:The assembly instructions give you a base setting for your slipper clutch. The <strong>SC10</strong> 4wd clutch is de-coupled, so theouter slipper hub drives the rear wheels and the inner slipper hub drives the belt to the front. The Team recommendmaking slipper settings at the track, where the grip level is at race conditions.Torque bias front and rear is adjustable by changing the center hole diameter in the slipper pads.Belt Tension:The <strong>SC10</strong> 4x4 belt is 5mm wide neoprene canvas backed. It will stretch slightly over its life, so the belt tensioners willneed to be adjusted from the initial settings after about 20-30 minutes of running. By touch, the belt should feel tightwhen pressing on top surface between the pulleys, and you should only be able to depress the belt about 3mm or 1/8”.After an initial run-in on the truck and setting the belt tension, you can verify that there is not excessive belt drag.With the motor pinion removed, the truck should roll 10-15 feet with a slight push on level, smooth ground.On the setup sheet, the tension slots are broken into 5 tension locations, with 3 being the middle. Since the rear pulleyis the drive, we will start with tension setting 3 in rear, and 4 in front. As the belt breaks-in, adjust the front tensionertighter until you are at the mid 3 setting. After that, any future tension adjustments to tighten the belt should be madeequally front and rear.Belt Tension with 19 Tooth Front Over-Drive or Rear Under-Drive Pulleys:WARNING: Do not run the 19 tooth pulley for both front and rear. Only run one 19 tooth pulley on the truck at any time.Changing the drive pulleys only affects front wheel speed. The drive speed of the rear wheels is fixed through thegearbox. If you want to try the optional 19 tooth over-drive “O” front pulley OR 19 tooth under-drive “U” rear pulley, thenyou will need to set the tensioner to setting 1 (tightest setting) on the end of the car with the smaller 19T pulley.Then adjust the belt tension on the opposite pulley to get the proper overall tension (usually 3 or 2 tension setting on theopposite gearbox). The Team recommend to start with the standard 20 tooth pulleys (equal drive) and then test thealternate pulleys to determine which works best for you.Front over-drive (“O” pulley in front) makes the front wheels turn faster than the rear, and gives the front end more drivemid-to-exit. This can improve the steering feel in lower grip situations, or whenever you want more grip and steering.Front under-drive (“U” pulley in rear) makes the front wheels turn slower than the rear, which can also help stabilize thetruck in certain conditions. You must dis-assemble the slipper clutch to change the rear pulley.

42:: Tuning Tips (cont.)Front Clicker:For your first run with the <strong>SC10</strong> 4x4, we recommend to start with full-time 4wd until you get a feel for the truck.Then, you can try loosening the front clicker nut which will allow the clicker to operate.The front clicker will take away front wheel braking and let the front tires spin freely off-power. This gives the front endmore grip, and gives more steering in the turns. To allow the clicker to operate, set the nut at 2mm gap between thenut and the end of the front topshaft. If you want to lock the clicker (called “full-time 4wd”) then tighten the nut until itbottoms (about 3mm or more gap from the nut to the end of the topshaft).If you are running full-time 4wd with the clicker nut locked down, you may hear the belt skip 4-5 teeth as it changesdirection from drive to brakes at top speed. Under normal circumstances, the belt should not skip under braking fromanything but top-speed (30+ m.p.h.). Running full-time 4wd will put more stress on the belt, and belt wear should bemonitored more closely, inspecting the belt and pulleys after every day of running (about 45 minutes run time).Shock Piston and Fluid:The <strong>SC10</strong> 4x4 kit is built with 4 hole, 1.2mm hole diameter pistons. All pistons have a number molded into the top.12 denotes 1.2mm diameter holes. The optional 1.1 and 1.3mm hole diameter pistons are included.As a rule of thumb, larger hole pistons decrease damping which can help the truck in bumpy and low-grip situations.On smoother tracks, or for large jumps, you may want use smaller hole pistons which increase damping and take awaysome grip.Typically, your <strong>SC10</strong> 4x4 shocks will work best with shock fluid rates between 25 and 35 wt (275 - 425 CST).Use the thicker fluids in the range when changing to larger hole pistons, and also use the thinner weight fluids whenchanging to a smaller hole pistons.Front Camber Link Length & Number of Washers Under Ballstuds:Changing the length of the camber link is considered a bigger step than adjusting the ballstud height. Your first settingchange on the track should be to try the inside vs. outside locations on the shock tower. Typically shortening the camberlink (or lowering the ballstud) will give the front end less grip which is more stable. Lengthening the camber link (or raisingthe ballstud) will give the front more grip at low speed but it can have slower steering response mid-to -exit of the turns.Front Camber:A good starting camber setting is –1 degrees (top of the tire leaning in). Positive camber, where the top of the tire isleaning out, is typically not recommended. Trick: Set your car on a flat surface, and set a soda can next to your tire asa reference for vertical, or zero camber. Both sides should be equal in setting. For serious racers, Associated makesthe #1719 Factory Team camber gauge.Front Toe-in:Zero degree toe-in (tires pointing straight forward) is the setting that should be used in almost all track conditions.Occasionally you can increase turn in by adding a little toe-out (front of tires point slightly out). Front toe in is not a typicaltuning adjustment used by The Team.Front Arm Hole:The kit blue springs and outside front arm hole will work best in most cases. Changing to the inner hole will soften thesuspension and give more front end grip. Typically you will want to change to a heavier spring when changing arm holelocation inward.Front Tower hole:The kit setting of the middle hole is a good standard setting for most tracks. Moving the shock out on the tower willmake the truck easier to drive and normally will decrease entry steering but increase mid to exit steering. Whenrunning the inside tower hole, try running a heavier spring to compensate for the steeper shock angle.Front Ride Height:The standard front ride height setting is 27mm (without body). Check the ride height by lifting up the entire truck about8-12 inches off the bench and drop it. After the suspension “settles” into place, raise or lower the shock collars as necessaryuntil there is 27mm gap from the bottom of the chassis to the ground.Tuning Guide: Making large ride height adjustments up or down from this setting will tend to make the truck feelunpredictable.

43:: Tuning Tips (cont.)Anti-Squat:Anti-squat denotes the angle of the rear arms relative to the ground. Zero anti-squat means that the rear arms areflat, parallel with the ground. The kit setting is 2 degrees, and can increased to 3 degrees of anti-squat by changingto the included 3+3 rear suspension mount. Adding anti-squat tends to make the car “rotate” more in corners, butdoesn’t handle as well through the bumps.Rear Camber Link Length & Number of Washers Under Ballstuds:Changing the length of the camber link is considered a bigger step than adjusting the ballstud height on the rear chassisbrace. Typically shortening the camber link (or lowering the ballstud) will give the rear end less roll and the car will tendto accelerate or “square up” better. Lengthening the camber link (or raising the ballstud) will give the rear more roll andmore cornering grip. You should normally use the kit setting (inside on tower, middle “B” hole on hub) and only adjust theballstud height.Rear Hub Spacing:You have 3 options for rear hub spacing, FORWARD, MIDDLE, & BACK. The kit setting MIDDLE provides the most reartraction, and will be used most often. For additional weight on the rear tires in slick conditions, run hubs FORWARD. Forimproved handling in bumps or rhythm sections, try moving the hubs to BACK. This can also make the car handle betterin 180 degree turns.Rear Camber:A good starting camber setting is –1 degrees. Use the included #1719 camber gage to set your camber as seenbelow. Adding a small amount of positive camber, where the top of the tire is leaning out, will tend to improve straight-lineacceleration on loose tracks.Front and Rear Swaybars:The optional #91123 4x4 front and #91124 rear swaybar set (a.k.a. anti-roll bar set) allows you to add roll resistance tostabilize the truck in turns. The recommended bars are 1.5. 2.0, and 2.2 mm (from softest to stiffest).Start with the same diameter wire front and rear. A swaybar has minimal effect on handling over bumps and jumps.It is especially helpful tuning item if your truck needs high-speed stability to stop traction rolling.Rear Arm Hole:The inner hole in the arm tends to work the best over the bumps and jump sections. Changing to the outer hole in therear arm will tend to make the rear end feel more “locked in” and less responsive. You may need to run a softer springwhen using outside in the rear arm.Rear Tower Hole:Try adjusting the shock tower hole before changing springs or arm mount location. The kit setting of the middle holewill be optimal on most tracks. Moving the shock out on the tower will increase typically yield more sidebite (corneringtraction) on corner exit and less bite on entry. Moving the shock in on the tower will yield more stability on entry and lesscornering traction on exit, and is typically better in bumps.Rear Ride Height:The rear ride height setting you should use most often is 27mm (without body). Check the ride height by lifting up theentire truck about 8-12 inches off the bench and drop it. After the suspension “settles” into place, raise or lower theshock collars as necessary until there is 27mm gap from the bottom of the chassis to the ground. The chassis shouldlook level from the side.Tuning Guide: Making large ride height adjustments up or down from this setting will tend to make the car feelunpredictable.Setup Sheets:Most often, the best way to get your car handling right is to go to our website www.rc10.com and click on the links toSetup Sheets, then <strong>SC10</strong> 4x4 setups. Our team of professional drivers help develop these setups at National events.Also, most drivers have a “base” setup that they use as a starting point for every event. Try running some of our basesetups OR look for track conditions and tires that are similar to your local track and mimic that setup.Remember, each adjustment has a purpose, so copy everything from the setup sheet and then make adjustmentsbased on the recommendations in here and in our online tuning guide.

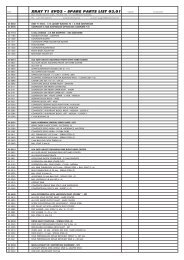

46:: Front Clip96302519025191252152562089218892248922689454910049101491029Aluminum Ballstud WasherM3x14mm SHCSM3x18mm SHCSM3 Locknut, BlackM3x10mm SHCSM3x8mm WasherM3x16mm SHCSM3x26mm SHCSM3x12mm SHCS<strong>4X4</strong> Inner Body Mounts<strong>4X4</strong> Front Chassis Plate/Brace<strong>4X4</strong> Front Arm Mount (A)1020202020101010101119100491014892248921825620251912519096309101489226910299102925215256208945489454:: Front Suspension2518725215252172523831510892028922391025910269102791028910309103591040910429104391044910489104991069M3x14mm BHCSM3 LocknutM4 Locknut w/Flange6x12x4mm BearingsM2x4mm BHCSM3x12mm BHCSM3x8mm SHCS<strong>4X4</strong> Front Arms<strong>4X4</strong> Steer/Caster Block<strong>4X4</strong> Wheel Hexes / Pins<strong>4X4</strong> Steel Hat BushingsFront Axle Crush Tube<strong>4X4</strong> Inner Hinge Pins (Fr, Rr)<strong>4X4</strong> Front CVA Bones<strong>4X4</strong> CVA Axles<strong>4X4</strong> CVA Pin Retainer<strong>4X4</strong> CVA Rebuild KitHD Ballstuds, 8mmHD Ballstuds, 10mmShock Mount Pin, Steel20202026101022ea41022ea22218849104091044910359104491042910439104391025910269104825238910288922389202315108920291049252159102691030910279102725238252172518791069251879102891028

47:: Front Gearbox9630252383151089225910099101091011910129101791156Aluminum Ballstud Washer6x12x4 BearingsM2x4mm BHCSM3x24mm SHCS<strong>4X4</strong> Front Gearbox<strong>4X4</strong> Idler Gear<strong>4X4</strong> Idler Gear Shaft<strong>4X4</strong> Top Shaft, Front<strong>4X4</strong> Top Shaft Spacers5x10x3mm Bearings1026101211229100925238910179101291156910109115691011910172523891009315109630963089225:: Front Belt Covers, Tensioners, Clicker Drive25215256203140231531892238952891013910889108991091911589115991167M3 Locknut, BlackM3x10mm SHCS4x8mm BearingsM3x6mm BHCSM3x8mm SHCSM2.5x5mm washer<strong>4X4</strong> Pulley/Clicker Set<strong>4X4</strong> Belt Covers<strong>4X4</strong> Belt Cover CapBelt Tension HardwareM3x4mm BHCSM2.5x5mm SHCS<strong>4X4</strong> Pulleys, Front & Rear202026101011ea2110101ea9108925620892239108891088895289109131531910919115991158314029101325215910919101391013910139116791013

48:: Belt, Center Belt Covers, Battery Strap92382520131532892188945491085910889109391152Foam Battery SpacersM3x8mm FHCSM3x8mm BHCSM3x8mm WashersM3x12mm SHCS<strong>4X4</strong> Battery Strap<strong>4X4</strong> Belt Covers<strong>4X4</strong> Drive Belt<strong>4X4</strong> ESC Tray/Battery Wall2206101011ea11252012520191088910938921831532910858945491085911529108889218315329238:: Chassis, Electronics Tray252018922389454910709108391084910869108791152M3x8mm FHCSM3x8mm SHCSM3x12mm SHCS13mm Shock Bumpers<strong>4X4</strong> Chassis<strong>4X4</strong> Nerf Bars<strong>4X4</strong> Receiver Box<strong>4X4</strong> Reveiver Box Seals<strong>4X4</strong> ESC Tray/Battery Wall201010411ea111910848945491083892239108691087894548945491086911528945489454910849107091087911522520191152:: Slipper Gear Assembly / Pinions748596032521691090910929109491095910969109791161911629116391164911659116691167FT V2 Slipper HubsSlipper PadsM3 Locknut w/Flange<strong>4X4</strong> Slipper Hardware<strong>4X4</strong> Inner Slipper HubSpur Gear, 32P-62T (Kit)Spur Gear, 32P-60TSpur Gear, 32P-58TSpur Gear, 48P-93T (Kit)5mm to 1/8 Pinion Adapter11T 32P Pinion Gear12T 32P Pinion Gear13T 32P Pinion Gear14T 32P Pinion Gear15T 32P Pinion Gear<strong>4X4</strong> Pulleys, Front & Rear12201111111111111ea9116791090960391092960391094 - 32P91077 - 48P91090748525216

49:: Motor Plate, Rear Belt Cover25190256583140231531892238952891013910189108891089910919115891159M3x14mm SHCSM3x6mm SHCS4x8mm BearingsM3x6mm BHCSM3x8mm SHCSSteel Washer 3x5.6mm<strong>4X4</strong> Pulley/Clicker Set<strong>4X4</strong> Motor Plate<strong>4X4</strong> Belt Covers<strong>4X4</strong> Belt Cover CapsBelt Tensioner HardwareM3x4mm BHCSM2.5x5mm SHCS2020261010111ea2110103153191159910188952891091910919109131402 91013911589108889528892232565889223910882519091089:: Rear Gearbox9630252383151089225910109101191015910169101791156Aluminum Ballstud Washer6x12x4mm BearingsM2x4mm BHCSM3x24mm SHCS<strong>4X4</strong> Idler Gear<strong>4X4</strong> Idler Gear Shaft<strong>4X4</strong> Rear Gearbox<strong>4X4</strong> Rear Top Shaft<strong>4X4</strong> Top Shaft Spacers5x10x3mm Bearings10261021112289225892259630315109101525238910179101691156910109115691011910172523891015

50:: Rear Clip633896302519025191252158921989223892268922789454910199103491100Antenna Tube 12” & CapAluminum Ballstud WasherM3x14mm SHCSM3x18mm SHCSM3 Locknut, BlackM3x5mm SetscrewM3x8mm SHCSM3x26mm SHCSM3x28mm SHCSM3x12mm SHCS<strong>4X4</strong> Rear Chassis Plate/Brace<strong>4X4</strong> Rear Arm Mount (D)<strong>4X4</strong> Rear Skid Plate1102020201010101010111892266338633889219892272519025191963025190910199101991034251902521525190892238945491100:: Rear Suspension252152521725238892188922391027910319103291033910359103691037910419104291044910489106991155M3 LocknutM4 Locknut w/Flange6x12x4mm BearingsM3x8mm WashersM3x8mm SHCS<strong>4X4</strong> Wheel Hexes / Pins<strong>4X4</strong> Rear ArmsRear Hub CarriersRear Axle Crush Tube<strong>4X4</strong> Inner Hinge Pins, Fr & Rr<strong>4X4</strong> Rear Outer Hinge PinsRear Hub Wheelbase Shim<strong>4X4</strong> Rear CVA Bones<strong>4X4</strong> CVA Axles<strong>4X4</strong> CVA Rebuild KitHD Ballstuds, 8mmShock Mount Pin, Steel12x18x4 Bearings, Rubber202021010411ea22ea282228429104191044910449104291155910482521591032910339102791031892232523891069910359103625217892182521591037

52:: Factory Team and Option Parts1654173417351736694374959787983698379838983998439844984598469847984898499862986325391253923128631550911089110991110911119111291113911149111591116911179111891119911209112191122911239112491125911269112791128911299113091131911329113591136911379116091161911689116991170FT Solid Axle PinsFT Body Clips, 4 Long, 6 ShortFT Long Body Clips, BlueFT Short Body Clips, BlueFT Blue 8-32 LocknutsVented Slipper Hub (fits outside only for <strong>4X4</strong>)Chassis Protective Sheet<strong>SC10</strong> Clear Body<strong>SC10</strong> 09’ Championship Clear Body<strong>SC10</strong> RTR Body, KMC<strong>SC10</strong> RTR Body, Lucas Oil<strong>SC10</strong> RTR Decal Sheet, KMC<strong>SC10</strong> RTR Decal Sheet, Lucas Oil<strong>SC10</strong> RTR Decal Sheet, Bullydog<strong>SC10</strong> RTR Decal Sheet, Pro Comp<strong>SC10</strong> RTR Decal Sheet, Team AE<strong>SC10</strong> RTR Body, Ready Lift<strong>SC10</strong> RTR Decal Sheet, Ready Lift<strong>SC10</strong> 09’ Body, Rockstar-Makita<strong>SC10</strong> 09’ Decals, Rockstar-MakitaFT 4mm Locknuts, BlueFT 3mm Locknuts, BlueAluminum Ballstud Washers, BlueM3 Aluminum Locknuts, BlueFT 13x26mm Shock Kit, HardFT 13x30mm Shock Kit, HardFT 26mm Shock Body, HardFT 30mm Shock Body, HardTi Nitride Shock Shaft, 26mmTi Nitiride Shock Shaft, 30mmBlank Shock Pistons, 13mmTi HD Turnbuckle, 65mmTi HD Turnbuckle, 80mmTi HD Turnbuckle Set, <strong>SC10</strong> <strong>4X4</strong>Ti Nitride HD Ballstud 6mmTi Nitride HD Ballstud 8mmTi Nitride HD Ballstud 10mmTi Nitride HD Ballstud 12mmHard Anodized Hat BushingsFront Swaybar SetRear Swaybar SetHard Anodized Pivot BallsSwaybar HardwareTi Nitride Front Inner Hinge PinsTi Nitride Rear Inner Hinge PinsLight Weight Gear Diff OutdrivesLight Weight Top Shaft, FrontLight Weight Top Shaft, RearAluminum Idler ShaftFront CVA Bones, ShinyRear CVA Bones, ShinyCVA Pin Retainer, AluminumBody Clip, 1.3mm Thick5mm to 1/8 Pinion Adapter<strong>SC10</strong> <strong>4X4</strong> Underbody<strong>SC10</strong> <strong>4X4</strong> Decal SheetHi -Torque Slipper Pad4104642111111111111111010261122224221222221141222111222101112:: XP Electronics291072912529126291412914229150291552915629158291602916129162291642916529166291772920929210292112921229221292222922329224:: Reedy Motors and ESC’s916917918919936937938939:: Reedy Batteries302303627628632633634637681682683684685686689693694695700709712713714723724725730731732S1903 Metal Gear SetS1903MG ServoS2008MG ServoXP SC450-BL Brushless ESCXP ESC Fan OptionXP RX/TX CHarger 110vXP3D FM Radio System 27mHzXP3D FM Radio System 75mHzXP3D 3ch Digital Transmitter Only27mHz Module AM for XP3D27mHz Module FM, for XP3D75mHz Module FM for XP3DMicro RX 3ch FM 27mHzMicro RX 3ch FM 75mHzXP DS1313 Digital ServoXP DS1015 Digital ServoGear Set, DS1313Gear Set, DS1015Servo Case , DS1313 / DS1015Accessory Pack, DS1313 / DS1015XP3SS 2.4GHz Radio SystemTRS401SS 2.4GHz 4Ch Receiver2.4GHz Module and RX (XP3D)2.4GHz Module (XP3D)540R Brushless Motor 3300kV540R Brushless Motor 3900kV540R Brushless Motor 4900kV540R Brushless Motor 6100kVXP SC450-BL/Reedy 540R 3300kV ComboXP SC450-BL/Reedy 540R 3900kV ComboXP SC450-BL/Reedy 540R 4900kV ComboXP SC450-BL/Reedy 540R 6100kV ComboAA Alkaline 1.5V (4)AA 2700mAh NiMH 1.2V RechargeableLiPo 60C 5200mAh 7.4V SPLiPo 60C 5500mAh 7.4VTX Lightweight Battery 1350mAh 11.1VTX Battery - 3PK, M11 3000mAh 11.1VTX Battery - Helios, Z1 2400mAh 11.1VTX Battery - M11X 2500mAh 7.4VWolfpack 2400mAh 7.2V w/DEANS® connectorWolfpack 3000mAh 7.2V w/DEANS® connectorWolfpack 3600mAh 7.2V w/DEANS® connectorWolfpack 4200mAh 7.2V w/DEANS® connectorLiPo 40C+ 5000mAh 7.4VLiPo 40C+ 4200mAh 7.4V SPR-Power 1700mAh 7.2V w/TAM connectorWolfpack 2400mAh 7.2V w/TAM connectorWolfpack 3000mAh 7.2V w/TAM connectorWolfpack 3600mAh 7.2V w/TAM connectorWolfpack 4200mAh 7.2V w/TAM connectorLiPo 5000mAh 7.4V 35C ROAR SpecLiPo 4200mAh 7.4V 35C SP EFRA SpecLiPo 2400mAh 7.4V 20C StickLiPo 3400mAh 7.4V 25C StickLiFe 4000mAh 6.6V 30CWolfpack 3000mAh 8.4V w/DEANS® connectorWolfpack 3600mAh 8.4V w/DEANS® connectorWolfpack LiPo 3000mAh 7.4V 25C w/DEANS®Wolfpack LiPo 3300mAh 7.4V 35C w/DEANS®Wolfpack LiPo 3400mAh 7.4V 35C w/DEANS®1111111111111111111111111111111111111111111111111111111111111

:: Reedy Accessories604605606607610651652653654655656657658659660661662663664665666667716SP35MSP35LSP35XLSP35XXLSP35XXXLSP36MSP36LSP36XLSP36XXLSP36XXXLSP417526-S AC/DC 2S-6S LiPo/LiFe ChargerMotor Cooling Fans (2)Charge Harness 2S Saddle Pack 4mmCharge Harness 2S Standard Pack 4mm447-S AC/DC NiMH Peak ChargerBattery Bars (8)Battery Bars (30)Battery Bars (100)4.0mm plugs (2M, 2F)4.0mm plugs (2M, 10F)4.0mm plugs (10F)4.0mm plugs (100F)4.0mm plugs (10M)4.0mm plugs (30M)3.5mm plugs (3M, 3F)3.5mm plugs (10F)3.5mm plugs (100F)3.5mm plugs (10M)3.5mm plugs (30M)Single Cell Shrink - Clear (12)Single Cell Shrink - Clear (30)Single Cell Shrink - Clear (100)Reedy 09 Decal SetReedy Logo T-Shirt - White MReedy Logo T-Shirt - White LReedy Logo T-Shirt - White XLReedy Logo T-Shirt - White XXLReedy Logo T-Shirt - White XXXLReedy Logo T-Shirt - Black MReedy Logo T-Shirt - Black LReedy Logo T-Shirt - Black XLReedy Logo T-Shirt - Black XXLReedy Logo T-Shirt - Black XXXLFactory Team 1/10 Motor Storage Bag:: LRP Charger, Power Supply, Balancer, IronLRP41281LRP41555LRP43150LRP45200LRP65800LRP65802LRP65803LRP65804:: LRP Speed ControlsLRP80100LRP80150LRP80400LRP80905LRP80915LRP80955Quadra Pro 2 ChargerPulsar Touch Competition ChargerPower Supply CompetitionLiPo Parallel BalancerHigh Power Solder StationSoldering Tip 5mmSoldering Tip 1.2mmSoldering HandleAI Brushless ReverseAI Brushless Pro ReverseSPX Brushless Super ReverseSXX Competition V.2SXX Stock-Spec V.2SXX TC-Spec V.2:: LRP Brushless MotorsLRP50642LRP50652LRP50662LRP50672LRP50682LRP50687LRP50692LRP50702LRP50712LRP50722LRP50832LRP50842LRP50852LRP50862LRP X-12 9.5 TurnLRP X-12 8.5 TurnLRP X-12 7.5 TurnLRP X-12 6.5 TurnLRP X-12 5.5 TurnLRP X-12 5.0 TurnLRP X-12 4.5 TurnLRP X-12 4.0 TurnLRP X-12 3.5 TurnLRP X-12 3.0 TurnLRP X-12 Stock-Spec 10.5 TurnLRP X-12 Stock Spec 13.5 TurnLRP X-12 Stock Spec 17.5 TurnLRP X-12 Stock Spec 21.5 Turn11111111111111111111111111111111111111111111111111111111111111:: LRP Brushless CombosLRP80677LRP80678LRP80679LRP80694LRP80695LRP80696LRP80697LRP80698LRP80699LRP80790LRP80791LRP80792LRP80793LRP80794LRP80795LRP80796LRP80797LRP80798LRP80799:: LRP Misc.LRP50620LRP50621LRP50622LRP50623LRP50624LRP50625LRP50626LRP50632LRP50633LRP50634LRP80135LRP82511LRP82520LRP82530LRP82531LRP819307LRP819310LRP819315LRP819320:: ApparelSP35**SP36**SP58**SP59**SP62**SP63**SP64**SP65**SP66**SP67**SP100SP101SP102SP103SP411SSP411LSP416SP417SP420**715110684SXX Stock-Spec V2/ X-12 Stock-Spec 10.5 TurnSXX Stock-Spec V2/ X-12 Stock-Spec 13.5 TurnSXX Stock-Spec V2/ X-12 Stock-Spec 17.5 TurnSXX COMP v.2 / X-12 5.0 TurnSXX COMP v.2 / X-12 5.5 TurnSXX COMP v.2 / X-12 6.5 TurnSXX COMP v.2 / X-12 7.5 TurnSXX COMP v.2 / X-12 8.5 TurnSXX COMP v.2 / X-12 9.5 TurnSXX TC v.2 / X-12 3.0 TurnSXX TC v.2 / X-12 3.5 TurnSXX TC v.2 / X-12 4.0 TurnSXX TC v.2 / X-12 4.5 TurnSXX TC v.2 / X-12 5.0 TurnSXX TC v.2 / X-12 5.5 TurnSXX TC v.2 / X-12 6.5 TurnSXX TC v.2 / X-12 7.5 TurnSXX TC v.2 / X-12 8.5 TurnSXX TC v.2 / X-12 9.5 TurnX-12 Replacement Ball BearingsX-12 Optional Ceramic Ball BearingsX-12 Small parts SetX-12 PreciSensor UnitX-12 Replacement alum Front canX-12 Lightweight Alum CanX-12 Alum Rear CoverX-12 12.0mm sintered rotorX-12 12.5mm sintered rotorX-12 13.0mm sintered rotorBEC stabilizing capacitorBrushless Low Profile FanBrushless/Brushed Cooling SetPower Cap 3.7 - 4.8VPower Cap 6.0 - 7.4V70mm High Flex Sensor Wire100mm High Flex Sensor Wire150mm High Flex Sensor Wire200mm High Flex Sensor WireReedy 09’ White T-Shirt (M, L, XL, 2XL, 3XL)Reedy 09’ Black T-Shirt (M, L, XL, 2XL, 3XL)AE Logo Black T-Shirt (M, L, XL, 2XL)AE Logo Blue T-Shirt (M, L, XL, 2XL)AE Vertigo Long Sleeve T-Shirt (S, M, L, XL, 2XL)AE Vertigo White T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)AE Vertigo Blue T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)AE Vertigo Black T-Shirt (S, M, L, XL, 2XL, 3XL, 4XL)AE Stencil Blue T-Shirt (S, M, L, XL, 2XL, 3XL)AE Stencil Gray Sweatshirt (S, M, L, XL, 2XL, 3XL)1/8 Inner and Outer Boxes Only, Set1/8 Inner Boxes Only, Set1/10 Inner and Outer Boxes Only, Set1/10 Inner Boxes Only, SetAE Hat 11’ Flatbill Black S/MAE Hat 11’ Flatbill Black L/XL1/10 Car Carrier Bag Only1/10 FT Motor BagAE Pit Gloves (M, L, XL)Reedy 2009 Track BannerTeam Associated Track Banner** Use part number plus the desired size when ordering!5311111111111111111111111111111111111111111111111111111111Pr.11

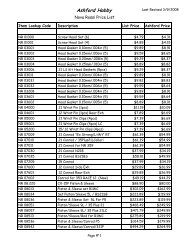

54:: 1/18 Kits and RTR’s20100201012010320105201062011020115201182012020130RC18T RTR (ready-to-run)RC18T2 2.4ghz RTR (ready-to-run)RC18B2 - RC18T2 Team KitRC18B RTR (ready-to-run)RC18B2 2.4ghz RTR (ready-to-run)RC18MT RTR (ready-to-run)RC18R Kamino RTR (ready-to-run)RC18R Niteline RTR (ready-to-run)SC18 RTR (ready-to-run)RC18LM RTR (ready-to-run):: 1/12, 1/10 Kits and RTR’s203320424019702370277029703070327034703670377040704170437044708070928021903690389039906120515301053010630111:: 1/8 Kits and RTR’s205032050480902809048090580912809218092280923809248092580932FT Nitro TC3 KitNitro TC3 RTR Plus (ready-to-run)FT 12R5.1 KitRC10T4.1 FT Kit<strong>SC10</strong> 2WD Short Course Race Truck Kit<strong>SC10</strong> Associated/RC10.com Truck RTR (ready-to-run)<strong>SC10</strong> KMC Wheels Race Truck RTR (ready-to-run)<strong>SC10</strong> Ready Lift RTR (ready-to-run)<strong>SC10</strong> FT KitRC10T4.1 RTR 2.4GHz Brushed (ready-to-run)RC10T4.1 RTR 2.4GHz Brushless (ready-to-run)<strong>SC10</strong> RTR, 2.4ghz Brushless Lucas Oil Body<strong>SC10</strong> RTR, 2.4ghz Brushless Speed Tech/Bully Dog Body<strong>SC10</strong> RTR, 2.4ghz Brushless Pro Comp Body<strong>SC10</strong> RTR, 2.4ghz Brushless Rockstar / Makita BodyFT GT2 Nitro Truck KitGT2 RS Truck Nitro RTR (ready-to-run)FT RC10R5-OVAL KitRC10B4.1 FT KitRC10B4.1 RTR 2.4GHz Brushed (ready-to-run)RC10B4.1 RTR 2.4GHz Brushless (ready-to-run)FT B44.1 4WD Buggy KitMGT 3.0 Nitro Monster Truck RTR (ready-to-run)FT TC5R Rubber Tire Edition 4WD Touring Car KitFT TC6 4WD Touring Car KitTC4 4WD Touring Car RTR (ready-to-run)Limited Edition MGT 4.60 Nitro RTR, w/flag body(ready-to-run)Limited Edition MGT 8.0 Nitro RTR, w/flag body(ready-to-run)FT RC8B Nitro Buggy KitFT RC8Be Electric Buggy KitRC8RS “Race Spec” Nitro Buggy RTR (ready-to-run)RC8T Championship EditionSC8 Short Course Race Truck, Lucas Oil Nitro RTR(ready-to-run)SC8 Short Course Race Truck, KMC Wheels Nitro RTR(ready-to-run)SC8 Short Course Race Truck, Bully Dog Nitro RTR(ready-to-run)SC8 Short Course Race Truck, AE Team Nitro RTR(ready-to-run)SC8 Short Course Race Truck, Pro Comp Nitro RTR(ready-to-run)SC8e Short Course Race Truck Rockstar/Makita RTR(ready-to-run)111111111111111111111111111111111111111111111111:: Tools1111144914501541154215431544154515461547154815511553155415611562156315641565156615671589159015921655165616571658165916601661166216631664166516661667166816691670167116721673167417191737371837193720398764296956770991107FT Turnbuckle WrenchOffroad Ride Height GaugeFT Ride Height GaugeFT Hex Driver Set, (7 pcs)FT .050” Silver Hex DriverFT 1/16” Black Hex DriverFT 1.5mm Purple Hex DriverFT 5/64” Blue Hex DriverFT 3/32” Gold Hex DriverFT 2.5mm Green Hex DriverFT 3mm Red Hex DriverFT Screwdriver SetFT Phillips Silver ScrewdriverFT Silver Spring Hook ToolFT Nut Driver Set, (6 pcs)FT 3/16” Black Nut DriverFT 1/4” Red Nut DriverFT 5.5mm Red Nut DriverFT 11/32” Green Nut DriverFT 7.0mm Silver Nut DriverFT 8mm Gold Nut DriverFT 5/64” Blue Ball Hex DriverFT 3/32” Gold Ball Hex DriverFT Ball Hex Driver Set, (3 pcs)FT 8-Piece 1/4” Hex Drive SetFT 1/4” Hex Drive Handle, without tipsFT 1/4” Hex Drive .050” TipFT 1/4” Hex Drive 1/16” TipFT 1/4” Hex Drive 5/64” - 2.0mm TipFT 1/4” Hex Drive 3/32” TipFT 1/4” Hex Drive 1.5mm TipFT 1/4” Hex Drive 2.5mm TipFT 1/4” Hex Drive 3/16” Nut Driver TipFT 1/4” Hex Drive 1/4” Nut Driver TipFT 1/4” Hex Drive 11/32” Nut Driver TipFT 1/4” Hex Drive 5.5mm Nut Driver TipFT 1/4” Hex Drive 7.0mm Nut Driver TipFT 1/4” Hex Drive 8.0mm Nut Driver TipFT 1/4” Hex Drive 5/64” - 2.0mm Ball End TipFT 1/4” Hex Drive 3/32” Ball End TipFT 1/4” Hex Drive Standard Screwdriver TipFT 1/4” Hex Drive Phillips Screwdriver TipFT 1/4” Hex Drive 2.5mm Ball End TipFT 1/4” 5 Piece Power Tool Tips Set (5/64-2.0mm,1.5mm, 2.5mm, 5/64”- 2.0mm ball, 2.5mm ball)FT Camber + Track Width ToolFT Body Scissors12 Inch Nylon Wire Ties6 Inch Nylon Wire Ties8 Inch Nylon Wire TiesFT Droop GaugeShock Building ToolMolded Tools, Set4 Inch Nylon Wire Ties13mm Shock Tools1111111111111111111111111111111111111111111111121212111121

55:: Contact InformationAssociated Electrics, Inc.26021 Commercentre DriveLake Forest, CA 92630-8853 USAhttp://www.TeamAssociated.comhttp://www.RC10.comhttp://twitter/Team Associatedhttp://bit.ly/AEonFacebookcall: (949) 544-7500fax: (949) 544-7501Check out the following web sites for all of our electric kits, currentproducts, new releases, setup help, tips, and racing info!www.TeamAssociated.com. - www.RC10.com

56:: Notes

:: Notes57

Front SuspensionSteeringStop Gap:Setup SheetWashers:BumpsteerWashers:Driver:Track:Conditions:Rear SuspensionWheelbase:LongMediumShortDate:Event:A B CRev.1Anti Roll Bar:1.5mm2.0mm2.2mmNone1234I OUniversalCVA321Anti Roll Bar:1.5mm2.0mm2.2mmNoneCamber:1234I O3UniversalCVA21Camber:Ride Height:Toe:Ride Height:3 4 521Washers:Front Pulley:20T (standard)19T (overdrive)2 1Toe Block: 3+23+354321Washers:Rear Pulley:20T (standard)19T (underdrive)2 1ElectronicsMotor & Wind:Pinion:Spur Gear:Batteries:Battery Placement: Front Middle BackOtherDifferentialsFront Diff Fluid:Rear Diff Fluid:Front TiresTire:Insert:Notes:Clicker:Full Time <strong>4X4</strong>:Front ShocksSpring:Piston:Shock Fluid:Limiter:Rebound: Bladder EmulsionCompound:Wheel:Race and Vehicle CommentsQualify: Main: Finish: TQ:Comments:OtherBody Type:Body Notes:Rear TiresTire:Insert:Notes:Slipper Pad Notes:Rear ShocksSpring:Piston:Shock Fluid:Limiter:Rebound: Bladder EmulsionRadio:Throttle / Brake e.p.a:Throttle / Brake expo:Servo:Steering Expo:ESC:ESC Profile: --- --- ---Compound:Wheel:Track InfoSmooth: Bumpy: Blue Groove:Traction: High: Medium: Low:Soft Dirt: Grass: Clay: Wet:Dusty: Other::: For more setups, visit RC10.com and click on “Setup Sheets”

Front SuspensionSteeringStop Gap:Setup SheetWashers:BumpsteerWashers:00Driver:Track:Conditions:<strong>SC10</strong> <strong>4X4</strong> Standard SetupRear SuspensionWheelbase:LongMediumShortDate:Event:A B CRev.1Anti Roll Bar:1.5mm2.0mm2.2mmNoneCamber:Toe:Ride Height:3 4 5210-1271234I OWashers:Front Pulley:20T (standard)19T (overdrive)UniversalCVA3212 1Anti Roll Bar:1.5mm2.0mm2.2mmNoneCamber:Ride Height:5-1Toe Block: 3+23+34271234321I OWashers:321Rear Pulley:20T (standard)19T (underdrive)UniversalCVA2 1DifferentialsFront Diff Fluid:Rear Diff Fluid:Front TiresTire:Insert:Notes:Clicker:Full Time <strong>4X4</strong>:Race and Vehicle CommentsQualify: Main: Finish: TQ:Comments:OtherBody Type:Body Notes:Rear TiresTire:Insert:Notes:Slipper Pad Notes:Front ShocksRear ShocksSpring: Blue 4.3 lbPiston: 1.2 Spring: Blue 2.8 lbPiston: 1.2Shock Fluid: 30 wt Limiter: 0 Shock Fluid: 25 wtLimiter: 0Rebound: 1/2 Bladder Emulsion Rebound: Bladder EmulsionElectronicsMotor & Wind: 4.5Pinion: 12tSpur Gear: 62tBatteries:Battery Placement: Front Middle BackOther3000 cst3000 cstCompound:Wheel:Radio:Throttle / Brake e.p.a:Throttle / Brake expo:Servo:Steering Expo:ESC:ESC Profile: --- --- ---Compound:Wheel:Track InfoSmooth: Bumpy: Blue Groove:Traction: High: Medium: Low:Soft Dirt: Grass: Clay: Wet:Dusty: Other::: For more setups, visit RC10.com and click on “Setup Sheets”

60:: Hardware - 1:1 Scale ViewCap Head (shcs) Flat Head (fhcs) Button Head (bhcs)2.5x5mm (91159)2.5x6mm (4675)2x4mm (31510)2.5x8mm (89222)3x8mm (25201)3x4mm (91091)3x6mm (25658)3x14mm (89208)3x6mm (31531)3x8mm (89223)3x10mm (25620)3x12mm (89454)3x14mm (25190)3x16mm (89224)3x20mm (25192)BallstudsHD 6mm (91047)Ti Nitride HD 6mm (91118)HD 8mm (91048)Ti Nitride HD 8mm (91119)HD 10mm (91049)Ti Nitride HD 10mm (91120)Ball Bearings3x8mm (31532)3x14mm (25187)3x8x4mm (91002)4x8x3mm (31402)Nuts (lock/plain)3x24mm (89225)3x26mm (89226)3x28mm (89227)Shims and WashersHD 12mm (91050)Ti Nitride HD 12mm (91121)2.5x5mm Washer (91091)5x10x3mm (91156)6x12x4mm (25238)M3 Locknut (25215)M3 Alum. Locknut, Blue (31550)M3 Locknut w/Flange (25612)FT 3mm Locknuts, Blue(25392)M4 Locknut (89216)M4 Locknut w/Flange (25217)FT M4 Locknuts w/Flange,Blue (25391)M3x5.6mm Washer (89528)3x6mm Washer (91091)3x8mm Washer (89218)Rear Hub Spacer (91037)Axle Shim (91043)10x16x4mm (91157)12x18x4mm (91155)Thrust Washer (91090)

Setup SheetFront SuspensionSteeringWashers:Stop Gap:BumpsteerWashers:Driver:Track:Conditions:Rear SuspensionWheelbase:LongMediumShortDate:Event:ABCRev.1Anti Roll Bar:1.5mm2.0mm2.2mmNone1234I OUniversalCVA321Anti Roll Bar:1.5mm2.0mm2.2mmNoneCamber:12 3 4I O3UniversalCVA21Camber:Ride Height:Toe:Ride Height:3 4 521Washers:Front Pulley:20T (standard)19T (overdrive)2 1Toe Block: 3+23+354321Washers:Rear Pulley:20T (standard)19T (underdrive)2 1Clicker:Slipper Pad Notes:Full Time <strong>4X4</strong>:Front ShocksRear ShocksSpring:Piston:Spring:Piston:Shock Fluid:Limiter:Shock Fluid:Limiter:Rebound: Bladder EmulsionRebound: Bladder EmulsionElectronicsMotor & Wind:Radio:Pinion:Throttle / Brake e.p.a:Spur Gear:Throttle / Brake expo:Batteries:Servo:Steering Expo:Battery Placement: Front Middle BackESC:OtherESC Profile: --- --- ---DifferentialsFront Diff Fluid:OtherBody Type:Rear Diff Fluid:Body Notes:Front TiresRear TiresTire:Compound:Tire:Compound:Insert:Wheel:Insert:Wheel:Notes:Notes:Race and Vehicle CommentsTrack InfoQualify: Main: Finish: TQ:Smooth: Bumpy: Blue Groove:Comments:Traction: High: Medium: Low:Soft Dirt: Grass: Clay: Wet:Dusty:Other::: For more setups, visit RC10.com and click on “Setup Sheets”

Associated Electrics, Inc.26021 Commercentre Dr.Lake Forest, CA 92630 USAhttp://www.TeamAssociated.comhttp://www.RC10.comhttp://twitter/Team_Associatedhttp://bit.ly/AEonFacebookcall: (949) 544-7500 - fax: (949) 544-7501Check out the following web sites for all of our kits,current products, new releases, setup help, tips, and racing info!www.TeamAssociated.com. - www.RC10.com