Construction Construction - Engineering News-Record - McGraw ...

Construction Construction - Engineering News-Record - McGraw ...

Construction Construction - Engineering News-Record - McGraw ...

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

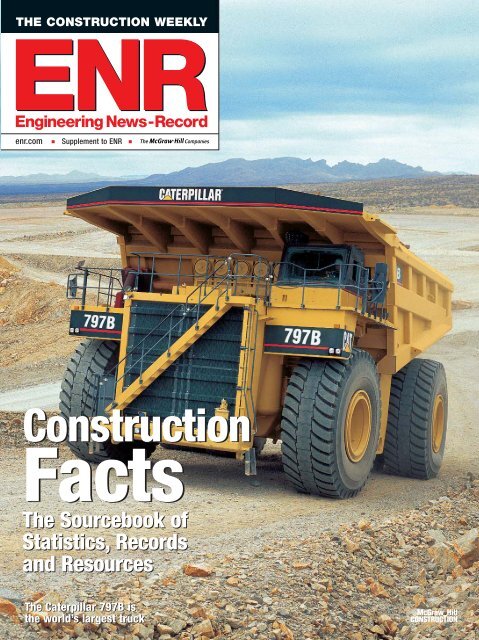

TRUCK World’s Largest TruckCaterpillar 797BMANUFACTURERCaterpillar Inc.MODEL797BWHERE MANUFACTUREDDecatur, Illinois, U.S.A.YEAR INTRODUCED2002 (Previous version 797, 1998)WORKING WEIGHT1,375,000 lbPAYLOAD380 tonsHORSEPOWER3,370 hpOVERALL LENGTH47 ft, 8 in.OVERALL WIDTH32 ft, 0 in.OVERALL HEIGHT24 ft, 11 in.TIRE DIAMETER13 ft, 6 in.TOP SPEED42 mphPRICE (U.S.$)$5,750,000NOTEWorld’s largest and heaviest mechanical-drive truck.Used in largest surface mines to haul ore and rock.2004 CONSTRUCTION FACTS 7

<strong>Record</strong>sEXCAVATOR World’s Largest Hydraulic ExcavatorTerex RH-400MANUFACTURERTerex Mining (Formerly O&K)MODELRH-400WHERE MANUFACTUREDDortmund, GermanyYEAR INTRODUCED1997WORKING WEIGHT1,000 tonsSHOVEL CAPACITY57 cu yd or 93 tonsHYDRAULIC PRESSURE5,220 psiOVERALL LENGTH55 ft, 0 in.OVERALL WIDTH32 ft, 1 in.OVERALL HEIGHT34 ft, 0 in.PRICE (U.S.$)$11,000,000 U.S.NOTEUsed in the largest surface mines. Only six built.HORSEPOWER4,400 hp (Two Cummins engines)8 CONSTRUCTION FACTS 2004

CABLE SHOVEL World’s Largest Cable ShovelP&H 4100XPBMANUFACTURERP&H Mining EquipmentMODEL4100XPBWHERE MANUFACTUREDMilwaukee, Wisconsin, U.S.A.YEAR INTRODUCED1999 (Previous version 4100A, 1990)WORKING WEIGHT1,517 tonsSHOVEL CAPACITYMaximum 82 cu yd or 100 tons (Range 67-82 cu yd depending on material)HORSEPOWER4,555 hp (Six DC electric motors—hoist, swing and crowd)OVERALL LENGTH95 ft, 6 in.OVERALL WIDTH47 ft, 1 in.OVERALL HEIGHT69 ft, 0 in.MAXIMUM CUTTING HEIGHT59 ft, 3 in.PRICE (U.S.$)$12,000,000NOTELarger cable shovels were the giant stripping shovelsof the Midwest coal mines. Largest of these (nowscrapped) was “The Captain,” a Marion 6360 shovelwith 180 cu yd capacity.2004 CONSTRUCTION FACTS 9

<strong>Record</strong>sWHEEL LOADER World’s Largest Wheel LoaderLeTourneau L-2350MANUFACTURERLeTourneau Inc.MODELL-2350WHERE MANUFACTUREDLongview, Texas, U.S.A.YEAR INTRODUCED2000WORKING WEIGHT578,000 lbBUCKET CAPACITY57 cu yd or 80 tonsHORSEPOWER2,300 hpOVERALL LENGTH64 ft, 8 inOVERALL WIDTH22 ft, 4 in.OVERALL HEIGHT21 ft, 0 in.TIRE DIAMETER12 ft, 6 in.TOP SPEED10.5 mphPRICE (U.S.$)$5,250,000NOTEDiesel-electric drive with DC electricmotors in each wheel.10 CONSTRUCTION FACTS 2004

<strong>Record</strong>sSCRAPER World’s Largest ScraperCaterpillar 657EMANUFACTURERCaterpillar Inc.MODEL657EWHERE MANUFACTUREDDecatur, Illinois, U.S.A.YEAR INTRODUCED1984 (Previous version 657B, 1969)WORKING WEIGHT152,290 lbBOWL CAPACITY44 cu yd (heaped)GROSS VEHICLE WEIGHT256,290 lb (loaded)OVERALL LENGTH53 ft, 1 in.OVERALL WIDTH14 ft, 3 in.OVERALL HEIGHT15 ft, 5 in.TOP SPEED31 mphPRICE (U.S.$)$1,400,000NOTEScrapers larger than the 657E were built byLeTourneau in the 1960s, but as experimentalmodels. Largest of these was the LT-360 at 216cu yd capacity.HORSEPOWER1,045 hp (605 hp front, 440 hp rear)12 CONSTRUCTION FACTS 2004

<strong>Record</strong>sPAVER World’s Largest Asphalt PaverABG Titan 525MANUFACTURERAllgemeine Baumaschinen-Gesellschaft MBHMAXIMUM PAVING WIDTH52 ft 10 in.1MODELTitan 525WHERE MANUFACTUREDHameln, GermanyYEAR INTRODUCED2002WORKING WEIGHT65,000 lbMAXIMUM PAVING THICKNESS19 in.LAYDOWN RATE1,650 tons/hourTRANSPORT SPEED2.24 mphPRICE (U.S.$)$849,000HORSEPOWER352 hpHOPPER CAPACITY17.5 tons14 CONSTRUCTION FACTS 2004

GRADER World’s Largest GraderCaterpillar 24HMANUFACTURERCaterpillar Inc.MODEL24HWHERE MANUFACTUREDDecatur, Illinois, U.S.A.YEAR INTRODUCED1996WORKING WEIGHT136,611 lbHORSEPOWER500 hpLENGTH OF BLADE (MOLDBOARD)24 ftOVERALL LENGTH51 ft, 10 in.OVERALL WIDTH13 ft, 10 in.OVERALL HEIGHT14 ft 3 in.TOP SPEED23.4 mphPRICE (U.S.$)$1,900,000NOTEGraders larger than the 24H were built in the pastbut no longer are available. The largest grader everconstructed was a one-of-a-kind monster built byItalian contractor Umberto Acco in 1980. It hadengines front and rear with 1,700 total hp.2004 CONSTRUCTION FACTS 15

<strong>Record</strong>sTOWER CRANE World’s Largest Tower CraneKroll 10000MANUFACTURERKrøll Cranes A/SMODELK-10000WHERE MANUFACTUREDCopenhagen, DenmarkYEAR INTRODUCED1978MAXIMUM LIFT CAPACITY264 tons @ 144-ft radiusLOAD AT MAXIMUM REACH103 tons @ 328-ft radiusMAXIMUM HEIGHT UNDER HOOK311 ft, 8 in.OVERALL HEIGHT393 ft, 8 in.MAIN TOWER DIMENSION28-ft squareSERVICE CRANE ATOP MAIN CRANE6.6 tons @ 66-ft radiusPRICE (U.S.$)$9,000,000NOTEUsed in specialized lifting applications,such as powerplant construction.Only 15 made to date.16 CONSTRUCTION FACTS 2004

<strong>Record</strong>sCRANE World’s Largest Lattice-Boom Crawler CraneLampson LTL-2600MANUFACTURERNeil F. Lampson Inc.MODELLTL-2600WHERE MANUFACTUREDKennewick, Washington,U.S.A.YEAR INTRODUCED1994LIFT CAPACITY1,543 tons @ 164-ftradius with 341-ft boom300 tons @ 459-ft radiuswith 459-ft boomHEIGHT TO BOOM TIP402 ft, 6in. with 459-ftboomOVERALL HEIGHT393 ft, 8 in.WORKING WEIGHT1,322 tons withoutcounterweight2,425 tons to 3,086 tonswith counterweightsHORSEPOWER3,400 hpPRICE (U.S.$)$14,000,000NOTECrane takes 90 truckloads to transport.Contains 9.46 miles of1-in.-diameter wire rope.18 CONSTRUCTION FACTS 2004

<strong>Record</strong>sCRANE World’s Largest Telescopic-Boom Truck CraneLiebherr LTM-1800MANUFACTURERLiebherr-Werk Ehingen GMbHMODELLTM-1800WHERE MANUFACTUREDEhingen, GermanyYEAR INTRODUCED1988MAXIMUM LIFT CAPACITY875 tons @ 10-ft radius(basic boom and 176-ton counterweight)1,000 tons with derrick attachmentand maximum 264-ton counterweightMAXIMUM LIFT HEIGHT WITH LATTICE JIB EXTENSION479 ftMAXIMUM REACH WITH LATTICE JIB EXTENSION413 ftWORKING WEIGHT177 tons without counterweightHORSEPOWERTotal 978 hp (408 hp crane, 570 hp carrier)NOTECarrier has 16 wheels—8 driven, 12 steered. Fortransport, boom is carried on separate vehicle.MAXIMUM BASIC BOOM LENGTH FULLY EXTENDED197 ft20 CONSTRUCTION FACTS 2004

<strong>Record</strong>sTUNNELING World’s Largest Tunnel-Boring MachineBENTON’AIR Slurry MachineMANUFACTURERNFM TechnologiesMODELBENTON’AIR pressurized slurry TBMWHERE MANUFACTUREDLe Creusot, Burgundy, FranceYEAR INTRODUCED2001CUTTING HEAD DIAMETER14.87 mCUTTER HEAD HORSEPOWER4,691CUTTER HEAD WEIGHT357 tonsTOTAL SHIPPING WEIGHT3,416 tonsEARTHMOVING CAPACITYSlurry flow 216 cu m per hourMOST SUBSURFACE MATERIAL EXCAVATED IN 24 HOURS5,200 cu mTOTAL VOLUME EXCAVATED AT GREEN HEART TUNNEL2,865,000 tonsNUMBER OF WORKERS NEEDED TO OPERATE IT12 including maintenance staffTOTAL LENGTH OF BACKUP108 mNOTEThis machine was first used to bore the Green HeartTunnel, a high-speed rail tunnel in the Netherlands.Upon completion of the bore in Dec. 2003, it was dismantledand shipped by freighter to China, where itpresently is boring two 1,200 m tunnels in Shanghai.2004 CONSTRUCTION FACTS 21

PeopleINNOVATORS Notable Equipment Innovators<strong>Construction</strong> would be less safe, productive and economical without today's machines that dig earth, bore tunnels, lift steel, pave roads and pour concrete. Over theyears, the cast of forward-thinkers who invented, researched, developed and promoted heavy equipment have played a key role in the evolution of modern construction.William S. Otis ––––––––– (1813-1839)William Smith Otis of Canton, Mass., wasthe inventor of the first steam-poweredexcavator. As a 22-year-old partner in thecontracting firm of Carmichael, Fairbanks& Otis, he saw the need for mechanizedearthmoving on his firm’s railroad contracts.In 1835, he designed and built theshovel that is recognized as the grandfather of all constructionmachines. Unfortunately, he met an untimelydeath in 1839 when he succumbed to typhoid fever, buthis family and partners meticulously maintained thepatents for almost 40 years. When the patents ran out inthe 1880s, other companies began building Otis-styledshovels, which became known as “railroad shovels.”These companies laid the foundations for today’s moderncable excavators.Simon Ingersoll –––––––– (1818-1894)The introduction of the first steam-powered rock drill in1871 by Simon Ingersoll marked the beginning of significantchanges for construction. A founding father of today'sIngersoll-Rand Co., Ingersoll developed a drill that was tripod-mounted,required less set-up effort and was fasterand longer lasting than conventional equipment. Contractorssoon discovered that they could significantly increasethe productivity of workers who previously were usingcumbersome machines that drilled an average depth ofonly 8 to 10 ft per day. Today’s rock drills incorporate Ingersoll’sinnovations and can be found on most major constructionand excavation sites around the world.Thomas Aveling –––––––– (1818-1894)After watching laborers manhandle a concrete-filled ironcylinder to compact stone into a smooth road surface inRochester, England, Thomas Aveling conceived the idea ofusing a steam traction engine to replace the manpower. In1865, he built the first of several experimental rollers and,in 1867, produced what is regarded as the world’s firstcommercially successful steam roller. This was an instantsuccess and allowed his company, Aveling & Porter, todevelop a multitude of self-propelled roller types. In theearly years, a large portion of the machines were exported,including the first two steam rollers ever to work in theU.S. in 1869. As Aveling-Barford Ltd. from 1930, the companyexpanded into diesel and gasoline-powered rollersand, keeping pace with modern technology, in the 1960sand 1970s moved into vibrating and rubber-tired rollers.Daniel Best ––––––––––– (1838–1923)In 1871, Daniel Best pioneered a graincleaning machine and in 1885 startedbuilding combine harvesters, initiallypulled by horses and later by steam tractionengines built by his company. In 1908,Best sold his traction engine business toHolt Manufacturing Co.,DANIEL BESTwhich had pioneeredcrawler tracks on a steam tractor in 1904.Daniel’s son, C.L. Best, was made managerof Holt’s San Leandro, Calif., plant.After a disagreement, C.L. left to found hisC.L. BESTown company C.L. Best Gas Traction Co.in 1910. Both Holt and Best prospered incompetition with each other until 1925 when they finallymerged and the Caterpillar Tractor Co. was born. C.L.Best’s well-designed and robust crawler tractors, includingthe famous SIXTY of which almost 19,000 were sold,became well-respected Caterpillar products.Benjamin Whitaker Jr. ––– (1849-1919)Matthew Whitaker –––––– (1852-1931)Samuel Whitaker ––––––– (1845-1914)Founded by their father, Benjamin Whitaker, the companythat became known as Whitaker Brothers in 1872 iscredited with inventing the first successful fully-revolvingsteam shovel. Originally quarry owners and brick makersnear Leeds, England, the three brothers—Benjamin Jr.,Matthew and Samuel—wanted to load rail wagons directlybehind the rail-mounted shovels of the day. So, in1884, they attached a shovel boom and dipper stick to amodified revolving rail-mounted crane and eliminated theneed to build parallel tracks alongside the shovel. Themachine attracted immediate attention and over the nexttwo decades, steam shovels of all sizes up to 3 cu ydwere built and shipped, many overseas. In 1910, thecompany was sold to Ruston, Proctor & Co., forerunnerof Ruston-Bucyrus Ltd.Benjamin Holt ––––––––– (1849-1920)From his roots as the founder of a wood-and-iron-wheelmaking company in 1883 in Stockton, Calif., and as one ofthe three principals of the Holt Brothers lumber mill, BenjaminHolt grew a booming steam-engine business. One ofhis later engines was quite successful in logging and in theexport markets of Australia, Kenya and South Africa. But2004 CONSTRUCTION FACTS 23

Notable Equipment InnovatorsPeopletractor wheels often became mired in softearth, so Holt in 1904 replaced them witha track-type tread. The tread became popularworldwide, and Holt Manufacturingeventually became Caterpillar Inc., theworld's largest heavy equipment maker.Richard Russell –––––––– (1850-1917)Richard Russell and his partner, C.K. Stockland, in 1903established the Russell Grader Manufacturing Co. inStephen, Minn., putting in motion a company that eventuallywould establish Caterpillar in the grader business.One of the first Russell products was a horse-drawn elevatinggrader with a gas-engine driven conveyor. Otherproducts developed by Russell included blade graders,drag and wheel scrapers and plows. A prototype selfpropelledgrader appeared in 1919. Russell’s successfulgrader designs attracted the attention of Caterpillar TractorCo. and it took over the Russell company in 1928.This marked the first of many diversifications by Caterpillarto build products other than crawler tractors andthe original Russell designs formed the basis of subsequentCaterpillar graders.William Dana Ewart ––––– (1851-1908)A young farm implement dealer in BellePlaine, Iowa, William Ewart invented the“linked belt” in 1874 and forever changedthe mobility of heavy equipment. Ewart’sinvention was a square-shaped, detachablelink for chain belts that was easier torepair in the field than existing chains andeventually became the standard for modern mechanicalpower transmission. Ewart founded the Link-Belt MachineryCo. in 1880 and Link-Belt <strong>Engineering</strong> Co. in 1888.Ten years later, the two fledgling firms developed the firstwide-gauge, steam-powered, coal-handling clamshellcrane, the ancestral lifting equipment of today’s Link-Belt<strong>Construction</strong> Equipment Co.Link to Past. Link-Belt machine was first steam-driven clamshell crane.Joseph D. Adams –––––– (1853-1924)Joseph Adams found fame with his innovations ingraders. His experience with road maintenance in the1870s as a township trustee near Indianapolis, Ind.,motivated him to design a new type of grader withadjustable leaning wheels to offset the side force producedby the angled blade. It also enabled the grader towork on slopes previously impossiblewith straight-wheeled machines. Firstpulled by horses and later by steam tractors,Adams’ graders were widely used tomaintain the thousands of graveledroads across America. Eventually, allgrader manufacturers adopted the leaning-wheelprinciple. Adams further refined the grader anddeveloped self-propelled models and power-operatedblade controls. In 1954, the J.D. Adams Co. was purchasedby LeTourneau-Westinghouse Co. (later Wabco),which continued graders in its product line.Chester T. Foote ––––––– (1858-1938)Charles E. Foote ––––––– (1863-1918)Brothers Chester and Charles Foote were concrete contractorsin Nunda, N.Y. In 1896 they built a hand-operated,revolving-drum machine that produced about 4 cu yd ofconcrete per hour. It was not the first hand mixer on themarket, but the Footes continued to experiment with mixersand gasoline engines. Their first power mixer was usedto lay several thousand feet of concrete sidewalks in Perry,N.Y. in 1900. Three years later, they formed the FooteManufacturing Co. and soon were shipping machinesacross the U.S. The firm later developed a self-propelledmixer-paver and the first high-lift boom for pouring concreteup to 23 ft above the ground. The Multi-Foote 34Emixer was the standard paver used by the Army Corps ofEngineers during World War II. In 1948, the Foote Co. waspurchased by Blaw Knox.George A. Armington Sr. – (1865–1954)Raymond Q. Armington –– (1907-1993)The Armington family is synonymous with the name Euclid,pioneer in 1934 of the first truck designed specifically foroff-highway use. In 1909, George Armington Sr. establishedthe Euclid Crane & Hoist Co. near Cleveland, Ohio,initially building towed scrapers and wagons. All five of hissons played important roles in the company, but Raymondwas most influential in transforming it into an earthmovingequipment builder. Renamed the Euclid Road MachineryCo. in 1931, Euclid went on to develop all types of haulers,2004 CONSTRUCTION FACTS 25

PeopleNotable Equipment Innovatorsdozers and scrapers for high-speed earthmoving, includingmotor scrapers from 1938. By the early 1950s, theEuclid name was known worldwide as a builder of theworld’s most powerful trucks. The company became theEuclid Division of General Motors in 1954.William H. Coleman –––– (1873–1964)After an early career as an engineer and metallurgist,William H. Coleman joined steam-shovel and dredgebuilder Bucyrus Co. in 1905 as foundry superintendent.By 1910, he was in charge of engineering, manufacturingand sales promotion, and he rose to president in1911. Under his direction, the company attained worldleadership in the crane and excavating machinery manufacturingbusiness, taking over the Erie Steam ShovelCo. in 1927 and becoming Bucyrus-Erie. Coleman andhis team of engineers are credited with many innovationsin the excavating field, including the first crawlermountedexcavator (1912), the first quarry and mineshovel (1925) and the world’s largest shovel (1962). Heserved the company for 60 years, 46 of which he waschairman and president.Charles Johnson ––––––– (1877-1941)To feed the voracious demand for low-cost concrete tobuild Hoover Dam, Charles Johnson developed the firstautomatic, mass-production concrete plant. <strong>Construction</strong>began in 1931 on the four-story, 78 x 118-ft steelframestructure. When completed, it provided all of theconcrete for the diversion-tunnel linings, powerhousefoundations and two-thirds of the dam. The system featureda hopper, scale system and tilting mixer. With eightbatchers, it mixed more than 4 million cu yd and set thebenchmark for dam-site batch plants. Johnson alsopatented several pieces of aggregate-storing and batchingequipment for highway construction use.Harry H. Barber –––––––– (1878-1948)In 1916, Harry H. Barber and William B.Green quit working at a machine manufacturingcompany to co-found Barber-Green Co. to design and build standardizedmaterial-handling equipment. In1931, Barber introduced the firstmachine to combine the mixing andplacing of asphalt pavement in a single operation. Withthis development, paving secondary roads with hot-mixasphalt became economical. Barber received 70 patentsfor construction and material-handling equipment. Until1945, he served as president of Barber-Green. Caterpillarbought the firm in 1991 and continues to make Barber-Greenbrand machines.Stephen Stepanian ––––– (1882-1964)While working for a sand-and-gravelcompany in 1916, Stephen Stepaniandesigned and patented a rotating drumthat could efficiently transport mixed concrete.His design led to the introduction ofthe first concrete-mix trucks in the 1920sand the start of the ready-mixed concreteindustry. Today, there are about 80,000 ready-mix concretetrucks in use in the U.S. Stepanian stayed heavilyinvolved in the industry, including being part owner ofColumbus, Ohio-based Arrow Sand and Gravel Co. Heserved as president of the National Ready Mixed ConcreteAssociation in 1943-44.R.G. LeTourneau ––––––– (1888-1969)Robert Gilmore LeTourneau’s influenceon the earthmoving equipment industry issecond to none. With more than 200patents to his credit, he built the first allweldedscraper, the first tractor-mountedcable winch, the first self-propelledscraper and the first skid-steer tractor. Healso was responsible for developing the sheepsfoot roller,tractor-drawn ripper and mobile crane. LeTourneaudesigned a single machine that would build an entire concretehouse and he built one of the first offshore jack-upoil-drilling platforms, now used extensively in the oilindustry. Letourneau also pioneered the electric wheel,used today in large off-highway trucks. Devoutly religious,he gave away 90% of his earnings for Christian missionarywork and founded LeTourneau University inLongview, Texas. Today, the company that bears hisname builds the world’s largest wheel loader.Frank G. Hough –––––––– (1890-1965)Frank G. Hough’s name is synonymous with the wheeledloader. As early as 1920, he mounted a cable-operatedloader on a farm tractor. But it is Hough’s model HSwheel loader of 1939, designed and built solely for thepurpose, that is regarded as the forerunner of the modernwheel loader. Under his leadership, the Frank G.Hough Co. claimed a long line of achievements in loaderdesign, including the first hydraulic-lift arms (1941), firsthydraulic-bucket tilt (1944) and first four-wheel-driveloader (1947). Hough sold his company and the HoughPayloader name to International Harvester in 1952.Howard Hall –––––––––– (1894-1971)While serving as president of Iowa Steel and Iron, Hallpurchased Bertschy <strong>Engineering</strong> Co. in 1923, thus forgingIowa Manufacturing Co. Less than one year later, Hall26 CONSTRUCTION FACTS 2004

had led the development of the first portable rock crusher.The concept combined the processes of crushing,conveying and screening aggregate into one machine.For the first time, a contractor could move a so-called“one-piece outfit” on and off of a jobsite without loss oftime and profit. Hall’s innovative approach also provideda solution to military forces. His machine could be hauledfrom project to project at speeds up to 50 mph for constructionof airfield landing strips and roads wherevertroops needed them.Ray Ferwerda ––––––––– (1899-1978)Koop Ferwerda –––––––– (1900-1955)The unique machine known as theGradall traces its roots back to the early1940s and brothers Ray and Koop Ferwerda,partners in a Cleveland, Ohio, constructioncompany. With a need to finegrade steep slopes on road construction—ajob normally done by hand, theyKOOP FERWERDAinvented a fully-hydraulic truck-mounted telescopicboom with a fixed blade at the end to smooth the dirt atany angle. Improving on the design, they added tilt andwrist motions and a bucket, allowing the machine tosimulate human hand movements. Patented in 1944, theFerwerdas’ machine became the world’s first hydraulicexcavator. Warner & Swasey, Cleveland, purchased therights to manufacture the machine in 1945 and introducedits first Gradall the following year. Today, Gradallis owned by JLG Industries and survives as one of thevery few excavator manufacturers with a pure Americanheritage.Ralph Kress –––––––––– (1904-1995)Dubbed “the father of America’s offhighwaytruck,” Ralph Kress influencedthe modern mining truck more than anyother person. After an early career inautomotive sales and highway vehicledesign with Dodge, Borg Warner,Chevrolet and General Motors, Kresswas appointed general manager of Dart trucks in 1950.He designed the world’s largest truck in 1951, a Dart75-tonner. He then designed a revolutionary new truckfor Wabco in 1957 featuring an offset cab and V-shaped body, a style that has remained unchangedtoday. He designed Caterpillar trucks from 1962 and in1969 joined his son Ted’s company, Kress Corp., Brimfield,Ill. There, he introduced the world to his rigidframebottom-dumping coal hauler, which still is beingmanufactured.Clarence E. Killebrew –––––––– (1912-)Armed with a mechanical engineering degree and sixyears of teaching experience, Clarence E. Killebrew in1940 joined the Frank G. Hough Co., where he spent 12years developing the first wheel loader used in agriculture,and later the first in the construction industry. Hejoined Clark Equipment Co. in 1952 and within a yearintroduced the first loaders with hydraulic torque converters,power shift transmissions and planetary axles.As a corporate director and vice president of engineering,his team’s machine was the first designed as a truewheel loader, rather than a modified farm tractor. It hadcapacities three to four times greater than conventionalmachines.Hans Liebherr ––––––––– (1915-1993)While running the family constructionbusiness in Kirchdorf, Germany, in thelate 1940s, Hans Liebherr developed anidea for an easy-to-erect, low-priced towercrane. By 1949, the crane proved asuccess and the Liebherr companychanged from a builder to a manufacturer.In 1954, Liebherr unveiled his first hydraulic excavator.Expansion was rapid, with the firm establishing newmanufacturing facilities in many countries over the followingtwo decades, including Newport <strong>News</strong>, Va., in1972. Liebherr today has over 90 subsidiary companiesworldwide and over 21,000 employees. Today’s productline for construction includes all types of cranes,hydraulic excavators, crawler tractors and loaders, wheelloaders, concrete mixers and plants and a line of electricdrivemining trucks that includes the world’s largest at400-ton capacity.Joseph Cyril Bamford ––– (1916-2001)J.C. Bamford, founder of the companyknown worldwide by his initials, madehis very first product—a farm trailer—ina rented garage at Uttoxeter, England.From that meager beginning in 1945,Bamford steadily expanded his businessand developed a bolt-on hydraulicloader for farm tractors in 1948. Five years later, hedeveloped a backhoe attachment called the JCB Mk.1and promoted selling tractors equipped with bothattachments. In 1956, the company launched the firstloader-backhoe built as an integrated unit, the Hydra-Digger-Loadall. Today, JCB is one of the world’s largestand most successful construction equipment manufacturers,with over 180 current models available in 11product groups.2004 CONSTRUCTION FACTS 27

PeopleNotable Equipment InnovatorsNeil F. Lampson –––––––– (1917-1996)Innovations in heavy lifting equipmentbrought fame to Neil F. Lampson afterestablishing his crane venture in 1946 atKennewick, Wash. Starting with a singlecrane, Lampson soon gained a reputationfor service and ingenuity. When the world’scrane manufacturers could not provide himwith lift capacities to meet his needs, he built his ownequipment. In 1967, Lampson conceived a crawler transporterfor oversized loads and in 1971 developed a heavyliftcrawler crane called the Transi-Lift. In 1980, Neil’s sonBill took over the business and boosted the company internationally.Under his leadership, the company has continuedto grow, with crawler transport capabilities increasingto 4,000 tons and Transi-Lift capacities to 2,600 tons. It nowis the world’s largest-capacity land-based crane.John L. Grove ––––––––– (1921-2003)Most innovators have a major brand ofconstruction equipment named afterthem, but John Landis Grove has two. In1947, Grove, his brother Dwight and partnerWayne Nicarry established GroveManufacturing Co. in the village of ShadyGrove, Pa. A manufacturer of farm wagons,Grove needed a small yard-type crane to lift steelplates. After an unsuccessful search, he finally built hisown in 1949. The 2-ton capacity crane was mounted ona three-wheel frame with a simple twin-cylinder hydraulichoist. By 1955, Grove was supplying cranes to dozens ofneighboring businesses. Over the next 12 years, Grovegrew his company into one of the largest crane manufacturersin the world. He sold it in 1967 and in 1969 purchasedFulton Industries with partner Paul Shockey.Grove renamed the company to JLG Industries, reflectinghis initials, and became known as the father of theelevating work platform. Grove Worldwide was acquiredin 2002 by Manitowoc Co. Inc. JLG, whichalso owns the Gradall,Skytrak and Lullbrands, still is theworld’s largestmanufacturer ofself-propelled aerialwork platforms.Elton Long ––––––––––– (1921-2003)As assistant design engineer at American Tractor Corp.(ATC), Churubusco, Ind., Elton Long was instrumentalin designing a hydraulic backhoe to be on an agriculturaltractor. When Case took over ATC in 1957, itacquired the backhoe rights and madeLong chief engineer. An ideal tractor forthe backhoe had not yet been found, soa prototype machine was built around amodified Case 300 farm tractor. It incorporatedthe Case loader and the ATCbackhoe. Case launched this innovativemachine in 1957 as America’s first loader-backhoe.Designed by Long, it was known as the Model 320.Long later went on to design the famous Case 580<strong>Construction</strong> King, the machine that made Case theloader-backhoe market leader in the 1960s and 1970sin the U.S.Edwin Malzahn –––––––––––– (1921-)From its roots as Charlie’s Machine Shop,a small firm founded by Edwin Malzahn’sfather, Charles Machine Works now is aworldwide company because of Malzahn’sinvention of the first compacttrenching machine. Replacing pick-andshovellabor, the Ditch Witch revolutionizedutility trenching. It was able to dig where large,wheel-type service trenchers were impractical. Small,in-line, portable and mobile trenchers have played amajor role in the way the world’s utility companies placeservice lines.Cyril Keller ––––––––––––––– (1922-)Louis Keller –––––––––––––– (1923-)Brothers Cyril and Louis Keller are credited with inventingthe skid-steer compact loader. They first built a smallthree-wheel loader for cleaning out turkey barns. It featureda single caster rear wheel and steered by independentdrive to the two front wheels. In 1957, the machinecaught the eye of the Melroe brothers of the Melroe Man-Trailblazers. Cyril (left) and Louis Keller launched skid steers in 1950s.28 CONSTRUCTION FACTS 2004

ufacturing Co., Gwinner, N.D. They immediately saw theloader’s potential, purchased the manufacturing rightsand hired the Kellers to develop the machine. Theimproved M-200 was introduced in 1958 as Melroe’s firstbranded loader. In 1960, the three-wheel design wasreplaced by a four-wheel-drive loader utilizing the skidsteerprinciple and a new class of compact equipmentwas born. In 2001, the 500,000th Bobcat skid-steerloader rolled out of the Gwinner plant.Raymond F. Pitman ––––––––– (1925-)Called the “father” of the boom truck,Ray Pitman put a crane behind the cab ofa flatbed and made the delivery of constructionmaterials a safer, one-personoperation. A World War II Army veteranand former utility contractor in Olathe,Kan., Pitman in 1964 founded RO ProductsInc., a prolific boom-truck firm that eventually wassold to Terex Corp. Pitman’s early work coincided withRoy O. Billings of Milwaukee and his “Hydro-Crane,”which did not carry a payload but was so popular thatBucyrus-Erie Co. bought the design in 1948. From Pitman’sthink tank of “envisioneers” came some of theworld’s first digger derricks, cherry pickers, fire-fightingbucket lifts and airplane de-icing machines.Picking Up. First boom trucks met a lot of practical business needs.G.W. (Bill) Swisher –––––––––– (1930-)Founder of CMI Corp., Bill Swisher hasbeen prominent in the grade-finishingand paving business since he introducedthe first automatically-controlled finegradetrimmer in 1964. Called “Autograde,”the high-production, accuratelycontrolled trimmer paved the way for aseries of automated placing and slipform concretepaving machines and automated graders. With morethan 50 patents to his credit, Swisher also developedthe first purpose-built pavement milling machines usedin road rehabilitation, a continuous excavator for largescaleearthmoving and the “Autoblade,” a large graderwith automatic control of grade elevation. Swisher’sinnovations have revolutionized concrete paving overthe past four decades and strongly influenced thedesign of today’s paving equipment.Revolutionary. Swisher was first to develop dedicated milling machine.Richard J. Robbins–––––––––– (1933-)By refining the cutting technology firstdeveloped by his father, James, RichardRobbins made mechanical rock excavationpossible and economical. His workled to the development of a range ofmechanical excavation techniques andthe tunnel boring machine. A TBM typicallyallows an entire cross section of a tunnel or shaft tobe bored in a single continuous process. Because of itsdevelopment, underground construction and tunnelinghave become more efficient, cost-effective and safe.Reinhard Wirtgen ––––––– (1943-1997)Originally a road contractor in Germany,Wirtgen in 1965 built his first concretebreakingmachine as a cost-effectivealternative to the demolition ball. Hiseponymous company in 1971 developedthe first hot-milling machine for removingasphalt pavement and in 1976 developedthe first hot recycler for insitu re-profiling. This laterbecame known as the “remix” process and is popular onroad construction and maintenance worldwide. In 1977,Wirtgen began focusing on developing and manufacturingspecialized paving machines and in 1978 developeda cold-milling process for pavements. The firm’s contractingactivities were liquidated in 1981, and WirtgenAmerica Inc. today is a subsidiary of Wirtgen GmbH andis a leading road and mining equipment manufacturer.2004 CONSTRUCTION FACTS 29

PeopleNotable Equipment InnovatorsKeith Haddock, who wrote many of the profiles of equipmentinnovators on the preceding pages, and Tudor Hampton, whoobtained many of the photos, received assistance from manycompanies, archives and individuals. Our thanks to:Association of Equipment ManufacturersBobcat Co.Case <strong>Construction</strong> Equipment LLCInstitution of Civil EngineersJLG Industries Inc.Link-Belt <strong>Construction</strong> Equipment Co.Manitowoc Crane Group Inc.Minnesota Historical SocietyTerex Corp.Bruce Bernard, Coneco Equipment Co.Tom Berry, Historical <strong>Construction</strong> Equipment AssociationBen Brooks, JCB Sales Ltd.Wolfgang EsbruchClaudia Fernus, Wirtgen Group GmbHRay Ferwerda Sr.Antonia Harland-Lang, Leeds Archives, EnglandWilliam Hindman and Jim Jobes, Industrial Marketing ServicesSharon Holling, Caterpillar Inc.Ray Hooley, Lincoln, EnglandMerilee Hunt, Liebherr AmericaBill Koehn, North American <strong>Construction</strong>Michele Lefevre, Local Studies, Leeds, EnglandParker McLean, Alberta Fuel Distributors Inc.David Monroe, Caterpillar Inc.Lee Nehring, Albian Sands/ShellEric C. Orlemann, ECO Industrial CommunicationsBryan F. Pepin-Donat, Lampson CraneDarrol Pierson, Indiana State LibraryRay Pitman, Pitman ManufacturingRandy Provencal, Syncrude Canada. Ltd.Janet Ragland, LeTourneau UniversityAmber Reid, Two Rivers Marketing GroupMarc Schulte, Finning Canada Ltd.Lawrence Sunsdahl, Minnesota historianNicole Thaxton, Caterpillar Inc. corporate archivesJack Toll, MammoetPatty Traverso, Kennecott EnergyTim Twichell, Gowanda, N.Y.PHOTO CREDITSPage 23Photo of William S. Otis, courtesy of the Historical<strong>Construction</strong> Equipment Association. Photos of C.L.and Daniel Best, courtesy of Caterpillar Inc. corporatearchives.Page 25Photo of Benjamin Holt, courtesy of Caterpillar Inc.corporate archives. Photo of William D. Ewart andequipment, courtesy of Link-Belt <strong>Construction</strong>Equipment Co. Photo of Joseph D. Adams, courtesyof Indiana State Library.Page 26Photo of Harry Barber, courtesy of AEM. Photo ofR.G. LeTourneau by Keith Haddock.Page 27Photo of Koop Ferwerda, courtesy of the Ferwerdafamily. Photo of Ralph Kress, courtesy of Historical<strong>Construction</strong> Equipment Association. Photo of HansLiebherr, courtesy of Liebherr Group. Photo ofJoseph Cyril Bamford, courtesy of JCB Inc.Page 28Photo of Neil Lampson, courtesy of Lampson InternationalLLC. Photo of John Grove and equipment,courtesy of JLG Industries Inc. Photo of Cyril andLouis Keller, courtesy of Bobcat Co.Page 29Photo of Raymond Pitman and boom truck, courtesyof Raymond F. Pitman. Photo of G.W. (Bill) Swisherand grader, courtesy of Terex Corp. RoadbuildingArchives. Photo of Reinhard Wirtgen, courtesy ofWirtgen Group.30 CONSTRUCTION FACTS 2004

<strong>Record</strong>sMOVING Tallest Building Ever MovedThe waters off North Carolina’s Outer Banks are known asthe “Graveyard of the Atlantic,” and cover hundreds ofshipwrecks. Built in 1870, the 199-ft-high Cape HatterasLighthouse—the tallest lighthouse in the U.S.—wasdesigned to warn ships that they were approaching HatterasIsland, one of the barrier islands forming the OuterBanks. But the lighthouse also is at the mercy of the seasand encroaching waters required it to be moved in 1999.Owned by the National Park Service, the 4,400-ton lighthouseis a double-walled masonry structure with a 45-ftdiameter granite and brick base. Hatteras Island is migratingwestward and efforts to protect the lighthouse from thesea included installing sheetpile groins in the 1930s andbeach nourishment in the 1970s. But by the 1980s, erosionhad brought the high tide line almost to the lighthousebase. Engineers feared that a dropping water table woulddestabilize the tower by exposing its timber footings to rot.The relocation was performed by International ChimneyCo., Buffalo, as a design-build project. It took more than sixmonths, beginning with the clearing, grading, and compactingof the travel corridor. The foundation’s graniteplinth was cut using heavy-duty wire saws, as well ashydraulic chain saws. A series of tunnels were boredthrough the foundation and the tunnel floors were firmed upwith steel mats and timber cribbing.The process continued until the entire weight of the lighthousewas transferred to 135 shoring posts. Tilt and vibrationsensors were installed at the top and bottom of thelighthouse. Steel beams were inserted to form a 61 x 72 ftgrid. A lift system of 100 interconnected hydraulic jacksoperating in unison lifted the lighthouse 6 ft to bring thebase above grade and clear space for the rolling system.Expert House Movers, Sharptown, Md., installed thebeams and did the lifting and transportation. Pete Friesen,inventor of the jacking system, was a consultant.Beginning on June 17, 1999, five push-jacks were used2004 CONSTRUCTION FACTS 31

<strong>Record</strong>sWorld’s Tallest Building Movedto move the lighthouse in 5-ftincrements at the rate ofabout 1 ft per minute. As themoving crew gained confidence,the distance traveledeach day grew, peaking at 355ft. The 2,900-ft transportphase to the new foundationlasted 23 days. The lighthousenow is 1,600 ft from the hightideline, the same distance itwas when it was built.The sequence of removingthe roll beams and rollers andlowering the lighthouse to itsnew elevation took eight days,and was completed on July17. Bricking of the new foundationon top of the 60 x 60 x5 ft concrete footer lasted untilSeptember. The move cost$11.8 million.32 CONSTRUCTION FACTS 2004

<strong>Record</strong>sMOVING Heaviest Building Ever MovedAfval CentraleThe Afval Centrale (Waste Center) in Amsterdam is thecity’s waste processing center, a reinforced-concretebuilding 164 ft long, 104 ft wide and 65 ft high, weighing7,600 tons. Residential and commercial garbage isburned in it, generating steam, which is delivered to anearby powerplant to generate electricity. To makeroom for a new high-yield incineration plant, the wastecenter had to be moved. Mammoet, a Dutch firm specializingin heavy lifting and transport work—mostnotably the recovery of the Russian submarineKursk—got the assignment. For the first stage, Mammoetpartnered with Dutch foundation specialistBresser/Van’t Wout to excavate a 6.5-ft-deep cavityunder the building, fill it with a layer of sand and steelplates and place 35,000 cu m of concrete piles. Next,eight “trains”—lines of Scheuerle and Kamag self-propelledmodular transporters (SPMTs) hitched to eachother—were driven into position in parallel lines underthe building. The SPMTs rested on 278 axles and 1,112wheels. On Oct. 18, 2003, the machines’ hydraulicswere activated, raising the transporters’ beds intoposition and lifting the building clear of its supportpiles. Then, the SPMTs, with 2,500 hp in self-containedpowerpacks, rolled the structure at 0.6 mph to its newdestination 3,280 ft away. It traveled over a 92-ft widepath comprised of steel plates. Once in position on topof new pilings, flat jacks were installed, new permanentsupports were poured and the building was lowered.2004 CONSTRUCTION FACTS 33

<strong>Record</strong>s1970 Longest Running ProjectsThird Water TunnelNew York City’s water supply is collected in 18reservoirs and conveyed by aqueducts to two storage/balancingreservoirs. Water tunnels #1 (completed1917) and #2 (completed 1936) connect thosereservoirs with the distribution system serving 8 millionresidents. Tunnels #1 and #2 have never beenshut down and drained for inspection, as officials areunsure that their aging valves will function properly.Tunnel #3 is being driven through hard rock (gneiss,schist and limestone) with a 24-ft-dia tunnel boringmachine 200 ft to 800 ft underground. It is a branchingtunnel, with 27 miles of the 60-mile total excavatedto date. Its valves will be housed in three enormousunderground chambers, making themaccessible for repair and maintenance, unlike theolder tunnels. The largest valve chamber is 620 ftlong, 42 ft wide and 41 ft high. As each of its fourstages is completed, Tunnel #3 will provide redundancyand dependability to the water system. Tunnelcapacity will be 1.3 billion gal per day and it will costan estimated $6 billion by completion in 2020.PHOTO COURTESY OF NEW YORK CITY DEPARTMENT OF ENVIRONMENTAL PROTECTION34 CONSTRUCTION FACTS 2004

1972 Longest Running ProjectsTunnel and Reservoir PlanPHOTOS COURTESY OF MWRDGCChicago’s long-term solution tocombined sewer overflowsbegan in 1972 as the Tunnel andReservoir Plan (TARP). The massiveproject’s long list of engineeringfeats has advanced tunneldesign and excavationprocesses around the world.Known by Chicagoans as simplythe “Deep Tunnel,” the 109.4-mile dolomite labyrinth sits as faras 350 ft below the Cook Countyarea. The complex infrastructureincludes about 250 vertical dropshafts, 600 substations, threepumping stations and 15.6 billiongal of storage in three massivereservoirs. The first 31 milesof tunnels were finished in 1985 and the first reservoirwas put into service in 1998. The MetropolitanWater Reclamation District of Greater Chicago,which operates TARP, expects to finish tunnel constructionby early 2005. Work will continue on thetwo remaining reservoirs until the entire $3.4-billionsystem goes on-line. Engineers expect total projectcompletion in 2019.2004 CONSTRUCTION FACTS 35

<strong>Record</strong>s1984 Longest Running ProjectsGreat Man-Made River ProjectThis massive water transfer scheme will extract water from sandstoneaquifers deep beneath the central Libyan desert and transportit to the country’s coastal regions for urban and agriculturaluses. The project owner is the Great Man-Made River Authority.Brown & Root Ltd. (U.K.) served as the consulting engineer andconstruction manager. The general contract was awarded to theDong Ah Consortium of Korea. Dong Ah subcontracted PriceBrothers Co., Dayton, Ohio, to design the pipe factories and supplypipe-making equipment, as well as provide design and expertisefor the pipe system. The Phase One pipemaking and constructioncontracts were awarded in 1984 and totaled $3.3 billion.Phase One, involving 1,900 km of prestressed concrete piperanging from 1.6 to 4 m in diameter, was completed in 1993. DuringPhase One, the work force peaked at 8,000. Following theimposition of U.S. sanctions in 1986, Price Brothers Ltd. (U.K.)assumed sole responsibility for the company’s obligation. Two ofthe project's four phases now are completed. Phase Three wellfields and pipelines are expected to come online after 2010. Severalpipeline blowouts have occurred in recent years, which weretraced to corrosion. Phase Four is downstream work for distributionsystems and irrigation networks. The project ultimately willirrigate 387,000 acres and supply water to several major cities.The present general contractor is the Al Nahr Co. of Libya. Thefinal cost is $27 billion, with completion expected sometimebetween 2025 and 2030.36 CONSTRUCTION FACTS 2004

<strong>Record</strong>sWORK FORCE Largest Work ForcesYellow River DikesChina. The Yellow River (Huang He) is the world’s muddiestriver, packing 60 times the sediment load of theMississippi River, mostly from Shansi and Shensiprovinces. Upon reaching the plains of North China theriver deposits its load, building up the river bed six toseven meters above the level of the surrounding countryside.The floodprone region is an important agriculturalarea and has been densely inhabited for millennia.Over 1,500 floods have been recorded since 602 B.C.A 1933 flood breached dikes in 50 locations, inundatingover 3,000 villages and towns, and taking 18,000lives. In the 1950s massive efforts were launched torepair and reinforce the region’s dikes, incorporating350 million cu m of earthworks and 9 million cu m ofstoneworks. As many as two million peasants and soldierswere busy during some of the most critical periods,when floodwaters nearly overtopped the dikes. Inall, 1,800 kilometers of dikes hold the river in place, 700along the north bank, 600 along the south bank, andthe remainder along tributaries or enclosing flood diversionareas. Dozens of major hydroelectric dams on theriver’s upper stretches, as well as over 600,000 smallersilt-precipitation dams, have reduced the river’s siltload significantly.Chengtu ProjectChina. In 1944 new B-29 “Superfortress” bombers, ableto carry 20,000 lb of bombs to targets 1,500 miles fromtheir bases, arrived in the Allies’ China theater of operations.Their mission was to attack the home islands ofJapan from bases in China. A system of five bomber andsix fighter airfields with extra-long runways was builtNagarjunasagar Dambetween January and May 1944 by the Chinese nationalists,under the direction of U.S. Gen. Claire Chennault.Some 400,000 Chinese workers labored with primitivetools, using ancient methods of construction. The first raidwas launched from the bases in June, but within weeksseven of the bases were captured by the Japanese.India. The three-milelong gravity dam, with acentral masonry sectionalmost one mile longand flanked by earthand rockfill embankments,was built almostentirely by hand. It islocated on the KrishnaRiver in Andhra Pradeshstate in central India.Tower cranes were usedbut laborers carried basketsof mortar up rampssupported by bambooscaffolding. The workforce was 50,000 in1967. Two associatedaqueducts had a separatework force of80,000. The dam wasbuilt from 1955-69, andcost $194 million (ENR6/8/67 p. 44).38 CONSTRUCTION FACTS 2004

Erie CanalNew York. 1817-25. The365-mile long waterway connectingthe Hudson Riverwith Lake Erie was the majorartery linking eastern marketsto the Midwest beforerailroads. It was 40 ft wide atthe top, 28 ft at the bottom,and 4 ft deep. Eighty-threelocks lowered boats travelingwest to east 627 verticalfeet. Local farmers werecontracted to build the initialsections, but permanentwork crews developed,drawing laborers from faraway. The project sparkedinnovations, including astump-pulling machine with16-ft-dia wheels, as well asa horse-operated boomor crane. The work forcepeaked at 50,000.Clinton Engineer WorksTennessee. 1943-45. The Manhattan Projectwas the federal government’s top-secretcrash program to produce an atomic bomb.The first production complex, in Tennessee,housed a plutonium pile and separationfacility, an electromagnetic plant, and athermal diffusion plant. The work forcepeaked at 47,000. After WWII it wasrenamed the Oak Ridge National Laboratory,which now specializes in uranium andnational security research.2004 CONSTRUCTION FACTS 39

<strong>Record</strong>sLargest Work ForcesHanford Engineer WorksWashington. 1943-45. Another partof the Manhattan Project, Hanfordwas built on a 630-sq-mile site onthe Columbia River. It was a plutoniumproduction plant that includedthree nuclear reactors, two chemicalseparation areas, and a plant formaking uranium slugs and testingpile reactor materials. It included alarge construction camp at Hanford,and a town for operating personnelat Richland. The work force peakedat 50,000. But its legacy is ominous—53million gal of radioactiveand chemical wastes stored in 177aging underground tanks, requiring a$5.6-billion cleanup that is due to becompleted in 2028.Egypt. A truly multinational effort, the dam’s originaldesign was developed by the British firm Sir AlexanderGibb and Partners, with recommendations from German,French, and American experts. But the U.S. and Britainwithdrew their pledges to help finance it after Egypt concludedan arms deal with Czechoslovakia. The SovietUnion then offered to finance the project, and also madeAswan Damchanges to the design. Within the first year 3,000 workerswere excavating the diversion channel and buildinghaul roads. Soviet personnel did most of the tunneling.The work force peaked at 33,500 in 1964, including20,000 Egyptians and 2,000 Russians using mostly Russianequipment. <strong>Construction</strong> lasted from 1960-1970.(ENR 5/21/64 p. 55)PHOTOS COURTESY OF THE DEPT. OF ENERGY40 CONSTRUCTION FACTS 2004

Ledo RoadDuring World War II the problem of sending military suppliesinto China loomed large. With Japanese forcesoccupying China’s coastal regions, China’s primary supplyroute was the Burma Road, built by the British andChinese and opened in 1938. Despite storied defensiveefforts by the “Flying Tigers” squadron, Japanese forcescaptured the Burma Road’s southernterminus in April 1942. Opening a newoverland route was vital, and the jobwas assigned to American forces. Workbegan on Christmas Day, 1942, outsideLedo, the railhead in northeast India.The route traversed the 9,000-ft PatkaiHills in northern Burma (Myanmar), wentthrough the Hukawng Valley, crossedthe Irrawaddy River, and joined up withthe Burma Road at Mong-Yu. Greatnumbers of U.S. bulldozers, cranes,power shovels and steam rollers wereshipped halfway around the world. Chineseand Indian laborers and Americanmilitary engineers struggled to cut the route through wildjungles, deep valleys and swamps. The work forcepeaked at 30,000. Mud, malaria, typhoid and Japanesesnipers took their toll. The 465-mile-long, two-lane gravelroute was completed in late 1944, with the first convoyreaching Kunming, China in February 1945.PHOTOS COURTESY OF THE US ARMYItaipu DamAstride the Parana River on the Brazil/Paraguay border,Itaipu Dam’s 12,600 MW of hydropower will be surpassedonly by China’s Three Gorges Dam. Itaipu supplies25% of Brazil’s power needs and 78% ofParaguay’s. The complex of dam structures stretches4.8 miles across the river and reaches a height of 643ft. The main structure is a 3,114-ft-long hollow concretegravity dam with a 357-ft-high powerhouse at itsbase. It tapers into a right abutment dam that ties intoa concrete buttress structure carrying the spillway. Onthe Brazilian side, rock and earthfill embankmentsstretch nearly three miles. The contractor consortiumhad five large Brazilian and six smaller Paraguayanfirms. Work began in 1975 and the work force peakedat 30,000 in 1978, with the diversion of the river andthe closure of the two main cofferdams. Ice-cooledconcrete was poured at a monthly rate of 440,554 cuyd in November 1979, a rate close to the Grand Couleerecord. The dam was completed in 1991, at a cost of$18 billion (ENR 5/27/91 p. 18).2004 CONSTRUCTION FACTS 41

<strong>Record</strong>sLargest Work ForcesEgypt. French diplomat Ferdinand de Lesseps spearheadedthe canal effort, by dint of a personal friendshipwith Said Pasha, who became viceroy of Egypt in 1854.de Lesseps had to overcome British hostility to his idea,given Britain’s position as the dominant maritime powerand its influence with the Ottoman Empire, the nominalrulers of Egypt. In 1858 the Ottomans and the emperorof France joined in financing the canal. Followinggroundbreaking in 1859, small work crews were enlisted.But Egyptian peasants (fellahin) were deeplyattached to their land, and could not be enlisted to leavetheir households to venture into the desert. Progress wassporadic, with an eight-month strike the first year. In1861 the Ottoman rulers permitted de Lesseps and hiscontractor, Alphonse Hardon, to conscript laborers towork for one-month terms. Hardon’s agents visitedEgypt’s 2,500 villages, taking two men from each, whilede Lesseps rounded up conscripts in Palestine. By late1861 the preliminary channel had been extended 38miles south of Port Said, mostly by dry excavation, withsome use of small bucket dredgers. The monthly laborTrans-Alaska PipelineOil was discovered at Prudhoe Bay, 250 miles north of the ArcticCircle, in 1968. Alyeska Pipeline Service Co., a consortiumof eight oil companies, took on the mission of building a pipelineto deliver the oil to the port of Valdez, 800 miles south of PrudhoeBay. The route crosses a 4,800-ft-high pass in the BrooksRange, spans the Yukon River on a 2,300-ft-long steel box girderstructure and climbs a 3,300-ft-high pass in the ChugachMountains. <strong>Construction</strong> began in 1974 with the completion inseven months of a two-lane gravel haul road stretching 360miles from the Yukon River to the North Slope. The 28-ft-wideroad embankment was 5 ft deep, to protect the permafrost.Alyeska let the pipeline in six sections. Half of the 48-in.-diapipeline is buried in rock or well-drained permafrost. Most of therest had to be elevated and insulated because the heat of theoil, about 130 F, would quickly cause permafrost to decomposeinto a slushy mass with no bearing capacity. The above-groundline runs in a zigzag pattern to convert any pipe movement fromexpansion and contraction into sideways movement. Every 700to 1,800 ft the pipes are clamped firmly in anchor assemblies toprevent horizontal movement. Between the anchors the pipesare mounted in sliding shoe assemblies. At over 500 places theline allows for animal crossings. The first section of pipe was laidin March 1975, and oil flowed through it in June 1977. Workersin the 29 camps were trained in Arctic survival. Building themarine terminal involved 4 million cu yd of earthmoving to constructship berths and a large tank farm. The project’s work forcepeaked at 21,600 in August 1975. At $8 billion, it was the largestprivately funded construction project up to that time.Suez Canalquota was raised repeatedly, and the work force peakedat 23,318 in April 1862. Despite the wastefulness of themonthly turnover, the labor contingents excavated 18.5million cu yd, piercing the plateau of El Guisr, the backboneof the isthmus, which stretched for eight miles, 33ft above sea level. French-Ottoman political tensions,along with a new Egyptian ruler, Ismail Pasha, broughtthe use of forced labor to a halt in 1864. The canal companywas forced to hire more European labor, and ordermuch additional machinery. Alexandre Lavalley’s troughdredgerdeposited spoil directly on the bank withoutintermediary barges, cranes, or wagons. In 1867 the elevatorwas introduced, an inclined tramway which carriedboxes of spoil upward for deposit on the top of the bankbeyond the reach of cranes. With a bottom width of 22meters, a surface width of 60 m and an 8-m depth, the163-kilometers-long canal was completed in 1869.Although its dimensions now limit the size of vessels thatcan pass, in 2003, an average of 43 ships per day madethe 12-hour transit. The canal’s net annual tonnage comprised7.5% of the world’s seaborne trade.These are a selected group of projects that employed very large work forces. It is not comprehensive.42 CONSTRUCTION FACTS 2004

<strong>Record</strong>sSTRUCTURES Famous StructuresThe KremlinFor centuries, the Kremlin has been the seat and symbolof Russia’s power. During the Cold War, it was themysterious, menacing metaphor for the global threat ofSoviet Communism, the grim backdrop for reviewingMay Day parades of fearsome ICBMs. But the Kremlin’sorigin in about 1147, was as humble as a raggeddandelion on the steppe.The Kremlin first appears in chronicles as a fortifiedsettlement, like a frontier trading post in the AmericanWest, with a moat, rampart and palisade on a low hillwhere the Neglinnaya River flows into the Moskva River.By 1300, it had become the seat of the Grand Prince ofMoscow, the core of what became the Russian Empire.Today, the 68-acre Kremlin is still the seat of Russia’sgovernment. Its 1.4-mile-long massive brick wall, rangingin height from 26 to 62 ft, encloses an irregular triangleholding the Senate, which houses the Residence ofthe President of Russia and the Premises of the RussianFederative Assembly, or parliament.The complex also incorporateschurches, cathedrals,palaces and other architecturaltreasures dating backto 1479, as well as more recent additions built in the20th century. Some of the newer buildings, such as onebuilt as a military school in 1934, displaced conventsand monasteries in what was essentially a politicalstatement by the antireligious government. <strong>Construction</strong>of other buildings, like the former Palace of Congresseserected in 1961, demolished historic buildings for utilitarianreasons. Today, there is a movement for preservationof historic structures, which likely would blocksuch construction.The mausoleum built in 1931 tohouse the remains of V.I. Lenin,founder of the Soviet state, is justoutside the eastern wall,overlooking the 22-acreexpanse of RedSquare.Constructed in only 16 months in the early years of WorldWar II, the five-wedge shaped Pentagon in Arlington, Va.,just outside of Washington, D.C., is the headquarters ofthe U.S. Dept. of Defense, including all four military services—Army,Navy, Air Force and Marines. With 6.63 millionsq ft, it is the world’s largest office building.Architect George Edwin Bergstrom designed the fivestorysteel and reinforced concrete structure to be fiveconcentric pentagons—known as rings—with 10 spokelikeconnecting corridors. The building is 77 ft high andits outer walls are each 921 ft long. It contains threetimes the floor space of the Empire State Building and17.5 miles of corridors.With approximately 25,000 military and civilianemployees, the Pentagon is like a small-sized-city, withits own restaurants, shops, medical clinics, health clubPentagonand fire department. At least one part of it resembles themovies: the National Military Command Center, wherewatch teams monitor the world 24 hours a day, sevendays a week.The Pentagon was born out of the former War Dept.’scritical office space situation. Before the U.S. enteredWorld War II, the department was operating from 17 facilitiesscattered throughout Washington, D.C.The general contractor was John McShain Inc., whichbuilt or renovated scores of federal buildings, includingthe Jefferson Memorial, State Dept., a senate office buildingand the White House (1949-52 renovation).Ground was broken for the Pentagon on Sept. 11,1941. After the U.S. entered World War II in December,McShain was told that the size of the building wouldneed to be doubled. The original plans were scrapped44 CONSTRUCTION FACTS 2004

and 300 architects were put towork drawing up new ones, withan increase from three abovegroundfloors to five.About 435,000 cu yd of concretewas used in the construction,which was completed onJan. 15, 1943. The work forcepeaked at 15,000. It has a 29-acre footprint, with a five- acrecourtyard. The building cost$49.6 million.The Pentagon is undergoing a$1.2-billion gut renovation, whichbegan in 1993 and is scheduledto be completed in 2010. OnSept. 11, 2001, a hijacked AmericanAirlines plane crashed intothe northern-most point of its southwest side, known asWedge One. It penetrated the building’s three outer ringsand killied 123 Pentagon employees and visitors, in additionto the passengers on the plane. The renovation ofWedge One was just days away from completion at thetime. The newly installed blast-resistant elements therewere believed to have significantly reduced the number ofcasualties in the building.Great Wall of ChinaDesigned and constructed as a defense against nomadic tribes,the Great Wall of China is one of the world’s great constructionand engineering achievements and a prime tourist destination.Varying in height between 18 and 30 ft, the 4,163-mile structureextends along the northern edge of China, crossing deserts,grasslands, mountains and plateaus from Bo Hai, a gulf off theYellow Sea in the east, to a point deep in Gansu province in thewest.The origins of the wall date to the 7th and 8th centuries B.C.when as series of independent defense fortification walls werebuilt by three different states. It did not become the “Great Wall”until approximately 214 B.C. when Shih Huang-ti, the first emperorof a united China, succeeded in joining the walls together intoa single system. The project took 10 years. Further extensionsand structural improvements were carried out by succeedingdynasties. Virtual armies of often forced laborers were used in theconstruction phases. This included the use of 1.8 million conscriptedlaborers who built a 279-mile section in about 555 A.D.In addition to the walls, the structure included passes and signaltowers. The passes were situated at key positions, usually ontrade routes, and were needed to control access to and from Chineseterritory. The construction was complex and could vary froma simple double wall to a castle-like structure to repel an invasion.Located on hilltops and other high points, the signal towers wereused to warn other garrisons of enemy movement. This was donewith smoke signals during the day and fire at night.Originally constructed with masonry and earth, the Great Wallwas substantially rebuilt in later times, especially in the 15th and16th centuries.TOP PHOTO COURTESY OF DOD BY TECH. SGT. ANDY DUNAWAY, U.S. AIR FORCE; BOTTOM PHOTO BY CLIFF PEARSON FOR CONSTRUCTION FACTS2004 CONSTRUCTION FACTS 45

<strong>Record</strong>sFamous StructuresGrand Mosque in MeccaRinged by seven towering minarets and 64 gates, this monumentalbuilding in Mecca is the largest mosque in the worldwith160,000 sq yd of floor space and the capability of holdingmore than 1.2 million pilgrims simultaneously.The mosque has its roots in ancient times. Ancient Meccawas an oasis on the caravan route that linked theMediterranean world with South Arabia, East Africa andSouth Asia. By Roman times, it had developed into animportant trade and religious center. According to somesources, God directed the Jewish prophet Abraham to builda shrine there about 1900 BC. The prophet Gabriel thenbrought a magic stone for the sanctuary. This stone, whichmay be a meteorite, was a sacred object of the pre-Islamicnomads who settled around the Zamzam spring.The original sanctuary, known as the Ka’ba is a cubicstone structure roughly 50 ft in each dimension. Embeddedin the corner of the Ka’ba is the Black Stone. Over time, acollection of 360 stone idols were housed in and around theKa’ba. They represented deities such as Awf, the great bird;Hubal the Nabatean god; and statues of Mary and Jesus.The prophet Mohammed was born in Mecca in 570 AD.When he and his followers took control in 630, theydestroyed the 360 pagan idols, with the exception of thestatues of Mary and Jesus. Mohammed, the founder ofIslam, then made the Ka’ba and the sacred stone it housedthe centerpiece of the Muslim religion based on his beliefthat he was a prophetic reformer who had been sent by Godto restore the rites first established by Abraham, which hadbeen corrupted over the centuries by pagan influences.According to Mohammed’s words, one of the fundamentalMuslim practices, known as the “Five Pillars of Islam,” isthe hajj pilgrimage. The Hajj is an obligation to be performedat least once by all Muslims whose health and finances permit.The pilgrimage takes place during a five-day periodeach year in the 12th month of the Islamic lunar calendar,most recently Jan. 28-Feb. 1, 2004. Pilgrims are believed toenter a state of holiness and purity near Mecca.Entering the Grand Mosque, pilgrims first walk seventimes around the Ka’ba shrine counterclockwise. This ritualis called turning, or tawaf. Next they enter the shrine andkiss the sacred stone. The area around the Ka’ba wasenclosed by a wall in 638 to create a defined space for thetawaf ritual. In 709, a wooden roof resting upon marblecolumns was added to protect the arcades of the mosque.Large-scale renovations were undertaken in 1564 during theOttoman period, in which minarets were rebuilt and thewooden roofs were replaced with stone domes.Over the last half century, the complex has been vastlyexpanded to its present configuration. The Ka’ba, Zamzamwell and various holy burial sites now are all enclosed in thevast structure called the Haram al-Sharif, “The Noble Sanctuary.”About 2 million people perform the Hajj each year,about 40,000 of them Americans. The Hajj serves as a unifyingforce in Islam by bringing together followers from manycountries and language groups. Devout Muslims face Meccaas they perform their prayers five times daily.46 CONSTRUCTION FACTS 2004

<strong>Record</strong>sPROJECTS <strong>Construction</strong>’s Dream ProjectsBering Strait BridgeIn 1958, noted bridge designer T.Y. Lin proposed hisconcept for a bridge linking Alaska and Siberia acrossthe 53-mile-wide Bering Strait. He called it the Inter-Continental Peace Bridge, expressing his wish that itwould help foster commerce and greater understandingbetween the two primary Cold War superpowers,the U.S. and Soviet Union.Lin envisioned the bridge with three levels: the topfor vehicular traffic, the middle for high-speed trainsand the bottom for oil and gas pipelines. With a pricetag of $105 billion, such a span would have to promiseeconomic incentives, so the lowest level of the bridgewould be enclosed and house pipelines carrying oiland gas from Siberia to North America. The rail levelalso would be enclosed and function year-round. Thetop would be open to cars and trucks for only fourmonths per year.The bridge not only would be the world’s longest, butwould have to deal with a uniquely harsh environment—massiveicebergs, violent seas and temperaturesreaching as low as 40° F below zero. Site constructionwould be limited to four months a year.The 220 50-ton piers would be constructed of highperformanceconcrete designed to resist the radicaltemperature changes and the wear and tear of seawaterand ice. Each would be shaped at the waterline likethe rounded bow of an icebreaker ship and have a “TiltMeter” to warn engineers of excessive ice pressure.The piers would be topped by a precast concretespan. Massive cables sheathed in concrete wouldhelp to hold the bridge in place, 200 ft above the straitconnecting the Bering Sea with the Arctic Ocean.Such a bridge would have to be accompanied bythousands of miles of new highways and rail linesleading to the bridge from both sides. This “ArcticCorridor” would span 4,000 miles from central Siberiato southern Canada, linking the great population centersof Europe and North America. Given the absenceof any such peripheral development at present, thisremains a very distant dream.These five projects stretch the limits of present engineering ability. At first glance they may seem impossible to build. But this has beentrue of most of the trailblazing projects throughout history. The Channel Tunnel was a dream for many political leaders and engineers forover a century before being built and the contract for the bridge linking Sicily with Italy across the Strait of Messina is about to beawarded, a project that was almost unthinkable not long ago.48 CONSTRUCTION FACTS 2004

Taiwan Strait CrossingChinese academics have put forth detailed plans for severalbridge and tunnel links that would connect Taiwanwith China, even though the possibility of political unificationis remote. The shortest proposed route would featurea 12-mile long bridge and a 78-mile tunnel—morethan twice as long as Japan’s Seikan Tunnel, currentlythe world’s longest road or rail tunnel. A 2002 conferencein Xiamen brought together scholars from both mainlandChina and Taiwan to discuss several possible links. Theyincluded a more ambitious southern route that would usethe Taiwan-controlled islands of Quemoy and Penghu asstepping stones. It would extend 151 miles, including an81-mile tunnel between Jinmen and Penghu islands.Political barriers facing the project would rival the technicalchallenges, with China and independence-mindedTaiwan not even currently sharing air or sea links. Chinais clearly the more interested party of the two. “<strong>Construction</strong>of a cross-straits tunnel has become a dreamof the Chinese people,” Britain’s Guardian newspaperquoted Xi Jinping, the governor of Fujian province.Despite the many uncertainties, Chinese scholars believethe project is feasible, albeit in the long term. SaidQinghua University Professor Wu Zhiming in theGuardian: “The special feature of macro-economic projectsis that the period of preparation vastly exceeds theperiod of construction.”“A cable extending from Earth to space that could beascended by mechanical means” was first conceived byRussian scientist Yuri Artsutanov in 1960 and laterappeared in Arthur C. Clarke’s novel Fountains of Paradise.But no material strong enough for such a cableexisted. The discovery of carbon nanotubes in 1991held promise and generated interest within the scientificcommunity. Physicist Bradley C. Edwards, using agrant from the NASA Institute for Advanced Concepts,led a two-year effort to produce an initial design for aSpace Elevatorspace elevator, resulting in a report issued in 2003. Acarbon nanotube ribbon, 8 in. wide and thinner than asheet of paper, would be anchored to a floating shipplatform, the Liftport. It would be a refurbished oildrillingplatform. The Liftport’s proposed location, on theequator about 2,000 miles west of Ecuador, was chosenfor its benign weather patterns and wide distance fromair and sea routes. The tube would be tethered to asatellite orbiting 62,000 miles above Earth. The “lifters,”or elevators, would be powered by a combination ofground-based lasers and lifter-mounted solar panels.The lasers would direct their beams onto the solar panels,which then would power electric motors on thelifters. Initial clients likely would be telecommunications,earth monitoring and military satellites. Other possibleuses include solar energy satellites, biomedicalresearch and space tourism. <strong>Construction</strong> costs areestimated at $10 billion, with the system operationalwithin 15 years. A nascent funding effort is under way,by LiftPort Inc. (www.liftport.com), with separate investmentstreams planned for research into the key technologies—carbonnanotubes, lasers, photovoltaic cells,and robotics.2004 CONSTRUCTION FACTS 49

<strong>Record</strong>s<strong>Construction</strong>’s Dream ProjectsMillennium TowerCommissioned by Obayashi Corp., the U.K. architecture firm Foster andPartners in 1989 designed a conical building 2,625 ft high, with 170 stories.Foster’s idea was to transform skyscrapers into fully functioning communities.The structure would have up to 52,000 occupants in a mix of offices,apartments, hotels, restaurants and cinemas. Rising out of Tokyo Bay, itshelical steel cage and shape were designed to resist hurricanes and earthquakes.High-speed elevator cars carrying 160 passengers would stop atevery 30th floor, where individuals would continue by local elevator or escalator.The bursting of Japan’s real estate bubble in 1991 ended any hope ofits realization there. But interest from Hong Kong has spurred Foster partnerDavid Nelson to reimagine it, relocated in Hong Kong’s harbor, whereits cost is estimated at $10-billion.Kra CanalA sea level canal across the KraIsthmus of southern Thailand haslong intrigued influential businesspeople,academics and politiciansin Asia. The canal would provide astrategic and lucrative short cut onthe primary shipping route betweenthe Middle East oilfields andoil-hungry nations in East Asia. Italso would allow ships to avoid thenavigational challenges of theStraits of Malacca, which narrowto 12.5 kilometers and are prone toincidents of piracy. In 1973, TAMS,an international engineering firm,was hired by the Thailand Educationand Public Welfare Foundationto conduct a preliminary engineeringand economic survey report.TAMS recommended a 102-kmlongroute from Songkhla in theeast to a point north of Satun in thewest. The project remains politicallycontroversial. Malaysia and Indonesiacould be economicallyand strategically affected, and Singaporecould become a less importantregional hub. In 2003, accordingto the Bangkok Post, theThai cabinet hired Phuket PassProject Ltd., a Hong Kong company,to conduct a feasibility study.With an estimated cost of $20 billion,further debate will need totake place if the proposal is to betaken seriously.MAP BY SUE PEARSALL FOR CONSTRUCTION FACTS50 CONSTRUCTION FACTS 2004

<strong>Record</strong>sPROJECTS <strong>Construction</strong>’s White ElephantsShoreham Nuclear PowerplantNew York. Ordered in 1967, and constructed between1973-84, Long Island Lighting Co.’s 800-MW ShorehamNuclear Power Station in Brookhaven, N.Y., wasthe victim of intense local opposition to nuclear power,especially after the Three Mile Island accident in 1979.After that accident, New York state and Suffolk Countyrefused to take part in developing the emergency evacuationplans that were required for an operating licensefrom the Nuclear Regulatory Commission. After years ofdelays that drove costs up to $5.5 billion, the plant wascompleted and licensed by NRC. It completed its 5%power testing, but was never put into operation. N.Y.Gov. Mario Cuomo (D), who opposed startup, brokereda deal with the public utilities commission that allowedTexas. The centerpiece of the Dept. of Energy’s SuperconductingSuper Collider project in Waxahachie, Texas,was to be a 14-ft-diameter, 54-mile-long tunnel ringingthe town. The loop was to house a particle acceleratorthat would send subatomic particles around the loop atgreat speed, guided by a network of magnets. The particleswould “collide,” allowing physicists to study theirbehavior. Engineers designed the tunnel to follow a truemathematical plane instead of the earth’s curvature, witha tolerance of 1 1 ⁄2 in. over its circumference. Tunnel excavationbegan in 1990 but the project was terminated byCongress in 1993. Termination came after contractorshad completed just 20% of the job and spent about $2billion. By the time the project was stopped, costs hadballooned from $4.4 billion to $11 billion.The massive DOE project, which emphasized theoreticalexperiments over practical application, broughttogether big science and big government. A particleaccelerator of its size had never before been built, makingcosts difficult to predict. Federal audits revealedproblems in the program’s management and administration.In the end, only 14 miles of tunnel were built. Atthe time of its closure, the site included a 550,000-sqftoffice and lab, a magnet test laboratory, a magnetdevelopment laboratory, and an accelerator systemstring test facility. In 1994, DOE gave the property backto the state of Texas, which had contributed more than$500 million to the project. Public pressure ended whathad appeared to scientists to be a promising endeavor.Competition from “small” scientific projects and othersin need of government funding, coupled with thegrowing costs of the project in a time of economicuncertainty, led to the project’s demise. Many arguedthat “small” science addressed the problems of people,LILCO to pass the cost of the plant onto Long Islandratepayers if it was decommissioned. The plant wasclosed permanently in 1989.Superconducting Super Colliderversus “big” science like the Super Collider, whichsolved more abstract problems. The SSC site included16 sq miles of surface property and the rights to buildunder about 10 sq miles. About 600 residents and 180structures were removed from the area to make roomfor the Super Collider. (ENR 11/1/93 p.12)BOTOOM PHOTO COURTESY OF DOE52 CONSTRUCTION FACTS 2004

Dabhol PowerplantIndia. Enron signed an initial memorandum of understandingwith the Maharashtra state government in 1992 to builda 2,184-MW natural gas-fired powerplant, the world’slargest. Dabhol was the biggest single foreign investmentin India. At its peak, the plant’s work force totalled 15,000.It was 90% complete when production and constructionstopped in May 2001, bringing an end to a job that beganunder duress.<strong>Construction</strong> began in 1995, but within months a newstate government scrapped the project, alleging corruptionand high costs. Later that year the project was re-negotiated,with the Maharashtra State Electricity Board (MSEB),which increased its ownership stake in Dabhol Power Co.from 10 to approximately 15%. Enron’s ownership stakewas 65% at that time.The first 740-MW phase of the project began operatingin May 1999. In 2000, various Maharashtra governmentallies demanded the project be scrapped because of risingpower costs. In October 2000, MSEBdefaulted on its monthly payment to DPCand the power company’s board authorizedmanagement to terminate the contractin April 2001.As of July 2002, Enron’s unsecured debtto Indian financial institutions was over$1.5 billion, with an additional $650 millionto U.S. lenders. Enron’s interest in DPCwas acquired by its U.S. partners, GeneralElectric and Bechtel, after Enron’s bankruptcy.GE and Bechtel have continued topursue the recovery of their investmentand of the value of the power purchaseagreement in several international arbitrationvenues. They have also indicatedtheir willingness to help re-start the plant,which has been idle for over three years.Washington Public Power Supply System (WPPSS)During the 1970’s this Washington state joint operating agencyembarked on a plan to build five nuclear powerplants producing6,130 MW, at a cost of $4 billion. WPPSS managers had noprevious experience with nuclear engineering or such largescaleprojects. The combination helped doom the program andbring about a $2.25-billion bond default, the largest municipalbond default in U.S. history, to that time. Inflation and designchanges plagued the projects. Plant 2, at Hanford, was completedin 1984 at a cost of $3.2 billion, eight times the originalestimate. Plant 1, also at Hanford, and Plant 3, in Satsop, alsosuffered delays and cost escalation. In 1982,with total costs projected to surpass $24 billion,the WPPSS board stopped construction onPlants 4 and 5. Consequently, the take-or-payarrangements that had been backing the bondswere ruled void by the Washington StateSupreme Court. Plant 1 was 75% complete andPlant 3 65% complete at the time of default,and were mothballed until 1995. The two unfinishedplants in Satsop, near Olympia, are surroundedby a growing business park thatmakes use of their infrastructure. The two unfinishedplants at Hanford remain abandoned.2004 CONSTRUCTION FACTS 53