SWS - Stemco Quick Reference 2011 - CARQUEST Auto Parts

SWS - Stemco Quick Reference 2011 - CARQUEST Auto Parts

SWS - Stemco Quick Reference 2011 - CARQUEST Auto Parts

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

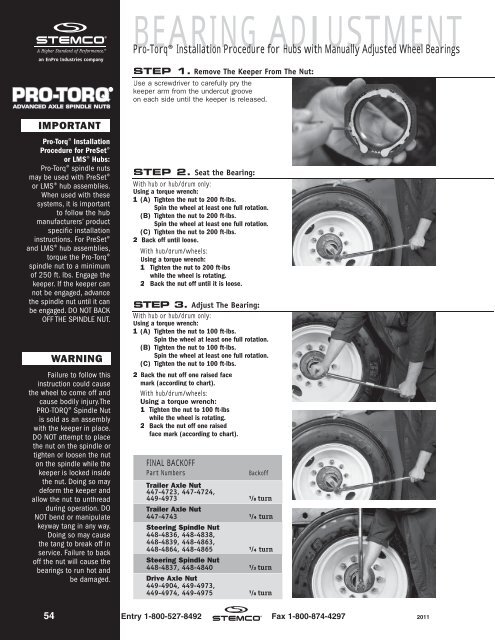

BEARING ADJUSTMENTPro-Torq® Installation Procedure for Hubs with Manually Adjusted Wheel Bearingsan EnPro Industries companySTEP 1. Remove The Keeper From The Nut:Use a screwdriver to carefully pry thekeeper arm from the undercut grooveon each side until the keeper is released.IMPORTANTPro-Torq ® InstallationProcedure for PreSet ®or LMS ® Hubs:Pro-Torq ® spindle nutsmay be used with PreSet ®or LMS ® hub assemblies.When used with thesesystems, it is importantto follow the hubmanufacturers’ productspecific installationinstructions. For PreSet®and LMS ® hub assemblies,torque the Pro-Torq ®spindle nut to a minimumof 250 ft. lbs. Engage thekeeper. If the keeper cannot be engaged, advancethe spindle nut until it canbe engaged. DO NOT BACKOFF THE SPINDLE NUT.WARNINGFailure to follow thisinstruction could causethe wheel to come off andcause bodily injury.ThePRO-TORQ ® Spindle Nutis sold as an assemblywith the keeper in place.DO NOT attempt to placethe nut on the spindle ortighten or loosen the nuton the spindle while thekeeper is locked insidethe nut. Doing so maydeform the keeper andallow the nut to unthreadduring operation. DONOT bend or manipulatekeyway tang in any way.Doing so may causethe tang to break off inservice. Failure to backoff the nut will cause thebearings to run hot andbe damaged.STEP 2. Seat the Bearing:With hub or hub/drum only:Using a torque wrench:1 (A) Tighten the nut to 200 ft-lbs.Spin the wheel at least one full rotation.(B) Tighten the nut to 200 ft-lbs.Spin the wheel at least one full rotation.(C) Tighten the nut to 200 ft-lbs.2 Back off until loose.With hub/drum/wheels:Using a torque wrench:1 Tighten the nut to 200 ft-lbswhile the wheel is rotating.2 Back the nut off until it is loose.STEP 3. Adjust The Bearing:With hub or hub/drum only:Using a torque wrench:1 (A) Tighten the nut to 100 ft-lbs.Spin the wheel at least one full rotation.(B) Tighten the nut to 100 ft-lbs.Spin the wheel at least one full rotation.(C) Tighten the nut to 100 ft-lbs.2 Back the nut off one raised facemark (according to chart).With hub/drum/wheels:Using a torque wrench:1 Tighten the nut to 100 ft-lbswhile the wheel is rotating.2 Back the nut off one raisedface mark (according to chart).FINAL BACKOFFPart NumbersBackoffTrailer Axle Nut447-4723, 447-4724,449-4973 1/8 turnTrailer Axle Nut447-4743 1/4 turnSteering Spindle Nut448-4836, 448-4838,448-4839, 448-4863,448-4864, 448-4865 1/4 turnSteering Spindle Nut448-4837, 448-4840 1/3 turnDrive Axle Nut449-4904, 449-4973,449-4974, 449-4975 1/8 turn54 Order Entry 1-800-527-8492 Fax 1-800-874-4297 <strong>2011</strong>