RT 800 WP - Guhring

RT 800 WP - Guhring RT 800 WP - Guhring

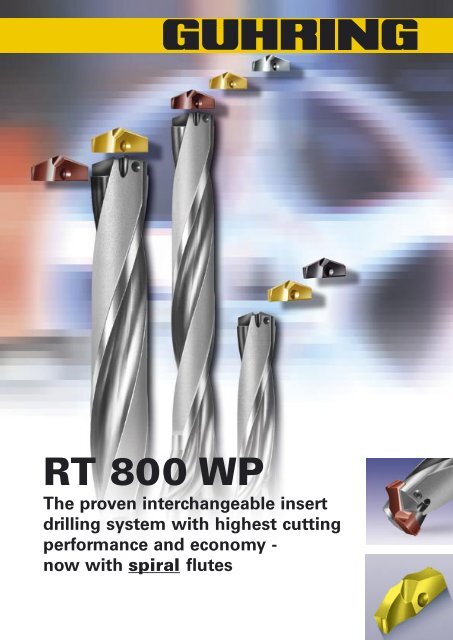

RT 800 WPThe proven interchangeable insertdrilling system with highest cuttingperformance and economy -now with spiral flutes

- Page 2 and 3: RT 800 WPIf you predominantly produ

- Page 4 and 5: Availability/discount group 405242I

- Page 6 and 7: Availability/discount group 411047I

- Page 8 and 9: Cost in €Tool life in Lf (m)Cost

- Page 10 and 11: RT 800 WP . General technical infor

- Page 12: Guhring oHGP.O. Box 100247 · D-724

<strong>RT</strong> <strong>800</strong> <strong>WP</strong>The proven interchangeable insertdrilling system with highest cuttingperformance and economy -now with spiral flutes

<strong>RT</strong> <strong>800</strong> <strong>WP</strong>If you predominantly produce deep holesin the diameter-range 16.0 to 40.5 mm, youshould take a closer look at type <strong>RT</strong> <strong>800</strong><strong>WP</strong>. The holder is nickel-plated with coolantducts, the interchangeable inserts are producedin ultra fine grain carbide. Type <strong>RT</strong> <strong>800</strong><strong>WP</strong> offers exceptional performance, especiallycompared to brazed carbide tools. Withregard to accuracy and surface quality ofthe hole the <strong>RT</strong> <strong>800</strong> <strong>WP</strong> drilling systemoffers outstanding efficiency:• high rigidity and optimumchip flow thanks to compactdesigh with spiral flutes,for the drilling depths3xD, 5xD and 7xD.• highest economic efficiency through highfeed rates due to complete 2-edged pointgeometry = Ratio geometry.• outstanding hole qualities through lateralcircular lands on the inserts.• indexing with adjusting screw in tool holder.The clamping screw ensures accurateand solid positioning.The interchangeable insert can be replacedquickly with ease in the clamped holderdirectly on the machine.Cutting rates for materials to be machinedcan be found on page 10.2

Interchangeable insert holder- high-quality, high tensile strength tool steel- nickel-plated surface finish- spiral flute design with internalcooling for optimum chip flow- shank with drive flat toDIN 6535-HE (3 x D and 5 x D),in addition with collar toDIN 6595 (7 x D)- in standard lengths for drillingdepths 3 x D, 5 x D and 7 x D5×D7×D3×Dcollar toDIN 6595straight shank toDIN 6535-HE5242 5243 5248Interchangeable inserts (Ø16.0 … 40.5 mm)- two geometries, three types (bright, TiN, FIRE)- solid carbide (ultra fine grain), K for bright finish,K/P for coated tools- high toughness and bending strength- relieved cone, 140° point angle andRatio point grind result in a self-centeringcutting edge geometry- cutting edge tolerance h7- compatible to straight-fluted holders2747brightsuitable to machinecast materials, aluminium andaluminium-alloyssuitable forgeneral machining1047TiN-coatedsuitable forhigh heat applications2485FIRE-coated3

Availability/discount group 405242Interchangeable insert holderfor 3 x Dholderavailabilitysize0123456•5243Interchangeable insert holderfor 5 x Dholdersize0123456availability•5248Interchangeable insert holderfor 7 x Dholderavailabilitysize0123456•d 1holdersize0.10.21.11.22.12.23.13.24.14.25.15.26.16.2honly for 7 x Dcutting edge-Ø-ranged 1mm16.00...17.0017.01...17.9918.00...19.0019.01...20.0020.01...21.0021.01...22.5022.51...24.0024.01...25.5025.51...27.5027.51...29.5029.51...32.0032.01...34.5034.51...37.5037.51...40.50l 3d4d 3l 2l 1codeno.17.00017.00517.99017.99519.00019.00520.00020.00521.00021.00522.50022.50524.00024.00525.50025.50527.50027.50529.50029.50532.00032.00534.50034.50537.50037.50540.50040.505collar toDIN 6595insert-seatwidthb*mml 4holderØd 3mmd 2standard dimensions for 3×D t4.55.05.56.37.38.510.015.716.717.718.719.720.722.223.725.227.229.231.734.037.0shank-Ød 2h6mm2019.052019.052019.052019.052525.42525.42525.42525.43231.753231.753231.753231.753231.753231.75for interchangeable inserts in inches *s. page 64

straightshank toDIN6535-HEstraightshank toDIN6535-HEo 7×Dshanklengthl 4mmoverall lengthincl. insertl 1mm52423×Dflutelengthl 2mmeffect.drilling depthl 3mmoverall lengthincl. insertl 1mm52435×Dflutelengthl 2mmeffect.drilling depthl 3mmcollarØd 4mmoverall lengthincl. insertl 1mm52487×Dflutelengthl 2mmeffect.drilling depthl 3mm<strong>Guhring</strong>no.holdersize505056566060601301381531611701821901982062182317684931011101181261341421541675460667278849096102114120166178197209222238250262274292311112124137149162174186198210228247• Attention! When ordering please always state <strong>Guhring</strong> no. and code no.!9010011012013014015016017019020025253131313838383838382022182412572742943103263423663911481641811972142302462622783023271261401541681821962102242382662<strong>800</strong>.10.21.11.22.12.23.13.24.14.25.15.26.16.25

Availability/discount group 411047Interchange. insert (incl. clamp. screw)TiN-coatedforholder size0123456availability•1071Clamping screwsfor interchangeable insertsforholder sizeavailabilityall •1612Screw driversfor interchangeable insertsfor code availabilityTorx no.T6T8T106.0008.00010.000•2485Interchange. insert (incl. clamp. screw)FIRE-coatedforholder size0123456availability•2747Interchange. insert (incl. clamp. screw)brightforholder size0123456code4915Torque key forclamping screwsavailability•availabilityno.5.001 •4917Torx-Bits fortorque keyfor Torxclamping screwT6T8T10availability•Interchangeable insertsd3forholdersize0.10.21.11.22.12.23.1l5h41/ 6421/ 3243/ 6411/ 1645/ 6423/ 3247/ 643/ 449/ 6425/ 3251/ 6413/ 1653/ 6427/ 3255/ 647/ 857/ 6429/ 3259/ 6415/ 162747Solid carbideKnom.-Ø*d 1h7inchmm16.0016.2716.5016.6717.0017.0717.4617.5017.8618.0018.2618.5018.6519.0019.0519.4519.5019.8420.0020.2420.5020.6421.0021.0321.4321.5021.8322.0022.2222.5022.6223.0023.0223.4223.5023.8124.00bright S TiN-coated F FIRE-coatedbcuttingpointl 5mm2.93.03.03.03.13.13.13.23.33.33.33.43.43.53.53.53.53.63.63.63.73.83.83.83.93.94.04.04.04.14.14.24.24.34.34.34.4Precise clamping of interchangeableinsert ensures safeclamping in holder.sizeTorxT6T8T10widthbmm4.54.55.05.05.55.56.3Ø-rangemm≥16.0 - 25.5>25.5 - 34.5>34.5 - 40.5torqueM d (N cm)721803451047Solid carbideK/PSheighthmm8.08.08.08.08.88.810.0forholdersize3.24.14.25.15.26.16.26

Ainterchangeable inserttool holderAclamping screw(secured)locking screw(locked)<strong>Guhring</strong>no.Code no.Torque key49155.001Torx-Bits4917depends on Torx: see table belowTorxMdmarkingfor clamping screwsection A...A1/4” driveoverall length 160 mmtorque 1...5 Nm1/4” driveoverall length 25 mm2485Solid carbideK/PF<strong>Guhring</strong>no.Tool materialCarbide gradeSurface finishClamping screws1071Screw driver1612d1l 1nom.-Ø*d 1h7inch61/ 6431/ 321mm24.2124.5024.6125.0025.4025.5026.0026.5027.0027.5028.0028.5029.0029.5030.0030.5031.0031.5032.0032.5033.0033.5034.0034.5035.0036.0037.0037.5038.0039.0040.0040.50cuttingpointl 5mm4.44.54.54.54.64.64.74.84.95.05.15.25.35.45.55.65.65.75.85.96.06.16.26.36.46.66.76.86.97.17.37.4*intermediate sizes on requestwidthbmm6.37.37.38.58.510.010.0heighthmm10.011.611.613.613.616.016.0forholdersize0.10.21.11.22.12.23.13.24.14.25.15.26.16.2threadGM3×0.35M3×0.35M3.5×0.35M4×0.5M4.5×0.5M5×0.5codeno.3.0063.0003.5004.0004.5005.000lengthl 1mm6.007.008.009.0010.0011.00withTorxT6T6T6T8T8T10codeno.6.0008.00010.000• Attention! When ordering please always state <strong>Guhring</strong> no. and code no.!forTorxT6T8T107

Cost in €Tool life in Lf (m)Cost in €Cost in €<strong>RT</strong> <strong>800</strong> <strong>WP</strong> . General technical informationCost and performance comparisonsTotal cost for 40,000 holesTotal cost for 90,000 holesCentering aswell as finalreaming notrequired with<strong>RT</strong><strong>800</strong>130,000120,000110,00080,00070,00060,00050,00040,00030,00020,00010,0005040302010Cost advantage in %17130,000120,000110,00080,00070,00060,00050,00040,00030,00020,00010,0005040302010Cost advantage in %34.9<strong>RT</strong><strong>800</strong>Competitor<strong>RT</strong><strong>800</strong> Competitor<strong>RT</strong> <strong>800</strong> CompetitorTools<strong>Guhring</strong> no.Interchangeable insert/coating 2485 F -Insert holder/tool 5242 HSS-drillWorkpiece (on MoriSeiki machining centre, vertical spindle)Workpiece material 42CrMo4 (1.7225)Drill-Ø mm 17.0Drilling depth mm 19.0Cutting parametersCutting speed v c (m/min) 99 27Feed rate f (mm/rev.) 0.18 0.25Quantity of holes per cutting edge (insert)/HSS-tool 1660 500Tool change (holder) after 15xinsert repl. 3xregrindCost in €Cost per hole 0.25 0.30Total cost 10,001 12,309<strong>RT</strong> <strong>800</strong> CompetitorTools<strong>Guhring</strong> no.Interchangeable insert/coating 2485 F TiNInsert holder/tool 5242 Insert-drillWorkpiece (on CNC Cincinnati turning machine)Workpiece material 42CrMo4 (1.7225)Drill-Ø mm 21.4Drilling depth mm 38.1Cutting parametersCutting speed v c (m/min) 98 74Feed rate f (mm/rev.) 0.32 0.36Quantity of holes per cutting edge (insert) 680 280Tool change (holder) after 15xinsert repl. 15xinsert repl.Cost in €Cost per hole 0.38 0.59Total cost 33,991 52,508Total cost for 250,000 holes130.000120.000110.00080.00070.00060.00050.00040.00030.00020.00010.0005040302010Cost advantage in %39,3Tool life comparison504033,23022,92010<strong>RT</strong><strong>800</strong> Competitor<strong>RT</strong> <strong>800</strong> CompetitorTools<strong>Guhring</strong> no.Interchangeable insert/coating 1047 S -Insert holder/tool 5243 brazed drill<strong>RT</strong><strong>800</strong><strong>WP</strong>with TiN interchangeable insertv c = 70 m/minf = 0.35 mm/rev.quality IT9Sconventionalindexable insert drillv c = 180 m/minf = 0.12 mm/rev.quality IT12Workpiece (on Toshiba machining centre, horizontal spindle)Workpiece material C 22 (1.0402)Drill-Ø mm 19.5Drilling depth mm 82.55Workpiece material: 42CrMo4Tensile strength R m: 1000 N/mm 2Tool diamerter: 20 mmDrilling depth a p: 2 x DCutting parametersCutting speed v c (m/min) 85 70Feed rate f (mm/rev.) 0.33 0.2Quantity of holes per cutting edge (insert)/HSS-tool 500 500Tool change (holder) after 15xinsert repl. 2xregrindCost in €Cost per hole 0.34 0.52Total cost 85,177 130,726S TiN-coatedFFIRE-coated8

Troubleshooting-12 tips to help diagnose problemsThe drawings show our HT<strong>800</strong>-interchangeable inserts.The recommended wear is valid for <strong>RT</strong><strong>800</strong> interchangeable inserts, too.Cutting edgebuild upCrumbling ofouter cornersHeavywearat flankCauseRemedyCauseRemedyCauseRemedylowcutting speedexcessive honingof cutting lipbright finish cutting lipincreasecutting speedreducecutting lip honinghavetool coatednon rigid conditions,insufficientworkpiece clampingdev. fr. conc. too largeinterrupted cutrigid clampingof workpiececheck and correct concentricityif possiblereduce feedcutting speedtoo highfeed to lowclearance angle toosmalldecreasecutting speedincrease feedincrease clearance angleCrumblingoncutting lipsLandwearScoring ontool bodyCausenon rigid conditions,insufficientworkpiece clampinginterrupted cutmaximum wear valueshave been exceededwrong tool typeRemedyrigid clampingof workpiecereduce feedreduce toolchange intervalsapply suitabletoolCausenon rigid conditions,insufficientworkpiece clampingdev. fr. conc. too largeback taper too smallwrong coolant/lubricat.(oil), coolant too weakRemedyrigid clampingof workpiececheck and correctconcentricityif possibleincrease back taperincrease strength ofcoolant or use neat oilCausenon rigid conditions,insufficientworkpiece clampingdeviation fromconcentricity too largeinterrupted cutabrasive workpiecematerialRemedyrigid clampingof workpiececheck and correctconcentricityif possiblereduce feedincrease stength ofcoolant or use neat oilHeavychisel edgewearCrumbling atintersection,web thinningand cutting lipPlasticdeformationof outer cornerCausecutting speedtoo lowfeed too highexcessive honing ofcutting lipRemedyincreasecutting speeddecrease feedreduce cuttinglip honingCauseclear. angle too smallexcessive honingof cutting lipwrong tool typeRemedyincrease clearance anglereducecutting lip honingapplysuitable toolCausecutting speedtoo highinsufficientcoolantincorrect or nohoning at cornerRemedydecreasecutting speedincreasecoolantvolume/pressurecorrect honingMisalignmentHeavyburring onbreakthroughUnsatisfactorysurface qualityRaCauseRemedyCauseRemedyCauseRemedynon rigid conditions,insufficientworkpiece clampingdev. fr. conc. too largespotting areatransversechisel edge too largerigid clampingof workpiececheck and correctconcentricity if possibleuse milling cutter(twin-fluted) for spottingreducechisel edgefeed too highmaximum wear valueshave been exceededexcessive honingof cutting lipdecrease feedreduce toolchange intervalsreducecutting lip honingnon rigid conditions,insufficientworkpiece clampingdeviation fromconcentricity too largeinsufficient coolantvolumerigid clampingof workpiececheck and correctconcentricity if possibleincreasecoolantvolume/pressure9

<strong>RT</strong> <strong>800</strong> <strong>WP</strong> . General technical informationGUHRINGGUIDE . Application recommendations• tools with bold feed column nos. are preferred choice.• for through holes supporting lands mustremain in permanent contact.• for 7 x D, centering is recommended with equal toor larger than 140° point angle tomin. 2/3 cutting edge diameter.• interrupted cutting (grooves, transverse holes) is not recommended.without prior tests. For interrupted cutting (max. 0.2 x D) it is recommendedto reduce the feed rate whenever possible.• in contrast to conventional indexable inserts, <strong>RT</strong> <strong>800</strong> is also suitablefor the drilling of stacked sheets.• when replacing the inserts, it is recommended to also replace theoriginal clamping screw with the included polyamide-coated screw.If this screw proves difficult to screw in, unscrew it again and removeany excess plyamide-coating.Drill-Ømm16,0020,0025,0031,5040,000,1000,1250,1600,1600,200Material groupFeed column no.1 2 3 4 5 6 7 8f (mm/rev.)0,1250,1600,2000,2000,250Common structural steelsFree-cutting steels0,1600,2000,2500,2500,315Unalloyed heat-treatable steelsAlloyed heat-treatable steelsUnalloyed case hardened steelsAlloyed case hardened steelsNitriding steelsTool steelsHigh speed steelsSpring steelsStainless steels, sulphuredausteniticmartensiticHardened steelsSpecial alloysCast ironSpheroidal graphite iron andmalleable cast ironChilled cast ironTitanium and Ti-alloysAluminium and Al-alloysAl wrought alloysAl cast alloys ≤ 10 % Si> 10 % SiMagnesium alloysCopper, low alloyedBrass, short-chippinglong-chippingBronze, short-chippingBronze, long-chippingDuroplasticsThermoplasticsKevlarGlass/carbon fibre0,2000,2500,3150,3150,4000,2500,3150,4000,4000,5000,3150,4000,5000,5000,6300,4000,5000,6300,6300,<strong>800</strong>0,5000,6300,<strong>800</strong>0,<strong>800</strong>1,00090,6300,6300,<strong>800</strong>1,0001,250Surface finish:brightS TiN-coatedF FIRE-coatedMaterial specific coolants:soluble oiloilairMaterial examples, new description (further in brackets)Figures in bold = material no. to DIN EN1.0035 S185(St33),1.0486 P275N(StE285),1.0345 P235GH(H1),1.0425 P265GH(H2)1.0050 E295 (St50-2), 1.0070 E360 (St70-2), 1.8937 P500NH (WStE500)1.0718 11SMnPb30 (9SMnPb28), 1.0736 11SMn37 (9SMn36)1.0727 46S20 (45S20), 1.0728 (60S20), 1.0757 46SPb20 (45SPb20)1.0402 C22, 1.1178 C30E (Ck30)1.0503 C45, 1.1191 C45E (Ck45)1.0601 C60, 1.1221 C60E (Ck60)1.5131 50MnSi4, 1.7003 38Cr2, 1.7030 28Cr41.5710 36NiCr6, 1.7035 41Cr4, 1.7225 42CrMo41.0301 (C10), 1.1121 C10E (Ck10)1.7043 38Cr41.5752 15NiCr13 (15NiCr13), 1.7131 16MnCr5, 1.7264 20CrMo51.8504 34CrAl61.8519 31CrMoV9, 1.8550 34CrAlNi71.1750 C75W, 1.2067 102Cr6, 1.2307 29CrMoV91.2080 X210Cr12, 1.2083 X42Cr13, 1.2419 105WCr6, 1.2767 X45NiCrMo41.3243 S 6-5-2-5, 1.3343 S 6-5-2, 1.3344 S 6-5-31.5026 55Si7, 1.7176 55Cr3, 1.8159 51CrV4 (51CrV4)1.4005 X12CrS13, 1.4104 X14CrMoS17, 1.4105 X6CrMoS17, 1.4305 X8CrNiS18-91.4301 X5CrNi18-10, 1.4541 X6CrNiTi18-10, 1.4571 X6CrNiMoTi 17 12 21.4057 X17CrNi16-2 (X17CrNi16-2), 1.4122 X39CrMo17-1, 1.4521 X2CrMoTi18-2–Nimonic, Inconel, Monel, Hastelloy0.6010 EN-GJL-100(GG10), 0.6020 EN-GJL-200(GG20)0.6025 EN-GJL-250(GG25), 0.6035 EN-GJL-350(GG35)0.7050 EN-GJS-500-7(GGG50), 0.8035 EN-GJMW-350-4(GTW35)0.7070 EN-GJS-700-2(GGG70), 0.8170 EN-GJMB-700-2(GTS70)–3.7024 Ti99,5, 3.7114 TiAl5Sn2,5, 3.7124 TiCu23.7154 TiAl6Zr5, 3.7164 TiAl6V4, 3.7184 TiAl4Mo4Sn2,5, - TiAl8Mo1V13.0255 Al99,5, 3.2315 AlMgSi1, 3.3515 AlMg13.0615 AlMgSiPb, 3.1325 AlCuMg1, 3.3245 AlMg3Si, 3.4365 AlZnMgCu1,53.2131 G-AlSi5Cu1, 3.2153 G-AlSi7Cu3, 3.2573 G-AlSi93.2581 G-AlSi12, 3.2583 G-AlSi12Cu, - G-AlSi12CuNiMgMgMn2, G-MgAl8Zn1, G-MgAl6Zn32.0070 SE-Cu, 2.1020 CuSn6, 2.1096 G-CuSn5ZnPb2.0380 CuZn39Pb2, 2.0401 CuZn39Pb3, 2.0410 CuZn43Pb22.0250 CuZn20, 2.0280 CuZn33, 2.0332 CuZn37Pb0,52.1090 CuSn7ZnPb, 2.1170 CuPb5Sn5, 2.1176 CuPb10Sn2.0790 CuNi18Zn19Pb2.0916 CuAl5, 2.0960 CuAl9Mn, 2.1050 CuSn102.0980 CuAl11Ni, 2.1247 CuBe2Bakelit, Resopal, Pertinax, MoltoprenPlexiglass, Hostalen, Novodur, MakralonKevlarGFK/CFKTesn. strength Hardness CoolantN/mm 2≤500>500-850≤850850-1000≤ 700700-850850-1000850-10001000-1200≤750850-10001000-1200≥850-10001000-1200≤850850-1000≥650-1000≤850≤850≤850≤1200≤850850-1200≤400≤450≤600≤600≤450≤400≤600≤600≤600>600-850≤850850-1000≤330 HB≤40-48 HRC>48-60 HRC≤240 HB

Tool materialSurface finish<strong>Guhring</strong> no.Carb.-UF2747Carb.-UF Carb.-UFSF1047 2485Cutting edge honing of carbide toolsMachining by detaching material(with the honed cutting edge)honed cuttingedge forconventionalcarbideCHIPCUTTING WEDGEadvanced fracturepredominantly for the machining of:52485242cast materials,aluminiumandAl-alloysgeneralsteels5243honed cuttingedge forUF carbidee≤5xDwith interchangeableinsertsSF≤7xDwith interchangeableinsertsSFCutting edge width bfor the most important materialsMaterialsheat-treatable steelscarbon steelshigh tensile steelscast ironWidth bmm 700.1-0.3600.05-0.150.02-0.1500.02-0.05Coolant pressure (bar)Internal cooling 20conveyable coolant volumemin.30opt.b25°FLUTEGOUJURE40 1610 400cooling 10 15 20 25 30 35 40Tool diameter (mm)282420128Coolant volume V (l/min)Feedcolumn no.v c m/mnFeedcolumn no.v c m/mnFeedcolumn no.3065766656576454543233322777623277777676666555559070706010180180140110180701801207050453550505050958095809590808065958055805540354035403025202015011011090253025200200170140200802101408065504080808080125105125105125120105105851251057010570555055505540352525195145145120354035260260220180260105270180105856555105105105105657666565764545432333227776232777776766665555590707060101801801401101807018012070504535505050509080908090857575659075558055403540354030252020150110110902530252002001701402008021014080655040808080801201051201051201101001008512010070105705550555055403525251951451451203540352602602201802601052701801058565551051051051055465554546544343222221166652216666656555544444Coolant volume V (l/min)Required coolant pressureand volumeThe optimal, good and minimum required coolant volumes shown in the diagrambelow are only valid for Ratio drills and T<strong>800</strong> tools re-spectively and are dependant onthe machine, because machines are equipped with different cooling systems and subsequentlyhave different leakage characteristics. Therefore, the pressure values illustratedserve only for information purposes and assessing the size of volume.optimalgoodminimum requirementCoolant pressure (bar)252015105070605040 16302010 20 30 40Coolant pressure P (bar)10 40010 15 20 25 30 35 40Tool diameter (mm)40 mm Ø32 mm Ø25 mm Ø20 mm Ø15 mm Ø282420128Coolant volume V (l/min)30(l/min)252040 mm Ø32 mm Ø25 mm Ø20 mm Ø11

<strong>Guhring</strong> oHGP.O. Box 100247 · D-72423 AlbstadtHerderstr. 50-54 · D-72458 AlbstadtTelephone: +49 74 31 17-0Fax: +49 74 31 17-2 79www.guehring.deOur product range:1. Drilling Toolsin High Speed Steel and CarbideTwist drillsRatio drillsMicro-precision drillsOil feed drillsSubland drillsCentre drillsCore drillsGun drills2. Thread Cutting Toolsin High Speed Steel and CarbideHand tapsMachine taps and fluteless tapsOil feed taps and oil feed fluteless tapsThread milling cuttersDies3. Milling Cuttersin High Speed Steel and CarbideRatio end millsLong hole milling cuttersSlot drillsEnd millsRadius profile cuttersHard profile cuttersDiesinking cutters4. Reaming Toolsin High Speed Steel and CarbideHand reamersMachine reamersMachine taper reamersQuick spiral and expanding machine reamersMachine bottoming reamers, shell reamers5. Countersinking Toolsin High Speed Steel and CarbideCountersinks, counterbores and spot facersShort counterbore systemBack spot facers6. Cutting Toolsin ultra-hard materialsCermet and ceramic toolsPCD- and PCB-tipped tools7. Coated ToolsA-tools, TiAlN-coatedC-tools, TiCN-coatedF-tools, FIRE-coated(allround)S-tools, TiN-coated(allround)M-tools, MolyGlide-coated8. Modular Tooling SystemsTooling system GM 300for rotary and stationary tools, offering a largecombination of tool holding possibilitiesFlexible tooling system GE 100a tooling system for the combined machiningoperations facing, chamfering, boring, centeringand so onCartridge tooling system DP 200with indexable inserts for roughing and finishingoperations in complex workpieces9. Special Toolsto sketch or drawing, the more complex, the better10. Carbidefor precision cutting tools, for metal formingand punching tools11. Tungsten Carbide Forming Toolsfor the production of nuts and bolts:Cold forming toolsHeading die inserts, punching pins12. HSC Motor Spindles,Hydro expansion chucks,Shrink fit chucks and systems13. Tool Restoration ServiceRe-grinding, re-coating, tool management115 953/0464-VII-15No liability can be accepted for printing errors or technical changes of any kind.Our Conditions of Sale and Terms of Payment apply. Available on request.