T1617 Halyard Aquadrive No2 ID2.indd

T1617 Halyard Aquadrive No2 ID2.indd

T1617 Halyard Aquadrive No2 ID2.indd

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

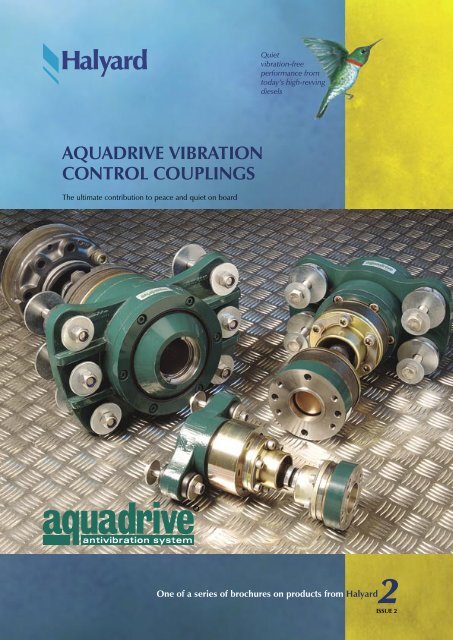

Quietvibration-freeperformance fromtoday’s high-revvingdieselsAQUADRIVE VIBRATIONCONTROL COUPLINGSThe ultimate contribution to peace and quiet on boardOne of a series of brochures on products from <strong>Halyard</strong>2ISSUE 2

WHY FIT AN AQUADRIVE?An <strong>Aquadrive</strong> system willreduce structure bornenoise and vibration by up to90%. It will reduce overallnoise levels by up to 75%.It will end shaft alignmentproblems on installation,and for ever more!It will allow the engine to be installedflat, because the <strong>Aquadrive</strong> allowsangles between the engine and theshaft. It will ease problems whenre-engining. And it’s a gift when reenginingan older boat.How does it removeso much noise?Marine engines traditionally havebeen coupled directly to thepropeller drive shaft, perhaps witha stiff flexible coupling between thetwo. Most of the vibration is sentstraight down the shaft, and theengine mounts can’t do their jobproperly because they are strainedforwards by propeller thrust. Sovibration gets into the hull, andvibration equals noise.The <strong>Aquadrive</strong> puts free movementbetween engine and shaft. It takesthe propeller thrust straight onto thehull, and allows free movement ofup to 25mm between engine andshaft – up and down, sideways, orfore and aft. No vibration goes downthe shaft, The mounts are no longerstrained forwards by the propeller’sthrust. The <strong>Aquadrive</strong> allows somuch movement that you can evenfit special softer mounts on enginesof four cylinders or more.What’s the result?Modern hulls are made from GRPor steel. Both materials carry noisebadly, so structure borne noise isa particular problem. The chartshows just how much noise can becancelled by fitting <strong>Aquadrive</strong>.2

AQUADRIVE TO SUITALL ENGINESModuline <strong>Aquadrive</strong>The new Moduline range. Twentyyears of development has produceda completely new range with lessweight, less length, more powercapacity, and all the advantages ofthe original concept. The <strong>Aquadrive</strong>special drive shaft has been upratedto take more power. Thethrust bearing assembly is nowcast from specially treated alloys toreduce weight. The shaft couplingis hidden away inside the thrustbearing to reduce length and weightdramatically.Long shaft <strong>Aquadrive</strong>sSystems with longer <strong>Aquadrive</strong>special drive shafts allow the engineposition to be varied enormously.Shafts up to 4 metres long allowengines to be raised or loweredrelative to the propeller shaft, oreven moved over to one side.3

AQUADRIVEHow does it solve shaftalignment problems?Marine engines are supported ontimber or steel bearers fixed into thehull. These bearers are positioned toallow the engine to line up roughlywith the shaft. The engine is thenadjusted on its mounts so that it linesup with the propeller shaft couplingwithin a few thousands of an inch.All this takes hours of painstakingwork. And then when you launchthe boat, or tighten the backstay on ayacht, it all moves slightly and needsto be done again!The <strong>Aquadrive</strong> changes all the rules.The propeller shaft fits into the<strong>Aquadrive</strong>’s thrust bearing, which isfixed firmly into the hull. The engineis connected using the <strong>Aquadrive</strong>’sspecial drive shaft. This allowsmisalignment of 12.5mm (1/2”) – ormore on larger <strong>Aquadrive</strong>s. Enginealignment can even vary whilerunning, so the movement on anolder or timber hull is not a problem.Can the engine beinstalled flat?Marine engines are normally lined upwith the propeller shaft, which hasto angle down through the bottom ofthe boat. The engine therefore endsup with its front higher than its back,wasting precious headroom.Fit an <strong>Aquadrive</strong> between the engineand the shaft and suddenly you havean angle of ten degrees or more,allowing the engine to be fittedhorizontally. The <strong>Aquadrive</strong> thrustbearing takes the propeller shaft(and the thrust!), and the specialdrive shaft is simply installed withthe desired angle at each end. Themaximum angle depends on theshaft speed.Will <strong>Aquadrive</strong> helpme re-engine?The biggest problem in choosing anew engine is fitting it in the existingspace, with the fewest possiblechanges to the craft. Just imaginethe flexibility if you could put anangle between the new engine andthe existing shaft. Or use a longer<strong>Aquadrive</strong> to lower the wholeengine. Or fit the <strong>Aquadrive</strong> totake out movement between a newengine with flexible mounts andtraditional solid sterngear.<strong>Aquadrive</strong>s installed with 400hpengines on a 15m motor yacht.<strong>Aquadrive</strong> with a Yanmar 2GMengine in a Contessa 32.How does the <strong>Aquadrive</strong>help with older boats?Older boats have two particularproblems, both of which makelife a misery when re-engining.The stern tube and shaft arerigidly mounted in the hull, sothe extra vibration of a new andflexibly mounted engine willsimply destroy the sterngear.And older hulls, particularlytimber ones, flex a great dealin the water causing the enginealignment to change. <strong>Aquadrive</strong>solves both problems by allowingfree movement between theengine and the shaft. Themovement of the new softmounts, and alignment changesdue to hull flexing, can beignored.4

WHAT’S INSIDE AN AQUADRIVE?The <strong>Aquadrive</strong> has four maincomponents. The gearboxadaptor is ready made to coupleour drive to your gearbox.Behind this comes the <strong>Aquadrive</strong>special drive shaft, with a toughconstant velocity joint at eachend. Then the thrust bearing,engineered to take forwardand reverse thrust, and rubbermounted to reduce noise. Finallythe shaft coupling, produced fora wide variety of shaft diameters.The thrust bearing is incredibly tough andbuilt with races which can be replaced evenafter many years running. Sealed ball bearingraces require zero maintenance on smaller<strong>Aquadrive</strong>s. Taper roller units are built into thelarger systems.The <strong>Aquadrive</strong> special drive shaft will take anangle of up to 8 degrees at each end, and thentake even more movement due to vibration.It will even take fore and aft movement – it iseasy to forget that an engines vibrates fore andaft as much as it does up and down!Gearbox adaptors are produced for almostevery gearbox on the market today. They aresupplied with all the correct nuts, bolts andwashers.Specially engineered shaft clamps, with boltssafely hidden inside the thrust bearing, are builtinto the new Moduline series of <strong>Aquadrive</strong>s toreduce length and weight.5

AQUADRIVE AS DRIVE SHAFTSTHE ONLY DRIVE SHAFT IN THEWORLD WITH FREE END FLOAT<strong>Aquadrive</strong> special drive shafts canbe used to connect Jet drives, Vdrives, thrusters and stern-drives.They remove vibration and takeout misalignment in just the sameway as the complete <strong>Aquadrive</strong>,but they have one huge advantageover rubber jointed drive shaftsand older universally jointed units– they allow the engine to vibratefreely fore and aft.No more vibration transmissionthrough rubber joints. No more ofthe torsional lock-up to be foundon shafts with sliding splines in thecentre. Just give us details of thecraft, power, and length and we’ll dothe rest.<strong>Aquadrive</strong> CVT systemsare designed for use where thereis no gearbox, and no drive plateto absorb the engine’s torsionalvibration. All the same advantages asa complete <strong>Aquadrive</strong>, and the sameunique free end float which no otherdrive shaft can offer.<strong>Aquadrive</strong> triplejoint shafts have a third joint anda support bearing partway alongtheir length. These specialised driveshafts allow total lengths of up to 9mfor installations where flexibility ofengine positioning is the key.<strong>Aquadrive</strong> extended shaftsup to 2 metres long, allowing majorengine position changes.6

AQUADRIVE ENGINE MOUNTSCOMPLIMENTING THE AQUADRIVE’SFLEXIBILITYWhat makes a mountgood – and safe?•Only natural rubber isused. Each size of mount ismanufactured with up to fourdifferent rubber stiffness grades.•The steel hood covers thewhole top of the mount, reducingthe risk of diesel attacking thenatural rubber.•The mount is “fully captive”.Even if the engine turns overand the rubber elements rip, theengine is held tight.The bolt holes are slotted•one way at each end so you canadjust their position.50210 mountsThe baby of the range. 38mmhigh with a 12mm stud. Fourrubber grades are available forweights up to 60kgs.The <strong>Aquadrive</strong> system creates free movement betweenthe engine and the shaft. One result is that the engine’smountings can be much softer than normal, partlybecause the engine can vibrate freely relative to theshaft, and partly because no propeller thrust reaches themounts and strains them forwards. <strong>Aquadrive</strong> enginemounts are used with engines of four cylinders or more,and our expert staff will rapidly select the correct rubberstiffness for the machinery involved.502405023050220 mountsThe most versatile mount ever,taking weights up to 200kgs ormore and available with fivedifferent rubber grades. Themount is 50mm high, with a16mm stud.50230 mountsThe big one. 68mm high with a20mm stud, the 50230 comes inthree rubber grades and will takeweights up to 700kgs.50240 mountsThe Giant. 110mm high andsecured with four bolts, the50240 has a 24mm stud andcomes in four rubber gradestaking up to almost 3000kgs.5022050210TrademarksModuline and <strong>Aquadrive</strong> areregistered trade marks.7

Literature Code HMI 81/02AQUADRIVE VIBRATIONCONTROL COUPLINGSOne of a series of brochures on products from <strong>Halyard</strong>We must reserve the right to change specifications without prior notice. <strong>Halyard</strong> and <strong>Aquadrive</strong> are trade marks.Phone and ask us ifyou’d like more help.We’re happy to talkthrough the details ofany installation.HALYARD (MARINE & INDUSTRIAL) LIMITEDWhaddon Business Park, Southampton Road, Whaddon,Salisbury SP5 3HF, United Kingdom.Telephone +44 (0)1722 710922 Fax: +44 (0)1722 710975http://www.halyard.eu.com e-mail: techhelp@halyard.eu.com<strong>Halyard</strong> holds ISO900Quality Assurance.All products in this brochure meet therequirements of the Recreational CraftDirective at 1st September 2003.