HCS 2.4/3.0. The countersinkable compression screw.

HCS 2.4/3.0. The countersinkable compression screw.

HCS 2.4/3.0. The countersinkable compression screw.

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

Instructions for Use<strong>HCS</strong> <strong>2.4</strong>/<strong>3.0.</strong> <strong>The</strong> <strong>countersinkable</strong><strong>compression</strong> <strong>screw</strong>.

Table of ContentsIntroductionFeatures and Benefits 2Functional Principle 3Indications 4Surgical TechniqueSurgical Technique for <strong>HCS</strong> <strong>2.4</strong>/3.0 6(illustrated using the <strong>HCS</strong> 3.0)Screw Extraction 13Product InformationImplants <strong>HCS</strong> <strong>2.4</strong> 14Instruments <strong>HCS</strong> <strong>2.4</strong> 16Setlist <strong>HCS</strong> <strong>2.4</strong> 18Implants <strong>HCS</strong> 3.0 19Instruments <strong>HCS</strong> 3.0 21Setlist <strong>HCS</strong> 3.0 23Image intensifier controlWarningThis description is not sufficient for immediate application ofthe instrumentation. Instruction by a surgeon experienced inhandling this instrumentation is highly recommended.Synthes 1

Features and BenefitsSelf-drilling and self-tapping flutesShorter surgery due to simplified surgicaltechniqueCannulationFor minimally invasive technique andguided insertionReverse-cutting flutesFacilitate <strong>screw</strong> removal and preventpotential breaking of implantsSelf-tapping flutesFacilitate countersinking of <strong>screw</strong>Two different thread lengths of the shaft<strong>The</strong> optimal implant for every case due to threads available in different lengthsIdentical pitch of head and shaft threadsFor controlled closure and <strong>compression</strong> of the fracture gapAvailable in steel and titaniumAll Headless Compression <strong>screw</strong>s from Synthes are available both in stainless implant-grade steel and high-quality biocompatibletitanium alloy (TAN).2 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

Functional PrincipleLag Screw Technique with Compression SleeveStep 1: Screw insertionInsertion of the <strong>screw</strong> into the bonewith the <strong>compression</strong> sleeve.Step 2: Closure of gap and<strong>compression</strong>Once the tip of the <strong>compression</strong> sleevelies on the bone, the fracture gap isclosed and compressed by further turningof the sleeve.Step 3: CountersinkingOnce the desired degree of <strong>compression</strong>is reached, the <strong>screw</strong> is countersunkinto the bone with the <strong>screw</strong>driverwhile the <strong>compression</strong> sleeve is heldstationary. During countersinking no additional<strong>compression</strong> is generated.Synthes 3

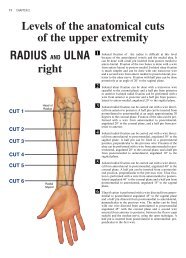

IndicationsFixation of intra-articular and extra-articular fractures andnon-unions of small bones and small bone fragments;arthrodeses of small joints; bunionectomies and osteotomies.Examples include, but are not limited to scaphoid and othercarpal bones, metacarpals, tarsals, metatarsals, patella, ulnarstyloid, capitellum, radial head and radial styloid.4 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

Overview of product lineThread Material Thread length Screw length Guide wire <strong>2.4</strong> mm Steel/TAN Short thread (variable) 9 – 40 mm 1.1 mmLong thread (variable) 16 – 40 mm3.0 mm Steel/TAN Short thread (variable) 10 – 40 mm 1.1 mmLong thread (variable) 16 – 40 mmSynthes 5

Surgical Technique for <strong>HCS</strong> <strong>2.4</strong>/3.01Insert the guide wireInstruments292.622 Guide Wire 1.1 mm with threaded tiporwith trocar, length 150 mm, Stainless Steel292.623 Guide Wire 1.1 mm with trocar tip,length 150 mm, Stainless Steel312.151 Double Drill Guide 2.0/1.1While monitoring with the image intensifier, advance theguide wire through the drill guide into the bone until thethread tip is anchored in the far cortex.Note: Do not forcefully insert the guide wire. This may causeit to bend.2Determine <strong>screw</strong> and thread lengthInstruments03.226.002 Direct Measuring Device for <strong>HCS</strong> –Headless Compression Screw 3.0 mm292.622 Guide Wire 1.1 mm with threaded tiporwith trocar, length 150 mm, Stainless Steel292.623 Guide Wire 1.1 mm with trocar tip,length 150 mm, Stainless SteelSlide the narrow end of the measuring device over the guidewire to the bone.<strong>The</strong> measurement on the measuring device shows the depthof the guide wire in the bone in millimeters and directly theappropriate <strong>screw</strong> length.Note: Only use the guide wire in its original length to ensurecorrect measurement.6 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

<strong>The</strong> position of the fracture line determines the threadlengthCorrectly selected thread length<strong>The</strong> shaft thread lies completely within the distal fragmentduring <strong>compression</strong>. Fragments can hence be compressed.Incorrect thread length<strong>The</strong> shaft thread lies over the fracture gap or the osteotomy.Fragments cannot be compressed.Note: If there is no good bone quality in the distal part ofthe bone, the distal <strong>screw</strong> thread can strip-out if too much<strong>compression</strong> is applied.Synthes 7

Surgical Technique for <strong>HCS</strong> <strong>2.4</strong>/3.03PredrillingInstruments310.221 Drill Bit 2.0/1.15 mm, cannulated,length 150/48 mm, 3-flute, for QuickCoupling312.151 Double Drill Guide 2.0/1.1Predrilling makes it substantially easier to insert the <strong>screw</strong> indense bone.Slide the drill guide with the drill bit over the guide wire andpre-drill to the desired depth.Remove the drill guide and verify the effective drilling depthwith the image intensifier.Note: Do not drill beyond the tip of the guide wire. Slowlypull the drill bit straight out while running the power tool in“forward mode” to ensure that the guide wire stays in place.8 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

4Pick up <strong>screw</strong>InstrumentFor <strong>HCS</strong> <strong>2.4</strong>03.226.016 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw <strong>2.4</strong> mmFor <strong>HCS</strong> 3.003.226.000 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw 3.0 mmTwist the <strong>compression</strong> sleeve over the head thread of the<strong>screw</strong> to remove the <strong>screw</strong> from the <strong>screw</strong> rack.Synthes 9

Surgical Technique for <strong>HCS</strong> <strong>2.4</strong>/3.05Insert <strong>screw</strong> and compress fragmentInstruments03.226.006 Handle for Compression Sleeve, for <strong>HCS</strong>For <strong>HCS</strong> <strong>2.4</strong>03.226.016 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw <strong>2.4</strong> mmFor <strong>HCS</strong> 3.003.226.000 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw 3.0 mmSlide the handle into the <strong>compression</strong> sleeve. Insert the <strong>screw</strong>into the bone until the fracture gap or the osteotomy isclosed and compressed.Notes– Verify the correct position of the shaft thread in the distalfragment using the image intensifier. If the thread lies overthe fracture gap or the osteotomy, the gap cannot be compressed.– Carefully tighten the <strong>screw</strong> with the <strong>compression</strong> sleeve.Forceful tightening could cause stripping of the shaftthread.– If the thread strips, some or all of the <strong>compression</strong> will belost. If the <strong>screw</strong> is then countersunk correctly, the threadwill regain purchase, thereby reducing the danger of postoperative<strong>screw</strong> loosening.– If loss of <strong>compression</strong> makes <strong>screw</strong> extraction necessary,follow the instructions on <strong>screw</strong> extraction on page 13.10 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

6Countersink <strong>screw</strong>Instruments03.226.004 Screwdriver Shaft, cannulated,Stardrive, T8, with colored marking,for <strong>HCS</strong>311.430 Handle with Quick Coupling,length 110 mmFor <strong>HCS</strong> <strong>2.4</strong>03.226.016 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw <strong>2.4</strong> mmFor <strong>HCS</strong> 3.003.226.000 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw 3.0 mmRemove the <strong>compression</strong> sleeve handle and slide the cannulated<strong>screw</strong>driver through the <strong>compression</strong> sleeve.Countersink the <strong>screw</strong> by turning the <strong>screw</strong>driver shaft whilesimultaneously holding the <strong>compression</strong> sleeve stationary.Verify the <strong>screw</strong> position with the image intensifier. Ensurethat the <strong>screw</strong> tip does not penetrate the distal cortex.Remove and dispose of the guide wire.Synthes 11

Surgical Technique for <strong>HCS</strong> <strong>2.4</strong>/3.0Color markings<strong>The</strong> color markings on the <strong>screw</strong>driver shaft show the positionof the <strong>screw</strong>driver tip and the head thread of the <strong>screw</strong>.Green mark at the top end of the<strong>compression</strong> sleeve<strong>The</strong> <strong>screw</strong>driver tip is seated correctlyin the Stardrvie recess of the <strong>screw</strong>.Yellow mark at the top end of the<strong>compression</strong> sleeve<strong>The</strong> top end of the head thread is evenwith the bone surface.Note: If the <strong>screw</strong> is inserted at an angle,it must be countersunk furtherthan the yellow mark so that it doesnot project from surface.Red mark at the top end of the<strong>compression</strong> sleeve<strong>The</strong> top end of the head thread isapproximately 2 mm below the bonesurface.12 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

Screw ExtractionInstruments314.467 Screwdriver Shaft, Stardrive, T8,orself-holding03.226.004 Screwdriver Shaft, cannulated,Stardrive, T8, with colored marking,for <strong>HCS</strong>311.430 Handle with Quick Coupling,length 110 mmFor <strong>HCS</strong> <strong>2.4</strong>03.226.016 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw <strong>2.4</strong> mmFor <strong>HCS</strong> 3.003.226.000 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw 3.0 mmFor the extraction of the <strong>HCS</strong> use a Stardrive <strong>screw</strong>driver orScrewdriver Shaft in combination with the handle.If the <strong>screw</strong> strips, use the following procedure:Twist the <strong>compression</strong> sleeve over the head thread and insertthe <strong>screw</strong>driver through the <strong>compression</strong> sleeve into theStardrive recess of the <strong>screw</strong>.Remove the <strong>screw</strong> by simultaneously pulling on the <strong>compression</strong>sleeve and turning both the <strong>screw</strong>driver and the <strong>compression</strong>sleeve in counterclockwise direction.Note: If necessary, expose the recess and part of the headthread with a hollow reamer (e.g. 309.035) or preferredmethod.Synthes 13

Implants <strong>HCS</strong> <strong>2.4</strong><strong>HCS</strong> <strong>2.4</strong> mm – Headless Compression Screw,short threadArt. No. Screw length Shaft thread length(mm)(mm)LSSL2 mm0X.226.209 9 40X.226.210 10 40X.226.211 11 40X.226.212 12 40X.226.213 13 40X.226.214 14 40X.226.215 15 40X.226.216 16 40X.226.217 17 40X.226.218 18 40X.226.219 19 40X.226.220 20 40X.226.221 21 40X.226.222 22 40X.226.223 23 40X.226.224 24 50X.226.225 25 50X.226.226 26 50X.226.227 27 60X.226.228 28 60X.226.229 29 60X.226.230 30 70X.226.232 32 70X.226.234 34 80X.226.236 36 90X.226.238 38 90X.226.240 40 10X = 2: Stainless SteelX = 4: Titanium Alloy (TAN)All <strong>screw</strong>s are also available sterile packed.14 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

<strong>HCS</strong> <strong>2.4</strong> mm – Headless Compression Screw,long threadArt. No. Screw length Shaft thread length(mm)(mm)LSSL2 mm0X.226.316 16 50X.226.317 17 60X.226.318 18 60X.226.319 19 70X.226.320 20 70X.226.321 21 80X.226.322 22 80X.226.323 23 80X.226.324 24 80X.226.325 25 80X.226.326 26 100X.226.327 27 100X.226.328 28 100X.226.329 29 100X.226.330 30 120X.226.332 32 120X.226.334 34 140X.226.336 36 140X.226.338 38 160X.226.340 40 16X = 2: Stainless SteelX = 4: TANAll <strong>screw</strong>s are also available sterile packed.Synthes 15

Instruments <strong>HCS</strong> <strong>2.4</strong>292.623 Guide Wire 1.1 mm with trocar tiplength 150 mm, Stainless Steel312.151 Double Drill Guide 2.0/1.1For protecting soft tissue during insertionof guide wires and predrilling03.226.002 Direct Measuring Device for <strong>HCS</strong>For determining the appropriate <strong>screw</strong>length310.221 Drill Bit 2.0/1.15 mm, cannulated,length 150/48 mm, 3-flute, for QuickCouplingFor predrilling03.226.016 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw <strong>2.4</strong> mmFor closing the fracture gap andcompressing the bone fragments03.226.006 Handle for Compression Sleeve for <strong>HCS</strong>311.430 Handle with Quick Coupling,length 110 mmFor Stardrive T8 Screwdriver Shafts(03.226.004 and 314.467)03.226.004 Screwdriver Shaft, cannulated, Stardrive,T8, with coloured marking, for <strong>HCS</strong> –Headless Compression Screw 3.0 mmFor countersinking the <strong>screw</strong>; with colormarkings to control countersink depth16 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

314.467 Screwdriver Shaft, Stardrive T8,self-holdingFor <strong>screw</strong> extraction; with self-retaining tip319.970 Screw Forceps, self-holding, length 85 mm319.292 Cleaning Stylet 1.1 mmFor cleaning cannulated instrumentsduring surgery319.291 Cleaning Brush 1.25 mmFor postoperative cleaning of cannulatedinstrumentsSynthes 17

Setlist <strong>HCS</strong> <strong>2.4</strong>Instrument Set for <strong>HCS</strong> – <strong>2.4</strong> mm for Vario Case01.226.012 Instrument and Implant Setin Stainless Steel01.226.014 Instrument and Implant Set in Titanium18 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

Implants <strong>HCS</strong> 3.0<strong>HCS</strong> 3.0 mm – Headless Compression Screw,short threadArt. No. Screw length Shaft thread length(mm)(mm)LSSL2 mm0X.226.010 10 40X.226.011 11 40X.226.012 12 40X.226.013 13 40X.226.014 14 40X.226.015 15 40X.226.016 16 40X.226.017 17 40X.226.018 18 40X.226.019 19 40X.226.020 20 40X.226.021 21 40X.226.022 22 40X.226.023 23 40X.226.024 24 50X.226.025 25 50X.226.026 26 50X.226.027 27 60X.226.028 28 60X.226.029 29 60X.226.030 30 70X.226.032 32 70X.226.034 34 80X.226.036 36 90X.226.038 38 90X.226.040 40 10X = 2: Stainless SteelX = 4: Titanium Alloy (TAN)All <strong>screw</strong>s are also available sterile packed.Synthes 19

Implants <strong>HCS</strong> 3.0<strong>HCS</strong> 3.0 mm – Headless Compression Screw,long threadArt. No. Screw length Shaft thread length(mm)(mm)LSSL2 mm0X.226.116 16 50X.226.117 17 60X.226.118 18 60X.226.119 19 70X.226.120 20 70X.226.121 21 80X.226.122 22 80X.226.123 23 80X.226.124 24 80X.226.125 25 80X.226.126 26 100X.226.127 27 100X.226.128 28 100X.226.129 29 100X.226.130 30 120X.226.132 32 120X.226.134 34 140X.226.136 36 140X.226.138 38 160X.226.140 40 16X = 2: Stainless SteelX = 4: TANAll <strong>screw</strong>s are also available sterile packed.20 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

Instruments <strong>HCS</strong> 3.0Standard instruments292.622 Guide Wire 1.1 mm with threaded tipwith trocar, length 150 mm, Stainless Steel292.623 Guide Wire 1.1 mm with trocar tiplength 150 mm, Stainless Steel312.151 Double Drill Guide 2.0/1.1For protecting soft tissue during insertionof guide wires and predrilling03.226.002 Direct Measuring Device for <strong>HCS</strong>For determining the appropriate <strong>screw</strong>length310.221 Drill Bit 2.0/1.15 mm, cannulated,length 150/48 mm, 3-flute, for QuickCouplingFor predrilling03.226.000 Compression Sleeve for <strong>HCS</strong> – HeadlessCompression Screw 3.0 mmFor closing the fracture gap andcompressing the bone fragmentsSynthes 21

03.226.006 Handle for Compression Sleeve, for <strong>HCS</strong>311.430 Handle with Quick Coupling,length 110 mmFor Stardrive T8 Screwdriver Shafts(03.226.004 and 314.467)03.226.004 Screwdriver Shaft, cannulated, Stardrive,T8, with coloured marking, for <strong>HCS</strong> –Headless Compression Screw 3.0 mmFor countersinking the <strong>screw</strong>; with colormarkings to control countersink depth314.467 Screwdriver Shaft, Stardrive T8,self-holdingFor <strong>screw</strong> extraction; with self-retaining tip319.970 Screw Forceps, self-holding, length 85 mm319.292 Cleaning Stylet 1.1 mmFor cleaning cannulated instrumentsduring surgery319.291 Cleaning Brush 1.25 mmFor postoperative cleaning of cannulatedinstruments22 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

Setlist <strong>HCS</strong> 3.0Instrument Set for <strong>HCS</strong> – 3.0 mm in Vario Case01.226.002 Instrument and Implant Setin Stainless Steel01.226.004 Instrument and Implant Set in TitaniumCase68.226.000 Vario Case for Instrument Set for <strong>HCS</strong> 3.0 mm, without Lid, without ContentsSynthes 23

24 Synthes <strong>HCS</strong> <strong>2.4</strong>/3.0 Instructions for Use

Presented by:0123036.000.323 SE_152904 AB 30070114 © 05/2008 Synthes, Inc. or its affiliates All rights reserved Synthes and Stardrive are trademarks of Synthes, Inc. or its affiliates