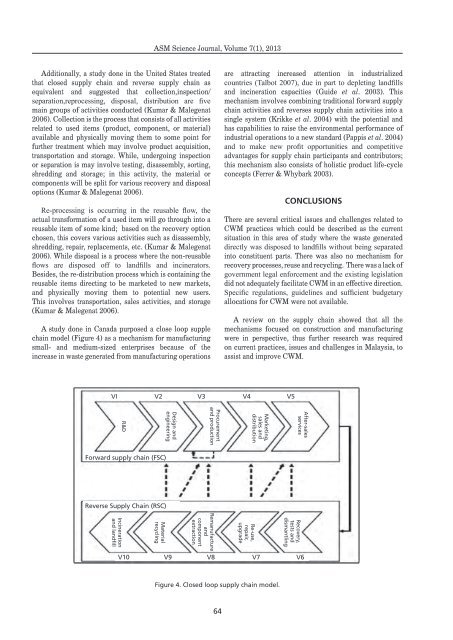

ASM Science Journal, Volume 7(1), 2013Additionally, a study done in the United States treatedthat closed supply chain and reverse supply chain asequivalent and suggested that collection,inspection/separation,reprocessing, disposal, distribution are fivemain groups of activities conducted (Kumar & Malegenat2006). Collection is the process that consists of all activitiesrelated to used items (product, component, or material)available and physically moving them to some point forfurther treatment which may involve product acquisition,transportation and storage. While, undergoing inspectionor separation is may involve testing, disassembly, sorting,shredding and storage; in this activity, the material orcomponents will be split for various recovery and disposaloptions (Kumar & Malegenat 2006).Re-processing is occurring in the reusable flow, theactual transformation of a used item will go through into areusable item of some kind; based on the recovery optionchosen, this covers various activities such as disassembly,shredding, repair, replacements, etc. (Kumar & Malegenat2006). While disposal is a process where the non-reusableflows are disposed off to landfills and incinerators.Besides, the re-distribution process which is containing thereusable items directing to be marketed to new markets,and physically moving them to potential new users.This involves transportation, sales activities, and storage(Kumar & Malegenat 2006).A study done in Canada purposed a close loop supplechain model (Figure 4) as a mechanism for manufacturingsmall- and medium-sized enterprises because of theincrease in waste generated from manufacturing operationsare attracting increased attention in industrializedcountries (Talbot 2007), due in part to depleting landfillsand incineration capacities (Guide et al. 2003). Thismechanism involves combining traditional forward supplychain activities and reverses supply chain activities into asingle system (Krikke et al. 2004) with the potential andhas capabilities to raise the environmental performance ofindustrial operations to a new standard (Pappis et al. 2004)and to make new profit opportunities and competitiveadvantages for supply chain participants and contributors;this mechanism also consists of holistic product life-cycleconcepts (Ferrer & Whybark 2003).CONCLUSIONSThere are several critical issues and challenges related toCWM practices which could be described as the currentsituation in this area of study where the waste generateddirectly was disposed to landfills without being separatedinto constituent parts. There was also no mechanism forrecovery processes, reuse and recycling. There was a lack ofgovernment legal enforcement and the existing legislationdid not adequately facilitate CWM in an effective direction.Specific regulations, guidelines and sufficient budgetaryallocations for CWM were not available.A review on the supply chain showed that all themechanisms focused on construction and manufacturingwere in perspective, thus further research was requiredon current practices, issues and challenges in <strong>Malaysia</strong>, toassist and improve CWM.VIV2 V3 V4 V5After-salesservicesMarketing,sales anddistributionProcurementand productionDesign andengineeringR&DForward supply chain (FSC)Reverse Supply Chain (RSC)Incinerationand landfillMaterialrecyclingRemanufactureandcomponentextractionRe-use,repair,upgradeRecovery,tests anddismantlingV10 V9 V8 V7 V6Figure 4. Closed loop supply chain model.64

M.N.N. Husna et al.: Construction Waste Management: Issues, Challenges and Supply Chain Management MechanismsACKNOWLEDGEMENTSThe authors are grateful to Universiti Teknologi MARA forfunding the research work. Prof Ahmad Ruslan MohdRidzuan and Dr Intan Rohani Endut are acknowledged fortheir continuous support and encouragement.Date of submission: May 2011Date of acceptance: February 2013REFERENCESAgamuthu, P, Hamid, FS & Khidzir, K 2009, ‘Evolution of solidwaste managemnt in <strong>Malaysia</strong>: impacts and implicationsof solid waste bill’, 2007, J. Mater. Cycles Waste Manag.,vol. 11, pp. 96–103.Andrew, RT & Dainty, Richard, TB 2004, ‘Towards improvedconstruction waste minimisation: a need for improvedsupply chain integration?’, Emerald Research Register,vol. 22, no. 1, pp. 20–29.Beamon, BM, 1999, ‘Designing the green supply chain’,Logistic Information Management’, vol. 12, no. 4 , pp.332–342.Beamon, BM 1998, ‘Supply chain design and analysis modelsand methods’, International Journal of ProductionEconomics, vol. 55, no. 3, pp. 281–229.Begum, et al. 2006, ‘Implemetation of waste managementand minimization in the connstruction industry of<strong>Malaysia</strong>’, Universiti Kebangsaan <strong>Malaysia</strong>, Bangi.Begum, RA, Siwar, C, Pereira, JJ & Jaafar, AH, 2007,‘Implementation of waste management and minimisationin the construction industry of <strong>Malaysia</strong>', Resouces,Conservation and Recycling, vol. 51, pp.190–202.Chong, TT, Tang, HH & Larsen, IB, 2001, Environmentalperformance: articles on waste and river management,Sarawak Government/DANCED Sustainable UrbanDevelopment Project, Sarawak.Coelho, AD 2006, Construction and demolition wastemanagement in Portugal, Instituto Superior Tecnico,Universidade Technica de Lisbone, Portugal.Dale, BG, Lascelles, DM & Lloyd, A (eds), 1994, Supply chainmanagement and development, in Managing quality, edBG Dale, Prentice Hall, New York.Economic Planning Unit, 2006–2010, Ninth <strong>Malaysia</strong> Plan,The Economic Planning Unit, Putrajaya, <strong>Malaysia</strong>.Ferrer & Whybark 2003, ‘The economics of remanufacturing,in guide’, in business aspect of closedloop supply chain:exploring the issues, eds VDR Jr. & VanWassenhove, Carnegie Mellon University Press, Pittsburg,PA., USA.Guide et al. 2003, ‘The Challenge of Closed loop supplychain, Interfaces’, vol. 33, no. 3, pp. 3–6, .Hussein, J & Abd Hamid, Z 2010, ‘Issues and challengesin sustainable construction in the built environment:<strong>Malaysia</strong>n construction industry initiatives’, viewed 18October 2010.Idris, A, Inanc, B & Hassan, MN, 2004, ‘Overview of wastedisposal and landfills/dumps in Asian countries’, MaterialCycles and Waste Management in Asia, vol. 6, pp. 104–110.Kofoworola, OF & Gheewala, SH 2009, ‘Estimation ofconstruction waste generation and management inThailand’, Waste Management, vol. 29, pp. 731–738.Krikke et al. 2004, ‘Product modularity and the designof closed loop supply chain’, California ManagementReview, vol. 46, no. 2, pp. 23–39.Kumar, S & Malegenat, P 2006, ‘Strategic alliance in a closedloop supply chain, a case of manufacturer and eco-nonprofitorganization’, Technovation, vol. 26, no. 10, pp.1127–1135.Lambert, DM, Cooper, MC & Pajh, JD 1998, ‘Supply chainmanagement: implementation issues and researchopportunities’, International Journal of LogisticsManagement, vol. 9, no. 2, pp. 1–18.Lamming, R & Hampson, J 1996, ‘The environment as asupply chain issues’, British Journal of Management, vol.7, pp. 45–62.Ministry of Housing and Local Government 2005, Nationalstrategic plan for sloid waste management, .Pappis et al. 2004, ‘LCA as a tool for the evaluation of endof life options of spent products’, in Reverse logistic:quantitative models for closed loop supply chain, eds RDekker et al., Springer-Verlag, Heibelberg, pp. 333–356.Poon, CS, Ann, TW & Ng, LH 2001, ‘On-site sorting of constructionand demolition waste in Hong Kong’, Resources,Conservation and Recycling, vol. 32, pp. 157–172.Royat, S 1994, ‘Development strategy of construction industryin Indonesia, in Workshop on Strategic Managementin Construction Industry, Bandung.Shen, LY, Tam, VWY, Tam, CM & Ho, S 2000, ‘Materialwastage in construction activities—a Hong Kong survey’,in Proceedings of the 1st CIB-W107 InternationalConference — Creating a Sustanable ConstructionIndustry in Developing Countries, pp. 125–131.Sheu et al. 2005, ‘An integrated logistics operational modelfor green supply chain management’, TransportationResearch Part E. Solid Waste and Public CleaningDepartment, (Act 672), Laws of <strong>Malaysia</strong>.Solvang, WD, Deng, Z & Solvang, B 2007, ‘A closed-loopsupply chain model for managing overall optimization ofeco-efficiency’, in POMS 18th Annual Conference, Dallas,Texas, USA.Stevens 1989, ‘Integrating the supply chain’, InternationalJournal of Physical Distribution and MaterialManagement, vol. 19, no. 8, pp. 3–8.Symonds 1999, ‘Construction and demolition wastemanagement practices and their economic impacts’, inreport to DGXI.Talbot S 2007, ‘Closed loop supply chain activities andderived benefits in manufacturing SMEs’, Journal of65

- Page 1 and 2:

ContentsASM Sc. J.Volume 7(1), 2013

- Page 3 and 4:

INTERNATIONAL ADVISORY BOARDAhmed Z

- Page 5:

The Academy of SciencesMalaysia (AS

- Page 8 and 9:

NEWS FOCUSBio-Jet Fuel — Challeng

- Page 10 and 11:

ASM Science Journal, Volume 7(1), 2

- Page 12 and 13:

NitrogengasAcetylene gasFume hoodGa

- Page 14 and 15:

ASM Science Journal, Volume 7(1), 2

- Page 16 and 17:

ASM Science Journal, Volume 7(1), 2

- Page 18 and 19:

ControllerN 2N 2ValveValvePreheater

- Page 20 and 21:

ASM Science Journal, Volume 7(1), 2

- Page 22 and 23: ASM Science Journal, Volume 7(1), 2

- Page 24 and 25: ASM Science Journal, Volume 7(1), 2

- Page 26 and 27: ASM Sci. J., 7(1), 18-22Electron-ph

- Page 28 and 29: v I= v MthASM Science Journal, Volu

- Page 30 and 31: ASM Science Journal, Volume 7(1), 2

- Page 32 and 33: ASM Science Journal, Volume 7(1), 2

- Page 34 and 35: ASM Science Journal, Volume 7(1), 2

- Page 36 and 37: ASM Science Journal, Volume 7(1), 2

- Page 38 and 39: ASM Science Journal, Volume 7(1), 2

- Page 40 and 41: 4.2 × 10 -5Magnetic energy (Em) Ma

- Page 42 and 43: 2.0 × 10 -5Inductance (L)Magnetic

- Page 44 and 45: ASM Science Journal, Volume 7(1), 2

- Page 46 and 47: addition, examination of the freque

- Page 48 and 49: equipped with a computer image anal

- Page 50 and 51: Storage modulus (Pa)1.80E+101.60E+1

- Page 52 and 53: (a)(b)(c)Figure 6. Micrographs: (a)

- Page 54 and 55: 0 20 40 60 80 100 120 140 160 180 2

- Page 56 and 57: 0.00 20 40 60 80 100 120 140 160180

- Page 58 and 59: 0 20 40 60 80 100 120 140 160Temper

- Page 60 and 61: 2.0100.00 20 40 60 80 100 120 140 1

- Page 62 and 63: 3.02.53.02.02.5CB10TSSAlbipoxTimber

- Page 64 and 65: Figure 18. SEM micrographs of the f

- Page 66 and 67: Crawford, E & Lesser, AJ 1998, ‘T

- Page 68 and 69: ASM Science Journal, Volume 7(1), 2

- Page 70 and 71: ASM Science Journal, Volume 7(1), 2

- Page 74 and 75: ASM Science Journal, Volume 7(1), 2

- Page 76 and 77: ASM Science Journal, Volume 7(1), 2

- Page 78 and 79: ASM Science Journal, Volume 7(1), 2

- Page 80 and 81: ASM Science Journal, Volume 7(1), 2

- Page 82 and 83: Climate Change — Environment andI

- Page 84 and 85: ASM Science Journal, Volume 7(1), 2

- Page 86 and 87: ASM Science Journal, Volume 7(1), 2

- Page 88 and 89: ASM Science Journal, Volume 7(1), 2

- Page 90 and 91: Announcements!!!!!!!!!!!!!!!!!!!!!!

- Page 93 and 94: ASM PublicationsMosquitoes and Mosq

- Page 95 and 96: ASM PublicationsEnhancing Animal Pr

- Page 97 and 98: ASM PublicationsThe Red Jungle Fowl

- Page 99 and 100: Vol. 3, No. 1, June : 1823-6782ASM

- Page 101 and 102: ASM PublicationsIn Pursuit of Excel

- Page 103 and 104: ASM PublicationsASM Lecture SeriesW

- Page 105 and 106: ASM PublicationsA Nobel Trip to Lin

- Page 107 and 108: Vol. 6, No. 2, December 2012 • IS

- Page 109 and 110: About the JournalMission StatementT

- Page 111: ASM SCIENCE JOURNAL(ASM Sc. J.)ORDE

- Page 114: NEWS FOCUSBio-Jet Fuel — Challeng