Contents - Akademi Sains Malaysia

Contents - Akademi Sains Malaysia

Contents - Akademi Sains Malaysia

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

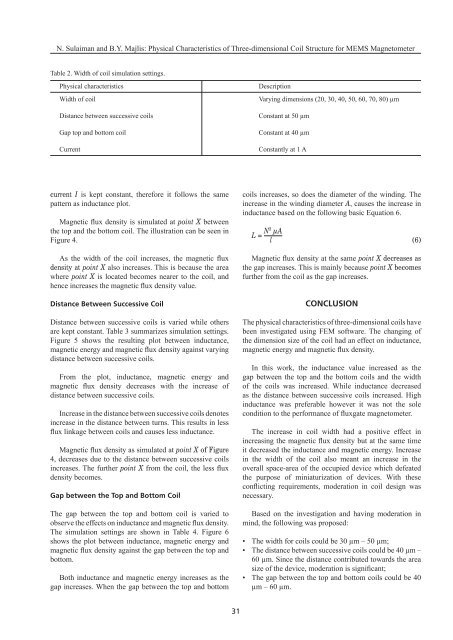

N. Sulaiman and B.Y. Majlis: Physical Characteristics of Three-dimensional Coil Structure for MEMS MagnetometerTable 2. Width of coil simulation settings.Physical characteristicsDescriptionWidth of coil Varying dimensions (20, 30, 40, 50, 60, 70, 80) µmDistance between successive coils Constant at 50 µmGap top and bottom coil Constant at 40 µmCurrentConstantly at 1 Acurrent I is kept constant, therefore it follows the samepattern as inductance plot.Magnetic flux density is simulated at point X betweenthe top and the bottom coil. The illustration can be seen inFigure 4.As the width of the coil increases, the magnetic fluxdensity at point X also increases. This is because the areawhere point X is located becomes nearer to the coil, andhence increases the magnetic flux density value.Distance Between Successive CoilDistance between successive coils is varied while othersare kept constant. Table 3 summarizes simulation settings.Figure 5 shows the resulting plot between inductance,magnetic energy and magnetic flux density against varyingdistance between successive coils.From the plot, inductance, magnetic energy andmagnetic flux density decreases with the increase ofdistance between successive coils.Increase in the distance between successive coils denotesincrease in the distance between turns. This results in lessflux linkage between coils and causes less inductance.Magnetic flux density as simulated at point X of Figure4, decreases due to the distance between successive coilsincreases. The further point X from the coil, the less fluxdensity becomes.Gap between the Top and Bottom CoilThe gap between the top and bottom coil is varied toobserve the effects on inductance and magnetic flux density.The simulation settings are shown in Table 4. Figure 6shows the plot between inductance, magnetic energy andmagnetic flux density against the gap between the top andbottom.Both inductance and magnetic energy increases as thegap increases. When the gap between the top and bottomcoils increases, so does the diameter of the winding. Theincrease in the winding diameter A, causes the increase ininductance based on the following basic Equation 6.L = N2 µAl (6)Magnetic flux density at the same point X decreases asthe gap increases. This is mainly because point X becomesfurther from the coil as the gap increases.CONCLUSIONThe physical characteristics of three-dimensional coils havebeen investigated using FEM software. The changing ofthe dimension size of the coil had an effect on inductance,magnetic energy and magnetic flux density.In this work, the inductance value increased as thegap between the top and the bottom coils and the widthof the coils was increased. While inductance decreasedas the distance between successive coils increased. Highinductance was preferable however it was not the solecondition to the performance of fluxgate magnetometer.The increase in coil width had a positive effect inincreasing the magnetic flux density but at the same timeit decreased the inductance and magnetic energy. Increasein the width of the coil also meant an increase in theoverall space-area of the occupied device which defeatedthe purpose of miniaturization of devices. With theseconflicting requirements, moderation in coil design wasnecessary.Based on the investigation and having moderation inmind, the following was proposed:• The width for coils could be 30 µm – 50 µm;• The distance between successive coils could be 40 µm –60 µm. Since the distance contributed towards the areasize of the device, moderation is significant;• The gap between the top and bottom coils could be 40µm – 60 µm.31