HAYNES® 556™ alloy - Haynes International, Inc.

HAYNES® 556™ alloy - Haynes International, Inc.

HAYNES® 556™ alloy - Haynes International, Inc.

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

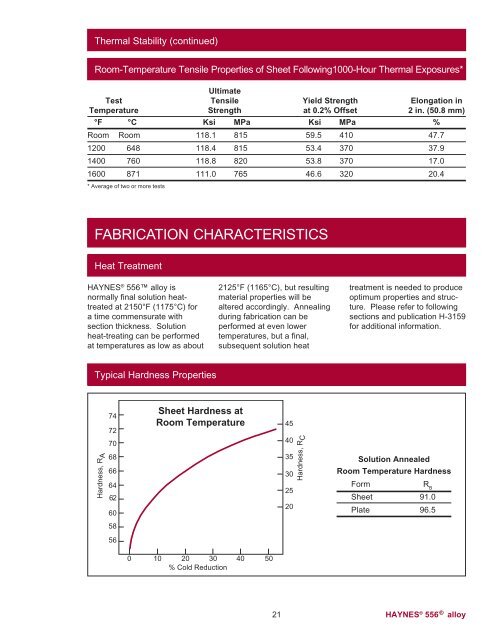

Thermal Stability (continued)Room-Temperature Tensile Properties of Sheet Following1000-Hour Thermal Exposures*TestTemperature°F °CUltimateTensileStrengthKsi MPaYield Strengthat 0.2% OffsetKsi MPaElongation in2 in. (50.8 mm)%RoomRoom118.1 81559.5 41047.71200 6481400 760118.4 815118.8 82053.4 37053.8 37037.917.01600 871111.0 76546.6 32020.4* Average of two or more testsFABRICATION CHARACTERISTICSHeat TreatmentHAYNES ® 556 <strong>alloy</strong> isnormally final solution heattreatedat 2150°F (1175°C) fora time commensurate withsection thickness. Solutionheat-treating can be performedat temperatures as low as about2125°F (1165°C), but resultingmaterial properties will bealtered accordingly. Annealingduring fabrication can beperformed at even lowertemperatures, but a final,subsequent solution heattreatment is needed to produceoptimum properties and structure.Please refer to followingsections and publication H-3159for additional information.Typical Hardness PropertiesHardness, R A7472706866646260Sheet Hardness atRoom Temperature454035302520Hardness, R CSolution AnnealedRoom Temperature HardnessFormR BSheet 91.0Plate 96.558560 10 20 30 40 50% Cold Reduction21HAYNES ® 556 TM <strong>alloy</strong>