YMA Modular Air Handling Units

YMA Modular Air Handling Units

YMA Modular Air Handling Units

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

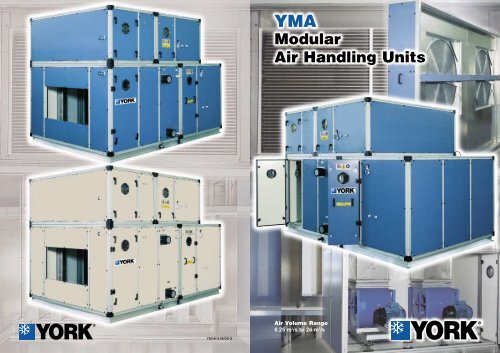

<strong>YMA</strong><strong>Modular</strong><strong>Air</strong> <strong>Handling</strong> <strong>Units</strong><strong>Air</strong> Volume Range0.25 m 3 /s to 26 m 3 /sY3014/12.00/GB Q

FiltersFilter sectionsare designedfor easy front orside withdrawalof the followingfilter types:PrefiltersSynthetic orglass-fibremedia panel filters, class EU2 to EU4 (EU3 suppliedas standard) arranged in galvanised steel frames orsliding rails.Main FiltersSynthetic or glass-fibremedia bag filters, classEU5 to EU8 (EU6 suppliedas standard) arranged ingalvanised steel frameswith gaskets to avoid airbypass.Cooling and Heating CoilsCooling and heating coils are computer selected toachieve the optimum psychrometric efficiency with lowair and water pressure drops.CoilsStandard coils are constructed from copper tubesmechanically bonded to aluminium fins, with threadedsteel headers, all contained in a galvanised steel frame.<strong>Air</strong> vents and drain connections are provided. Coils areFinal FiltersHigh efficiency compact cell filters, class EU10 toEU12 (HEPA 95 to 99.99% Nacl), fixed with brackets,nuts and bolts or clamps to a heavy galvanised steelgasketted structure. DOP testing of filter bankavailable if required.leak tested at 30 bar with a maximum design pressureof 15bar. The cooling coil assembly is located in a drainpan within the coil section on slide rails for easywithdrawal from either side.Condensate pans are a “dry pan” design, manufacturedfrom a choice of stainless steel or aluminium alloy toensure complete condensate removal.Aluminium droplet eliminators are fitted after coolingcoils when the air velocity exceeds 2.5m/s.Coil options are:◆ Medium/high pressure steam coils. ◆ Copper fins. ◆ Electro-tinned copper fins.◆ Pre-painted and epoxy coated fins. ◆ Copper headers. ◆All steel coils.◆ All aluminium coils. ◆ Direct expansion coils. ◆ Stainless steel slide rails.◆ Stainless steel drain pans.◆ Aluminium and PPTV droplet eliminators.Electric Heating CoilsManufactured from lowtemperature screenedstainless steel tube andspiral fin heatingelements secured to aheavy gauge steel frame.A manual reset safetythermostat, a hightemperature cutout andan airflow switch arefitted. Step or modulatingcontrol options areavailable.HumidifiersGenerated Steam HumidifierConsists of immersed electrodes, steam cylinder,stainless steel distribution pipe and electronic controlsfor water regulation and automatic flushing.<strong>Air</strong> WasherAn externally mounted pump, with a removable strainer,draws water from an aluminium alloy tank, which has aliquid level regulator, overflow, drain and flushingdevice. Spray distribution is via a nylon pipe andnozzles. Sprays may be single or double row.An air tight access hatch, with porthole, an internallight, a perforated air equaliser plate and a dropleteliminator are incorporated.Where plant space is at a premium plenum type fansmay be used. The plenum fan pressurises anacoustically lined fan chamber and circular orrectangular discharge duct connections can be locatedon the external faces of the chamber. This reduces thelength of the air handling plant by eliminating the needfor external attenuators or complicated ducttransformation pieces. Please contact local sales officefor fan application details.Fan Controls◆ Double speedfan motors.◆ Direct drivefans.◆ Fan speedfrequencyinverters.Wet Deck HumidifierA viscose-coated evaporating pack is moistened withwater, circulated by an internally mounted pump withremovable strainer, from a header tank. The base tankincludes a ball valve, overflow and drain. The assemblyis constructed from aluminium alloy sheets.OptionsGalvanised andpainted internalparts.Stainless steelstructure, tankand eliminators.Fans<strong>YMA</strong> units are supplied with one or two double inlet, double width forward or backward curved centrifugal fans. Faninlets are aerodynamically designed and wheels statically and dynamically balanced according to airflow and speed.Smaller fans have sealed for life bearings and larger versions have block type self aligning ball journals and splitblocks with grease points. Vee belt fan drives have removable fan guards.Motors are totally enclosed fan cooled type class F insulation to IP55 protection.The total fan assembly is installed on a separate frame isolated from the unit structure by spring anti-vibrationmounts.FanSectionAcoustically LinedFan SectionAttenuatorSectionTransformationPieceSupply <strong>Air</strong>DuctsSupply <strong>Air</strong>DuctsStandard Centrifugal Fan ConfigurationThe FrameThe low weight corrosion resistant aluminium alloy twinbox section profile is designed to provide strength andstability. Gaskets, between panels and profile, ensureairtight sealing. A thermal bridge free profile can beprovided. Unit sections are mounted on a 2.5mm thickgalvanised steel-bolted base frame.AccessPanels are fully removable.Access doors are equippedwith half turn nylon handlesand cam locks. Hinges arefibreglass re-inforced plasticwith stainless steel pivots.Optional double glazedviewing portholes can besupplied.StandardConstructionPanelsStandard 30mm or 60mm double skinned galvanisedpanels comprising 0.7mm internal and external skinsand 40kg/m 3 density pressure injected polymerisedpolyurethane foam insulation providing a thermaltransmission coefficient of K = 0.68 W/m o C. Otherforms of insulation can be supplied. Optional panelscan be manufactured from pre-plastic coated steel, prepaintedmetal or Peraluman. Panels are fixed to framewith stainless steel screws.DampersExtruded aluminiumdampers are the opposedor parallel blade type. Theflanged frame is pre-drilledfor ductwork connection.A gasket is installed tominimise air leakage.Spindles are manufacturedfrom aluminium or nylonand have Teflon bushes.Control links arealuminium.Cold BridgeFreeConstructionPlenum Fan Configuration

<strong>YMA</strong> <strong>Modular</strong> <strong>Air</strong> <strong>Handling</strong> <strong>Units</strong><strong>Air</strong> Volume Range 0.25 m 3 /s to 26 m 3 /sThe <strong>YMA</strong> family of air handling units consist of thirty one models having air volumes ranging from 0.25m 3 /s to 26 m 3 /s and total static pressures as high as 1600 Pascal. Custom designed units with largercapacities up to 50 m 3 /s are also available.All units are constructed from extruded aluminium profiles and have flush fitting panels and doors toprovide aesthetically pleasing lines. All panels are completely removable.The thermally insulated rigid enclosure is fully sealed and has a high acoustic performance.Accurate computer selection ensures cost effective matching of all components to satisfy the specifiedconditions.<strong>YMA</strong> <strong>Air</strong> <strong>Handling</strong> <strong>Units</strong> can be manufactured in varied configurations, with a wide selection ofcomponents, to meet customer requirements.They may include combinations of any of the following:◆ Single or double decked units.◆ Indoor or outdoor applications.Outdoor units are available with a flat or slopingroof, louvres, rainhoods, birdscreens and specialfinishes.◆ Site assembled units.Where space constraints restrict the size of a singleitem modules can easily be aligned and lockedtogether by gaskets and stainless steel boltsinserted into factory predrilled assembly holes.◆ <strong>Air</strong> mixing boxes.◆ Various filter options.◆ Cooling and heating coils.◆ Humidifiers.◆ Heat recovery systems.◆ Various fan types and drives.◆ Sound attenuation.◆ Factory fitted controls.◆ Miscellaneous components.◆ York Roof Top Packaged <strong>Air</strong> Systems.These include all necessary piping, wiring, controlsand refrigeration equipment to provide a completecentral air conditioning plant.Sound AttenuationStandard attenuation sections, having baffles ofgalvanised steel and hygroscopic material, areavailable in six lengths from 600mm to 1800mm.Perforated plate liners are optional.Heat RecoveryThe following forms of heat recovery equipment can besupplied:Plate Heat ExchangerManufactured from aluminium or plastic plates(optional stainless steel or polycarbonate) andturbulation channels to permit heat transfer from warmto colder air systems without mixing the two airstreams.Drain trays are provided for condensate collection.Heat PipeVertically mounted tubes, charged with refrigerant,exchange heat by the evaporation of warm air streamin the lower section and re-condensation in the cold airstream in the upper section.Thermal WheelAvailable with a hygroscopic or non-hygroscopic rotorfor recovering and transferring heat energy from theexhaust to the supply air streams.LightingOptional water resistant bulkhead lights and switchescan be supplied.Computer Selection ProgrammeThe flexible computerised programme provides theoptimum equipment selection, to satisfy thespecified conditions, and providesfull technical information andcertified drawings.