2007 Baja Project - Suspension - Motion Research Group

2007 Baja Project - Suspension - Motion Research Group

2007 Baja Project - Suspension - Motion Research Group

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

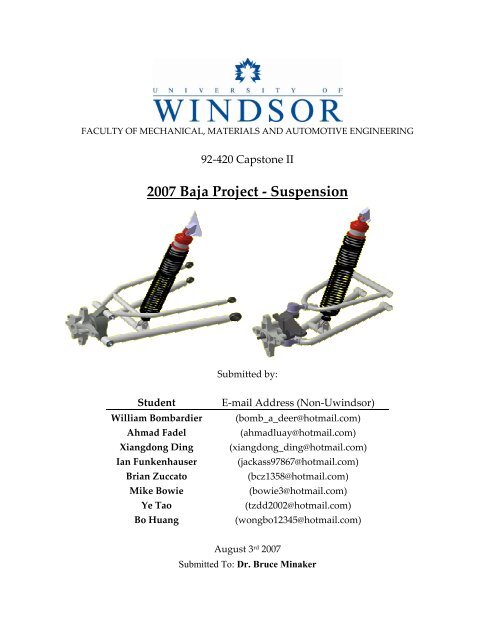

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>1) Table of Contents1) Table of Contents............................................................................................................. i2) List of Tables................................................................................................................. iv3) List of Figures................................................................................................................. v4) List of Equations............................................................................................................ix5) Nomenclature.................................................................................................................. x6) Introduction to <strong>Suspension</strong> Kinematics and Kinetics..................................................... 16.1) <strong>Suspension</strong> Kinetics................................................................................................. 16.1.1) Vehicle ride modeling (vertical dynamics) ...................................................... 26.1.2) Vehicle handling............................................................................................. 116.2) <strong>Suspension</strong> Kinematics.......................................................................................... 186.2.1) Track width and tire scrub.............................................................................. 186.2.2) Instant center and roll center position............................................................. 196.2.3) Camber angle.................................................................................................. 216.2.4) Caster angle and caster trail............................................................................ 246.2.5) Kingpin angle and scrub radius ...................................................................... 256.2.6) Toe angle, roll steer and bump steer............................................................... 276.2.7) Aligning torque or self centering moment...................................................... 306.2.8) Anti-dive/anti-squat........................................................................................ 306.2.9) <strong>Motion</strong> ratio and wheel rate............................................................................ 336.2.10) Roll stiffness................................................................................................. 346.2.11) Vehicle ride height........................................................................................ 356.2.12) Understeering/Oversteering characteristics of vehicle................................. 356.3) Spring rate determination ...................................................................................... 377) <strong>2007</strong> <strong>Suspension</strong> Kinematics........................................................................................ 387.1) Choosing the dimensions of the vehicle................................................................ 387.2) Choosing the suspension points............................................................................. 407.3) Choosing the suspension geometry angles ............................................................ 417.4) Choosing the inner suspension points ................................................................... 427.5) Choosing the steering tie rods lengths................................................................... 477.6) Choosing the strut mounting points....................................................................... 487.7) Design front and rear suspension to be consistent................................................. 498) <strong>2007</strong> <strong>Suspension</strong> kinetics.............................................................................................. 528.1) Handling analysis on 2006 vehicle........................................................................ 52i

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>8.2) Approach to designing <strong>2007</strong> suspension kinetics.................................................. 538.3) <strong>2007</strong> front and rear suspension shocks.................................................................. 548.4) The required spring rates based on the Olley criteria............................................ 548.5) CarSim model for <strong>2007</strong> vehicle............................................................................. 568.6) Necessary combination of Elka <strong>Suspension</strong>s springs............................................ 648.7) Evaluation of spring rate in CarSim ...................................................................... 658.8) Ride, bounce, pitch and wheel hop frequencies .................................................... 678.9) Prediction of vehicle performance in regards to the dynamic events.................... 729) <strong>Suspension</strong> Component Design.................................................................................... 749.1) Choice of Materials........................................................................................... 749.2) Front <strong>Suspension</strong> System.................................................................................. 759.2.1) Control Arms ............................................................................................ 759.2.2) Finite Element Analysis............................................................................ 769.2.3) Joints ......................................................................................................... 789.2.4) Steering tie rod and bump stop ................................................................. 809.3) Rear <strong>Suspension</strong> System........................................................................................ 829.3.1) Control Arms .................................................................................................. 829.3.2) Finite Element Analysis.................................................................................. 849.3.3) Joints............................................................................................................... 849.4) Installation ............................................................................................................. 8510) Shocks (Dampers & Springs) ..................................................................................... 8810.1) Chosen shocks ..................................................................................................... 8810.2) Adjustable Damping............................................................................................ 8910.3) Progressive spring rates....................................................................................... 9011) Hubs & Uprights......................................................................................................... 9311.1) Background & <strong>Research</strong>...................................................................................... 9311.2) Concepts & Brainstorming .................................................................................. 9311.3) CATIA Modeling ................................................................................................ 9411.4) FEA...................................................................................................................... 9511.5) Materials & Manufacturing Procedure Used....................................................... 9511.6) Finished Product.................................................................................................. 9511.6.1) Testing .......................................................................................................... 9511.7) Recommendations for Improvements.................................................................. 9612) Tires and Rims............................................................................................................ 9712.1) Background and <strong>Research</strong> .................................................................................. 97ii

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>12.2) Concepts and Brainstorming .............................................................................. 9712.3) CATIA Modeling ............................................................................................. 10512.4) Additional Analysis .......................................................................................... 10512.5) Materials and Manufacturing Procedures Used................................................ 10612.6) Finished Product............................................................................................... 10612.6.1) Product Assembly and Maintenance ......................................................... 10612.6.2) Testing ........................................................................................................ 10612.7) Recommendations for Improvement ................................................................ 10713) <strong>Suspension</strong> tuning and testing .................................................................................. 10813.1) <strong>Suspension</strong> kinematics adjustment and measurement....................................... 10813.2) Dynamic tuning of the suspension..................................................................... 11113.3) Problems during testing..................................................................................... 11214) Strain gage testing .................................................................................................... 11614.1) Background & <strong>Research</strong>.................................................................................... 11614.2) Concepts & Brainstorming ................................................................................ 11614.3) CATIA Modeling .............................................................................................. 11814.4) FEA.................................................................................................................... 11914.5) Additional Analysis ........................................................................................... 12014.6) Materials & Manufacturing Procedure Used..................................................... 12114.7) Recommendations for Improvements................................................................ 12115) <strong>Suspension</strong> Prototype ............................................................................................... 12215.1) Background & <strong>Research</strong>.................................................................................... 12215.2) Concepts & Brainstorming ................................................................................ 12215.3) ADAMS Modeling ............................................................................................ 12315.4) Additional Analysis ........................................................................................... 12715.5) CATIA & FEA .................................................................................................. 12715.6) Materials & Manufacturing Procedure Used..................................................... 12915.7) Finished Product................................................................................................ 13015.7.1) Product Assembly & Maintenance............................................................. 13015.7.2) Testing ........................................................................................................ 13215.8) Recommendations for Improvements................................................................ 13316) References and contacts............................................................................................ 13916.1) Contacts ............................................................................................................. 13916.2) Websites............................................................................................................. 14016.3) Books and professional papers .......................................................................... 141iii

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>17) Appendixes ............................................................................................................... 14317.1) Appendix A........................................................................................................ 143The derivation of the half car model....................................................................... 14317.2) Appendix B........................................................................................................ 145The derivation of the bicycle model........................................................................ 14517.3) Appendix C........................................................................................................ 14817.4) Appendix D........................................................................................................ 154Critical speed calculations of 2006 vehicle............................................................ 15417.5) Appendix E........................................................................................................ 15617.6) Appendix F ........................................................................................................ 157Predicted spring rates............................................................................................. 15717.7) Appendix G........................................................................................................ 158Acceleration Plots................................................................................................... 158Acceleration and Cornering ................................................................................... 160Braking.................................................................................................................... 161Braking and Cornering........................................................................................... 162S Shaped Plots......................................................................................................... 163<strong>2007</strong> Jump Performance......................................................................................... 165Cornering................................................................................................................ 16617.8) Appendix H........................................................................................................ 16717.9) Appendix I ......................................................................................................... 18017.10) Appendix J....................................................................................................... 193Spreadsheets to record the data during testing........................................................ 19317.11) Appendix K...................................................................................................... 19717.11.1) Rear suspension assembly Bill of Material: ................................................. 19717.11.2) Front suspension assembly Bill of Material ................................................. 20117.12) Appendix L...................................................................................................... 2052) List of TablesTable 1: Summary of vehicle dimensions......................................................................... 40Table 2: Static <strong>Suspension</strong> Angles.................................................................................... 42Table 3: Estimated cornering stiffness of the 2006 tires................................................... 52Table 4: Critical speed of 2006 vehicle ............................................................................ 52Table 5: Weight of the vehicle and weight distribution.................................................... 54iv

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Table 6: Ride frequencies of the 2005 vehicle.................................................................. 55Table 7: Required spring rates for <strong>2007</strong> vehicle based on Olley criteria.......................... 55Table 8: The main and auxiliary springs required to obtained the appropriate ridefrequencies ................................................................................................................ 64Table 9: Spring rate evaluation results.............................................................................. 66Table 10: The frequencies of the vehicle.......................................................................... 67Table 11: Summary of material properties ....................................................................... 74Table 12: 2003 Testing Data............................................................................................. 97Table 13: Tire Pressure ................................................................................................... 1073) List of FiguresFigure 1: Vehicle axis system............................................................................................. 2Figure 2: The quarter car model.......................................................................................... 3Figure 3: Bounce/pitch model............................................................................................. 5Figure 4: The half car model............................................................................................... 8Figure 5: The front and the rear suspension amplitudes as a function of time ................... 9Figure 6: Eigenvalues verses vehicle speed for an understeering vehicle........................ 15Figure 7: Oversteering and Understeering Vehicle .......................................................... 16Figure 8: The lateral force verses the slip angle ............................................................... 17Figure 9: Vehicle track width ........................................................................................... 19Figure 10: The roll axis of the vehicle.............................................................................. 19Figure 11: The effect of the jacking forces....................................................................... 20Figure 12: Roll center position of a double A-arm type of suspension ............................ 21Figure 13: Definition of camber angle (note in the figure one is looking at the vehiclefrom the front)........................................................................................................... 22Figure 14: The effect camber has on the tire contact patch .............................................. 22Figure 15: The effect of the camber angle on the cornering curve................................... 23Figure 16: Caster angle and caster trail............................................................................. 24Figure 17: Kingpin angle (steering inclination angle) and scrub radius........................... 26Figure 18: Toe angle (note the view in the figure is the top view)................................... 27Figure 19: The necessary steps to locate the tie rod position to have no toe angle changewith suspension travel............................................................................................... 29Figure 20: The pitch center............................................................................................... 31Figure 21: Anti-dive suspension geometry....................................................................... 32v

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Figure 22: Anti-squat suspension geometry ..................................................................... 32Figure 23: <strong>Motion</strong> ratio..................................................................................................... 33Figure 24: The lateral force verses the vertical force for a given slip angle..................... 36Figure 25: Vehicle Dimensions ........................................................................................ 38Figure 26: Rear end of vehicle.......................................................................................... 39Figure 27: Front and Rear Uprights.................................................................................. 40Figure 28: Wheel hub........................................................................................................ 41Figure 29: ADAMS/Car suspension modeling................................................................. 43Figure 30: Anti Squat Angle............................................................................................. 44Figure 31: Anti Squat Reaction......................................................................................... 44Figure 32: Longitudinal wheel travel................................................................................ 45Figure 33: Roll Center Height and Swing Arm Length.................................................... 46Figure 34: Camber Gain.................................................................................................... 46Figure 35: Steering tie rod length ..................................................................................... 47Figure 36: Tie rod clearance with control arm.................................................................. 48Figure 37: <strong>Motion</strong> Ratio.................................................................................................... 48Figure 38: Roll Center Lateral Position............................................................................ 50Figure 39: Roll Center Vertical Position .......................................................................... 50Figure 40: Roll Stiffness ................................................................................................... 51Figure 41: Track Width Change ....................................................................................... 51Figure 42: The three interfaces in CarSim........................................................................ 57Figure 43: Vehicle model in CarSim ................................................................................ 57Figure 44: The mass, Inertia and vehicle dimensions screen in CarSim .......................... 58Figure 45: The powertrain model in CarSim .................................................................... 59Figure 46: The brake model in CarSim............................................................................. 60Figure 47: The steering model in CarSim......................................................................... 61Figure 48: The front suspension kinematics model in CarSim......................................... 62Figure 49: The front suspension compliance model in CarSim........................................ 63Figure 50: <strong>Motion</strong> amplitude ratio for front excitation..................................................... 68Figure 51: Pitch/Excitation amplitude ratio for front excitation....................................... 68Figure 52: <strong>Motion</strong> of the rear unsprung mass/excitation amplitude for front excitation.. 69Figure 53: <strong>Motion</strong> of the front unsprung mass/excitation amplitude for front excitation 69Figure 54: <strong>Motion</strong> amplitude ratio for rear excitation ...................................................... 70Figure 55: Pitch/Excitation amplitude ratio for rear excitation ........................................ 70Figure 56: <strong>Motion</strong> of the front unsprung mass/excitation amplitude for rear excitation.. 71vi

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Figure 57: <strong>Motion</strong> of the rear unsprung mass/excitation amplitude for rear excitation ... 71Figure 58: The hill created to simulate the hill climb....................................................... 72Figure 59: <strong>Suspension</strong> and traction course ....................................................................... 73Figure 60: Front lower control arm................................................................................... 75Figure 61: Front upper control arm................................................................................... 76Figure 62: Front lower control arm FEA .......................................................................... 76Figure 63: Front upright FEA ........................................................................................... 77Figure 64: Front suspension assembly FEA ..................................................................... 78Figure 65: Laser cut tabs................................................................................................... 78Figure 66: Pivot joint construction ................................................................................... 79Figure 67: Caster adjustment mechanism......................................................................... 80Figure 68: Camber adjustment mechanism....................................................................... 80Figure 69: Steering tie rod ................................................................................................ 81Figure 70: Steering stop.................................................................................................... 81Figure 71: Schematic of rear lower control arm ............................................................... 82Figure 72: Rear control arms ............................................................................................ 83Figure 73: Aluminum rear upper control arm................................................................... 83Figure 74: Rear suspension assmebly FEA ...................................................................... 84Figure 75: Hiem joint........................................................................................................ 85Figure 76: Upright to control arm pivot............................................................................ 85Figure 77: Front control assembly .................................................................................... 86Figure 78: Rear control assembly ..................................................................................... 87Figure 79: Elka <strong>Suspension</strong>s coil over shock ................................................................... 88Figure 80: Rebound and compression damping adjustment............................................. 89Figure 81: <strong>Suspension</strong> springs with the crossovers .......................................................... 91Figure 82: Load versus displacement of Elka <strong>Suspension</strong> with longer sides of collarsfacing up.................................................................................................................... 92Figure 83: Load versus displacement of Elka <strong>Suspension</strong> with shorter sides of collarsfacing up.................................................................................................................... 92Figure 84: Final Catia model ............................................................................................ 94Figure 85: Rear Assembly FEA........................................................................................ 95Figure 86: Proposed test setup .......................................................................................... 96Figure 87: Tire internal cord scenarios ............................................................................ 98Figure 88 Tire contact patch reactions.............................................................................. 98Figure 89 Contact patch aligning moment........................................................................ 99vii

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Figure 90 Internal Pressure Model.................................................................................... 99Figure 91 Lateral force, traction force affect on slip %.................................................... 99Figure 92 Aligning moment for vertical loads and slip angles....................................... 100Figure 93 Lateral forces for brake forces at different slip angles................................... 101Figure 94 Lateral forces and aligning moments for different traction forces................. 101Figure 95 Vertical and longitudinal reactions for tire roll over a bump ......................... 103Figure 96 Tire natural frequency vibration modes ......................................................... 103Figure 97 Rolling loss factor graph ................................................................................ 104Figure 98 CATIA Model of Rim .................................................................................... 105Figure 99 CATIA Model of Rear <strong>Suspension</strong> Assembly ............................................... 106Figure 100: Caster angle measurement........................................................................... 109Figure 101: Toe angle measurement............................................................................... 110Figure 102: Camber angle measurement ........................................................................ 111Figure 103: Track with measurement ............................................................................. 112Figure 104: The protection layer on the control arms..................................................... 113Figure 105: The bend in the control arm ........................................................................ 113Figure 106: Angle iron to reinforce the rear control arms .............................................. 114Figure 107: The wear in the bushings............................................................................. 114Figure 108: Timken tapered needle roller bearings ........................................................ 115Figure 109: Strain gauge testing specimen ..................................................................... 117Figure 110: Bending of test specimen ............................................................................ 117Figure 111: Axial test on specimen ............................................................................... 118Figure 112: Specimen modeled in Catia......................................................................... 118Figure 113: 2004 lower control arm model .................................................................... 118Figure 114: 2004 lower control arm FEA for 500 lb loading......................................... 119Figure 115: Cantilever FEA simulation.......................................................................... 119Figure 116: Axial FEA simulation.................................................................................. 120Figure 117: <strong>2007</strong> control arm gauging locations ............................................................ 120Figure 118: Tailing arm and Semi trailing arm .............................................................. 122Figure 119: Semi trailing arm......................................................................................... 123Figure 120: Tailing arm .................................................................................................. 123Figure 121: New semi trailing arm ................................................................................. 124Figure 122: Camber angle comparison........................................................................... 124Figure 123: Roll centre comparison................................................................................ 125Figure 124: Toe angle comparison ................................................................................. 125viii

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Figure 125: Anti Squat comparison ................................................................................ 126Figure 126: Wheel travel track comparison.................................................................... 126Figure 127: Prototype <strong>Suspension</strong> Assembly 1 .............................................................. 128Figure 128: Prototype <strong>Suspension</strong> Assembly 2 .............................................................. 128Figure 129: Rear Lower Control Arm FEA.................................................................... 129Figure 130: Rear Upper Control Arm FEA .................................................................... 129Figure 131: Prototype front view.................................................................................... 130Figure 132: Prototype back view .................................................................................... 130Figure 133: Prototype top view....................................................................................... 131Figure 134: prototype side view ..................................................................................... 131Figure 135: Joint and axis control................................................................................... 132Figure 136: Camber checking 1...................................................................................... 132Figure 137: Camber checking 2...................................................................................... 133Figure 138: Semi trailing arm 1...................................................................................... 134Figure 139: Semi trailing arm 2...................................................................................... 134Figure 140: Tailing arm 1 ............................................................................................... 135Figure 141: Tailing arm 2 ............................................................................................... 135Figure 142: New Semi trailing arm 1 ............................................................................. 136Figure 143: New Semi trailing arm 2 ............................................................................. 136Figure 144: Other suspension 1 ...................................................................................... 137Figure 145: Other suspension 2 ...................................................................................... 137Figure 146: Other suspension 3 ...................................................................................... 1384) List of EquationsEquation 1: The equations of the quarter car model........................................................... 2Equation 2: The natural frequencies of the unsprung and sprung mass ............................. 3Equation 3: The natural frequency of the both the unsprung and sprung mass in hertz..... 4Equation 4: The amplitudes of displacements of both masses (unsprung and sprung) ...... 4Equation 5: Bounce and pitch equations of motion (neglecting damping)......................... 5Equation 6: <strong>Motion</strong> ratios at each of the natural frequency................................................ 5Equation 7: Natural frequencies in bounce and in pitch..................................................... 6Equation 8: Equations of motion in bounce and pitch........................................................ 6Equation 9: Bounce and pitch damped natural frequency .................................................. 7ix

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Equation 10: The half car model equations ........................................................................ 8Equation 11: Sprung and unsprung mass.......................................................................... 10Equation 12: The equations used in the bicycle model..................................................... 11Equation 13: Equations of motion in steady state cornering ............................................ 12Equation 14: Vehicle yaw rate as a function of the steering angle................................... 12Equation 15: The cornering radius as a function of the kinematic cornering radius ........ 12Equation 16: The kinematic turning radius....................................................................... 12Equation 17: Body slip angle............................................................................................ 13Equation 18: The body slip angle as a function of the steering angle .............................. 13Equation 19: The limit of the β/δ ratio for an understeering vehicle................................ 13Equation 20: Critical speed of an oversteering vehicle .................................................... 14Equation 21: Characteristic speed of an understeering vehicle ........................................ 14Equation 22: Solution to the transients associated with the bicycle model ...................... 15Equation 23: Magic tire Formula...................................................................................... 17Equation 24: Tire cornering stiffness................................................................................ 18Equation 25: Condition for proper Ackermann steering................................................... 29Equation 26: Aligning moment......................................................................................... 30Equation 27 : Wheel rate................................................................................................... 34Equation 28: Roll stiffness as a function of ride rate........................................................ 34Equation 29: 3 cases to determine whether the vehicle will oversteer or understeer basedon the bicycle model ................................................................................................. 35Equation 30: Ride frequency ............................................................................................ 37Equation 31: The spring rate of 4 springs in series........................................................... 64Equation 32: Caster angle from measurements .............................................................. 108Equation 33: Toe angle measurement............................................................................. 1105) NomenclatureRR0mrr&uabC fC rActual cornering radiusLow speed cornering radius (kinematic), obtained when cornering without lateralslip.Mass of the vehicleYaw rateRate of change of vehicle yaw rateVehicle’s forward velocityDistance between the center of mass and the front axleDistance between the center of mass and the rear axleThe cornering stiffness of both of the front tiresThe cornering stiffness of both of the rear tiresx

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>α f Front tire slip angleα r Rear tire slip angleF z Normal load at the tireF y Lateral Force at the tireµ yz Lateral force coefficientγ Camber angleC Cornering stiffnessE Tire belt compression modulusb t Tire belt thicknessw Tire belt widthr t Rim radiuss Sidewall vertical deflection when loaded (unitized percent)a t Tire aspect ratio (height/width)a lat Lateral accelerationδ Steering angleδ * Limit steering angle (based on a lateral acceleration of 0.5g’s)v Lateral velocityv& Rate of change of the lateral velocityI Yaw inertiaβ Body slip angleF f Lateral force on both of the front tiresF r Lateral force on both of the rear tiresx The coordinate direction from the center of gravity to the front of the car. Alsothis coordinate rotates with the vehicle, rotating frame of reference.y The coordinate direction from the center of gravity to the side of the vehicle (thelateral direction). Also this coordinate rotates with the vehicle, rotating frame ofreference.u t Forward velocity of the tirev t Lateral velocity of the tireα f Front tire slip angleα r Rear tire slip anglevt f Lateral velocity of the front tirev tr Lateral velocity of the rear tireut fr Forward velocity of the front right tireut fl Forward velocity of the front left tiret w Vehicle widtht TimemsMeters per secondm Meters per second squared2sgdegGravity Constant (9.81m/s^2)Degreerad Radians/secondsxi

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>sec, s Secondm MeterX Displacement of the vehicle in the x direction (forward)Y Displacement of the vehicle in the y direction (lateral)m Mass of the vehiclea Distance between the center of mass and the front axleb Distance between the center of mass and the rear axleI Pitch inertiat Timek f Front suspension spring constant (for both of the front suspensions)k r Rear suspension spring constant (for both of the rear suspensions)C f Front damping coefficient (for both of the front suspensions)C r Rear damping coefficient (for both of the rear suspensions)k tf Front tire spring constant (for both of the front tires)k tr Rear tire spring constant (for both of the rear tires)m s Sprung massm u Unsprung massm uf Portion of the unsprung mass associated with the front of the vehiclem ur Portion of the unsprung mass associated with the rear of the vehicler y Radius of gyration in pitchZ s Vertical motion of the vehicle bodyθ Vehicle pitch motionZ f Vertical motion associated with the unsprung mass at the front of the vehicleZ r Vertical motion associated with the unsprung mass at the rear of the vehicleh f Disturbance (excitation) motion at the front of the vehicleh r Disturbance (excitation) motion at the rear of the vehicleϖ n Natural frequencyϖ Frequency of excitationξ Damping ratiof 1 Approximate body motion frequencyf 2 Approximate wheel hop frequencym 2sdeg Degreerad Radians/secondssec, s Secondm MeterH z Hertzlb Poundin InchesN Newton’s per metermxii

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>N Newton’s per meter per secondmsxiii

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>6) Introduction to <strong>Suspension</strong> Kinematics and KineticsVehicle dynamics is the study of all forms of transportation (trains, airplanes,boats, and automobiles). However vehicle dynamics as we know it is the study of theperformance of the automobile in all of its motions (ride, acceleration, cornering, andbaking). The vehicles suspension plays a key roll in each of these motions. The study ofa vehicles suspension can be broken into two major categories: suspension kinetics andsuspension kinematics. <strong>Suspension</strong> kinetics is a dynamic and a vibration analysis on thevehicle and suspension systems. <strong>Suspension</strong> kinematics involves analyzing the motion ofthe tires as the suspension compresses and extends. Each of these two divisions will beanalyzed in depth in the following sections.6.1) <strong>Suspension</strong> Kinetics<strong>Suspension</strong> kinetics is an analysis that is important to the overall performance ofthe vehicle because it is what determines if the vehicle is capable of absorbing groundloads; it is what judges the comfort of the driver, it is what determines if the vehicle willroll or not; and it is what determines the resonant frequency of the chassis, the shock andthe tire; it is what determines the handling performance of the vehicle. The vehicle willsee a wide range of vibrations because of the speeds it travels and the boundaries ittravels on, thus it is important to analyze the resonant frequency of the suspensioncomponents and the chassis. The ride quality (or vertical dynamics) of a vehicle can beanalyzed using the half car model. The handling performance of the vehicle can beanalyzed using the bicycle model. However before each of these models are consideredit is important to define the vehicle axis and the appropriate rotations about each of theaxis.The conventional axis system is placed at the center of mass of the vehicle withthe x axis pointing towards the front of the vehicle, the y axis pointing towards the rightside of the vehicle, and the z axis pointing towards the bottom of the vehicle. The x axisis known as the longitudinal axis, the y axis is known as the lateral axis, and the z axis isknown as the vertical axis. The rotation about the x axis is know as roll, the rotationabout the y axis is known as pitch and the rotation about the z axis is known as yaw(Figure 1: Vehicle axis system).Vehicle ride modeling is the study of the motions transmitted to the vehiclechassis, and thus the motions felt by the passengers in the vehicle. The motionstransmitted to the vehicle chassis come from the vibration of the suspension as it absorbsthe motion coming from the disturbance at the ground. It is these vibrations that causethe passengers to feel uncomfortable when they are riding in a vehicle. Therefore,vehicle ride problems arise from the vibrations of the vehicle body (chassis). One of themain objectives of the suspension system is to control the vibrations of the vehicle bodyin order to provide a comfortable ride for the driver.1

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Figure 1: Vehicle axis system6.1.1) Vehicle ride modeling (vertical dynamics)Mechanical vibrations in a vehicle represent a very complex field, and usuallyrequire multiple degrees of freedom to accurately predict the vertical performance of thevehicle. However, there exist two simplified models which when combined give anaccurate approximation as to the ride quality of the vehicle. These include the quarter carmodel (corner model) (used to predict the motion of a single suspension unit) and thebounce/pitch model (used to predict the motions of the sprung mass of the vehicle).These models combined produce the half car model (four degrees of freedom model).The vertical performance of the vehicle is directly linked to the sprung mass, theunsprung mass, the pitch inertia, the suspension stiffness, the tire stiffness, the dampingin the tires, the damping in the suspension units, and the excitation frequency. Before thehalf car model is introduced, the quarter car model and the bounce/pitch models will beintroduced.The quarter car model is a model that models the motion of a single suspensionsystem (it models one corner of the car) (Figure 2: The quarter car model). The sprungmass in this model represents some portion of the total sprung mass of the system. Thetire is excited because of the shape of the path it is following (the shape is not flat,especially for an off road track). Applying Newton’s 2 nd law of motion the equations ofmotion that govern the quarter car model are as follows (Equation 1: The equations of thequarter car model).m && zm && zu2+ C( z&1− z&2) + ks( z1− z2) =( z&2− z&1) + ks( z2− z1) + Ctz&2+ ktz2= Ctz&0+ ktz0s 1+ Cs0sEquation 1: The equations of the quarter car model2

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Figure 2: The quarter car modelThis is a two degree of freedom system, thus there will be two natural frequencies (theunsprung and sprung mass will each have a resonant frequency). The wheel hopfrequency is the frequency associated with the unsprung mass it is usually around 10Hz.The body motion frequency is the frequency associated with the sprung mass and it isusually around 1 to 1.25 Hz. Note, the damping ratios in most suspension systems isrelatively low, therefore the majority of the time the undamped natural frequency will bereally close to the damped natural frequency thus the damped natural frequency is usuallycalculated by neglecting any damping in the system. The following equation can be usedto calculate the natural frequencies of the system. Note the natural frequencies arecalculated by neglecting damping in the system and neglecting any excitations (Equation2: The natural frequencies of the unsprung and sprung mass).⎡ms0 ⎤⎡&&z1⎤ ⎡ ks⎢+0⎥⎢⎥ ⎢⎣ mu⎦⎣&&z2⎦ ⎣−k2det[ k −ϖM ] = 0sk− kss+ kt⎤⎡z⎥⎢⎦⎣z12⎤ ⎡0⎤⎥ = ⎢0⎥⎦ ⎣ ⎦Equation 2: The natural frequencies of the unsprung and sprung massNote the above equation in matrix form leads to an eigenvalue problem by assuming thedisplacement of each mass to be harmonic (z = Zcos(ωt)). By solving the determinantwill lead to the natural frequencies of both masses in the system. The frequencies can beapproximated by the following equations (Equation 3: The natural frequency of the boththe unsprung and sprung mass in hertz).3

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>ff12==12π12πkkksssmmksut+ kt+ kt(body motion)(wheel hop)Equation 3: The natural frequency of the both the unsprung and sprung mass in hertzSome important observations can be made by solving the above equations. The firstobservation is that the sprung mass is well isolated at high frequency, however it will bepoorly isolated at low frequencies, and in some cases, at low frequencies the amplitude ofthe sprung mass can be amplified in such a way that it is greater than that of theexcitation amplitude.Damping will have an effect on the amplitudes of motion even though it does nothave a significant effect on the natural frequencies. The easiest way to solve for theamplitudes is to use a complex number approach (assume z = Ze iωt ). If this is taken intoconsideration the equations of motion will be as follows (Equation 4: The amplitudes ofdisplacements of both masses (unsprung and sprung)).2[ −ϖM + iϖC+ k]⎧z⎨⎩z12⎫⎬ =⎭⎧z1⎫ i⎨ ⎬e⎩z2⎭ϖt⎡ 0 ⎤ i= ⎢ Z0ekti t⎥⎣ + ϖ ⎦2−1⎡ 0 ⎤[ −ϖM + iϖC+ k] Z0⎢⎣kt+ iϖt⎥⎦Equation 4: The amplitudes of displacements of both masses (unsprung and sprung)Note, the result will be a complex number because of the phase lag between the motionand the disturbance (this is because of the damping in the system, note the i term next tothe C in the equation of motion above). The amplitude is simply the sum of the squaresfo the real and imaginary parts of the answer obtain from the above equation22( Z = real + imaginary ). The usual way to solve the equations to obtain theamplitudes is to assume the excitation is one, and calculate the amplitudes of theunsprung and sprung mass with respect to this input over a wide range of frequencies.This will allow the amplitude ratios to be obtained over a wide range of frequencies. Thedifference between the motion of the sprung and unsprung mass represents thesuspension shock travel, and the distance between the travel of the unsprung mass and theexcitation is the tire deflection. Tire deflection is a measure of handling because it is thenormal force that generates the necessary friction to propel the vehicle forward (ie if thenormal force is fluctuating up and down the tire is being prevented from griping theroad). Therefore, it can be seen that a stiffer suspension will hurt the tires capability fromgripping the road. The unsprung mass has almost no effect at low frequencies, but athigher frequencies a lower unsprung mass will lead to lower tire deflections and thusbetter handling performance of the vehicle. At mid range frequencies, a lower spring rateϖt4

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>leads to a reduction in tire deflections, and thus improves tire grip. However, a lowerspring rate allows for increased body motions which are detrimental to vehicle handling.The bounce/pitch suspension model models the vehicle motions separately fromthe wheel motions (Figure 3: Bounce/pitch model).Figure 3: Bounce/pitch modelThe equations of motion that govern this system can be obtained by applying Newton’ssecond law of motion in both pitch and bounce to the system (note damping will be firstneglected so that the natural frequency can be obtained) (Equation 5: Bounce and pitchequations of motion (neglecting damping)).m && z + kms2sryf&& θ −2s yI = m r( z − aθ) + kr( z + bθ) = 0k a( z − aθ) + k b( z + bθ)fr= 0Equation 5: Bounce and pitch equations of motion (neglecting damping)The equations of motion are coupled as can be seen above. If it is assumed that thedisplacements are harmonic then the natural frequencies can be obtained (z = Zcos(ωt)and θ=Θ cos(ωt)). The following is the equation that would be obtained from assumingthe motions are harmonic for the natural frequencies (Equation 7: Natural frequencies inbounce and in pitch). The motion ratios can be obtained at each of these frequencies bysubstituting each of the results back into the equation of motion (Equation 6).ZΘZΘD2=ϖ − D21221D2=ϖ − D1Equation 6: <strong>Motion</strong> ratios at each of the natural frequency5

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>ϖDDD1,2123=1=ms1=ms121=m r( D + D ) ± ( D − D )1( k + k )2( k b − k a)2s yfr142 2( k a + k b )frfr132D+rEquation 7: Natural frequencies in bounce and in pitchThe bounce and pitch natural frequencies are usually very close to one another. They areusually between 1 to 1.5 Hz. The bounce and pitch equations of motion can be re writtento include damping in the equation of motion (damping is important when it is desired toobtained the amplitudes of motion) (Equation 8: Equations of motion in bounce andpitch).⎧&&z⎫⎧z&⎫ ⎧ z ⎫M ⎨&&⎬ + C⎨⎬ + K ⎨ ⎬ = 0⎩θ&⎭ ⎩θ⎭ ⎩θ⎭⎧&&z⎫− ⎧z&1 ⎫ −1⎧ z ⎫⎨&&⎬ = −MC⎨⎬ − M K ⎨ ⎬⎩θ&⎭ ⎩θ⎭ ⎩θ⎭⎡ms0 ⎤M = ⎢2 ⎥⎣ 0 msry⎦⎡ kf+ krbkr− akf ⎤K = ⎢2 2 ⎥⎣bkr− akfb kr+ a kf ⎦⎡ Cf+ CrbCr− aCf ⎤C = ⎢2 2 ⎥⎣bCr− aCfb Cr+ a Cf ⎦Equation 8: Equations of motion in bounce and pitchThe above equations of motion can be solved to obtain the natural frequencies andamplitude ratios, as well as the amplitudes for a given frequency. This can be done byreducing the equations from second order to first order (Equation 9: Bounce and pitchdamped natural frequency).222y6

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>⎧z&⎫⎪ ⎪& θ⎡ 02⎨ ⎬ =z⎢⎪&&⎪ ⎣−M⎪&&⎩θ⎪⎭Assumez = Zest⎧ z ⎫ ⎧ z ⎫⎪ ⎪ ⎪ ⎪θstθ⎨ ⎬se= [ A]⎨ ⎬e⎪ sz ⎪ ⎪ sz ⎪⎪⎩sθ⎪⎭⎪⎩sθ⎪⎭⎧ z ⎫⎪ ⎪θ⎨ ⎬ = 0⎪ sz ⎪⎪⎩sθ⎪⎭s = eigenvalue[ Is − A]x2−1K& θ = Θe[ A]I− Mst2x2−1st⎧z⎫⎪ ⎪⎤θ⎬ =C⎥⎨⎦⎪z&⎪⎪ &⎩θ⎪⎭[ A]⎧z⎫⎪ ⎪θ⎨ ⎬⎪z&⎪⎪ &⎩θ⎪⎭Equation 9: Bounce and pitch damped natural frequencyIt is important to note that the eigenvalues will be complex numbers because of the phasechange; however the natural frequency is just the sum of squares of the real andimaginary values. The damping ratio is the negative of the real part divided by thenatural frequency (ζ=-a/ωn). The amplitudes at all frequencies can be solved byassuming a value for either the pitch angle or the bounce and then solving the other valueover a wide range of frequencies.The bounce/pitch model and the quarter car model are two of the most powerfulmodels to predict the vertical motion of the vehicle. These two models can be combinedto create the half car model. This model couples the motions of the front and rearsuspension through the motion of the sprung mass (both bounce and pitch). This modelallows the wheel hop frequencies to be obtained for both the front and rear suspensions atthe same time. As well as the pitch and body motion frequencies can be obtained. Thehalf car model predicts the motions of the both the front and both the rear suspensionunits at once. There are certain assumptions used in this model, and these include that thetires on either side of the vehicle have the same effect on the dynamics, and the width ofthe vehicle is assumed to be constant. Also, it is assumed that the springs are linear, andthat the damping can be modeled as viscous dampers. The model consists of fourcoupled equations used to find the motions associated with the sprung mass and both theunsprung masses (Equation 10: The half car model equations) (Figure 4: The half carmodel) (Appendix A).7

⎡m⎢⎢0⎢ 0⎢⎣ 0s⎡⎢+ ⎢⎢⎢⎣0I00( kf+ kr) ( akf− bkr)2 2( akf− bkr) ( a kf+ b kr)− kf− km0r00uf0 ⎤⎧Z&&s⎫⎡⎪ ⎪0⎥ ⎢&&⎥θ⎨ ⎬ + ⎢0 ⎥⎪Z&&f⎪⎢⎥⎪ ⎪⎢mur⎦⎩Z&&r⎭⎣− akfbkr( Cf+ Cr) ( aCf− bCr)2 2( aCf− bCr) ( a Cf+ b Cr)− Cf− Cr− kf− akf( kf+ ktf)0( kr+ ktr)Equation 10: The half car model equations<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>− Cf− Cr⎤⎧Z&s⎫⎪ ⎪− aC⎥f bCr&⎥θ⎨ ⎬− aCfCf0 ⎥⎪Z&f⎪⎥bCr0 Cr⎦⎪⎩Z&r⎪⎭− kr⎤⎧Zs⎫⎧ 0 ⎫bk⎥⎪⎪ ⎪ ⎪r⎥θ0⎨ ⎬ = ⎨( )( )( )( )⎪ ⎪ ⎬0 ⎥ ff tf⎪Z⎪ ⎪ h k⎥⎦⎪⎩Zr⎪⎭⎪⎩ hrktr⎭Figure 4: The half car modelThe following is a discussion on the important parameters that are applied in the half carmodel.The <strong>Suspension</strong> Stiffness and DampingThe suspension stiffness is one of the most important parameters whenconsidering the vertical performance of the vehicle. It is generally best to have amoderate spring rates. This is because low spring rates reduce the tire deflection whichincreases the tire grip, however it also allows for increased body motions (in roll and inpitch) which are harmful to the overall handling performance of the vehicle. Theopposite is true for high spring rates. Therefore, there should be a compromise betweenimplementing high and low suspension stiffness’. Also, according to Maurrie Olley thefollowing set of rules should be followed when designing a suspension system for thecomfort of the passenger, and they are:1. Front suspension should have a 30% lower ride rate than rear suspension8

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>2. Pitch and bounce frequencies should be close together, bounce frequency shouldbe 1.2 times the pitch frequency3. Neither the bounce nor the roll frequency should be greater than 1.3Hz.The reason for this is that the front of the vehicle will ride over the bump (ordisturbance) first creating an excitation in the front suspension, and then seconds later therear suspension will ride over the bump creating an excitation in the rear suspension. Ifthe two suspension rates are identical the phase lag between the front and the rearsuspensions will create an undesirable motion in pitch. There have been studies that haveshown that the driver/passenger is/are very uncomfortable in pitch motion, it tends tocause neck muscle strains. Therefore, by increasing the suspension rate in the rearsuspension allows for the rear of the vehicle to “catch up” to the front of the vehicle(Figure 5: The front and the rear suspension amplitudes as a function of time).Figure 5: The front and the rear suspension amplitudes as a function of timeIt can be seen from the figure above that there exists a phase lag between the front andthe rear excitations, and that by having a rear suspension rate higher than the frontsuspension rate allows for the rear excitation to catch up to the front excitation.The Tire Stiffness and DampingThe tires stiffness and the tires viscous damping coefficient are important to theride quality of the vehicle, but more importantly to the handling performance of thevehicle. In typical passenger car vehicles the stiffness of the tires is of an order ofmagnitude greater than the suspension stiffness. It is typically the tire deflection that isimportant for the handling performance of the vehicle, because the tire deflection is oneof the parameters in which decides the tires grip capabilities. As the deflection of the tireincreases, the grip capabilities of the tire will decrease. It is very important to not allowthe tire to lose contact with the ground, because if it does the car will not be controllable9

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>in handling. Typically, the damping coefficient of the tires is neglected because it isgenerally very low compared to the other parameters in the system, and neglecting itresults in a small error in the analysisThe Sprung and Unsprung MassThe mass of the vehicle is an important parameter in the analysis of the verticaldynamics of the vehicle. The mass of the vehicle is one of the main parameters in whichwill decide the deflections of both the front and the rear tires, and the suspension unitswhen they are excited. The mass of the vehicle is divided into two parts the sprung massand the unsprung mass. The sprung mass consists of everything the suspension unitshave to support, and these include the chasis, and the engine. The unsprung massconsists of everything the tires have to support, and these include the front and rear axles.Typically the sprung mass is of an order of magnitude greater than the unsprung mass.Therefore the following formula can be used to calculate the sprung mass and theunsprung mass based on the mass of the vehicle (Equation 11: Sprung and unsprungmass).m = ms+ mum = 10mu+ mu⎛ 0.4535924kg3290lbs⎜mlbsmu= =⎝1111ms =( 10)( 135.67kg) = 1356.65kg⎞⎟⎠= 135.67kgEquation 11: Sprung and unsprung massWhen implementing the half car model the unsprung mass has to be further divided intothe unsprung mass supported by the front tires of the vehicle, and the unsprung masssupported by the rear tires of the vehicle.The Pitch InertiaThe pitch inertia is the inertia that arises in the rotation of the front and rear of thevehicle with respect to the center of mass. The pitch inertia is usually calculated usingthe radius of gyration. It is important in the study of the ride quality of the vehiclebecause it is one of the significant parameters in which determine the amount ofdeflection a vehicle will have in pitch. Generally, in order to have good ride quality inpitch the radius of gyration should be around 1.2m, and the ratio of the radius of gyrationsquared to the location of the front axle from the center of mass times the location of thery 2rear axles from the center of mass (( a)( b)) should be between 0.8 and 1.2. Thesevalues provide a desirable ride in pitch because the center of oscillations in pitch and rollwill be close to the front and the rear axle, thus allowing the motion in pitch created atone axle to somewhat cancel out the motion in pitch created at the other axle, and10

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>therefore minimizing the overall motion in pitch felt by the driver.The half car model leads to a good prediction of the vertical performance of thevehicle or the ride quality of the vehicle.6.1.2) Vehicle handlingThe Handling performance of an automobile is important to the all aroundperformance of the vehicle. The handling performance will determine how the car willexecute in turning corners; its lateral performance. There are many important parametersthat determine the lateral performance of a vehicle, these include but are not limited tothe location of the center of mass, tire cornering stiffness, the steering angle, the lateralvelocity, the forward vehicle velocity, the lateral acceleration, the rotational speed (yawrate), the body slip angle, and the tire slip angle. The model usually used to predict thelateral performance of the vehicle is the linear bicycle model.There are certain assumptions used in this model, and these include that the tireson either side of the vehicle have the same effect on the dynamics, and the width of thevehicle is assumed to be constant. The model consists of two coupled equations used tofind the lateral acceleration and the rate of change of the vehicles yaw rate whileassuming the forward vehicle speed is held constant (its in the control of the driver)(Equation 12: The equations used in the bicycle model) (Note, for a clarification of themodel see the derivation in Appendix B).⎡m⎢⎣ 0⎡0⎤⎧v&⎫ ⎢⎨ ⎬ + ⎢I⎥⎦⎩r&⎭ ⎢⎣( Cf+ Cr) ( aCf− bCr)u2 2( aCf− bCr) ( a Cf+ b Cr)uuu⎤+ mu⎥⎧v⎫⎧ Cf⎫⎥⎨⎬ = ⎨ ⎬δ⎥⎩r⎭⎩aCf⎭⎦Equation 12: The equations used in the bicycle modelOnce the above equations of motion are solved for the yaw rate, lateral velocity, lateraldisplacement and the vehicle yaw several other parameters can be solved for, and certaincharacteristics of the vehicle can be determined. Also certain cases can be analyzed indetail, and one such case is steady state cornering (lateral acceleration and rate of changeof the yaw rate are equal to zero) (Equation 13: Equations of motion in steady statecornering). Solving the equations of motion in steady state leads to the followingimportant equations (Equation 14: Vehicle yaw rate as a function of the steering angle)(Equation 15: The cornering radius as a function of the kinematic cornering radius).11

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>⎡⎢⎢⎢⎣( Cf+ Cr) ( aCf− bCr)u2 2( aCf− bCr) ( a Cf+ b Cr)uuu⎤+ mu⎥⎧v⎫⎧ Cf⎫⎥⎨⎬ = ⎨ ⎬δ⎥⎩r⎭⎩aCf⎭⎦Equation 13: Equations of motion in steady state corneringrδ=2a + b −muu( aC − bC )( a + b) CfCrEquation 14: Vehicle yaw rate as a function of the steering angleRR0mu= 1−2( aC − bC )2( a + b) CfCrEquation 15: The cornering radius as a function of the kinematic cornering radiusThe second equation (equation 15) is important because it describes the path theundersteer/oversteer characteristics of the vehicle. If the vehicle was cornering with nolateral slipping than the vehicle would corner about a perfect circular path with a radiusof R 0 (R 0 is known as the kinematic turning radius) (Equation 16: The kinematic turningradius).ffrrEquation 16: The kinematic turning radiusThe kinematic turning radius is the radius in which the driver is aiming for the vehicle tofollow. Examination of equation 15 reveals that if aC f < bC r than the vehicle willundersteer. If the vehicle understeers, the radius of the path will increase with vehicle12

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>speed. In order to maintain the desired path of the vehicle the driver will have to increasethe steering angle with vehicle speed. If aC f > bC r the vehicle oversteers, and thecornering radius will decrease with vehicle speed. The driver will have to decrease thesteering angle as the speed of the vehicle increases in order to maintain the desired pathof the vehicle. If aC f = bC r the vehicle neutral steers and will turn on the kinematicturning radius. The radius of curvature will be independent of vehicle speed. It is alsoimportant to note that understeer/oversteer characteristics is also affecting by theinclination of the roll axis and the front and rear suspension roll stiffness as will be seenin the suspension kinematics section. The cornering stiffness of the driving wheels willchange as the traction (driving) force increases (as the traction force increases the lateralforce will decrease (friction circle)). For a front wheel drive vehicle this effect is to forcethe vehicle to understeer, and for a rear wheel drive to force the vehicle to oversteer.When the vehicle is cornering it does not point in the direction it is traveling in,this is known as body slip. The vehicle will experience a body slip angle (Equation 17:Body slip angle).vtan β ≈ β =uEquation 17: Body slip angleUsing the steady state bicycle model the body slip angle can be solved for as a functionof the steering angle (Equation 18: The body slip angle as a function of the steeringangle).βδb −=2mua + b −2amuC( a + b)( aC − bC )( a + b) CfCrEquation 18: The body slip angle as a function of the steering angleAt low speeds, the β/δ ratio will be positive which indicates that the rear wheels will trackinside the front wheels. However, at high speeds the opposite will be true; the rearwheels will track outside the front wheels. For an understeering vehicle the β/δ ratio willtend to a limit; at high speeds it will be a constant (Equation 19: The limit of the β/δ ratiofor an understeering vehicle).frrβδlim it=aCaCff− bCrEquation 19: The limit of the β/δ ratio for an understeering vehicleAn oversteering vehicle will have larger slip angles than an understeering vehicle, and theβ/δ ratio will tend to infinity at a critical vehicle speed. The vehicle will become unstable13

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>at the critical vehicle speed (Equation 20: Critical speed of an oversteering vehicle).ucritical=CfCr( a + b)( − bC )m aCfr2Equation 20: Critical speed of an oversteering vehicleIf the critical speed is reached the driver is capable of stabilizing the vehicle with steeringinputs. The r/δ ratio will also go to infinity at the critical speed for an oversteeringvehicle; however for an understeering vehicle the r/δ ratio will reach a maximum at thecharacteristic speed (the highest amount of yaw rate for a given steering angle will occurat this speed) (Equation 21: Characteristic speed of an understeering vehicle).ucharacteristic=CfCr( a + b)( − aC )m bCrf2Equation 21: Characteristic speed of an understeering vehicleThe transient effects of vehicle cornering can be considered by solving the bicyclemodel with zero steering angle; the model is solved assuming that the driver is not goingto react (the steering angle is zero). It is important that the transient effects die out overtime; that is the amplitude of vehicle oscillations tends to zero over time. If it does not goto zero, then the vehicle will be unstable. It is best to use an eigenvalue approach whensolving the bicycle model to analyze the transient effects of the vehicle (Equation 22:Solution to the transients associated with the bicycle model). If s is smaller than zero thevehicle will be stable. Analyzing the equation that determines the value of s will indicatethat if C is greater than zero than the vehicle will always be stable. This occurs for anundersteering vehicle. An understeering vehicle will always be stable. However, for anoversteering vehicle the value of C will become negative at the critical speed. This isimplying that an oversteering vehicle will be stable up until the critical speed, but oncethe critical speed is reached the vehicle will become unstable. It is also important to notethat the solution can take on real and complex solutions. We are generally looking forour vehicle to have a stable response (want s to be negative or a complex number with aas being negative) indicating that the yaw rate and lateral velocity will decayexponentially to zero. If we have an unstable response the yaw rate and the lateralvelocity will increase when excited causing the vehicle to loose control. It is generallybetter to design the vehicle so that it is an overall understeering vehicle because it isguaranteed to be stable. Negative eigenvalues are basically indicating that the system iscapable of correcting itself (allow for the yaw rate and the lateral velocity to decay backto zero) if excited without any input from the driver. The only difference between thereal and the imaginary parts is that in the imaginary part of the eigenvectors will fluctuateas they decay to zero, a frequency will exist (Figure 6: Eigenvalues verses vehicle speedfor an understeering vehicle).14

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Mx&+ Cx = 0⎧v⎫x = ⎨ ⎬⎩r⎭assume x = XeMsXest( Ms + C)Xdet( Ms + C)A = mIuB =C =+ CXe( aC − bC )⎡ Cf+ Crf r ⎤⎢ms++ mu ⎥Ms + C = ⎢u u2 2 ⎥⎢ ( aCf− bCr) ( a Cf+ b Cr)Is⎥⎢+⎣ uu ⎥⎦Solving the determinant leads to the following22 2mu( a Cf+ b Cr) + Iu( Cf+ Cr)22( a + b) C C − mu ( aC − bC )2− B ± B − 4ACs =2Ast= 0fst= 0= 0rfrEquation 22: Solution to the transients associated with the bicycle modelFigure 6: Eigenvalues verses vehicle speed for an understeering vehicleThe eigenvectors are the associated response of the vehicle when it is operating at that15

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>particular eigenvalue. As previously mentioned, these eigenvectors allow for the vehicleto be a stable vehicle. Also as the vehicle’s speed is increased the –s value decreases,indicating that the yaw rate and lateral velocity will approach zero at a slower rate. Thatis as the vehicle’s speed increases it’ll take a longer time for the yaw rate and the lateralvelocity to approach zero.The tire cornering stiffnessThe tire cornering stiffness is an important parameter in determining the handlingperformance of the vehicle. It is to some extent arbitrary; each tire has its own stiffness,and the tires on a vehicle can be changed. Therefore the cornering stiffness can bechosen by the user to precisely predict turning (cornering) characteristics of the vehicle.It is this parameter that will determine whether the car is an understeering (the actualcornering radius increases with vehicle speed) or an oversteering (the actual corneringradius decreases with vehicle speed) automobile because the center of mass of the vehicleis a fixed parameter (Figure 7: Oversteering and Understeering Vehicle). It is generallybetter to have an understeering vehicle, because the vehicle is normally more stable. Inan oversteering case, the vehicle oversteers the turn, and the driver will be forced todecrease the steering angle as he/she turns in order to stay on the desired path (the paththe vehicle takes when there is no lateral slipping).Figure 7: Oversteering and Understeering VehicleThere are also more chances that the vehicle spins on the spot (about its own z-axis). Inan understeering case, the car understeers and the driver is forced to increase the steeringangle in order to stay on the desired path. There are several ways to determine the tirescornering stiffness. Two of these ways are by using the magic tire model and second byusing an estimation given the tires dimensions.Magic tire modelThe stiffness can be estimated as the slope of the linear range on the lateral forceverses slip angle diagram, which can be obtained from the magic tire model (Figure 8:The lateral force verses the slip angle, on the following page).16

<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>Figure 8: The lateral force verses the slip angleHowever, tests will have to be done on the tire in order to determine the necessarycoefficients to apply the magic tire formula (Equation 23: Magic tire Formula).Fy = DsinC = a110D = µ yzFµ yz = a1Fz+ aE = a6Fz+ a7111{ C arctan[ B( 1−E)( α + Sh) + E arctan( B( α + Sh))]}⎡ ⎛ FBCD = a3sin⎢2arctan⎜⎣ ⎝ aB = BCDCDSh= a8γ+ a9Fz+ a10Sav= a2= a11γFz+ az12Fz+ aFz+ a11213z4⎞⎤⎟⎥⎠⎦( 1−a5γ)+ SvEquation 23: Magic tire FormulaTire Cornering Stiffness Obtained from the Tire GeometryThe tire cornering stiffness can also be obtained from the geometry of the tire byassuming that the tire is a cantilever beam. This cantilever beam is acted on by a selfaligningmoment and a shearing stress which act together to generate contact patch twistduring cornering. With some manipulation of the tire slip angle (deflection) obtainedfrom the cantilever beam an expression for the cornering stiffness can be obtained(Equation 24: Tire cornering stiffness).17

C =2[( rt+ wat)]⎡ ⎡ ⎛⎢sin⎢arccos⎜1−⎢⎣⎣ ⎝2swat3Ebtw⎞⎤⎤⎛⎡⎜⎛⎟⎥⎥π − sin⎢arccos⎜1−⎝<strong>2007</strong> <strong>Baja</strong> <strong>Project</strong><strong>Suspension</strong>swat⎞⎤⎞⎟⎥( r ) ⎜( ) ⎟ t + wat⎠⎦⎥⎦⎣ ⎝ rt+ wat⎠⎦⎠6.2) <strong>Suspension</strong> KinematicsEquation 24: Tire cornering stiffness<strong>Suspension</strong> kinematics is the study of the motions of the tire. It describes theorientation of the tire as a function of wheel travel and steering angle. The motions of thetire are highly dependent on the type of suspension. In general there are two types ofsuspension systems; solid axles and independent suspensions. A solid axle suspension isa suspension where the movement of one wheel is transmitted to the other wheel causingthem to move together. This type of suspension is essentially a dependent suspension,the motion of the two wheels are correlated to one another. The biggest advantage of thistype is that the camber angle is not affected by vehicle body roll. The majordisadvantage of this type of suspension is the vibrations which are induced into thesystem if the solid axle suspension also incorporates vehicle steering. Independentsuspension systems allow the left and right wheels to move independently; the movementof one wheel will have no effect on the other wheel. The advantages of independent typeof suspensions are: they provide better resistance to steering vibrations; they provide ahigh suspension roll stiffness; steering geometry is easily controlled; suspensiongeometry is easily controlled; and they allow for higher wheel travel. The majordisadvantages are: the camber angle changes quite a bit over suspension travel; increasedunsprung mass; and the high cost of the system.The study of suspension kinematics allows for several different suspensionparameters to be determined throughout suspension travel and steering angle. Some ofthe most important parameters include: roll center position and instant center, camberangle, caster angle, toe angle, tire scrub, kingpin angle, scrub radius, caster trail, aligningmoment, vehicle ride height, track width, wheel rates, roll stiffness, roll axis,understeer/oversteer characteristics, roll steer, bump steer, motion ratio, and antidive/anti-squat.The following will be a discussion of each of these parameters.6.2.1) Track width and tire scrubThe track width is a measure of the distance between the center of the tire contactpatches at the front and rear of the vehicle (Figure 9: Vehicle track width). The trackwidth will change as the wheels travel through the suspension travel, and this change isknown as tire scrub. The change in the track width is a measure of the location of theinstant center of motion of the suspension. As the track width is changing the tires areforced to push out or pull in at the ground, and thus the tires are forced to scrub againstthe ground. Typically, if the suspension is in compression the tires will scrub out, and ifthe suspension is in rebound the tires will scrub in. Tire scrub (track width change)18