GEA CAIRfricostar Produkt PR-2009-0061-GB.indd

GEA CAIRfricostar Produkt PR-2009-0061-GB.indd

GEA CAIRfricostar Produkt PR-2009-0061-GB.indd

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

Unit distribution according to air volume flow and water surfacesStandard seriesStandard unit typeCAM 320CAM 290CAM 250CAM 230CAM 200CAM 170CAM 150CAM 130CAM 110CAM 100CAM 083CAM 055CAM 045CAM 037CAM 030CAM 020CAM 01560 m 240 m 285 m 270 m 2950 m 2850 m 2745 m 2680 m 2590 m 2510 m 2435 m 2380 m 2325 m 2260 m 2195 m 2 Water surface max. (m 2 )130 m 2 Air temperature: 30 °C100 m 2Water temperature: 28 °C0 5000 10000 15000 20000 25000 30000 35000 40000 45000 50000Air volume flow (m 3 / h)Unit distribution according to air volume flow and water surfacesPerformance seriesPerformance unit typeCAM 360CAM 320CAM 290CAM 250CAM 230CAM 200CAM 170CAM 150CAM 130CAM 110CAM 100CAM 083CAM 055CAM 045CAM 037CAM 030CAM 020CAM 015100 m 2130 m 2 190 m 2 230 m 2830 m 2740 m 2670 m 2575 m 2530 m 2460 m 2400 m 2340 m 2300 m 2250 m 2Water surface max. (m 2 )85 m 2Air temperature: 30 °C70 m 2Water temperature: 28 °C60 m 235 m 20 5000 10000 15000 20000 25000 30000 35000 40000Air volume flow (m 3 / h)<strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>5

Mixed air dehumidification unit with heat pump<strong>GEA</strong> <strong>CAIRfricostar</strong> CAM13During swimming pool operation, the outside and exhaust air flap of theunit opens and the recirculating air flap is closed. The refrigeration systemis started for dehumidification and both fans are switched to level two. Apart of the obtained surplus energy of the refrigeration system can be releasedto the pool water with an optional pool water condenser.142Swimming pool operationwith dehumidification requirement1 Fans 2 Outside and exhaust air flap 3 Recirculating air flap 4 Mixed air flapPerformance series 1)Unit typeCAM_PU 015 025 030 037 045 055 083 100 110 130 150 170 200 230 250 320Unit dimensionsWidth mm 760 760 760 760 1080 1080 1080 1400 1720 2000 1720 2000 2320 2640 2320 2920Height mm 1120 1360 1360 1600 1360 1600 2240 2240 2240 2320 2880 2960 2960 2960 3600 3600Length mm 3000 3200 3300 3300 3300 3400 4000 4000 4000 4000 4400 4600 4600 4800 5000 5300Air volume flowMinimum m 3 /h 750 1500 2500 2994 3685 4492 5529 8293 9952 11058 12994 14745 17325 20274 23223 29029Maximum m 3 /h 1500 2500 2995 3686 4493 5530 8294 9953 11059 12995 14746 17326 20275 23224 25344 32256Rating for dehumidificationm 3 /h 1000 2000 2900 3600 4400 5500 7500 9900 11000 12500 14500 17000 20000 23000 25000 32000Rating forventilation m 3 /h 667 1333 1933 2400 2933 3667 5000 6600 7333 8333 9667 11333 13333 15333 16667 21333Dehumidification capacitySwimming pool operation(30% outs. air) kg/h 6 11 16 19 25 31 39 53 62 70 82 94 112 130 138 177Standby operation(recirculated air) kg/h 4 5 6 7 10 12 14 19 25 29 36 37 45 54 49 63VDI 2089 2) kg/h 6 13 18 23 28 35 48 63 70 80 92 108 127 146 159 204Thermal capacityAir condenserwithoutPWC operation kW 5.6 7.4 10.8 12.9 16.8 20.6 23.7 30.9 36.4 43.1 52.3 54.1 67.4 77.3 79.8 101.4Air condenserwithPWC operation kW 3.5 5.3 7.9 10.1 14.0 17.9 19.6 26.2 31.8 35.8 44.5 46.6 57.6 65.2 66.2 86.4Pool watercondenser3) kW 2.3 2.1 3.3 2.9 3.1 3.1 4.4 5.1 4.9 7.5 8.6 9.0 9.6 13.7 12.3 15.6Heatrecovery kW 3.5 7.0 8.7 10.9 14.1 17.7 24.3 33.5 39.8 45.2 52.1 61.3 73.2 85.6 92.0 118.1After heater 4) kW 9.5 15.3 20.0 24.7 30.8 38.8 56.3 72.7 86.9 98.6 115.5 132.7 158.9 185.2 199.3 288.2All data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum.3)Pool water condenser (PWC) = accessory4)Feed / return temperature = 70°C / 50°C<strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>9

<strong>GEA</strong> <strong>CAIRfricostar</strong> CMUMixed air dehumidification unit with heat pump<strong>GEA</strong> <strong>CAIRfricostar</strong> CMU was conceived for private and small public swimmingpools. The unit is especially suitable for pools in partial daily operation,i.e., hotels and therapeutic baths, and requires very little space. Therange of models is available in six sizes as well as for an air volume flow of750 up to 6,200 m³/h. The unit dehumidifies and heats the swimming poolin a mixed air operating mode. It is delivered with a DDC unit and controlsall functions of the plant fully automatically.Advantages of <strong>GEA</strong> <strong>CAIRfricostar</strong> CMU:Flexibility in featuresCompact solution with small spacerequirementsSmall dimensionsVariable control, drive and filtersWhen the swimming pool is in use, the outside and exhaust air flap of theunit opens and the recirculating air flap is closed. For dehumidification, therefrigeration system is started and both fans are switched to level two. Apart of the obtained surplus energy from the refrigeration system can bereleased to the pool water with an optional pool water condenser131421 Fans 2 Outside and exhaust air flap 3 Recirculating air flap 4 Mixed air flapSwimming pool operationwith dehumidification requirementStandard series 1)Unit typeCMU_SU 015 025 030 037 045 055Unit dimensionsWidth mm 760 760 760 760 1080 1080Height mm 1120 1360 1360 1600 1360 1600Length mm 2600 2700 2700 2740 2760 2800Air volume flowMinimum m 3 /h 750 1842 2755 3354 4128 5031Maximum m 3 /h 1843 2756 3355 4129 5032 6193Rating for dehumidification m 3 /h 1000 2000 3000 4000 5000 6000Rating for ventilation 2/3 m 3 /h 667 1333 2000 2667 3333 4000Dehumidification capacitySwimming pool operation (30% outs. air) kg/h 5 10 14 18 21 26Standby operation (recirculated air) kg/h 2 4 4 5 4 6VDI 2089 2) kg/h 6 13 19 25 32 38Thermal capacityAir condenser without PWC operation kW 7.0 13.0 16.6 21.0 24.2 30.0Air condenser with PWC operation kW 5.6 11.5 14.8 18.1 20.2 26.3Pool water condenser 3) kW 1.6 1.5 1.6 2.1 2.1 2.6After heater 4) kW 10.6 11.7 14.8 20.2 36.0 46.4All data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum.3)Pool water condenser (PWC) = accessory4)Feed / return temperature = 70°C / 50°C10 <strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>

Mixed air dehumidification unit with heat pump<strong>GEA</strong> <strong>CAIRfricostar</strong> CMP<strong>GEA</strong> <strong>CAIRfricostar</strong> CMP was conceived for private and public high-performanceswimming pools of all kinds. The range of models can be deliveredfor an air volume flow of 750 up to 37,500 m³/h. The unit dehumidifies andheats the swimming pool hall in a mixed air operating mode. Apart froma heat pump plant, this unit type is additionally equipped with a highly efficientheat recovery system (efficiency 82%) by means of double-plate heatexchanger (ECOPLAT 2 POWER PLATE). It is delivered with a DDC unitand controls all functions of the plant fully automatically.Advantages of <strong>GEA</strong> <strong>CAIRfricostar</strong> CMP:Multi-stage high-performance heatrecovery with two high-performance heatexchangers and heat pumpLow operating costsPerformance ratings for all pool areasWhen the swimming pool is being used, the outside and exhaust air flap ofthe unit opens and the recirculating air flap regulates the mixed air sharewith the DDC. For dehumidification, the refrigeration system is started andboth fans are switched to level two. A part of the obtained surplus energyof the refrigeration system can be released to the pool water with an optionalpool water condenser.132141 Fans 2 Outside and exhaust air flap 3 Recirculating air flap 4 Mixed air flapSwimming pool operationwith dehumidification requirementPerformance Series 1)Unit typeCMP_PU 015 025 037 055 083 110 130 150 170 200 250 320Unit dimensionsWidth mm 760 760 760 1080 1080 1720 2000 1720 2000 2320 2320 2920Height mm 1120 1360 1600 1600 2240 2240 2320 2880 2960 2960 3600 3600Length mm 4240 4480 4840 4880 5480 5720 5920 6600 6800 7080 7360 8120Air volume flowMinimum m 3 /h 750 1500 2500 3685 5529 8293 11058 12994 14745 17325 20274 29029Maximum m 3 /h 1500 2500 3686 5530 8294 11059 12995 14746 17326 20275 25344 32256Rating for dehumidification m 3 /h 1000 2000 3400 5000 7500 11000 12500 14000 17000 20000 25000 32000Rating for ventilation 2/3 m 3 /h 667 1333 2267 3333 5000 7333 8333 9333 11333 13333 16667 21333Dehumidification capacitySwimming pool operation (30% outs. air) kg/h 6 11 18 27 40 58 68 77 94 112 134 175Standby operation (Recirculated air) kg/h 4 5 8 13 17 25 31 37 46 57 61 84VDI 2089 2) kg/h 6 13 22 32 48 70 80 90 108 127 159 204Thermal capacityAir condenser without PWC operation kW 5.0 6.7 10.7 15.9 22.4 30.7 36.9 42.1 51.5 61.9 75.7 99.4Air condenser with PWC operation kW 2.6 3.9 7.7 12.1 17.6 25.2 29.0 32.9 39.9 50.0 59.9 75.6Pool water condenser 3) kW 2.6 2.9 3.2 3.8 5.4 5.6 8.1 8.5 12.2 12.7 16.2 21.9Heat recovery kW 3.6 6.9 11.3 16.6 25.6 37.5 44.2 51.8 63.0 74.5 84.2 111.4After heater 4) kW 8.4 13.4 21.2 31.6 48.9 77.8 90.9 98.1 120.7 139.3 180.4 234.6All data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum.3)Pool water condenser (PWC) = accessory4)Feed / return temperature = 70°C / 50°C<strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>11

<strong>GEA</strong> <strong>CAIRfricostar</strong> CPPMixed air dehumidification unit with heat pump<strong>GEA</strong> <strong>CAIRfricostar</strong> CPP was conceived for private and public high-performanceswimming pools of all kinds and can be delivered for an air volumeflow of 750 to up to 37,500 m³/h. The unit works in the mixed air operatingmode. A special characteristic is its reversible heat-pump circuit. In the summer,the cooling cycle of the swimming pool can be reversed for excess temperaturesto cool the supply air. The DDC control thus monitors the supplyair temperature in order to regulate the swimming pool temperature to thepre-set standard value, and selects the most favourable operating state. Theunit is equipped with a highly efficient heat recovery system by means ofdouble plate heat exchanger (ECOPLAT 2 POWER PLATE).Advantages of <strong>GEA</strong> <strong>CAIRfricostar</strong> CPP:Multi-stage high-performance heatrecovery with two high-performance heatexchangers and a heat pump plant witha reversible cooling cycle and summercooling functionPerformance ratings for all pool areasWhen the swimming pool is in use, the outside and exhaust air flap of theunit opens and the recirculating air flap regulates the mixed air share withthe DDC. For dehumidification, the refrigeration system starts and both fansare switched to level two. A part of the obtained surplus energy of the refrigerationsystem can be released to the pool water with the optional pool watercondenser.1 31421 Fans 2 Outside and exhaust air flap 3 Recirculating air flap 4 Mixed air flapSwimming pool operationwith dehumidification requirementPerformance Series 1)Unit typeCPP_PU 015 025 037 055 083 110 130 150 170 200 250 320Unit dimensionsWidth mm 760 760 760 1080 1080 1720 2000 1720 2000 2320 2320 2920Height mm 1120 1360 1600 1600 2240 2240 2320 2880 2960 2960 3600 3600Length mm 4240 4480 4840 4880 5480 5720 5920 6600 6800 7080 7360 8120Air volume flowMinimum m 3 /h 750 1500 2500 3685 5529 8293 11058 12994 14745 17325 20274 29029Maximum m 3 /h 1500 2500 3686 5530 8294 11059 12995 14746 17326 20275 25344 32256Rating for dehumidification m 3 /h 1000 2000 3400 5000 7500 11000 12500 14000 17000 20000 25000 32000Rating for ventilation 2/3 m 3 /h 667 1333 2267 3333 5000 7333 8333 9333 11333 13333 16667 21333Dehumidification capacitySwimming pool operation (30% outs. air) kg/h 6 11 18 27 40 58 68 77 94 112 134 175Standby operation (recirculated air) kg/h 4 5 8 13 17 25 31 37 46 57 61 84VDI 2089 2) kg/h 6 13 22 32 48 70 80 90 108 127 159 204Heating / cooling capacityAir condenser without PWC operation kW 5.0 6.7 10.7 15.9 22.4 30.7 36.9 42.1 51.5 61.9 75.7 99.4Air condenser with PWC operation kW 2.6 3.9 7.7 12.1 17.6 25.2 29.0 32.9 39.9 50.0 59.9 75.6Pool water condenser 3) kW 2.6 2.9 3.2 3.8 5.4 5.6 8.1 8.5 12.2 12.7 16.2 21.9Heat recovery kW 3.6 6.9 11.3 16.6 25.6 37.5 44.2 51.8 63.0 74.5 84.2 111.4After heater 4) kW 8.4 13.4 21.2 31.6 48.9 77.8 90.9 98.1 120.7 139.3 180.4 234.6Cooling capacity kW Data not known by copy deadlineAll data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum.3)Pool water condenser (PWC) = accessory4)Feed / return temperature = 70°C / 50°C12 <strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>

Mixed air dehumidification unit without heat pump<strong>GEA</strong> <strong>CAIRfricostar</strong> CWP<strong>GEA</strong> <strong>CAIRfricostar</strong> CWP was conceived for private and public high-performanceswimming pools of all kinds. The range of models can be deliveredwith an air volume flow from 750 up to 37,500 m³/h. The unit dehumidifiesand heats the swimming pool in a mixed air operating mode and is equippedwith an efficient heat recovery (ECOPLAT 2 POWER PLATE double-plate heatexchanger) without a heat pump. It is delivered with a DDC unit and controlsall the functions of the plant fully automatically.Advantages of <strong>GEA</strong> <strong>CAIRfricostar</strong> CWP:Multi-stage heat recovery with twohigh-performance heat exchangersHigh efficiency, low energy consumptionLow, internal pressure lossWhen the swimming pool is in use, the outside and exhaust air flap of theunit opens and the mixed air flap controls the mixed air share according tothe dehumidification requirement via the DDC. Both fans are switched to leveltwo.13211 Fans 2 Outside and exhaust air flap 3 Recirculating air flap 4 Mixed air flapSwimming pool operationwith dehumidification requirementPerformance Series 1)Unit typeCWP_PU 015 025 037 055 083 110 130 150 170 200 250 320Unit dimensionsWidth mm 760 760 760 1080 1080 1720 2000 1720 2000 2320 2320 2920Height mm 1120 1360 1600 1600 2240 2240 2320 2880 2960 2960 3600 3600Length mm 3600 3800 4100 4200 5700 5700 6000 6600 6800 7100 7400 8200Air volume flowMinimum m 3 /h 750 1500 2500 3685 5529 8293 11058 12994 14745 17325 20274 29029Maximum m 3 /h 1500 2500 3686 5530 8294 11059 12995 14746 17326 20275 25344 32256Rating for dehumidification m 3 /h 1000 2500 3400 5000 7500 11000 12500 14000 17000 20000 25000 32000Rating for ventilation 2/3 m 3 /h 667 1667 2267 3333 5000 7333 8333 9333 11333 13333 16667 21333Dehumidification capacityAccording to VDI 2089for rated airflow 2) kg/h 6 16 22 32 48 70 80 89 108 127 159 204Thermal capacityHeat recovery kW 2.1 5.1 6.8 10.1 15.3 25.3 26.1 30.0 36.4 42.8 49.9 65.0After heater 3) kW 8.4 15.4 21.2 31.6 48.9 78.9 90.9 98.1 120.7 139.3 180.4 234.5All data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum. Outside air state = 5°C / 85% rel. F.3)Feed / return temperature = 70°C / 50°C<strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>13

<strong>GEA</strong> <strong>CAIRfricostar</strong> CWRMixed air dehumidification unit without heat pump<strong>GEA</strong> <strong>CAIRfricostar</strong> CWR was conceived for private and public swimmingpools of all kinds. The range of models is available with 750 to 45,000 m³/hair volume flow. The unit dehumidifies and heats the swimming pool in amixed-air operating mode. This unit type is equipped with an efficient heatrecovery (ECOSTAT POWER TUBE heat pipe) without a heat pump. It is deliveredwith a DDC unit and controls all functions of the plant fully automatically.Advantages of <strong>GEA</strong> <strong>CAIRfricostar</strong> CWR:Efficient heat recoveryLower investment costs, since withoutheat pumpLow operation and maintenance costsIndividual and customised units accordingto requirementsStandard series 1)Unit typeCWR_SU 015 025 030 037 045 055 083 100 110 130 150 170 200 230 250 320Unit dimensionsWidth mm 760 760 760 760 1080 1080 1080 1400 1720 2000 1720 2000 2320 2640 2320 2920Height mm 1120 1360 1360 1600 1360 1600 2240 2240 2240 2320 2880 2960 2960 2960 3600 3600Length mm 2520 2560 2560 2680 2680 2720 3320 3360 3480 3520 3840 3800 3880 3880 4200 4320Air volume flowMinimum m 3 /h 750 2395 2755 3593 4423 5390 6635 9952 13270 16588 19491 22117 25988 30412 34835 43545Maximum m 3 /h 2396 2756 3594 4424 5391 6636 9953 13271 16589 19492 22118 25989 30413 34836 38016 48384Rating for dehumidificationm 3 /h 1500 2500 3000 4000 4800 6000 9000 12000 15000 17500 20000 23500 27000 31500 35000 44000Rating for ventilation2/3 m 3 /h 1000 1667 2000 2667 3200 4000 6000 8000 10000 11667 13333 15667 18000 21000 23333 29333Dehumidification capacityAccording to VDI 2089for ratedairflow 2) kg/h 10 16 19 25 31 38 57 76 95 111 127 150 172 200 223 280Thermal capacityHeatrecovery kW 2.6 4.6 5.2 6.9 8.7 10.9 16.6 22.5 28.5 32.9 37.3 44.3 51.5 60.2 66.5 84.3After heater 3) kW 12.5 19.1 20.6 28.9 34.8 43.9 66.5 88.8 110.0 133.2 147.3 177.4 188.2 227.1 242.6 321.9All data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum.3)Feed / return temperature = 70°C / 50°C14 <strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>

Mixed-air dehumidification unit without heat pump<strong>GEA</strong> <strong>CAIRfricostar</strong> CWRWhen the swimming pool is in use, the outside and exhaust air flap of theunit opens and the mixed air flap is closed, and both fans are switched tolevel two.1321Swimming pool operationwith dehumidification requirement1 Fans 2 Outside and exhaust air flap 3 Recirculating air flapPerformance series 1)Unit typeCWR_PU 015 025 030 037 045 055 083 100 110 130 150 170 200 230 250 320Unit dimensionsWidth mm 760 760 760 760 1080 1080 1080 1400 1720 2000 1720 2000 2320 2640 2320 2920Height mm 1120 1360 1360 1600 1360 1600 2240 2240 2240 2320 2880 2960 2960 2960 3600 3600Length mm 2520 2700 2700 2700 2800 2800 3300 3500 3500 3600 3600 3800 4000 4000 4200 4500Air volume flowMinimum m 3 /h 750 1500 2500 2994 3685 4492 5529 8293 9952 11058 12994 14745 17325 20274 23223 29029Maximum m 3 /h 1500 2500 2995 3686 4493 5530 8294 9953 11059 12995 14746 17326 20275 23224 25344 32256Rating for dehumidificationm 3 /h 1500 2500 2800 3300 4200 5000 7500 9900 11000 12800 14500 17000 20000 23000 25000 32000Rating for ventilation2/3 m 3 /h 1000 1667 1867 2200 2800 3333 5000 6600 7333 8533 9667 11333 13333 15333 16667 21333Dehumidification capacityAccording to VDI 2089for ratedairflow 2) kg/h 10 16 18 21 27 32 48 63 70 81 92 108 127 146 159 204Thermal capacityHeatrecovery kW 2.9 5.2 5.7 6.8 8.8 8.9 15.8 21.2 23.9 27.8 31.4 37.0 43.6 50.2 54.6 70.1After heater 3) kW 11.9 18.0 19.5 23.2 29.7 36.0 56.3 72.7 86.9 100.4 115.4 132.7 158.9 185.2 199.3 238.2All data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum.3)Feed / return temperature = 70°C / 50°C<strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>15

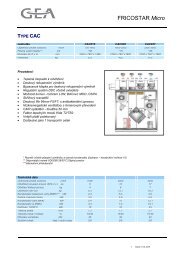

<strong>GEA</strong> Fricostar Micro CACCompact climate-control unit with heat pump<strong>GEA</strong> Fricostar Micro CAC was developed for small private and public swimmingpools, i.e., in hotel and therapeutic baths, and can be delivered in twomodel sizes as well as three performance ratings. Owing to its compact dimensionsand the special positioning of the connection fittings, the unit isespecially suited for installation in small technical rooms. Apart from a heatpump plant, it is equipped with an efficient heat recovery system (ECOPLATPOWER PLATE heat exchanger) and an intelligent DDC unit.Advantages of <strong>GEA</strong> Fricostar Micro CAC:Compact unit dimensionsConvenient fittings position, simpleconnectionsMulti-stage heat recoveryLow investmentWhen the swimming pool is in use with dehumidification, the warm swimmingpool hall exhaust air is cooled down in the plate heat exchanger anddehumidified in the evaporator. A part of the dried swimming pool hall airis now supplied to the fresh air with the mixed air flaps, pre-warmed in theplate exchanger, warmed further in the condenser, and made available tothe swimming pool hall with the fresh air fans. If necessary, the supply airis warmed to the final temperature with the post-heating register in orderto reach the desired swimming pool temperature.1 Plate heat exchanger 2 Evaporator 3 Mixed air flaps 4 Compressor5 Fresh air fans 6 Exhaust fan 7 Condenser351274Swimming pool operationwith dehumidification requirement6Standard series 1)Unit typeCAC_SU 015 030 037Unit dimensionsWidth mm 760 760 760Height mm 1480 1800 1800Length mm 1640 2760 2760Air volume flowMinimum m 3 /h 750 1600 2000Maximum m 3 /h 1600 2500 3600Rating for dehumidification m 3 /h 1000 2000 3050Rating for ventilation 2/3 m 3 /h 743 1320 2013Dehumidification capacitySwimming pool operation (30% outs. air) kg/h 5 12 17Standby operation (recirculated air) kg/h 4 6 7VDI 2089 2) kg/h 6 13 19Thermal capacityAir condenser without PWC operation kW 5.4 10.0 12.1Air condenser with PWC operation kW 3.3 7.2 10.1Pool water condenser 3) kW 2.4 3.2 3.0Heat recovery kW 3.0 5.9 6.9After heater 4) kW 10.0 16.2 23.2All data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum.3)Pool water condenser (PWC) = accessory4)Feed / return temperature = 70°C / 50°C16 <strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>

Compact climate-control unit without heat pump<strong>GEA</strong> Fricostar Micro CWC<strong>GEA</strong> Fricostar Micro CWC was developed for small private and public swimmingpools, i.e., hotel and therapeutic baths, and can be delivered in twosizes. Owing to its compact dimensions and the special position of the connectionfittings, it is especially suitable for small technical rooms. The unitis equipped with an efficient heat recovery (ECOPLAT POWER PLATE heatexchanger) and a DDC unit.When the swimming pool is in use with dehumidification, the warm swimmingpool hall exhaust air is cooled down in the plate heat exchanger. Apart of the swimming pool hall air is supplied by the mixed-air flaps to thefresh air. The fresh air is pre-warmed in the plate exchanger and made availableby the fresh air fans of the swimming pool hall. If necessary, the supplyair is further warmed with the after-heating register in order to reachthe desired swimming pool hall temperature.Advantages of <strong>GEA</strong> Fricostar Micro CWC:Compact unit dimensionsAdvantageous fittings position,simpler connectionHeat recoveryLow investmentLow maintenance costs34121 Plate heat exchanger 2 heater 3 Fresh air fan 4 exhaust fanSwimming pool operationwith dehumidification requirementStandard series 1)Unit typeCWC_SU 015 037Unit dimensionsWidth mm 760 760Height mm 1480 1800Length mm 1640 2760Air volume flowMinimum m 3 /h 750 1500Maximum m 3 /h 2000 3600Rating for dehumidification m 3 /h 1500 2500Rating for ventilation 2/3 m 3 /h 1000 1667Dehumidification capacityAccording to VDI 2089at rated airflow 2) kg/h 9.5 16Thermal capacityHeat recovery kW 2.8 4.8After heater 3) kW 16.0 23.0All data are rounded values and merely serve for an overview. For exact data of the current configuration, use <strong>GEA</strong> Air Treatment software.1)Standard series = max. air velocity approx. 2.8 m/s2)Condition of hall air: 30°C / 54% rel. hum.3)Feed / return temperature = 70°C / 50°C<strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>17

Standard equipment and accessories<strong>GEA</strong> <strong>CAIRfricostar</strong> and <strong>GEA</strong> Fricostar Micro<strong>GEA</strong> <strong>CAIRfricostar</strong><strong>GEA</strong> Fricostar MicroConstruction Modular CompactUnit type CAU CAM CMU CMP CPP CWP CWR CAC CWCSeries componentsHeat pump for dehumidificationaccording to VDI 6022Droplet eliminatorFan unit <strong>GEA</strong>centrifugal fanLESS ENERGY SYSTEM1 1)Fan unitHigh performance fan impellers<strong>GEA</strong> OPTIVENT 1)Filter according to DINwith pressure differentialswitch for filter monitoringHeating sectorPWW air heaters, heat exchangerwith Cu pipes and pressed-onaluminium laminations with aluminiumframe according to VDI 6022, extensible<strong>GEA</strong> motor 3-way mixing valveAir flap valve system for recirculated air/bypassHeat recovery with heat pipetechnology ECOSTAT POWER TUBEHeat recovery with double-plateheat exchangerECOPLAT 2 POWER PLATEHeat recovery with plateheat exchangerECOPLAT POWER PLATEAll-electronic controlDDC controlCorrosion protection Class KStandard protection for normal spasOptional accessoryValve-limit switch for the demanddependentcontrol of theafter-heating pump 9349W20Pool water pump, self-primingin corrosion resistant designof industrial quality F8ZBPCorrosion protection Class HProtection for spas with salt content up to 3%Corrosion protection Class PProtection for spas with salt content up to 3%1)The unit types CAM, CMU, and CWR can be furnished with the fan unit LESS ENERGY SYSTEM as well as with the fan unit <strong>GEA</strong> OPTIVENT.18 <strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>

<strong>GEA</strong> <strong>CAIRfricostar</strong> and <strong>GEA</strong> Fricostar MicroCorrosion protection classCorrosion protection class K H PStandard Salt content up to 3% Salt content over 3%FeaturesAluminium components in endangered areasAnti-corrosion Bumax screw connectorsV4A appliance parts with additional coating inendangered areasV4A flapsProtection paintwork for fansReinforced protection paintwork for fansProtection paintwork for cooling cycle and components(section dependent)Multicoat marine paint ULTRA HIGH SOLID for coolingcycle, flaps and various componentsPlastic laminated cooling cycle pipe work(section dependent)Alodyne coating of the heat exchangerlamellasS70 immersion-bath coating, heat exchangerSÄKA-TEC coating, evaporatorPlasTec capillary linesCoated stainless steel panelsTechnical information subject to change<strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>19

<strong>GEA</strong> open- and closed-loop control technologyIntelligent control technologyfor optimal operationAll <strong>GEA</strong> air handling units for swimming pool hall climatecontrol and dehumidification possess a uniform and intelligentcontrol for energy-optimised and demand-controlled operationSimple and rapid commissioning of the softwareThe software is loaded in the factory and preset as required. Onsitecommissioning therefore takes place considerably faster becauseonly the relevant functions for the respective executionappear in the display.<strong>GEA</strong> open- and closed-loop control systemConsisting of a separate switching cabinet forextensions or separate installation (depending onunit sizes) with all components necessary for themonitoring and control of the unit, wired accordingto VDE standardsIP55: electrical connections (by screw or terminalplugs) between switching cabinet and unit byprepared lines ready-to-installElectrical installation for the voltage supply formixing valve actuation and after-heating pumpIf necessary, exit for pool water pump, outdoorsensor and further options such as external switchfunction inputs provided by customer on siteThe switching cabinet is delivered freestanding– including mounting materials – for attachment tothe unit or as a standing cabinet (dependent on thetype of equipment)All electronic monitoring and control componentsare easily exchangedAll-electronic control for the unit type CAUThe electronic system controls the functions of the plant. Thepermissible humidity limit value is transferred to the controlwith a hygrostat located in the swimming pool hall with functiondisplays and switch. If the limit value is exceeded, the dehumidificationis initiated, the fan starts, and the compressorequipment runs. If the air humidity falls below the preset value,then the compressor stops again. The surplus heat gainedfrom the dehumidification procedure can be made available tothe swimming pool hall air and, provided a pool water condenseris installed, to the pool water as well. The control automaticallymonitors the cooling cycle of the system with a securitychain. With the remote control in the swimming pool hall, thehygrostat can adjust the humidity, a master switch switches theplant on or off, and LEDs inform on the operating state.DDC control for all other unit typesSophisticated DDC control automatically determines the mostfavourable method of operation and supports the economical operationof the air handling plant. In intermittent standby operation,the unit switches on or off in a predetermined cycle inorder to save energy and reduce noise emission. Free night coolingand intermittent standby operation round off the range offunctions. All units can be operated on location, or if requiredfrom a central control station. An optional modem permits remotesystem checks. Interfaces to all prominent building managementsystems present no problem for <strong>GEA</strong> <strong>CAIRfricostar</strong> and<strong>GEA</strong> Fricostar Micro. Systems such as BACnet, LON, MOD, EIB,<strong>PR</strong>OFIBUS, OPC, OSPA Blue Control, and Internet or SMS communicationcan be easily connected.20 <strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>

<strong>GEA</strong> Control and regulating technologyComponentsAll unit types (apart from CAU) with DDC controllerOpen- and closed-loop control functions– Operation and malfunction messages as plaintext– Display of all operation and control parameters– Multi-level access rights with code– Integrated timer switch– Automatic summer/winter switchover, week timer, holidays and special days programs– Malfunction storage with date and time stamp– Service hour counter, total working time and service intervals– Data logger function for important parameters, accessible– Separate supply and exhaust fan motor control– Air volume flow adjustment and display in m 3 /h, including monitoring for equipment with frequency converters– Fan motor monitoring with PTC resistor and motor protection relay– Filter monitoring– Compressor control (heat pump) with minimum run/standing times– Mixing flaps control with selectable minimum outside-air fraction and maximum limitation,automatically regulating depending on the outside and swimming pool hall air state– Control sequence with heat/cold-recovery system, heating unit, possibly compressor (heat pump), bypass flaps and mixed air flaps system– Exhaust air temperature cascade control with min/max limitation of the supply air temperature– Cooling with outside air (night cooling)– After-heater pump requirements control with stoppage protection function– Continuous moisture control– Possible automatic pool water pump requirement control with stoppage protection function– Automatic swimming pool operation/standby switchover– Intermittent pre-selectable standby operation– Several languages selectable in the display– Initial startup function for dampers– Inputs: external safety shut-off (i.e., fire-protection damper or chlorine gas warning)– Motor monitoring for switchable NE pump, with motor protection provided by the owner if necessary– Motor monitoring for switchable basin water pump, with motor protection provided by the owner if necessaryAll unit types (apart from CAU) with DDC controllerDigital control– Modular automation station incorporated in the control cabinet with secured software modules, as well as digital andanalogue inputs and outputs, equipped for all control and monitoring tasks of the swimming pool hall air dehumidification unit– Comfortable operator terminal with its own intelligent system supporting the display, the operating keys as well asthe data transfer incorporated in the control cabinet door– Aluminium face plate with sealed keyboard– Keyboard connector with plug connector– Safety protection class IP65 on the front side– LCD display with 8 lines of 40 characters each as plaintext display, monochrome– 6 function keys– Coloured back lighting, configurable, automatic illumination switching– LCD contrast adjustment is configurable– System bus CAN22 <strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>

Accessories<strong>GEA</strong> open- and closed-loop control technologyAll unit types (apart from CAU) with DDC controllerOptional accessoriesDesignation– Access expansion for on-site control action DEW– Floating contacts for messages DPK– Output expansion, 0 -10 V signal, return air humidity and exhaust air temperature DAW– Input expansion for on-site setpoint value logging, 0 -10 V signal,return air humidity, exhaust air temperature and minimum outside-air fraction– Fault notification fire protection flap / fire detection facility BSK– Operating display in separate enclosure as remote control (without cabinet display) DFB– Additional operator display in separate enclosure as remote control DFD– Automatic humidity setpoint value logging DFS– Air stream monitoring for supply and exhaust fan DLW– Emergency/manual operation for fans, NE valve, pump, damper actuator DNH– Automatic room temperature setpoint value adaptation (dependent on pool water temperature) DTA– Interface for GSM modem including operator control software GSM– Interface for ISDN modem including operator control software ISDN– Interfaces from <strong>GEA</strong> to the GFR building services management system DSG– Interface to OPC - S Bus OPC– Interface to BACnet Bus BACNET– Interface to LON Bus LON– Interface to OSPA Blue Control OSPA– Interface to MOD Bus MOD– Creation of data point list for respective BMS systems xxxDP– Support of the network technician for commissioning the connections of the BMSconnections on location (prerequisite is a complete on-site exclusion of units)– Interface for modem DSM– Comfortable touch operator terminal (LCD Display with 16 colours, graphic resolution 320 x 240 pixel) TBT– Software WEBVISION light WEVDFVxxxIBTechnical information subject to changeImage brochureApplication brochuresProduct brochuresData & Facts and operation manuals(available only as PDF)You are on this level of our documentation structure. You can order at no chargefrom the first 3 levels as printed copies, under: info@gea-airtreatment.com.You can download all brochures as PDF files from the following Internet site:www.gea-airtreatment.com.<strong>PR</strong>-<strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> · Subject to modification · Version 02/<strong>2009</strong>23

Customer proximity, sales structuresReachable always and everywhere!ABB<strong>GB</strong>IHBYCHCZCZDDD<strong>GEA</strong> KlimatechnikGmbH & Co KGA-4673 GaspoltshofenTel. +43 / 7735 / 8000-0<strong>GEA</strong> Happel Belgium N. V.B-1130 BrusselsTel. +32 / 2 / 2406161EVISS Ltd.BG-7000 RousseTel . +359 / 82 / 81000<strong>GEA</strong> KlimatechnikGmbH & Co KGRS-11070 Novi BeogradTel. +381 / 11 / 3193955<strong>GEA</strong> Klimatechnik UABLT-01141 VilniusTel. +370 / 5 / 2106060ATC Klimatec Schweiz AGCH-3065 Bolligen-StationTel. +41 / 31 / 9171919<strong>GEA</strong> LVZ, a.s.CZ-46312 LiberecTel. +420 / 48 / 5225-111<strong>GEA</strong> Klimatizace spol. s r.o.CZ-46312 LiberecTel. +420 / 48 / 5225-303<strong>GEA</strong> HappelKlimatechnik GmbHD-44625 HerneTel. +49 / 2325 / 468-00<strong>GEA</strong> HappelWieland GmbHD-44625 HerneTel. +49 / 2325 / 468-754<strong>GEA</strong> DeichmannUmwelttechnik GmbHD-36179 BebraTel. +49 / 6622 / 504-0The complete addresses are available on theInternet under: www.gea-air-eco2nomy.com.DDDKEESTFFFIN<strong>GB</strong><strong>GEA</strong> DelbagLufttechnik GmbHD-44625 HerneTel. +49 / 2325 / 468-700<strong>GEA</strong> Delbag-LuftfilterVertriebsgesellschaft mbHD-10709 BerlinTel. +49 / 30 / 43592-3<strong>GEA</strong> Klimateknik ApSDK-2610 RødovreTel . +45 / 38 / 887070<strong>GEA</strong> Air TreatmentMarketing Services Int.GmbH – oficina EspañaE-28036 MadridTel. +34 / 91 / 3837701<strong>GEA</strong> Klimatechnik UABLT-01141 VilniusTel. +370 / 5 / 2106060<strong>GEA</strong> DelbagFiltration de l‘airF-77450 MontryTel. +33 / 1 / 60043355<strong>GEA</strong> Happel France sarlF-59436 Roncq CedexTel. +33 / 3 / 20689020OY TEKNOCALOR ABFIN-01300 VantaaTel. + 358 / 10 / 8201100<strong>GEA</strong> Denco Ltd.UK-HR4 8DS HerefordTel. +44 / 1432 / 277 277HHRIEISLLTLVMWENNL<strong>GEA</strong> Klimatechnika KftH-1037 BudapestTel. +36 / 1 / 4393200<strong>GEA</strong> Klima-rashladnatehnika d.o.o.HR-10000 ZagrebTel. +385 / 1 / 6064900Aspect Environmental Ltd.Ardee, Co. Louth IrelandTel. +353 / 41 / 6858983Rafn JenssonIS-110 ReykjavikTel. +354 / 56 / 780-30<strong>GEA</strong> Happel LuxembourgL-4940 BascharageTel. +352 / 26 / 502970<strong>GEA</strong> Klimatechnik UABLT-01141 VilniusTel. +370 / 5 / 2106060<strong>GEA</strong> Klimatechnik UABLT-01141 VilniusTel. +370 / 5 / 2106060<strong>GEA</strong> KlimatechnikGmbH & Co KGRS-110 70 Novi BeogradTel. +381 / 11 / 3193955<strong>GEA</strong> Klimaprodukter ASN-0484 OsloTel. +47 / 220 / 27990<strong>GEA</strong> Happel Nederland B.V.NL-2909 LLCapelle a/d IjsselTel. +31 / 10 / 2350606PPLRORUSSSKSLOSRBTRUAUAENónio, Lda.P-1269-090 LisboaTel. +351 / 21 / 3826160<strong>GEA</strong> Klimatyzacja Sp. z o.o.PL-54610 WroclawTel. +48 / 71 / 3737952<strong>GEA</strong> Klimatechnik s.r.l.RO-300222 TimisoaraTel. +40 / 356 / 423703<strong>GEA</strong> KlimatechnikGmbH & Co KGRU-105094 MoskvaTel. +7 / 495 / 9566674<strong>GEA</strong> EXOS Ventilation ABS-74528 EnköpingTel. +46 / 171 / 85530<strong>GEA</strong> Klimatizácia s.r.o.SK-83104 BratislavaTel. +421 / 7 / 44457917<strong>GEA</strong> KlimatizacijskaTehnika d.o.o.SI-1000 LjubljanaTel. +386 / 1 / 2573850<strong>GEA</strong> KlimatechnikGmbH & Co KGRS-11070 Novi BeogradTel. +381 / 11 / 3193955<strong>GEA</strong> ISISANTR-80700Balmumcu IstanbulTel. +90 / 212 / 2757171<strong>GEA</strong> Ukraina t.o.v.UA-01135 KyivTel. +38 / 044 / 4619356<strong>GEA</strong> Air TreatmentMiddle EastUAE-DubaiTel. +971 / 4 / 887 3881<strong>PR</strong> - <strong>2009</strong>-<strong>0061</strong>-<strong>GB</strong> • Subject to modificationVersion 02/<strong>2009</strong> • Copyright <strong>GEA</strong> Air Treatment · www.papp.ccwww.gea-air-eco2nomy.com