datasheet - Dolomite Microfluidics

datasheet - Dolomite Microfluidics

datasheet - Dolomite Microfluidics

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

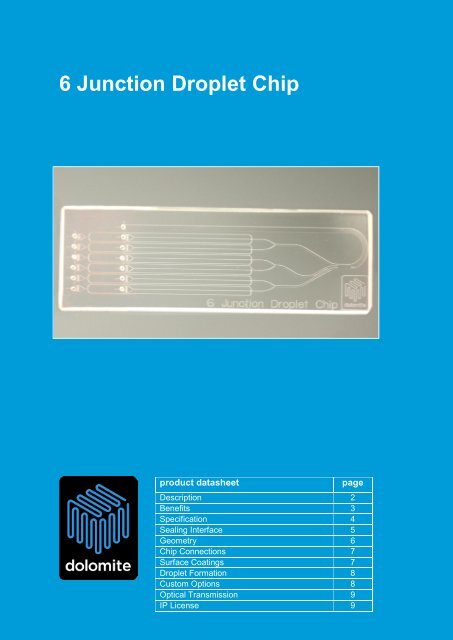

The <strong>Dolomite</strong> Centre LtdLeft: Double Flow Splitting Manifold 7-way (Part No. 3200308)Middle: Double Top Interface 7-way (Part No. 3200296)Right: Linear Connector 7-way (Part No. 3200148)Below: Droplets of water in oil generated simultaneously at 6 junctions and combined into a single wide channelBenefitsHigh throughput generation of droplets in the 20 to 60 μm size rangeFlexibility to use 1 – 6 parallel junctions in the experimentIdeal for producing and analysing micro-emulsionsNear-circular microchannel profile at the junction for stable droplet generationGenerates highly monodisperse droplets when used with the Mitos P-PumpHydrophilic and hydrophobic versionsOn-chip filters on inlet channels to prevent blockagesExcellent chemical compatibilityHigh visibility (excellent access for optics)Compatible with <strong>Dolomite</strong> Multiflux®-2 Linear Connectors for quick and reliablefluidic connectionMAR-000068 1.3 Page 3 of 10

The <strong>Dolomite</strong> Centre LtdSpecificationSpecification6 Junction Droplet Chip(Part No. 3200288)6 Junction Droplet Chip,Hydrophobic (Part No.3200289)Channel cross-section at junction(depth x width)Wide channel cross-section after junction(depth x width)Droplet size range50μm x 55μm50μm x 150μmØ 20 – 60μmSurface coating at 1 st junction Hydrophilic HydrophobicNumber of inputs 12Number of outputs 1Chip size (length x width x thickness)Chip top and base layer thicknessChannel length after junctionBack pressure with 100µl/min flow ofwaterSurface roughness of channels (R a )Max. operating pressureMaterialFabrication45.0mm x 15.0mm x 4mm2.0mm55mm0.8bar5nmup to 30barGlassHF etching and thermal bondingMAR-000068 1.3 Page 4 of 10

The <strong>Dolomite</strong> Centre LtdSealing InterfaceCross-sectional View of Sealing Interface with Top InterfaceConnectortubing (FEP)Connectorbody (PPS)Seal(FKM)Hole throughtop layerGlass microfluidic chipMicrochannelMAR-000068 1.3 Page 5 of 10

The <strong>Dolomite</strong> Centre LtdGeometryChannel at junctionWide channel50µm50µm55µm150µmMAR-000068 1.3 Page 6 of 10

The <strong>Dolomite</strong> Centre LtdChip ConnectionsThe 6-Junction Droplet Chip can be connected to the Double Flow Splitting Manifold 7-way (Part No. 3200308) to split the single fluid lines from the pumps into the 6 input portson the chip. Flow resistors can be inserted between the manifold and the chip if required.2 Input Linesfrom Pumps6 x 0.8 mm ODTubing Lines(Flow Resistors)6 x 0.8 mm ODTubing Lines(Flow Resistors)OutputDouble Flow Splitting Manifold7-way (3200308) in Double TopInterface 7-way (3200296)6-Junction Droplet Chip(3200288) in Double TopInterface 7-way (3200296)Recommended experimental set-up: 4 x Linear Connector 7-way (3200148), 2 x Double Top Interface 7-way (3200296), 6-Junction Droplet Chip (3200288), Double Flow Splitting Manifold 7-way (3200308)Surface CoatingsThe glass channel surface is naturally hydrophilic. This will form organic droplets in anaqueous carrier phase. To form aqueous droplets in an organic phase, a hydrophobiccoating is required. Part numbers for the two chip types are shown below:H 2 O (Aqueous) DropletsOil (Organic) Droplets6 Junction Droplet Chip –Hydrophobic (3200289)6 Junction Droplet Chip –Hydrophilic (3200288)The hydrophobic coating is resistant to organic solvents. It can be removed using acidic orbasic solutions, for example a 1M Sodium Hydroxide for 24 hours.MAR-000068 1.3 Page 7 of 10

The <strong>Dolomite</strong> Centre LtdDroplet FormationThe size, consistency, and production rate of droplet formation is a function of severalphysical parameters, including:Channel sizeViscosity and surface tension of the various fluidsPresence of surfactantsMiscibility of the fluidsUse of hydrophobic or hydrophilic coating on the channel wallsTotal flow rate and relative flow rate of each fluidFlow stabilityTo accelerate development work in droplet microfluidics, <strong>Dolomite</strong> offers a range ofmodular micro droplet systems featuring <strong>Dolomite</strong>’s industry leading microfluidic pumps,connectors and chips. The Droplet Advanced System is recommended for use with the 6Junction Droplet Chip for optimum results. This features the Mitos P-Pump, whichprovides stable, pulse-free flow for generation of droplets with extremely consistentdiameters (monodisperse). Please contact <strong>Dolomite</strong> to configure a droplet system that fitsyour requirements.Mitos P-Pump, Flow Resistors and Droplet Chips featured in the Droplet Advanced SystemCustom OptionsOther chip configurations are available on request. If you would like to generate dropletsof a different size, operate with challenging fluids or perform complex droplet functions,<strong>Dolomite</strong> can design the junction geometry required. The range of <strong>Dolomite</strong> servicesavailable covers all aspects of the development process from characterization of liquidsfor droplet generation to the design of commercial instruments in the field of dropletmicrofluidics. Please contact <strong>Dolomite</strong> to discuss your application.MAR-000068 1.3 Page 8 of 10

Transmittance, %The <strong>Dolomite</strong> Centre LtdOptical TransmissionSpectral Transmittance of 2mm glass layer100806040200250 350 450 550 650 750Wavelength, nmOptical Transmission of GlassIP License<strong>Dolomite</strong> is a licensee of Japan Science and Technology Agency (“JST”) under JST’smicrodroplet generation technology. Please see our website for further details.MAR-000068 1.3 Page 9 of 10

The <strong>Dolomite</strong> Centre LtdMAR-000068 1.3 Page 10 of 10