Suspension Tactics - Chris Alston's Chassisworks

Suspension Tactics - Chris Alston's Chassisworks

Suspension Tactics - Chris Alston's Chassisworks

- No tags were found...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

TECH<strong>Suspension</strong> <strong>Tactics</strong> THE FSC NOVA GETS SUSPENDED“The instruction guide did agreat job of outlining thedetails to get our suspensionsetup with a few tools.”the411First on the agenda wasthe installation of theupper and lower controlarms. The control arms inthe <strong>Chassisworks</strong> kit comefully powder-coated, soexpect to do some minortrimming in order to getthe ball joint screwed in. Todetermine what arm goeson which side,<strong>Chassisworks</strong> stamps a “D”and “P” in each arm.The last time you read about our big-blockNova we were installing the new subframefrom <strong>Chris</strong> Alston’s <strong>Chassisworks</strong>. With thenew frame we were able to scrap our rusted and damagedstocker for a much sturdier piece, while losingsome weight. Even with the frame bolted in, it stillseemed far off from being a “real car” again since thefront fenders, grill, and radiator support were stillmissing in action, but we were making some goodprogress. Once the frame was securely strapped to thecar, it was time to bolt up the springs, control arms,shocks, and brake assemblies. This turned out to be avery simple process due to <strong>Chris</strong> Alston Chassiswork’sthorough instructions. We will admit that we havementioned the instruction manual a couple times inthese past couple segments of the Godzilla Project, soit may seem like a blatant editorial plug, but it reallyis valid for mention since it makes the whole installprocess so much easier. Easy enough that us FSCstaffers were able to install the setup without anyproblems, and that’s saying a lot since the car owner,David Wong (who installed much of the suspensionhimself), hasn’t had much experience as a mechanic.Wong explained, “The instruction guide did a great jobBaseline MeasurementAs a baseline measurement, <strong>Chassisworks</strong>recommends 1-1/6-inches of thread remainingpast the jam nut on each upper control arm rodend. This is only to get your wheel alignmentclose to straight. The rod ends had to bere-adjusted later.With some anti-seize onthe threads, we theninstalled the ball jointusing the supplied wrench.We also made sure toinstall the rubber boot first.Ball JointControl Arms

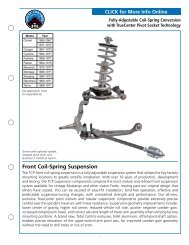

TECH<strong>Suspension</strong> <strong>Tactics</strong> THE FSC NOVA GETS SUSPENDEDAlignmentStainless Steel Allen Headed Pivot Studs<strong>Chassisworks</strong> includes these pretty trick stainless steel Allen headed pivot studs to attach both the upperand lower control arms. Before screwing them in, we made sure to clean the threads on both the frameprovision and the control arms bolt. They get locked in place with a set screw.Once the frame was securely strapped to the car, it wastime to bolt up the springs, control arms, shocks, andbrake assemblies.of outlining the details to get our suspension setupwith a few tools. The only real tools we needed werea basic 100-piece socket set, a level, a couple tapemeasures, and a pencil and paper to jot down themeasurements for the wheel alignment.” And yes, hesaid wheel alignment. The instruction manual willactually walk you through the alignment step-bystep,making the kit a true one-weekend project,meaning you don’t have to wait until Monday to getit aligned. The detailed guide has all of the photos,simple calculations, and instructions to take out all ofthe guesswork from this process.The first portion of the suspension we installedwas the tubular chrome-moly control arms.<strong>Chassisworks</strong> ships them powder-coated without theball joints installed. Before screwing them with thesupplied wrench, we made sure to trim the excesspowdercoat that had collected near the threads ofthe ball-joint provision. You also have to screw in therod ends in order to bolt the arms to the frame.Besides trimming the powdercoat, the assembly ofthe control arms was simple.With the frame in place, we also slapped on thesteering rack. Unlike most front sub-frame kits, thisone comes with an exclusive rack designed by <strong>Chris</strong>Alston, not a “Mustang II” rack. This, too, was aneasy install, and the polished mounting bracketsthat hold the piece are the kind of details that willmake the undercarriage of Godzilla look great whenit’s all together.The shock/coil assembly for our Nova project isone of our favorite parts on the car. The Vari-Shocksare double-adjustable using large, easy-to-turnknobs. The coils come silver powder-coated and canbe adjusted to lower or raise ride height. This setupwill allow for a ton of adjustments. When the car’srunning, these ride height and shock stiffness will bevery important to control the car’s front end for notonly street driving, but at the track too.We opted to go with the 14-inch slotted rotors inour kit. We are actually going to attempt to drive thisbeast on the street, otherwise we would’ve gone witha featherweight drag racing brake setup, which isalso an option with the kit. The brakes are alsoRubber MalletSpindlesthe411We also made sureto check the sub-framealignment. If thesubframe is tweaked inthe car, it could lead to bigalignment problems later.To do this, we simplymeasured from the edgeof the new frame to thebody seam.Once the rod ends weresecured to the controlarms, we tapped themonto the frame with arubber mallet. This canbe tricky since the controlarms are lined with Teflonbushings, which makes apretty tight fit. With a fewtaps of the mallet, thearms were on.With the controlarms bolted up, we theninstalled the shocksimulator. This is used tohold the lower control armin place while the spindleis installed.The spindles simplyget bolted up using thesupplied 9/16-inchcastle nut.

TECH<strong>Suspension</strong> <strong>Tactics</strong> THE FSC NOVA GETS SUSPENDED“The only real tools we needed were abasic 100-piece socket set, a level, acouple tape measures, and a pencil andpaper to jot down the measurements forthe wheel alignment.”1.2.Brackets3.4.Godzilla Alignment1. The first step in aligning the frontend is adjusting the tie rod ends. With the rack fully cocked to oneside, we measured the distance from the frame to the center of the bolt hole on the spindle.2. The camber measurement was next. We originally had trouble lining the level against the spindle, butthe ball joint wrench that is provided with the kit made for a solid flat base to get our camber adjustment.the411The steering rack isbolted up using these niftypolished aluminumbrackets. They get boltedto the front framecrossmember using Allenhead stainless screws.Here’s a shot of thecompleted spindle/shockassembly. The coils allowfor ride height adjustability,and the Vari-Shocks arealso double-adjustable.With the rack pushed allthe way against thebrackets, we fastened itto the frame. With themajor componentsinstalled, it was time toalign the frontend.AssemblyFastened3. The task of measuring and adjusting toe-in would have been easier with the help of another body tohold the tape measures in place to ensure precise measurements. We recommend enlisting the help of afriend on this one. With a little improvisation and patience, Wong took down the measurements 4-5 timesto ensure no drastic variance.4. To finish the installation, we finally bolted up our 11-inch rotors. Our goal was to get the suspension setup correctly following detailed instructions provided by our friends at <strong>Chris</strong> Alston’s. We’re confident thatwe achieved this goal. We will re-visit the suspension, specifically the shock adjustments, when we’re readyfor fine-tuning at the track.available in large 14-inch diameter for more of a“g-machine” or “pro touring” car, but we went with11-inchers so we could use a 15-inch rim, whereasthe 14-incher would have to have something larger,and we really didn’t want to put big rims on the car.In this story, we completed the install of the <strong>Chris</strong>Alston <strong>Chassisworks</strong>’ NoFab front clip and we mustsay, this is definitely something that could save yourcar from the scrapper, it did with ours. Plus, thissetup is perfect for those that want to replace theentire steering and front suspension in one fellswoop instead of putting a front end together pieceby piece. However, it ain’t cheap, but it actuallyworks out to be cheaper than if you were to buy thesame quality parts individually.