Apricus Solar Water Heating System Installation and Operation ...

Apricus Solar Water Heating System Installation and Operation ...

Apricus Solar Water Heating System Installation and Operation ...

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

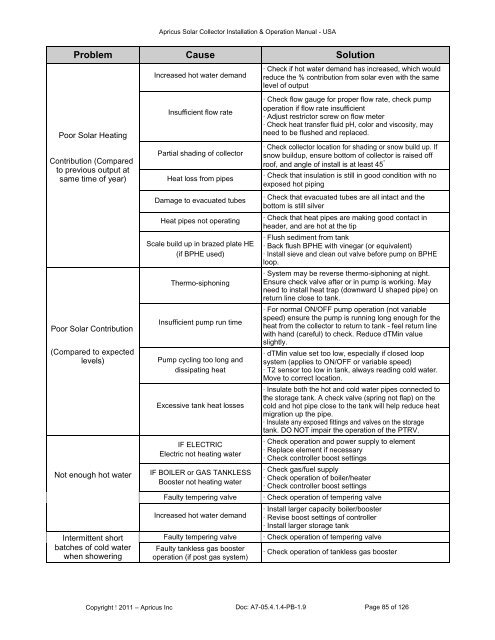

<strong>Apricus</strong> <strong>Solar</strong> Collector <strong>Installation</strong> & <strong>Operation</strong> Manual - USAProblem Cause SolutionPoor <strong>Solar</strong> <strong>Heating</strong>Contribution (Comparedto previous output atsame time of year)Poor <strong>Solar</strong> Contribution(Compared to expectedlevels)Not enough hot waterIntermittent shortbatches of cold waterwhen showeringIncreased hot water dem<strong>and</strong>Insufficient flow ratePartial shading of collectorHeat loss from pipesDamage to evacuated tubesHeat pipes not operatingScale build up in brazed plate HE(if BPHE used)Thermo-siphoningInsufficient pump run timePump cycling too long <strong>and</strong>dissipating heatExcessive tank heat lossesIF ELECTRICElectric not heating waterIF BOILER or GAS TANKLESSBooster not heating waterFaulty tempering valveIncreased hot water dem<strong>and</strong>Faulty tempering valveFaulty tankless gas boosteroperation (if post gas system)· Check if hot water dem<strong>and</strong> has increased, which wouldreduce the % contribution from solar even with the samelevel of output· Check flow gauge for proper flow rate, check pumpoperation if flow rate insufficient· Adjust restrictor screw on flow meter· Check heat transfer fluid pH, color <strong>and</strong> viscosity, mayneed to be flushed <strong>and</strong> replaced.· Check collector location for shading or snow build up. Ifsnow buildup, ensure bottom of collector is raised off°roof, <strong>and</strong> angle of install is at least 45· Check that insulation is still in good condition with noexposed hot piping· Check that evacuated tubes are all intact <strong>and</strong> thebottom is still silver· Check that heat pipes are making good contact inheader, <strong>and</strong> are hot at the tip· Flush sediment from tank· Back flush BPHE with vinegar (or equivalent)· Install sieve <strong>and</strong> clean out valve before pump on BPHEloop.· <strong>System</strong> may be reverse thermo-siphoning at night.Ensure check valve after or in pump is working. Mayneed to install heat trap (downward U shaped pipe) onreturn line close to tank.· For normal ON/OFF pump operation (not variablespeed) ensure the pump is running long enough for theheat from the collector to return to tank - feel return linewith h<strong>and</strong> (careful) to check. Reduce dTMin valueslightly.· dTMin value set too low, especially if closed loopsystem (applies to ON/OFF or variable speed)· T2 sensor too low in tank, always reading cold water.Move to correct location.· Insulate both the hot <strong>and</strong> cold water pipes connected tothe storage tank. A check valve (spring not flap) on thecold <strong>and</strong> hot pipe close to the tank will help reduce heatmigration up the pipe.· Insulate any exposed fittings <strong>and</strong> valves on the storagetank. DO NOT impair the operation of the PTRV.· Check operation <strong>and</strong> power supply to element· Replace element if necessary· Check controller boost settings· Check gas/fuel supply· Check operation of boiler/heater· Check controller boost settings· Check operation of tempering valve· Install larger capacity boiler/booster· Revise boost settings of controller· Install larger storage tank· Check operation of tempering valve· Check operation of tankless gas boosterCopyright 2011 – <strong>Apricus</strong> Inc Doc: A7-05.4.1.4-PB-1.9 Page 85 of 126