- Page 3 and 4:

120 Years of INNOVATIONRESIDENTIALw

- Page 5:

We’ve Got You CoveredComplete sol

- Page 8:

Table of Contents - Sections Overvi

- Page 11 and 12:

Section AStraight Blade DevicesInde

- Page 13 and 14:

Straight Blade DevicesHospital Grad

- Page 15 and 16:

Straight Blade Devices15 and 20 Amp

- Page 17 and 18:

Straight Blade Devices15 and 20 Amp

- Page 19 and 20:

Straight Blade DevicesHBL ® Extra

- Page 21 and 22:

Straight Blade Devices15 and 20 Amp

- Page 23 and 24:

Straight Blade Devices15 and 20 Amp

- Page 25 and 26:

Straight Blade Devices2008 NEC ® R

- Page 27 and 28:

Straight Blade Devices15 and 20 Amp

- Page 29 and 30:

Straight Blade Devices15 and 20 Amp

- Page 31 and 32:

Straight Blade Devices15 and 20 Amp

- Page 33 and 34:

Straight Blade DevicesInsulgrip ®

- Page 35 and 36:

Straight Blade DevicesElastogrip ®

- Page 37 and 38:

Straight Blade Devices15 and 20 Amp

- Page 39 and 40:

Straight Blade Devices15 and 20 Amp

- Page 41 and 42:

Straight Blade Devices15 and 20 Amp

- Page 43 and 44:

Straight Blade Devices20 Ampere, 12

- Page 45 and 46:

Straight Blade Devices15 and 20 Amp

- Page 47 and 48:

Straight Blade Devices30 Ampere, 12

- Page 49 and 50:

Straight Blade Devices50 Ampere, 12

- Page 51 and 52:

Straight Blade Devices60 Ampere, 12

- Page 53 and 54:

Straight Blade DevicesMiscellaneous

- Page 55 and 56:

Straight Blade DevicesAccessoriesFo

- Page 57 and 58:

Straight Blade DevicesAccessoriesFo

- Page 59 and 60:

Straight Blade DevicesTechnical Inf

- Page 61 and 62:

Straight Blade DevicesTechnical Inf

- Page 63 and 64:

Straight Blade DevicesTechnical Inf

- Page 65 and 66:

Straight Blade DevicesTechnical Inf

- Page 67 and 68:

Straight Blade DevicesTechnical Inf

- Page 69 and 70:

Straight Blade DevicesTechnical Inf

- Page 71 and 72:

Section BTwist-Lock ® and Hubbello

- Page 73 and 74:

Twist-Lock ® DevicesMidget Twist-L

- Page 75 and 76:

Twist-Lock ® Devices15 Ampere, 125

- Page 77 and 78:

Twist-Lock ® DevicesInsulgrip ® 1

- Page 79 and 80:

Twist-Lock ® Devices15 Ampere, 125

- Page 81 and 82:

Twist-Lock ® Devices15 Ampere, 125

- Page 83 and 84:

Twist-Lock ® DevicesThe Standard f

- Page 85 and 86:

Twist-Lock ® DevicesSafety-Shroud

- Page 87 and 88:

Twist-Lock ® Devices20 Ampere, 250

- Page 89 and 90:

Twist-Lock ® Devices20 Ampere, 125

- Page 91 and 92:

Twist-Lock ® Devices20 Ampere, 125

- Page 93 and 94:

Twist-Lock ® Devices20 Ampere, 3Ø

- Page 95 and 96:

Twist-Lock ® Devices20 Ampere, 3Ø

- Page 97 and 98:

Twist-Lock ® Devices30 Ampere, 125

- Page 99 and 100:

Twist-Lock ® Devices30 Ampere, 125

- Page 101 and 102:

Twist-Lock ® Devices30 Ampere, 3Ø

- Page 103 and 104:

Twist-Lock ® Devices30 Ampere, 3Ø

- Page 105 and 106:

Twist-Lock ® Devices30 Ampere, 480

- Page 107 and 108:

Twist-Lock ® DevicesSwitched Safet

- Page 109 and 110:

Twist-Lock ® DevicesMechanical Int

- Page 111 and 112:

Non-NEMA Twist-Lock ® Devices10 Am

- Page 113 and 114:

Non-NEMA Twist-Lock ® Devices20 Am

- Page 115 and 116:

Non-NEMA Twist-Lock ® Devices30 Am

- Page 117 and 118:

Non-NEMA Twist-Lock ® Devices30 Am

- Page 119 and 120:

Twist-Lock ® DevicesAccessoriesfor

- Page 121 and 122:

Twist-Lock ® DevicesAccessoriesfor

- Page 123 and 124:

Twist-Lock ® DevicesAccessoriesfor

- Page 125 and 126:

Twist-Lock ® Devices50 Ampere Plug

- Page 127 and 128:

Twist-Lock ® Devices50 Ampere, 125

- Page 129 and 130:

Twist-Lock ® Devices50 Ampere, 250

- Page 131 and 132:

Hubbellock ® DevicesPlugs and Conn

- Page 133 and 134:

Hubbellock ® Devices20 Ampere, 125

- Page 135 and 136:

Hubbellock ® Devices30 Ampere, 600

- Page 137 and 138:

Hubbellock ® Devices60 Ampere, 600

- Page 139 and 140:

Twist-Lock ® and Safety Shroud Dev

- Page 141 and 142:

Twist-Lock ® DevicesTechnical Info

- Page 143 and 144:

Switched Safety EnclosuresTechnical

- Page 145 and 146:

Section CSwitchesSwitched Enclosure

- Page 147 and 148:

SwitchesHBL ® Extra Heavy Duty Ind

- Page 149 and 150:

Switches15, 20 and 30 Ampere, 120-2

- Page 151 and 152:

Switches15 and 20 Ampere, 120-277 V

- Page 153 and 154:

Switches15, 20 and 30 Ampere, 120-2

- Page 155 and 156:

Switches600 to 1000 Watts, 120 Volt

- Page 157 and 158:

SwitchesHeavy Duty Panel MountBat H

- Page 159 and 160:

SwitchesPendant Pushbutton Station

- Page 161 and 162:

AC SwitchesAccessoriesRed Neon Pilo

- Page 163 and 164:

AC SwitchesAccessoriesNylon and Met

- Page 165 and 166:

AC Switches40, 50, 60 and 85 Ampere

- Page 167 and 168:

Disconnect SwitchesThermoplastic Co

- Page 169 and 170:

AC SwitchesTechnical InformationHBL

- Page 171 and 172:

AC SwitchesCertification ChartUL, C

- Page 173 and 174:

AC SwitchesToggle Switch Wiring Dia

- Page 175 and 176:

Switched EnclosuresCircuit-Lock ®

- Page 177 and 178:

Switched EnclosuresCircuit-Lock ®

- Page 179 and 180:

Switched EnclosuresCircuit-Lock ®

- Page 181 and 182:

Section DH-MOSS ® Occupancy Sensor

- Page 183 and 184:

H-MOSS ® Occupancy SensorsEnergy S

- Page 185 and 186:

H-MOSS ® Occupancy SensorsEnergy S

- Page 187 and 188:

H-MOSS ® Occupancy SensorsWall Swi

- Page 189 and 190:

H-MOSS ® Occupancy SensorsWall Swi

- Page 191 and 192:

H-MOSS ® Occupancy SensorsAdaptive

- Page 193 and 194:

H-MOSS ® Occupancy SensorsCeiling

- Page 195 and 196:

H-MOSS ® Occupancy SensorsSpecific

- Page 197 and 198:

H-MOSS ® Occupancy SensorsSpecific

- Page 199 and 200:

H-MOSS ® Occupancy SensorsWiring S

- Page 201 and 202:

Section EPin and Sleeve DevicesMech

- Page 203 and 204:

IEC Pin and SleeveWatertight Device

- Page 205 and 206:

IEC Pin and SleeveWatertight Device

- Page 207 and 208:

IEC Pin and SleeveWatertight Device

- Page 209 and 210:

IEC Pin and SleeveWatertight Device

- Page 211 and 212:

IEC Pin and SleeveWatertight Specif

- Page 213 and 214:

IEC Pin and Sleeve20 and 30A Low Pr

- Page 215 and 216:

IEC Pin and SleeveLow Profile Dimen

- Page 217 and 218:

IEC Pin and SleeveUnfused Circuit-L

- Page 219 and 220:

IEC Pin and SleeveUnfused Circuit-L

- Page 221 and 222:

IEC Pin and Sleeve“Reverse Servic

- Page 223 and 224:

IEC Pin and SleeveFused Circuit-Loc

- Page 225 and 226:

IEC Pin and SleeveFused Circuit-Loc

- Page 227 and 228:

UL 1686 C1 Pin and SleeveInsulgrip

- Page 229 and 230:

UL 1686 C1 Pin and SleeveInsulgrip

- Page 231 and 232:

UL 1686 C1 Pin and SleeveInsulgrip

- Page 233 and 234:

UL 1686 C1 Pin and SleeveInsulgrip

- Page 235 and 236:

Pin and SleeveInsulgrip ® Mechanic

- Page 237 and 238:

Pin and SleeveTechnical Information

- Page 239 and 240:

Section FSingle Pole DevicesIndexPr

- Page 241 and 242:

Single Pole Devices300 and 400 Ampe

- Page 243 and 244:

Single Pole Devices300 and 400 Ampe

- Page 245 and 246:

Section GIndustrial Connectivity an

- Page 247 and 248:

Control Integration Components 3A U

- Page 249 and 250:

Power System Distribution Assemblie

- Page 251 and 252:

Power System Supply AssembliesFeatu

- Page 253 and 254:

Mini-Quick ® Control Connectors2 -

- Page 255 and 256:

Mini-Quick ® Control Connectors2 -

- Page 257 and 258:

Mini-Quick ® Control Connectors7 -

- Page 259 and 260:

Mini-Quick ® Control Connectors7 -

- Page 261 and 262:

Mini-Quick ® Control ConnectorsCoi

- Page 263 and 264:

Mini-Quick ® Control ConnectorsFie

- Page 265 and 266:

Micro-Quick ® Control ConnectorsSi

- Page 267 and 268:

Micro-Quick ® Control ConnectorsSi

- Page 269 and 270:

Micro-Quick ® Control ConnectorsDu

- Page 271 and 272:

Micro-Quick ® Control ConnectorsDu

- Page 273 and 274:

Micro-Quick ® Control ConnectorsCo

- Page 275 and 276:

Micro-Quick ® Control ConnectorsFi

- Page 277 and 278:

Micro-Quick ®Splitter Connectors a

- Page 279 and 280:

Nano-Quick ® Control Connectors3 -

- Page 281 and 282:

Nano-Quick ® Control ConnectorsFie

- Page 283 and 284:

SignalPlex Micro Ports4 Port Enclos

- Page 285 and 286:

SignalPlex Micro Ports6 Port Enclos

- Page 287 and 288:

SignalPlex Micro Ports8 Port Enclos

- Page 289 and 290:

SignalPlex Micro PortsAccessoriesSi

- Page 291 and 292:

SignalPlex Mini PortsFeatures and B

- Page 293 and 294:

SignalPlex Mini Ports4, 6, and 8 Po

- Page 295 and 296:

Signal-Quick Sensor Mounting Access

- Page 297 and 298:

Signal-Quick Sensor Mounting Access

- Page 299 and 300:

Signal-Quick Sensor Mounting Access

- Page 301 and 302:

Signal-Quick Sensor Mounting Access

- Page 303 and 304:

Signal-Quick Sensor Mounting Access

- Page 305 and 306:

Signal-Quick Sensor Mounting Access

- Page 307 and 308:

Signal-Quick Sensor Mounting Access

- Page 309 and 310:

CableTrak ® Hose and Cable Carrier

- Page 311 and 312:

CableTrak ® Hose and Cable Carrier

- Page 313 and 314:

DIN Rail Utility BoxPower and DataC

- Page 315 and 316:

PANEL-SAFEPower and Data Access Por

- Page 317 and 318:

HI-IMPACTIndustrial Ethernet Patch

- Page 319 and 320:

Section HGround Fault ProductsIndex

- Page 321 and 322:

Ground Fault ProductsHeavy Duty Com

- Page 323 and 324:

Ground Fault ProductsHeavy Duty Com

- Page 325 and 326:

Ground Fault ProductsHeavy Duty Com

- Page 327 and 328:

Ground Fault ProductsHeavy Duty Com

- Page 329 and 330:

Ground Fault ProductsStraight Blade

- Page 331 and 332:

Ground Fault ProductsStraight Blade

- Page 333 and 334:

Ground Fault ProductsPortable GFCI

- Page 335 and 336:

Ground Fault ProductsHard Wired 30

- Page 337 and 338:

Section IHospital ProductsIndexProd

- Page 339 and 340:

Hospital ProductsHBL ® Extra Heavy

- Page 341 and 342:

Hospital Products15 and 20 Ampere,

- Page 343 and 344:

Hospital Products15 and 20 Ampere,

- Page 345 and 346:

Ground Fault ProductsHeavy Duty Tam

- Page 347 and 348:

Hospital ProductsSurge Protection D

- Page 349 and 350:

Hospital ProductsHubbellock ® Expl

- Page 351 and 352:

Hospital ProductsTechnical Informat

- Page 353 and 354:

Hospital ProductsTechnical Informat

- Page 355 and 356:

Section JSpikeShield ® Power Quali

- Page 357 and 358:

SpikeShield ® Power Quality Produc

- Page 359 and 360:

SpikeShield ® Power Quality Produc

- Page 361 and 362:

SpikeShield ® Power Quality Produc

- Page 363 and 364:

SpikeShield ® Power Quality Produc

- Page 365 and 366:

SpikeShield ® Power Quality Produc

- Page 367 and 368:

SpikeShield ® Power Quality Produc

- Page 369 and 370:

SpikeShield ® Power Quality Produc

- Page 371 and 372:

SpikeShield ® Power Quality Produc

- Page 373 and 374:

SpikeShield ® Power Quality Produc

- Page 375 and 376:

SpikeShield ® Power Quality Produc

- Page 377 and 378:

SpikeShield ® Power Quality Produc

- Page 379 and 380:

Section KWallplatesIndexProductPage

- Page 381 and 382:

WallplatesFeatures and BenefitsNylo

- Page 383 and 384:

WallplatesDuplex and Single Recepta

- Page 385 and 386:

WallplatesBlank WallplatesBlank Wal

- Page 387 and 388:

WallplatesDecorator WallplatesGFCI,

- Page 389 and 390:

WallplatesCombination Wallplates, 2

- Page 391 and 392:

WallplatesCombination Wallplates, 4

- Page 393 and 394:

WallplatesDecorator Snap-On Wallpla

- Page 395 and 396:

WallplatesCoaxial and Twinaxial “

- Page 397 and 398:

WallplatesJumbo, Metal WallplatesJu

- Page 399 and 400:

WallplatesPre-Marked “ISOLATED GR

- Page 401 and 402:

WallplatesAccessories and Selection

- Page 403 and 404:

WallplatesWeatherproof Covers for R

- Page 405 and 406:

WallplatesWeatherproof Switch Plate

- Page 407 and 408:

WallplatesWeatherproof Covers for D

- Page 409 and 410:

WallplatesWhile-In-Use Weatherproof

- Page 411 and 412:

WallplatesTechnical InformationSpec

- Page 413 and 414:

WallplatesCustom Metal WallplatesHo

- Page 415 and 416:

WallplatesCustom Metal WallplatesCo

- Page 417 and 418:

WallplatesCustom Metal WallplatesCo

- Page 419 and 420:

Section LFloor BoxesIndexProductPag

- Page 421 and 422:

Complies with UL514ATraditional Flo

- Page 423 and 424:

Floor BoxesHubbell SystemOne Metal

- Page 425 and 426:

Floor BoxesHubbell SystemOne Featur

- Page 427 and 428:

Floor BoxesFlush Round Single Servi

- Page 429 and 430:

Floor BoxesFlush Rectangular Non-Me

- Page 431 and 432:

Floor BoxesFlush Rectangular Stampe

- Page 433 and 434:

Floor BoxesRecessed 6-Gang Concrete

- Page 435 and 436:

Floor BoxesFlush Floor Boxes for Wo

- Page 437 and 438:

Floor BoxesAbove-Floor Service Fitt

- Page 439 and 440:

Floor BoxesAccessoriesProblem Solve

- Page 441 and 442:

Floor BoxesHubbell SystemOne Config

- Page 443 and 444:

Floor BoxesConvention Center Utilit

- Page 445 and 446:

Floor BoxesConvention Center Utilit

- Page 447 and 448:

Complies with UL514AFurniture FeedF

- Page 449 and 450:

Floor BoxesCONNEXION - Wiring Schem

- Page 451 and 452:

Floor BoxesUnloaded Raised Access F

- Page 453 and 454:

Floor BoxesFurniture Connectivity B

- Page 455 and 456:

Recessed Wall BoxesMulti-Connect -

- Page 457 and 458:

Section MFire-Rated Poke-ThroughsIn

- Page 459 and 460:

Traditional FRPTs for 3" and 2" cor

- Page 461 and 462:

Fire-Rated Poke-ThroughsHubbell Sys

- Page 463 and 464:

Fire-Rated Poke-ThroughsHubbell Sys

- Page 465 and 466:

Fire-Rated Poke-Throughs2X2 Flush F

- Page 467 and 468:

Fire-Rated Poke-ThroughsFlush Furni

- Page 469 and 470:

Fire-Rated Poke-ThroughsBrushed Alu

- Page 471 and 472:

Technical InformationHubbell System

- Page 473 and 474:

Technical InformationHubbell System

- Page 475 and 476:

Technical InformationHubbell System

- Page 477 and 478:

Technical InformationHubbell Flush

- Page 479 and 480:

Technical InformationHubbell Flush

- Page 481 and 482:

Technical InformationPedestal FRPTP

- Page 483 and 484:

photocourtesy ofconstruction ionpho

- Page 485 and 486:

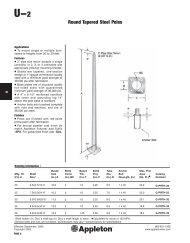

Aluminum Service PolesCustom Pole C

- Page 487 and 488:

Section OMetal and Non-Metallic Rac

- Page 489 and 490:

Metal RacewayHBL2000, HBL2000A, HBL

- Page 491 and 492:

Metal RacewayHBL500 and HBL750 Seri

- Page 493 and 494:

Metal RacewayHBL500 and HBL750 Seri

- Page 495 and 496:

Metal RacewayHBL500 and HBL750 Seri

- Page 497 and 498:

Metal RacewayHBL500 and HBL750 Seri

- Page 499 and 500:

Metal RacewayHBL500 and HBL750 Seri

- Page 501 and 502:

Metal RacewayHBL2000, HBL2000A, HBL

- Page 503 and 504:

Metal RacewayHBL2000 and HBL2000A S

- Page 505 and 506:

Metal RacewayMetal PlugTrak ®Metal

- Page 507 and 508:

Metal RacewayHBL2400 and HBL2400D S

- Page 509 and 510:

Metal RacewayHBL2400 and HBL2400D S

- Page 511 and 512:

301413121129101516 17 1819202123222

- Page 513 and 514:

Metal RacewayHBL3000 SeriesFeatures

- Page 515 and 516:

Metal RacewayHBL3000 SeriesFittings

- Page 517 and 518:

Metal RacewayHBL3000 SeriesDevice B

- Page 519 and 520:

Metal RacewayHBL4750 SeriesFeatures

- Page 521 and 522:

Metal RacewayHBL4750 SeriesFittings

- Page 523 and 524:

Metal RacewayHBL4750 SeriesFittings

- Page 525 and 526:

Metal RacewayHBL4750 SeriesOverlapp

- Page 527 and 528:

Metal RacewayHBL6750 SeriesFeatures

- Page 529 and 530:

Metal RacewayHBL6750 SeriesFittings

- Page 531 and 532:

Metal RacewayHBL6750 SeriesFittings

- Page 533 and 534:

Metal RacewayHBL6750 SeriesOverlapp

- Page 535 and 536:

Aluminum RacewayHBLALU5000 and HBLA

- Page 537 and 538:

Aluminum RacewayHBLALU2000 and Alum

- Page 539 and 540:

Aluminum RacewayHBLALU2000 SeriesBo

- Page 541 and 542:

Aluminum RacewayAluminum PlugTrak

- Page 543 and 544:

Aluminum RacewayHBLALU3800 and HBLA

- Page 545 and 546:

Aluminum RacewayHBLALU4800 SeriesRa

- Page 547 and 548:

Aluminum RacewayHBLALU3800 and HBLA

- Page 549 and 550:

Aluminum RacewayHBLALU5000 and HBLA

- Page 551 and 552:

Aluminum RacewayHBLALU7620 SeriesRa

- Page 553 and 554:

Metal and Aluminum RacewayTechnical

- Page 555 and 556:

Metal RacewayPlates and OutletsiSTA

- Page 557 and 558:

Metal Raceway - Cross ReferenceHBL2

- Page 559 and 560:

Metal Raceway - Cross ReferenceHBL6

- Page 561 and 562:

Hubbell RacewayRaceway Profiles - Q

- Page 563 and 564:

17151614281813262729302519242322202

- Page 565 and 566:

Non-Metallic RacewayComplete Line o

- Page 567 and 568:

Non-Metallic RacewayPT1 PremiseTrak

- Page 569 and 570:

Non-Metallic RacewayPP1 PremiseTrak

- Page 571 and 572:

Non-Metallic RacewayPL1 LANTrak ®

- Page 573 and 574:

Non-Metallic RacewayPW1 WallTrak ®

- Page 575 and 576:

Non-Metallic RacewayPW2 WallTrak ®

- Page 577 and 578:

Non-Metallic RacewayPB2 BaseTrak ®

- Page 579 and 580:

Non-Metallic RacewayPB3 BaseTrak ®

- Page 581 and 582:

Non-Metallic RacewayPS3 Super BaseT

- Page 583 and 584:

Non-Metallic RacewayOffice White Pl

- Page 585 and 586:

IntroductionPre-Wired RacewayHubbel

- Page 587 and 588:

Pre-Wired RacewayAluminum, Steel an

- Page 589 and 590:

Section PNetwork WiringEnterprise G

- Page 591 and 592:

Network WiringAudio/Video Keystone

- Page 593 and 594:

Network WiringiSTATION Face PlatesE

- Page 595 and 596:

Network WiringiSTATION Audio Visual

- Page 597 and 598:

Network WiringiSTATION Surface Moun

- Page 599 and 600:

Network WiringiSTATION Audio/Video

- Page 601 and 602:

Network WiringFiber AdaptersEnterpr

- Page 603 and 604:

Network WiringPatch Cords and Modul

- Page 605 and 606:

Network WiringFiber Enclosures and

- Page 607 and 608:

Network WiringWall Mounted Enclosur

- Page 609 and 610:

Network WiringCable Management Rack

- Page 611 and 612:

Network WiringLadder RacksEnterpris

- Page 613 and 614:

Network WiringTools and Accessories

- Page 615 and 616:

Network WiringHubbell Labeling Solu

- Page 617 and 618:

Section QHose and Cable Protection

- Page 619 and 620:

Hose and Cable Protection SystemsAc

- Page 621 and 622:

Hose and Cable Protection SystemsTr

- Page 623 and 624:

Section RCable, Cord and Hose Reels

- Page 625 and 626:

Cable, Cord and Hose ReelsWeatherpr

- Page 627 and 628: Wiring Device-KellemsCable, Cord an

- Page 629 and 630: Section STemporary Power and Lighti

- Page 631 and 632: Temporary Power Distribution System

- Page 633 and 634: Temporary Power Distribution System

- Page 635 and 636: Temporary Power Distribution System

- Page 637 and 638: Section TKellems ® Wire Management

- Page 639 and 640: Kellems ® Wire Management Products

- Page 641 and 642: Kellems ® Wire Management Products

- Page 643 and 644: Kellems ® Wire Management Products

- Page 645 and 646: Kellems ® Wire Management Products

- Page 647 and 648: Kellems ® Wire Management Products

- Page 649 and 650: Kellems ® Wire Management Products

- Page 651 and 652: Kellems ® Wire Management Products

- Page 653 and 654: Kellems ® Wire Management Products

- Page 655 and 656: Kellems ® Wire Management Products

- Page 657 and 658: Kellems ® Wire Management Products

- Page 659 and 660: Kellems ® Wire Management Products

- Page 661 and 662: Kellems ® Wire Management Products

- Page 663 and 664: Kellems ® Wire Management Products

- Page 665 and 666: Kellems ® Wire Management Products

- Page 667 and 668: Kellems ® Wire Management Products

- Page 669 and 670: Kellems ® Wire Management Products

- Page 671 and 672: Kellems ® Wire Management Products

- Page 673 and 674: Kellems ® Wire Management Products

- Page 675 and 676: Wire Management ProductsConduit Ris

- Page 677: Kellems ® Wire Management Products

- Page 681 and 682: Kellems ® Wire Management Products

- Page 683 and 684: Kellems ® Wire Management Products

- Page 685 and 686: Kellems ® Wire Management Products

- Page 687 and 688: Kellems ® Wire Management Products

- Page 689 and 690: Kellems ® Wire Management Products

- Page 691 and 692: Kellems ® Wire Management Products

- Page 693 and 694: Kellems ® Wire Management Products

- Page 695 and 696: Kellems ® Wire Management Products

- Page 697 and 698: Kellems ® Wire Management Products

- Page 699 and 700: Kellems ® Wire Management Products

- Page 701 and 702: Kellems ® Wire Management Products

- Page 703 and 704: Kellems ® Wire Management Products

- Page 705 and 706: Kellems ® Wire Management Products

- Page 707 and 708: Kellems ® Wire Management Products

- Page 709 and 710: Kellems ® Wire Management Products

- Page 711 and 712: Kellems ® Wire Management Products

- Page 713 and 714: Kellems ® Wire Management Products

- Page 715 and 716: Kellems ® Wire Management Products

- Page 717 and 718: Kellems ® Wire Management Products

- Page 719 and 720: Kellems ® Wire Management Products

- Page 721 and 722: Kellems ® Wire Management Products

- Page 723 and 724: Kellems ® Wire Management Products

- Page 725 and 726: Kellems ® Wire Management Products

- Page 727 and 728: Kellems ® Wire Management Products

- Page 729 and 730:

Kellems ® Wire Management Products

- Page 731 and 732:

Kellems ® Wire Management Products

- Page 733 and 734:

Kellems ® Wire Management Products

- Page 735 and 736:

Kellems ® Wire Management Products

- Page 737 and 738:

Kellems ® Wire Management Products

- Page 739 and 740:

Kellems ® Wire Management Products

- Page 741 and 742:

NOTES:Kellems ® Wire Management Pr

- Page 743 and 744:

Kellems ® Wire Management Products

- Page 745 and 746:

Kellems ® Wire Management Products

- Page 747 and 748:

Kellems ® Wire Management Products

- Page 749 and 750:

Kellems ® Wire Management Products

- Page 751 and 752:

Kellems ® Wire Management Products

- Page 753 and 754:

Section UOther Wiring ProductsIndex

- Page 755 and 756:

Other Wiring ProductsLockout Device

- Page 757 and 758:

Other Wiring ProductsReceptacle Cir

- Page 759 and 760:

Section VhomeSELECT - Residential D

- Page 761 and 762:

homeSELECT Single-Pole and Three-Wa

- Page 763 and 764:

homeSELECT Wiring Termination and S

- Page 765 and 766:

homeSELECT Combination Quiet Rocker

- Page 767 and 768:

homeSELECT Tamper-Resistant and Sta

- Page 769 and 770:

homeSELECT Snap-On WallplatesDecora

- Page 771 and 772:

homeSELECT Combination WallplatesDe

- Page 773 and 774:

homeSELECT Decorator FramesDecorato

- Page 775 and 776:

homeSELECT Molded-In Voice/Data/Vid

- Page 777 and 778:

homeSELECT Three- and Four-Way Togg

- Page 779 and 780:

homeSELECT Combination Switches/Dev

- Page 781 and 782:

homeSELECT Duplex and Single Recept

- Page 783 and 784:

homeSELECT Self Test GFCI Receptacl

- Page 785 and 786:

homeSELECT Range and Dryer Power Re

- Page 787 and 788:

homeSELECT Special Use ProductsSwit

- Page 789 and 790:

homeSELECT Slide Dimmers and Fan Sp

- Page 791 and 792:

homeSELECT Rotary Dimmers and Fan S

- Page 793 and 794:

homeSELECT Vacancy SensorsLighting

- Page 795 and 796:

homeSELECT Floor Boxes For Wood Flo

- Page 797 and 798:

homeSELECT Floor Boxes For Concrete

- Page 799 and 800:

homeSELECT Under Cabinet/Counter Po

- Page 801 and 802:

homeSELECT Incandescent Lampholders

- Page 803 and 804:

homeSELECT Lampholders AccessoriesL

- Page 805 and 806:

homeSELECT Plugs, Taps and Adapters

- Page 807 and 808:

Section VnetSELECT - Structured Wir

- Page 809 and 810:

netSELECTVoice/Data JacksData Commu

- Page 811 and 812:

netSELECTMultimedia Face PlatesData

- Page 813 and 814:

netSELECTHDMI ProductsData Communic

- Page 815 and 816:

netSELECT Molded-In Voice/Data/Vide

- Page 817 and 818:

netSELECT Molded-In PlatesData Comm

- Page 819 and 820:

netSELECT Telephone Wall JacksData

- Page 821 and 822:

netSELECT Advantages and Wiring Lay

- Page 823 and 824:

netSELECT Network ModulesStructured

- Page 825 and 826:

netSELECT AccessoriesStructured Wir

- Page 827 and 828:

Section WMarine ProductsIndexProduc

- Page 829 and 830:

Marine ProductsShip-to-Shore Select

- Page 831 and 832:

Marine Products30 Ampere, 125 Volt

- Page 833 and 834:

Marine Products30 Ampere, Cable Set

- Page 835 and 836:

Marine Products30 Ampere, 125 Volt

- Page 837 and 838:

Marine Products50 Ampere, 125 Volt

- Page 839 and 840:

Marine Products50 Ampere, 125/250 V

- Page 841 and 842:

Marine Products100 Ampere, 125/250

- Page 843 and 844:

Marine Products100 Ampere, 125/250

- Page 845 and 846:

Marine Products100 Ampere, 3ØY 120

- Page 847 and 848:

Marine Products200 Ampere, 600V AC/

- Page 849 and 850:

Marine ProductsInternationally Rate

- Page 851 and 852:

Marine ProductsAdapter Selection Gu

- Page 853 and 854:

Marine ProductsMolded Y AdaptersMol

- Page 855 and 856:

Marine ProductsTelephone and Cable

- Page 857 and 858:

Marine Products12 Volt DC Rated Swi

- Page 859 and 860:

Marine Products15 Ampere, 125 Volt

- Page 861 and 862:

Marine Products20 Ampere, 125 Volt

- Page 863 and 864:

Marine ProductsGFCI and Surge Prote

- Page 865 and 866:

Marine ProductsSwitches and Weather

- Page 867 and 868:

Marine ProductsCommunication Frames

- Page 869 and 870:

Marine ProductsBoatyard Accessory I

- Page 871 and 872:

Marine ProductsBoatyard Accessory I

- Page 873 and 874:

Section XGeneral Technical DataInde

- Page 875 and 876:

Technical DataIndustry Standards -

- Page 877 and 878:

Technical DataIndustry Associations

- Page 879 and 880:

Technical DataAC Switch Data and Ho

- Page 881 and 882:

Technical DataNEMA and IEC Classifi

- Page 883 and 884:

Technical DataEnclosure Types for N

- Page 885 and 886:

Technical DataCircuit Wiring Diagra

- Page 887 and 888:

Technical DataCircuit Wiring Diagra

- Page 889 and 890:

Technical DataElectrical Symbols an

- Page 891 and 892:

Technical DataHorsepower RatingsFor

- Page 893 and 894:

IndexHubbell Configuration ChartsIn

- Page 895 and 896:

STRAIGHT BLADE DEVICESReceptacleStr

- Page 897 and 898:

SAFETY-SHROUDTWIST-LOCK ® DEVICESW

- Page 899 and 900:

IEC WATERTIGHT PIN AND SLEEVE DEVIC

- Page 901 and 902:

50 AMP TWIST-LOCK ® DEVICESHUBBELL

- Page 903 and 904:

Wiring Device - KellemsCatalog Numb

- Page 905 and 906:

Wiring Device - KellemsCatalog Numb

- Page 907 and 908:

Wiring Device - KellemsCatalog Numb

- Page 909 and 910:

Wiring Device - KellemsCatalog Numb

- Page 911 and 912:

Wiring Device - KellemsCatalog Numb

- Page 913 and 914:

Wiring Device - KellemsCatalog Numb

- Page 915 and 916:

Wiring Device - KellemsCatalog Numb

- Page 917 and 918:

Wiring Device - KellemsCatalog Numb

- Page 919 and 920:

Wiring Device - KellemsCatalog Numb

- Page 921 and 922:

Wiring Device - KellemsCatalog Numb

- Page 923 and 924:

Wiring Device - KellemsCatalog Numb

- Page 925 and 926:

Wiring Device - KellemsCatalog Numb

- Page 927 and 928:

Wiring Device - KellemsCatalog Numb

- Page 929 and 930:

Wiring Device - KellemsCatalog Numb

- Page 931 and 932:

Wiring Device - KellemsCatalog Numb

- Page 933 and 934:

Wiring Device - KellemsCatalog Numb

- Page 935 and 936:

Wiring Device - KellemsRoHS Product

- Page 937 and 938:

Wiring Device - KellemsRoHS Product

- Page 939 and 940:

Wiring Device - KellemsRoHS Product

- Page 941 and 942:

Wiring Device - KellemsRoHS Product

- Page 943 and 944:

Wiring Device - KellemsRoHS Product

- Page 945 and 946:

Wiring Device - KellemsRoHS Product

- Page 947 and 948:

Hubbell Configuration ChartFor sele

- Page 949 and 950:

Hubbell’s New and Improved Websit