12.07.2015

•

Views

Swivels Kellems ® Wire Management ProductsKellems ® Wire Management ProductsSwivelsPulling Grips AccessoriesWARNING!It is important that you readall breaking strength, safetyand technical data relatingto this product on pagesT-17 through T-27.DAG20308001ASwivelsSwivels are essential to the efficiency and safety of any high tension application. They are particularlyimportant where continuous pulls develop higher and higher torque levels. Torque is intensified by thepull-resistance of the cable itself and the resistance of the high tension controlling equipment regulatingline sag. Ball bearing swivels release torque and prevent it from reaching dangerous levels that candamage the cable and obstruct the lines.SwivelsMaximum SafeWorking Load Dimensions in Inches (cm) CatalogLbs. (N) A B C D E F G Model Numbers2,250 (10,000) " (2.22) 2½" (6.35) 3" (8.57) " (1.11) " (0.95) " (0.79) " (2.46) A-13L 20308001A5,000 (22,240) 1¼" (3.17) 3" (9.37) 4¾" (12.06) 1" (1.35) 1" (1.35) " (1.03) 1" (3.25) BB-13L 20308002A9,000 (40,030) 1½" (3.81) 4¼" (10.79) 5" (14.29) " (1.75) 1" (1.51) ½" (1.27) 1" (3.97) B-13L 20308003A10,000 (44,480) 1" (4.13) 4½" (11.43) 6" (15.24) ¾" (1.90) " (1.75) " (1.59) 1" (4.36) C-13L 20308004A30,000 (133,440) 2" (6.03) 7" (19.37) 10" (25.40) 1" (3.02) 1" (2.62) " (2.22) 2" (7.06) D-13L 20308005ACBFET-16 www.hubbell-wiring.comDimensions in Inches (mm)

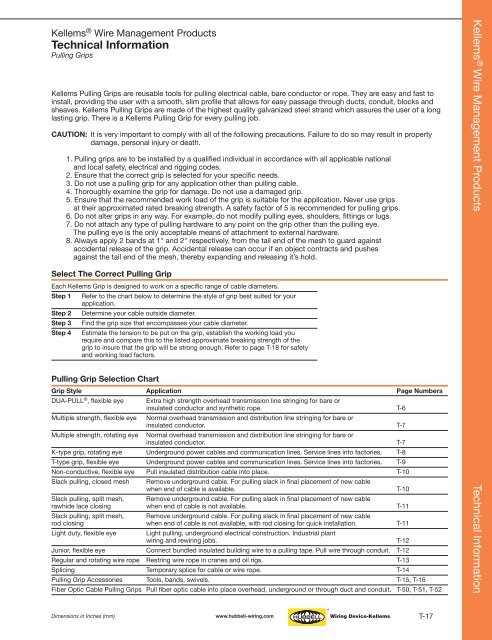

Kellems ® Wire Management ProductsTechnical InformationPulling GripsKellems Pulling Grips are reusable tools for pulling electrical cable, bare conductor or rope. They are easy and fast toinstall, providing the user with a smooth, slim profile that allows for easy passage through ducts, conduit, blocks andsheaves. Kellems Pulling Grips are made of the highest quality galvanized steel strand which assures the user of a longlasting grip. There is a Kellems Pulling Grip for every pulling job.CAUTION: It is very important to comply with all of the following precautions. Failure to do so may result in propertydamage, personal injury or death.1. Pulling grips are to be installed by a qualified individual in accordance with all applicable nationaland local safety, electrical and rigging codes.2. Ensure that the correct grip is selected for your specific needs.3. Do not use a pulling grip for any application other than pulling cable.4. Thoroughly examine the grip for damage. Do not use a damaged grip.5. Ensure that the recommended work load of the grip is suitable for the application. Never use gripsat their approximated rated breaking strength. A safety factor of 5 is recommended for pulling grips.6. Do not alter grips in any way. For example, do not modify pulling eyes, shoulders, fittings or lugs.7. Do not attach any type of pulling hardware to any point on the grip other than the pulling eye.The pulling eye is the only acceptable means of attachment to external hardware.8. Always apply 2 bands at 1" and 2" respectively, from the tail end of the mesh to guard againstaccidental release of the grip. Accidental release can occur if an object contracts and pushesagainst the tail end of the mesh, thereby expanding and releasing it’s hold.Select The Correct Pulling GripEach Kellems Grip is designed to work on a specific range of cable diameters.Step 1 Refer to the chart below to determine the style of grip best suited for yourapplication.Step 2 Determine your cable outside diameter.Step 3 Find the grip size that encompasses your cable diameter.Step 4 Estimate the tension to be put on the grip, establish the working load yourequire and compare this to the listed approximate breaking strength of thegrip to insure that the grip will be strong enough. Refer to page T-18 for safetyand working load factors.Pulling Grip Selection ChartGrip Style Application Page NumbersDUA-PULL ® , flexible eye Extra high strength overhead transmission line stringing for bare orinsulated conductor and synthetic rope. T-6Multiple strength, flexible eye Normal overhead transmission and distribution line stringing for bare orinsulated conductor. T-7Multiple strength, rotating eye Normal overhead transmission and distribution line stringing for bare orinsulated conductor. T-7K-type grip, rotating eye Underground power cables and communication lines. Service lines into factories. T-8T-type grip, flexible eye Underground power cables and communication lines. Service lines into factories. T-9Non-conductive, flexible eye Pull insulated distribution cable into place. T-10Slack pulling, closed mesh Remove underground cable. For pulling slack in final placement of new cablewhen end of cable is available. T-10Slack pulling, split mesh, Remove underground cable. For pulling slack in final placement of new cablerawhide lace closing when end of cable is not available. T-11Slack pulling, split mesh, Remove underground cable. For pulling slack in final placement of new cablerod closing when end of cable is not available, with rod closing for quick installation. T-11Light duty, flexible eye Light pulling, underground electrical construction. Industrial plantwiring and rewiring jobs. T-12Junior, flexible eye Connect bundled insulated building wire to a pulling tape. Pull wire through conduit. T-12Regular and rotating wire rope Restring wire rope in cranes and oil rigs. T-13Splicing Temporary splice for cable or wire rope. T-14Pulling Grip Accessories Tools, bands, swivels. T-15, T-16Fiber Optic Cable Pulling Grips Pull fiber optic cable into place overhead, underground or through duct and conduit. T-50, T-51, T-52Kellems ® Wire Management Products Technical InformationDimensions in Inches (mm)www.hubbell-wiring.comT-17

-

Page 3 and 4:

120 Years of INNOVATIONRESIDENTIALw

-

Page 5:

We’ve Got You CoveredComplete sol

-

Page 8:

Table of Contents - Sections Overvi

-

Page 11 and 12:

Section AStraight Blade DevicesInde

-

Page 13 and 14:

Straight Blade DevicesHospital Grad

-

Page 15 and 16:

Straight Blade Devices15 and 20 Amp

-

Page 17 and 18:

Straight Blade Devices15 and 20 Amp

-

Page 19 and 20:

Straight Blade DevicesHBL ® Extra

-

Page 21 and 22:

Straight Blade Devices15 and 20 Amp

-

Page 23 and 24:

Straight Blade Devices15 and 20 Amp

-

Page 25 and 26:

Straight Blade Devices2008 NEC ® R

-

Page 27 and 28:

Straight Blade Devices15 and 20 Amp

-

Page 29 and 30:

Straight Blade Devices15 and 20 Amp

-

Page 31 and 32:

Straight Blade Devices15 and 20 Amp

-

Page 33 and 34:

Straight Blade DevicesInsulgrip ®

-

Page 35 and 36:

Straight Blade DevicesElastogrip ®

-

Page 37 and 38:

Straight Blade Devices15 and 20 Amp

-

Page 39 and 40:

Straight Blade Devices15 and 20 Amp

-

Page 41 and 42:

Straight Blade Devices15 and 20 Amp

-

Page 43 and 44:

Straight Blade Devices20 Ampere, 12

-

Page 45 and 46:

Straight Blade Devices15 and 20 Amp

-

Page 47 and 48:

Straight Blade Devices30 Ampere, 12

-

Page 49 and 50:

Straight Blade Devices50 Ampere, 12

-

Page 51 and 52:

Straight Blade Devices60 Ampere, 12

-

Page 53 and 54:

Straight Blade DevicesMiscellaneous

-

Page 55 and 56:

Straight Blade DevicesAccessoriesFo

-

Page 57 and 58:

Straight Blade DevicesAccessoriesFo

-

Page 59 and 60:

Straight Blade DevicesTechnical Inf

-

Page 61 and 62:

Straight Blade DevicesTechnical Inf

-

Page 63 and 64:

Straight Blade DevicesTechnical Inf

-

Page 65 and 66:

Straight Blade DevicesTechnical Inf

-

Page 67 and 68:

Straight Blade DevicesTechnical Inf

-

Page 69 and 70:

Straight Blade DevicesTechnical Inf

-

Page 71 and 72:

Section BTwist-Lock ® and Hubbello

-

Page 73 and 74:

Twist-Lock ® DevicesMidget Twist-L

-

Page 75 and 76:

Twist-Lock ® Devices15 Ampere, 125

-

Page 77 and 78:

Twist-Lock ® DevicesInsulgrip ® 1

-

Page 79 and 80:

Twist-Lock ® Devices15 Ampere, 125

-

Page 81 and 82:

Twist-Lock ® Devices15 Ampere, 125

-

Page 83 and 84:

Twist-Lock ® DevicesThe Standard f

-

Page 85 and 86:

Twist-Lock ® DevicesSafety-Shroud

-

Page 87 and 88:

Twist-Lock ® Devices20 Ampere, 250

-

Page 89 and 90:

Twist-Lock ® Devices20 Ampere, 125

-

Page 91 and 92:

Twist-Lock ® Devices20 Ampere, 125

-

Page 93 and 94:

Twist-Lock ® Devices20 Ampere, 3Ø

-

Page 95 and 96:

Twist-Lock ® Devices20 Ampere, 3Ø

-

Page 97 and 98:

Twist-Lock ® Devices30 Ampere, 125

-

Page 99 and 100:

Twist-Lock ® Devices30 Ampere, 125

-

Page 101 and 102:

Twist-Lock ® Devices30 Ampere, 3Ø

-

Page 103 and 104:

Twist-Lock ® Devices30 Ampere, 3Ø

-

Page 105 and 106:

Twist-Lock ® Devices30 Ampere, 480

-

Page 107 and 108:

Twist-Lock ® DevicesSwitched Safet

-

Page 109 and 110:

Twist-Lock ® DevicesMechanical Int

-

Page 111 and 112:

Non-NEMA Twist-Lock ® Devices10 Am

-

Page 113 and 114:

Non-NEMA Twist-Lock ® Devices20 Am

-

Page 115 and 116:

Non-NEMA Twist-Lock ® Devices30 Am

-

Page 117 and 118:

Non-NEMA Twist-Lock ® Devices30 Am

-

Page 119 and 120:

Twist-Lock ® DevicesAccessoriesfor

-

Page 121 and 122:

Twist-Lock ® DevicesAccessoriesfor

-

Page 123 and 124:

Twist-Lock ® DevicesAccessoriesfor

-

Page 125 and 126:

Twist-Lock ® Devices50 Ampere Plug

-

Page 127 and 128:

Twist-Lock ® Devices50 Ampere, 125

-

Page 129 and 130:

Twist-Lock ® Devices50 Ampere, 250

-

Page 131 and 132:

Hubbellock ® DevicesPlugs and Conn

-

Page 133 and 134:

Hubbellock ® Devices20 Ampere, 125

-

Page 135 and 136:

Hubbellock ® Devices30 Ampere, 600

-

Page 137 and 138:

Hubbellock ® Devices60 Ampere, 600

-

Page 139 and 140:

Twist-Lock ® and Safety Shroud Dev

-

Page 141 and 142:

Twist-Lock ® DevicesTechnical Info

-

Page 143 and 144:

Switched Safety EnclosuresTechnical

-

Page 145 and 146:

Section CSwitchesSwitched Enclosure

-

Page 147 and 148:

SwitchesHBL ® Extra Heavy Duty Ind

-

Page 149 and 150:

Switches15, 20 and 30 Ampere, 120-2

-

Page 151 and 152:

Switches15 and 20 Ampere, 120-277 V

-

Page 153 and 154:

Switches15, 20 and 30 Ampere, 120-2

-

Page 155 and 156:

Switches600 to 1000 Watts, 120 Volt

-

Page 157 and 158:

SwitchesHeavy Duty Panel MountBat H

-

Page 159 and 160:

SwitchesPendant Pushbutton Station

-

Page 161 and 162:

AC SwitchesAccessoriesRed Neon Pilo

-

Page 163 and 164:

AC SwitchesAccessoriesNylon and Met

-

Page 165 and 166:

AC Switches40, 50, 60 and 85 Ampere

-

Page 167 and 168:

Disconnect SwitchesThermoplastic Co

-

Page 169 and 170:

AC SwitchesTechnical InformationHBL

-

Page 171 and 172:

AC SwitchesCertification ChartUL, C

-

Page 173 and 174:

AC SwitchesToggle Switch Wiring Dia

-

Page 175 and 176:

Switched EnclosuresCircuit-Lock ®

-

Page 177 and 178:

Switched EnclosuresCircuit-Lock ®

-

Page 179 and 180:

Switched EnclosuresCircuit-Lock ®

-

Page 181 and 182:

Section DH-MOSS ® Occupancy Sensor

-

Page 183 and 184:

H-MOSS ® Occupancy SensorsEnergy S

-

Page 185 and 186:

H-MOSS ® Occupancy SensorsEnergy S

-

Page 187 and 188:

H-MOSS ® Occupancy SensorsWall Swi

-

Page 189 and 190:

H-MOSS ® Occupancy SensorsWall Swi

-

Page 191 and 192:

H-MOSS ® Occupancy SensorsAdaptive

-

Page 193 and 194:

H-MOSS ® Occupancy SensorsCeiling

-

Page 195 and 196:

H-MOSS ® Occupancy SensorsSpecific

-

Page 197 and 198:

H-MOSS ® Occupancy SensorsSpecific

-

Page 199 and 200:

H-MOSS ® Occupancy SensorsWiring S

-

Page 201 and 202:

Section EPin and Sleeve DevicesMech

-

Page 203 and 204:

IEC Pin and SleeveWatertight Device

-

Page 205 and 206:

IEC Pin and SleeveWatertight Device

-

Page 207 and 208:

IEC Pin and SleeveWatertight Device

-

Page 209 and 210:

IEC Pin and SleeveWatertight Device

-

Page 211 and 212:

IEC Pin and SleeveWatertight Specif

-

Page 213 and 214:

IEC Pin and Sleeve20 and 30A Low Pr

-

Page 215 and 216:

IEC Pin and SleeveLow Profile Dimen

-

Page 217 and 218:

IEC Pin and SleeveUnfused Circuit-L

-

Page 219 and 220:

IEC Pin and SleeveUnfused Circuit-L

-

Page 221 and 222:

IEC Pin and Sleeve“Reverse Servic

-

Page 223 and 224:

IEC Pin and SleeveFused Circuit-Loc

-

Page 225 and 226:

IEC Pin and SleeveFused Circuit-Loc

-

Page 227 and 228:

UL 1686 C1 Pin and SleeveInsulgrip

-

Page 229 and 230:

UL 1686 C1 Pin and SleeveInsulgrip

-

Page 231 and 232:

UL 1686 C1 Pin and SleeveInsulgrip

-

Page 233 and 234:

UL 1686 C1 Pin and SleeveInsulgrip

-

Page 235 and 236:

Pin and SleeveInsulgrip ® Mechanic

-

Page 237 and 238:

Pin and SleeveTechnical Information

-

Page 239 and 240:

Section FSingle Pole DevicesIndexPr

-

Page 241 and 242:

Single Pole Devices300 and 400 Ampe

-

Page 243 and 244:

Single Pole Devices300 and 400 Ampe

-

Page 245 and 246:

Section GIndustrial Connectivity an

-

Page 247 and 248:

Control Integration Components 3A U

-

Page 249 and 250:

Power System Distribution Assemblie

-

Page 251 and 252:

Power System Supply AssembliesFeatu

-

Page 253 and 254:

Mini-Quick ® Control Connectors2 -

-

Page 255 and 256:

Mini-Quick ® Control Connectors2 -

-

Page 257 and 258:

Mini-Quick ® Control Connectors7 -

-

Page 259 and 260:

Mini-Quick ® Control Connectors7 -

-

Page 261 and 262:

Mini-Quick ® Control ConnectorsCoi

-

Page 263 and 264:

Mini-Quick ® Control ConnectorsFie

-

Page 265 and 266:

Micro-Quick ® Control ConnectorsSi

-

Page 267 and 268:

Micro-Quick ® Control ConnectorsSi

-

Page 269 and 270:

Micro-Quick ® Control ConnectorsDu

-

Page 271 and 272:

Micro-Quick ® Control ConnectorsDu

-

Page 273 and 274:

Micro-Quick ® Control ConnectorsCo

-

Page 275 and 276:

Micro-Quick ® Control ConnectorsFi

-

Page 277 and 278:

Micro-Quick ®Splitter Connectors a

-

Page 279 and 280:

Nano-Quick ® Control Connectors3 -

-

Page 281 and 282:

Nano-Quick ® Control ConnectorsFie

-

Page 283 and 284:

SignalPlex Micro Ports4 Port Enclos

-

Page 285 and 286:

SignalPlex Micro Ports6 Port Enclos

-

Page 287 and 288:

SignalPlex Micro Ports8 Port Enclos

-

Page 289 and 290:

SignalPlex Micro PortsAccessoriesSi

-

Page 291 and 292:

SignalPlex Mini PortsFeatures and B

-

Page 293 and 294:

SignalPlex Mini Ports4, 6, and 8 Po

-

Page 295 and 296:

Signal-Quick Sensor Mounting Access

-

Page 297 and 298:

Signal-Quick Sensor Mounting Access

-

Page 299 and 300:

Signal-Quick Sensor Mounting Access

-

Page 301 and 302:

Signal-Quick Sensor Mounting Access

-

Page 303 and 304:

Signal-Quick Sensor Mounting Access

-

Page 305 and 306:

Signal-Quick Sensor Mounting Access

-

Page 307 and 308:

Signal-Quick Sensor Mounting Access

-

Page 309 and 310:

CableTrak ® Hose and Cable Carrier

-

Page 311 and 312:

CableTrak ® Hose and Cable Carrier

-

Page 313 and 314:

DIN Rail Utility BoxPower and DataC

-

Page 315 and 316:

PANEL-SAFEPower and Data Access Por

-

Page 317 and 318:

HI-IMPACTIndustrial Ethernet Patch

-

Page 319 and 320:

Section HGround Fault ProductsIndex

-

Page 321 and 322:

Ground Fault ProductsHeavy Duty Com

-

Page 323 and 324:

Ground Fault ProductsHeavy Duty Com

-

Page 325 and 326:

Ground Fault ProductsHeavy Duty Com

-

Page 327 and 328:

Ground Fault ProductsHeavy Duty Com

-

Page 329 and 330:

Ground Fault ProductsStraight Blade

-

Page 331 and 332:

Ground Fault ProductsStraight Blade

-

Page 333 and 334:

Ground Fault ProductsPortable GFCI

-

Page 335 and 336:

Ground Fault ProductsHard Wired 30

-

Page 337 and 338:

Section IHospital ProductsIndexProd

-

Page 339 and 340:

Hospital ProductsHBL ® Extra Heavy

-

Page 341 and 342:

Hospital Products15 and 20 Ampere,

-

Page 343 and 344:

Hospital Products15 and 20 Ampere,

-

Page 345 and 346:

Ground Fault ProductsHeavy Duty Tam

-

Page 347 and 348:

Hospital ProductsSurge Protection D

-

Page 349 and 350:

Hospital ProductsHubbellock ® Expl

-

Page 351 and 352:

Hospital ProductsTechnical Informat

-

Page 353 and 354:

Hospital ProductsTechnical Informat

-

Page 355 and 356:

Section JSpikeShield ® Power Quali

-

Page 357 and 358:

SpikeShield ® Power Quality Produc

-

Page 359 and 360:

SpikeShield ® Power Quality Produc

-

Page 361 and 362:

SpikeShield ® Power Quality Produc

-

Page 363 and 364:

SpikeShield ® Power Quality Produc

-

Page 365 and 366:

SpikeShield ® Power Quality Produc

-

Page 367 and 368:

SpikeShield ® Power Quality Produc

-

Page 369 and 370:

SpikeShield ® Power Quality Produc

-

Page 371 and 372:

SpikeShield ® Power Quality Produc

-

Page 373 and 374:

SpikeShield ® Power Quality Produc

-

Page 375 and 376:

SpikeShield ® Power Quality Produc

-

Page 377 and 378:

SpikeShield ® Power Quality Produc

-

Page 379 and 380:

Section KWallplatesIndexProductPage

-

Page 381 and 382:

WallplatesFeatures and BenefitsNylo

-

Page 383 and 384:

WallplatesDuplex and Single Recepta

-

Page 385 and 386:

WallplatesBlank WallplatesBlank Wal

-

Page 387 and 388:

WallplatesDecorator WallplatesGFCI,

-

Page 389 and 390:

WallplatesCombination Wallplates, 2

-

Page 391 and 392:

WallplatesCombination Wallplates, 4

-

Page 393 and 394:

WallplatesDecorator Snap-On Wallpla

-

Page 395 and 396:

WallplatesCoaxial and Twinaxial “

-

Page 397 and 398:

WallplatesJumbo, Metal WallplatesJu

-

Page 399 and 400:

WallplatesPre-Marked “ISOLATED GR

-

Page 401 and 402:

WallplatesAccessories and Selection

-

Page 403 and 404:

WallplatesWeatherproof Covers for R

-

Page 405 and 406:

WallplatesWeatherproof Switch Plate

-

Page 407 and 408:

WallplatesWeatherproof Covers for D

-

Page 409 and 410:

WallplatesWhile-In-Use Weatherproof

-

Page 411 and 412:

WallplatesTechnical InformationSpec

-

Page 413 and 414:

WallplatesCustom Metal WallplatesHo

-

Page 415 and 416:

WallplatesCustom Metal WallplatesCo

-

Page 417 and 418:

WallplatesCustom Metal WallplatesCo

-

Page 419 and 420:

Section LFloor BoxesIndexProductPag

-

Page 421 and 422:

Complies with UL514ATraditional Flo

-

Page 423 and 424:

Floor BoxesHubbell SystemOne Metal

-

Page 425 and 426:

Floor BoxesHubbell SystemOne Featur

-

Page 427 and 428:

Floor BoxesFlush Round Single Servi

-

Page 429 and 430:

Floor BoxesFlush Rectangular Non-Me

-

Page 431 and 432:

Floor BoxesFlush Rectangular Stampe

-

Page 433 and 434:

Floor BoxesRecessed 6-Gang Concrete

-

Page 435 and 436:

Floor BoxesFlush Floor Boxes for Wo

-

Page 437 and 438:

Floor BoxesAbove-Floor Service Fitt

-

Page 439 and 440:

Floor BoxesAccessoriesProblem Solve

-

Page 441 and 442:

Floor BoxesHubbell SystemOne Config

-

Page 443 and 444:

Floor BoxesConvention Center Utilit

-

Page 445 and 446:

Floor BoxesConvention Center Utilit

-

Page 447 and 448:

Complies with UL514AFurniture FeedF

-

Page 449 and 450:

Floor BoxesCONNEXION - Wiring Schem

-

Page 451 and 452:

Floor BoxesUnloaded Raised Access F

-

Page 453 and 454:

Floor BoxesFurniture Connectivity B

-

Page 455 and 456:

Recessed Wall BoxesMulti-Connect -

-

Page 457 and 458:

Section MFire-Rated Poke-ThroughsIn

-

Page 459 and 460:

Traditional FRPTs for 3" and 2" cor

-

Page 461 and 462:

Fire-Rated Poke-ThroughsHubbell Sys

-

Page 463 and 464:

Fire-Rated Poke-ThroughsHubbell Sys

-

Page 465 and 466:

Fire-Rated Poke-Throughs2X2 Flush F

-

Page 467 and 468:

Fire-Rated Poke-ThroughsFlush Furni

-

Page 469 and 470:

Fire-Rated Poke-ThroughsBrushed Alu

-

Page 471 and 472:

Technical InformationHubbell System

-

Page 473 and 474:

Technical InformationHubbell System

-

Page 475 and 476:

Technical InformationHubbell System

-

Page 477 and 478:

Technical InformationHubbell Flush

-

Page 479 and 480:

Technical InformationHubbell Flush

-

Page 481 and 482:

Technical InformationPedestal FRPTP

-

Page 483 and 484:

photocourtesy ofconstruction ionpho

-

Page 485 and 486:

Aluminum Service PolesCustom Pole C

-

Page 487 and 488:

Section OMetal and Non-Metallic Rac

-

Page 489 and 490:

Metal RacewayHBL2000, HBL2000A, HBL

-

Page 491 and 492:

Metal RacewayHBL500 and HBL750 Seri

-

Page 493 and 494:

Metal RacewayHBL500 and HBL750 Seri

-

Page 495 and 496:

Metal RacewayHBL500 and HBL750 Seri

-

Page 497 and 498:

Metal RacewayHBL500 and HBL750 Seri

-

Page 499 and 500:

Metal RacewayHBL500 and HBL750 Seri

-

Page 501 and 502:

Metal RacewayHBL2000, HBL2000A, HBL

-

Page 503 and 504:

Metal RacewayHBL2000 and HBL2000A S

-

Page 505 and 506:

Metal RacewayMetal PlugTrak ®Metal

-

Page 507 and 508:

Metal RacewayHBL2400 and HBL2400D S

-

Page 509 and 510:

Metal RacewayHBL2400 and HBL2400D S

-

Page 511 and 512:

301413121129101516 17 1819202123222

-

Page 513 and 514:

Metal RacewayHBL3000 SeriesFeatures

-

Page 515 and 516:

Metal RacewayHBL3000 SeriesFittings

-

Page 517 and 518:

Metal RacewayHBL3000 SeriesDevice B

-

Page 519 and 520:

Metal RacewayHBL4750 SeriesFeatures

-

Page 521 and 522:

Metal RacewayHBL4750 SeriesFittings

-

Page 523 and 524:

Metal RacewayHBL4750 SeriesFittings

-

Page 525 and 526:

Metal RacewayHBL4750 SeriesOverlapp

-

Page 527 and 528:

Metal RacewayHBL6750 SeriesFeatures

-

Page 529 and 530:

Metal RacewayHBL6750 SeriesFittings

-

Page 531 and 532:

Metal RacewayHBL6750 SeriesFittings

-

Page 533 and 534:

Metal RacewayHBL6750 SeriesOverlapp

-

Page 535 and 536:

Aluminum RacewayHBLALU5000 and HBLA

-

Page 537 and 538:

Aluminum RacewayHBLALU2000 and Alum

-

Page 539 and 540:

Aluminum RacewayHBLALU2000 SeriesBo

-

Page 541 and 542:

Aluminum RacewayAluminum PlugTrak

-

Page 543 and 544:

Aluminum RacewayHBLALU3800 and HBLA

-

Page 545 and 546:

Aluminum RacewayHBLALU4800 SeriesRa

-

Page 547 and 548:

Aluminum RacewayHBLALU3800 and HBLA

-

Page 549 and 550:

Aluminum RacewayHBLALU5000 and HBLA

-

Page 551 and 552:

Aluminum RacewayHBLALU7620 SeriesRa

-

Page 553 and 554:

Metal and Aluminum RacewayTechnical

-

Page 555 and 556:

Metal RacewayPlates and OutletsiSTA

-

Page 557 and 558:

Metal Raceway - Cross ReferenceHBL2

-

Page 559 and 560:

Metal Raceway - Cross ReferenceHBL6

-

Page 561 and 562:

Hubbell RacewayRaceway Profiles - Q

-

Page 563 and 564:

17151614281813262729302519242322202

-

Page 565 and 566:

Non-Metallic RacewayComplete Line o

-

Page 567 and 568:

Non-Metallic RacewayPT1 PremiseTrak

-

Page 569 and 570:

Non-Metallic RacewayPP1 PremiseTrak

-

Page 571 and 572:

Non-Metallic RacewayPL1 LANTrak ®

-

Page 573 and 574:

Non-Metallic RacewayPW1 WallTrak ®

-

Page 575 and 576:

Non-Metallic RacewayPW2 WallTrak ®

-

Page 577 and 578:

Non-Metallic RacewayPB2 BaseTrak ®

-

Page 579 and 580:

Non-Metallic RacewayPB3 BaseTrak ®

-

Page 581 and 582:

Non-Metallic RacewayPS3 Super BaseT

-

Page 583 and 584:

Non-Metallic RacewayOffice White Pl

-

Page 585 and 586:

IntroductionPre-Wired RacewayHubbel

-

Page 587 and 588:

Pre-Wired RacewayAluminum, Steel an

-

Page 589 and 590:

Section PNetwork WiringEnterprise G

-

Page 591 and 592:

Network WiringAudio/Video Keystone

-

Page 593 and 594:

Network WiringiSTATION Face PlatesE

-

Page 595 and 596:

Network WiringiSTATION Audio Visual

-

Page 597 and 598:

Network WiringiSTATION Surface Moun

-

Page 599 and 600:

Network WiringiSTATION Audio/Video

-

Page 601 and 602:

Network WiringFiber AdaptersEnterpr

-

Page 603 and 604:

Network WiringPatch Cords and Modul

-

Page 605 and 606:

Network WiringFiber Enclosures and

-

Page 607 and 608:

Network WiringWall Mounted Enclosur

-

Page 609 and 610:

Network WiringCable Management Rack

-

Page 611 and 612:

Network WiringLadder RacksEnterpris

-

Page 613 and 614:

Network WiringTools and Accessories

-

Page 615 and 616:

Network WiringHubbell Labeling Solu

-

Page 617 and 618:

Section QHose and Cable Protection

-

Page 619 and 620:

Hose and Cable Protection SystemsAc

-

Page 621 and 622:

Hose and Cable Protection SystemsTr

-

Page 623 and 624:

Section RCable, Cord and Hose Reels

-

Page 625 and 626:

Cable, Cord and Hose ReelsWeatherpr

-

Page 627 and 628:

Wiring Device-KellemsCable, Cord an

-

Page 629 and 630:

Section STemporary Power and Lighti

-

Page 631 and 632:

Temporary Power Distribution System

-

Page 633 and 634:

Temporary Power Distribution System

-

Page 635 and 636:

Temporary Power Distribution System

-

Page 637 and 638:

Section TKellems ® Wire Management

-

Page 639 and 640:

Kellems ® Wire Management Products

-

Page 641 and 642:

Kellems ® Wire Management Products

-

Page 643 and 644:

Kellems ® Wire Management Products

-

Page 645 and 646:

Kellems ® Wire Management Products

-

Page 647 and 648:

Kellems ® Wire Management Products

-

Page 649 and 650:

Kellems ® Wire Management Products

-

Page 651:

Kellems ® Wire Management Products

-

Page 655 and 656:

Kellems ® Wire Management Products

-

Page 657 and 658:

Kellems ® Wire Management Products

-

Page 659 and 660:

Kellems ® Wire Management Products

-

Page 661 and 662:

Kellems ® Wire Management Products

-

Page 663 and 664:

Kellems ® Wire Management Products

-

Page 665 and 666:

Kellems ® Wire Management Products

-

Page 667 and 668:

Kellems ® Wire Management Products

-

Page 669 and 670:

Kellems ® Wire Management Products

-

Page 671 and 672:

Kellems ® Wire Management Products

-

Page 673 and 674:

Kellems ® Wire Management Products

-

Page 675 and 676:

Wire Management ProductsConduit Ris

-

Page 677 and 678:

Kellems ® Wire Management Products

-

Page 679 and 680:

Kellems ® Wire Management Products

-

Page 681 and 682:

Kellems ® Wire Management Products

-

Page 683 and 684:

Kellems ® Wire Management Products

-

Page 685 and 686:

Kellems ® Wire Management Products

-

Page 687 and 688:

Kellems ® Wire Management Products

-

Page 689 and 690:

Kellems ® Wire Management Products

-

Page 691 and 692:

Kellems ® Wire Management Products

-

Page 693 and 694:

Kellems ® Wire Management Products

-

Page 695 and 696:

Kellems ® Wire Management Products

-

Page 697 and 698:

Kellems ® Wire Management Products

-

Page 699 and 700:

Kellems ® Wire Management Products

-

Page 701 and 702:

Kellems ® Wire Management Products

-

Page 703 and 704:

Kellems ® Wire Management Products

-

Page 705 and 706:

Kellems ® Wire Management Products

-

Page 707 and 708:

Kellems ® Wire Management Products

-

Page 709 and 710:

Kellems ® Wire Management Products

-

Page 711 and 712:

Kellems ® Wire Management Products

-

Page 713 and 714:

Kellems ® Wire Management Products

-

Page 715 and 716:

Kellems ® Wire Management Products

-

Page 717 and 718:

Kellems ® Wire Management Products

-

Page 719 and 720:

Kellems ® Wire Management Products

-

Page 721 and 722:

Kellems ® Wire Management Products

-

Page 723 and 724:

Kellems ® Wire Management Products

-

Page 725 and 726:

Kellems ® Wire Management Products

-

Page 727 and 728:

Kellems ® Wire Management Products

-

Page 729 and 730:

Kellems ® Wire Management Products

-

Page 731 and 732:

Kellems ® Wire Management Products

-

Page 733 and 734:

Kellems ® Wire Management Products

-

Page 735 and 736:

Kellems ® Wire Management Products

-

Page 737 and 738:

Kellems ® Wire Management Products

-

Page 739 and 740:

Kellems ® Wire Management Products

-

Page 741 and 742:

NOTES:Kellems ® Wire Management Pr

-

Page 743 and 744:

Kellems ® Wire Management Products

-

Page 745 and 746:

Kellems ® Wire Management Products

-

Page 747 and 748:

Kellems ® Wire Management Products

-

Page 749 and 750:

Kellems ® Wire Management Products

-

Page 751 and 752:

Kellems ® Wire Management Products

-

Page 753 and 754:

Section UOther Wiring ProductsIndex

-

Page 755 and 756:

Other Wiring ProductsLockout Device

-

Page 757 and 758:

Other Wiring ProductsReceptacle Cir

-

Page 759 and 760:

Section VhomeSELECT - Residential D

-

Page 761 and 762:

homeSELECT Single-Pole and Three-Wa

-

Page 763 and 764:

homeSELECT Wiring Termination and S

-

Page 765 and 766:

homeSELECT Combination Quiet Rocker

-

Page 767 and 768:

homeSELECT Tamper-Resistant and Sta

-

Page 769 and 770:

homeSELECT Snap-On WallplatesDecora

-

Page 771 and 772:

homeSELECT Combination WallplatesDe

-

Page 773 and 774:

homeSELECT Decorator FramesDecorato

-

Page 775 and 776:

homeSELECT Molded-In Voice/Data/Vid

-

Page 777 and 778:

homeSELECT Three- and Four-Way Togg

-

Page 779 and 780:

homeSELECT Combination Switches/Dev

-

Page 781 and 782:

homeSELECT Duplex and Single Recept

-

Page 783 and 784:

homeSELECT Self Test GFCI Receptacl

-

Page 785 and 786:

homeSELECT Range and Dryer Power Re

-

Page 787 and 788:

homeSELECT Special Use ProductsSwit

-

Page 789 and 790:

homeSELECT Slide Dimmers and Fan Sp

-

Page 791 and 792:

homeSELECT Rotary Dimmers and Fan S

-

Page 793 and 794:

homeSELECT Vacancy SensorsLighting

-

Page 795 and 796:

homeSELECT Floor Boxes For Wood Flo

-

Page 797 and 798:

homeSELECT Floor Boxes For Concrete

-

Page 799 and 800:

homeSELECT Under Cabinet/Counter Po

-

Page 801 and 802:

homeSELECT Incandescent Lampholders

-

Page 803 and 804:

homeSELECT Lampholders AccessoriesL

-

Page 805 and 806:

homeSELECT Plugs, Taps and Adapters

-

Page 807 and 808:

Section VnetSELECT - Structured Wir

-

Page 809 and 810:

netSELECTVoice/Data JacksData Commu

-

Page 811 and 812:

netSELECTMultimedia Face PlatesData

-

Page 813 and 814:

netSELECTHDMI ProductsData Communic

-

Page 815 and 816:

netSELECT Molded-In Voice/Data/Vide

-

Page 817 and 818:

netSELECT Molded-In PlatesData Comm

-

Page 819 and 820:

netSELECT Telephone Wall JacksData

-

Page 821 and 822:

netSELECT Advantages and Wiring Lay

-

Page 823 and 824:

netSELECT Network ModulesStructured

-

Page 825 and 826:

netSELECT AccessoriesStructured Wir

-

Page 827 and 828:

Section WMarine ProductsIndexProduc

-

Page 829 and 830:

Marine ProductsShip-to-Shore Select

-

Page 831 and 832:

Marine Products30 Ampere, 125 Volt

-

Page 833 and 834:

Marine Products30 Ampere, Cable Set

-

Page 835 and 836:

Marine Products30 Ampere, 125 Volt

-

Page 837 and 838:

Marine Products50 Ampere, 125 Volt

-

Page 839 and 840:

Marine Products50 Ampere, 125/250 V

-

Page 841 and 842:

Marine Products100 Ampere, 125/250

-

Page 843 and 844:

Marine Products100 Ampere, 125/250

-

Page 845 and 846:

Marine Products100 Ampere, 3ØY 120

-

Page 847 and 848:

Marine Products200 Ampere, 600V AC/

-

Page 849 and 850:

Marine ProductsInternationally Rate

-

Page 851 and 852:

Marine ProductsAdapter Selection Gu

-

Page 853 and 854:

Marine ProductsMolded Y AdaptersMol

-

Page 855 and 856:

Marine ProductsTelephone and Cable

-

Page 857 and 858:

Marine Products12 Volt DC Rated Swi

-

Page 859 and 860:

Marine Products15 Ampere, 125 Volt

-

Page 861 and 862:

Marine Products20 Ampere, 125 Volt

-

Page 863 and 864:

Marine ProductsGFCI and Surge Prote

-

Page 865 and 866:

Marine ProductsSwitches and Weather

-

Page 867 and 868:

Marine ProductsCommunication Frames

-

Page 869 and 870:

Marine ProductsBoatyard Accessory I

-

Page 871 and 872:

Marine ProductsBoatyard Accessory I

-

Page 873 and 874:

Section XGeneral Technical DataInde

-

Page 875 and 876:

Technical DataIndustry Standards -

-

Page 877 and 878:

Technical DataIndustry Associations

-

Page 879 and 880:

Technical DataAC Switch Data and Ho

-

Page 881 and 882:

Technical DataNEMA and IEC Classifi

-

Page 883 and 884:

Technical DataEnclosure Types for N

-

Page 885 and 886:

Technical DataCircuit Wiring Diagra

-

Page 887 and 888:

Technical DataCircuit Wiring Diagra

-

Page 889 and 890:

Technical DataElectrical Symbols an

-

Page 891 and 892:

Technical DataHorsepower RatingsFor

-

Page 893 and 894:

IndexHubbell Configuration ChartsIn

-

Page 895 and 896:

STRAIGHT BLADE DEVICESReceptacleStr

-

Page 897 and 898:

SAFETY-SHROUDTWIST-LOCK ® DEVICESW

-

Page 899 and 900:

IEC WATERTIGHT PIN AND SLEEVE DEVIC

-

Page 901 and 902:

50 AMP TWIST-LOCK ® DEVICESHUBBELL

-

Page 903 and 904:

Wiring Device - KellemsCatalog Numb

-

Page 905 and 906:

Wiring Device - KellemsCatalog Numb

-

Page 907 and 908:

Wiring Device - KellemsCatalog Numb

-

Page 909 and 910:

Wiring Device - KellemsCatalog Numb

-

Page 911 and 912:

Wiring Device - KellemsCatalog Numb

-

Page 913 and 914:

Wiring Device - KellemsCatalog Numb

-

Page 915 and 916:

Wiring Device - KellemsCatalog Numb

-

Page 917 and 918:

Wiring Device - KellemsCatalog Numb

-

Page 919 and 920:

Wiring Device - KellemsCatalog Numb

-

Page 921 and 922:

Wiring Device - KellemsCatalog Numb

-

Page 923 and 924:

Wiring Device - KellemsCatalog Numb

-

Page 925 and 926:

Wiring Device - KellemsCatalog Numb

-

Page 927 and 928:

Wiring Device - KellemsCatalog Numb

-

Page 929 and 930:

Wiring Device - KellemsCatalog Numb

-

Page 931 and 932:

Wiring Device - KellemsCatalog Numb

-

Page 933 and 934:

Wiring Device - KellemsCatalog Numb

-

Page 935 and 936:

Wiring Device - KellemsRoHS Product

-

Page 937 and 938:

Wiring Device - KellemsRoHS Product

-

Page 939 and 940:

Wiring Device - KellemsRoHS Product

-

Page 941 and 942:

Wiring Device - KellemsRoHS Product

-

Page 943 and 944:

Wiring Device - KellemsRoHS Product

-

Page 945 and 946:

Wiring Device - KellemsRoHS Product

-

Page 947 and 948:

Hubbell Configuration ChartFor sele

-

Page 949 and 950:

Hubbell’s New and Improved Websit