In Mold Decorating of Injection Molded Parts - Esterline

In Mold Decorating of Injection Molded Parts - Esterline

In Mold Decorating of Injection Molded Parts - Esterline

- No tags were found...

Create successful ePaper yourself

Turn your PDF publications into a flip-book with our unique Google optimized e-Paper software.

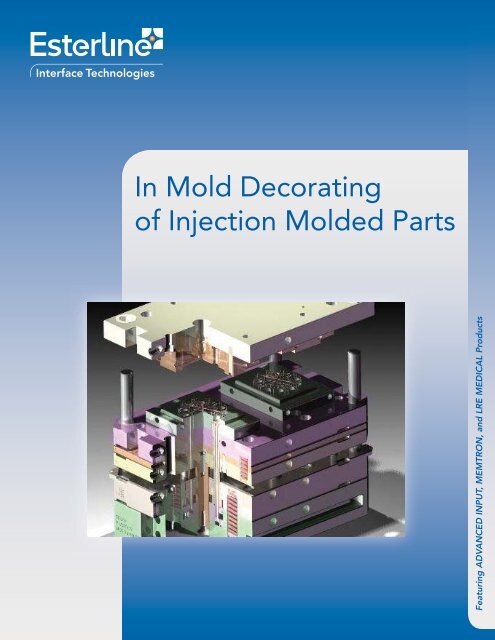

<strong>In</strong> <strong>Mold</strong> <strong>Decorating</strong> <strong>of</strong> <strong>In</strong>jection <strong>Mold</strong>ed <strong>Parts</strong>IMD <strong>of</strong>fers many design flexibilityand productivity advantages versusother decoration methods done aftermolding. These benefits includedesign flexibility, multiple colorsand effects, textures with a singleoperation, long lasting graphics,manufacturing productivity, andsystems cost reductions.Steps in the IMD Process<strong>In</strong>-mold Decoration (IMD), also known asFilm <strong>In</strong>sert <strong>Mold</strong>ing (FIM), is a versatile andcost effective method <strong>of</strong> decorating andmanufacturing durable plastic parts.The process <strong>of</strong> in-mold decorating a plasticcomponent consists essentially <strong>of</strong> 4 stages:Printing, Forming, Cutting and <strong>Mold</strong>ingPrinting:The printing operation is used to create thedecorative appearance <strong>of</strong> the product. While avariety <strong>of</strong> standard technologies can be used forthis stage, silk screen printing is most commonlyused.Forming:Film is screen printed(decorated) on firstand/or second surface.Film is then formed toshape and cut to finalsize.The forming process converts the flat 2D-printedimage into a 3D part which is sometimesreferred to as a formed appliqué. This process issometimes referred to as ‘thermo-forming’ whichis a catchall term to include vacuum forming,hydro forming and high pressure forming. <strong>In</strong> allthree <strong>of</strong> these techniques, the flat printed imageis shaped over or into a tool using negative orpositive pressure. The tool can be either male orfemale, and each type has its own advantagesand disadvantages.Cutting: Cutting <strong>of</strong> the 3D film may beperformed before or after the molding operationdepending on a number <strong>of</strong> factors and usuallyspecified by the IMD supplier.<strong>Mold</strong>ing:Film is inserted into special moldtool and part is injection molded,permanently bonding decorated film.The IMD foil(s) is then placed in the cavity <strong>of</strong>the mold tool and the required resin is injectedbehind it. The foil can be manually or roboticallyplaced into the tool depending on the volumerequired and the need for a fast cycle time. Themolding process itself will almost certainly haveto be optimized to suit the foil. Since all IMDtechniques are intended to create cosmeticallyattractive parts, it will be clear that care inhandling <strong>of</strong> the product is a key issue.

Advantages - Disadvantages - ApplicationsOne <strong>of</strong> the most efficient and cost-effective ways <strong>of</strong> decorating a part is todo it during the molding cycle. <strong>In</strong> <strong>Mold</strong> Decoration (IMD) can provide severalimportant advantages over other decoration methods.Advantages:• Design Flexibility allows customers to expresstheir personalities while the products areeasily manufactured.• Multiple colors, effects and textures with asingle operation that are complete when thepart comes out <strong>of</strong> the mold.• Legend/graphics wear is almostindestructible with second surface printing.• A cost effective solution over alternativedecorating techniques.• Changing legends / languages / graphics isvery easy by simply changing the printing.Disadvantages:• Time to market issues with necessarydevelopmental iterations.• Some graphics such as concentric circles,long lines and parallel lines should beavoided because <strong>of</strong> the unavoidabledistortion induced by the IMD process.• Some shape limitations.• Materials are limited to non V-0 rated Polycarbonateand ABS resins.Keytops, Buttons and Key Pads• For scratch/abrasion resistance legends andgraphics.• For multi-color legends and graphics.• For art graphics/decoration• Translucent legends for back lighting.Panels• For scratch/abrasion resistance legends andgraphics.• For art graphics/decoration.• For multi-color legends and graphics.• <strong>In</strong>tegrating components such as a lens /window & a panel.

Common TermsAbrasion Resistance - Ability <strong>of</strong> a printed imageto withstand wear and tear during handling andgeneral product usage.Artwork - Name given to the image to betransferred to the plastic component during thedecoration process.Carrier Film - Film material used to temporarilycarry a printed image. The carrier film doesnot become part <strong>of</strong> the finished product and isdiscarded during the cutting process.Cavity side - Term used to describe one half <strong>of</strong> aninjection mold tool. Generally this side will formthe external surface <strong>of</strong> the product and is most<strong>of</strong>ten the fixed half <strong>of</strong> the tool.Core side - Term used to describe one half <strong>of</strong> aninjection mold tool. Generally this side will formthe internal surface <strong>of</strong> the product and is most<strong>of</strong>ten the moving half <strong>of</strong> the tool.Draft Angle - Slight angle introduced onnominally vertical walls <strong>of</strong> a molded component toease the process <strong>of</strong> ejection from the mold tool.Draw Depth/Draw Height - Depth/Height towhich a decorated foil is formed (drawn) prior tocutting and molding.Dual Layer construction - See laminated filmconstruction.Ejection - The process <strong>of</strong> pushing a moldedcomponent <strong>of</strong>f <strong>of</strong> the core side <strong>of</strong> a mold tool.Female Tool - Negative impression forming toolinto which a decorated film is pushed to create anFIM foil.Film - Raw material onto which the decorativeimage is printed in the FIM process. Generally thiswill be a polycarbonate type material.FIM (Film <strong>In</strong>sert <strong>Mold</strong>ing) - IMD process in whicha pre-decorated, pre-formed foil is placed in thecavity <strong>of</strong> a molding tool prior to resin injection.During the molding cycle, the resin and the foilfuse together.First Surface Decoration - Components in whichthe decorative image is on the outer surface.Generally such components will be liable toabrasion and may have additional lacquersapplied to protect them from this.Flow Direction - The direction <strong>of</strong> travel <strong>of</strong>molding resin during the injection moldingprocess.Flow line - Visible defects on moldedcomponents caused by the flow pattern <strong>of</strong> theresin during the injection process. <strong>In</strong> many casesthis feature can be masked by the presence <strong>of</strong> anIMD foil.Foil - Name given to the printed film in the IMD(FIM) process once it has been decorated, formedand cut.Form Tool - Male or female tool used to shapethe flat, decorated film into a 3D foil.Forming - The process <strong>of</strong> shaping a flat decoratedfilm into a three-dimensional format. Often thisprocess is referred to as “thermo-forming” sinceheat is generally used.Gate/Gating - The location on a mold tool wherethe resin is injected into the cavity to create thecomponent.Hardcoat - Lacquer applied to a film or foil toincrease the abrasion resistance. This can beapplied either as a sprayed coating on a 3Dcomponent or as a pre-coating <strong>of</strong> the film used inthe decoration process. Generally, hard coatingwill be an essential requirement with first surfacedecorated parts.Height to Space Ratio - Ratio used to specify therequired distance between adjacent raised areason a formed foil. Particularly important in thedesign <strong>of</strong> IMD keypads where it governs the pitchbetween adjacent keys depending on the height<strong>of</strong> the key.

Common TermsHPF (High Pressure Forming) - Formingtechnology in which flat films are converted into3D foils using a combination <strong>of</strong> heat and highpressure air in a sealed chamber.Hydro forming - Forming technology in whichflat films are converted into 3D foils using a liquidin a sealed bladder.<strong>In</strong>jection <strong>Mold</strong>ing - The process <strong>of</strong> injectionmolten plastic resin into the cavity <strong>of</strong> a mold toolto create 3D plastic components.<strong>In</strong>sert <strong>Mold</strong>ing - The inclusion <strong>of</strong> additionalcomponents during the plastic injection moldingprocess. Typically used to produce moldings withmechanical components such as threaded metalbosses. Film <strong>In</strong>sert <strong>Mold</strong>ing is a variant <strong>of</strong> thisprocess.Image - Term used to describe the decoration,graphics or legend to be applied to a plasticcomponent. See also artwork.IMD (<strong>In</strong><strong>Mold</strong> Decoration) - Catchall term used todescribe any one <strong>of</strong> a number <strong>of</strong> processes usedto decorate plastic products during the injectionmolding cycle.IML (<strong>In</strong><strong>Mold</strong> Labeling) - IMD process in whicha flat (2D) decorated foil is placed in the cavity<strong>of</strong> a molding tool prior to resin injection.Generally this process is used where the finishedcomponent is flat or only slighted shaped. It canalso be used to decorate flat localized areas on aproduct.<strong>In</strong>k Blow/<strong>In</strong>k Wash - Defect in IMD componentsin which a portion <strong>of</strong> the image is distorted ordisplaced during the injection molding process.Male Tool - Positive impression forming tool overwhich a decorated film is shaped to create an FIMfoil.Parting Line - The point on a molding tool atwhich the core and cavity halves <strong>of</strong> the tool meet.Post-<strong>Mold</strong>ing - Operation carried out oncompleted moldings to complete the productionprocess. Can include, de-gating, de-flashing andseveral decoration techniques.Pr<strong>of</strong>ile Tool - 3D cutting tool used to stamp out3D formed films into foils suitable for insertioninto the injection mold tool.Registration - The process <strong>of</strong> controlling theposition <strong>of</strong> the printed image (decoration) on thecompleted plastic component.Second Surface Decoration - Componentsin which the decorative image is on the innersurface <strong>of</strong> a layer <strong>of</strong> plastic material. Suchcomponents are more difficult to manufacturethan first surface types but have far superiorabrasion resistance.Solvent based ink - Thermally curing (drying) inkused in the decoration process.Substrate - Term used by the printing industry todescribe the material onto which the images areprinted.Surface Finish - The level <strong>of</strong> texture, or polish, onthe surface <strong>of</strong> a plastic component. This can becontrolled by the texture on the mold tool, and/orthe texture on any foil used in the IMD process.Therm<strong>of</strong>orming - The process used to convertflat 2D decorated films, into 3D foils.UV Cured <strong>In</strong>k - <strong>In</strong>k used in the decorationprocess which is cured (dried) using UV light.Vacuum Forming - Well establishedtherm<strong>of</strong>orming technique in which a heated filmis drawn down onto a forming tool.Wall Thickness - The nominal wall thickness <strong>of</strong> amolded plastic component.Weld line - Cosmetic defect on a molded plasticcomponent caused by the coming together <strong>of</strong>different mold flow fronts.

Featuring ADVANCED INPUT, MEMTRON, and LRE MEDICAL ProductsAmericas Europe AsiaHeadquarters600 W. Wilbur AvenueCoeur d’Alene, ID 83815208-765-8000530 N. Franklin StreetFrankenmuth, MI 48734989-652-2656H<strong>of</strong>er Straße 5D-86720 Nördlingen, Germany+49 (0) 9081 800-1Caoheijing High Tech Park6th Floor, Block 87,No. 1199 Quin Zhou Bei RoadShanghai, Chinaeit.sales@esterline.comwww.esterline.com/interfacetechnologies