Kuriyama Couplings.pdf

Kuriyama Couplings.pdf

Kuriyama Couplings.pdf

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

New Products HighlightedEZ-Seal- Leak ResistantQuick-Acting <strong>Couplings</strong>EZ-Seal- Leak Resistant PinLug <strong>Couplings</strong>Kuri-Clamp CenterPunch ClampsThreaded SwivelFittingsBrass Pin Lug<strong>Couplings</strong>Kuri-KrimpCrimping SleevesNew & Improved“CAM-BARB” Design!IRRI-LOCGalvanized <strong>Couplings</strong>BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.4KCCA1110

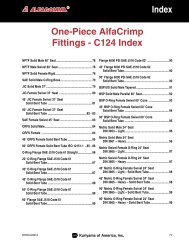

Aluminum Quick-Acting <strong>Couplings</strong>Agriculture • Chemicals/Petroleum • Construction • Material HandlingAluminum Part A Male Adapter x Female NPTPartNumberSizeWeightEach (lbs.)StandardCartonAL-A050 1/ 2" X 1 / 2" 0.10 100AL-A075 3/4" 0.13 50AL-A100 1" 0.12 70AL-A125 1 1/4" 0.20 40AL-A150 1 1/2" 0.28 30AL-A200 2" 0.38 40AL-A250 2 1/2" 0.58 50AL-A300 3" 0.70 35AL-A400 4" 1.58 20AL-A500 5" 1.74 4AL-A600 6" 2.95 15AL-A800 8" 7.58 2*AL-A1000 10" 9.88 2*HDAL-A801 8" 9.48 2Aluminum Part D Female Coupler x Female NPTPartWeight StandardSizeNumberEach (lbs.) CartonAL-D800●* † 8" 9.50 2AL-D050‡ 1/ 2" X 1 / 2" 0.18 100AL-D075● 3/4" 0.22 50AL-D100● 1" 0.42 30AL-D125● 1 1/4" 0.68 40AL-D150● 1 1/2" 0.80 30AL-D200● 2" 0.92 40AL-D250● 2 1/2" 1.18 35AL-D300● 3" 1.80 20AL-D400● 4" 2.16 10AL-D500● 5" 3.42 4AL-D600● 6" 4.24 10† AL-D1000● 10" 12.52 2Aluminum Part E Male Adapter x Hose ShankAluminum Part B Female Coupler x Male NPT* † AL-B050‡ 1/ 2" X 1 / 2" 0.18 100AL-B075● 3/4" 0.24 50AL-B100● 1" 0.36 30AL-B125● 1 1/4" 0.62 45AL-B150● 1 1/2" 0.70 30AL-B200● 2" 0.86 50AL-B250● 2 1/2" 1.02 40AL-B300● 3" 1.56 25AL-B400● 4" 2.42 25AL-B500● 5" 3.34 4AL-B600● 6" 4.98 10AL-B800●* † 8" 8.03 2† AL-B1000● 8" 12.13 2*Aluminum Part C Female Coupler x Hose ShankAluminum Part F Male Adapter x Male NPTAL-E050 1/ 2" X 1 / 2" 0.08 100AL-E075 3/4" 0.11 50AL-E100 1" 0.20 50AL-E125 1 1/4" 0.26 30AL-E150 1 1/2" 0.38 40AL-E200 2" 0.60 50AL-E250 2 1/2" 0.86 20AL-E300 3" 1.32 18AL-E400 4" 2.10 20AL-E500 5" 3.56 4AL-E600 6" 6.16 6AL-E800 8" 7.73 2AL-E1000 10" 12.90 1*HDAL-E801 8" 9.75 2AL-C050‡ 1/ 2" X 1 / 2" 0.20 100AL-C075● 3/4" 0.26 50AL-F050 1/ 2" X 1 / 2" 0.14 100AL-C100● 1" 0.42 60AL-F075 3/4" 0.16 50AL-C125● 1 1/4" 0.68 35AL-F100 1" 0.20 45AL-C150● 1 1/2" 0.74 30AL-F125 1 1/4" 0.34 30AL-C200● 2" 0.98 40AL-F150 1 1/2" 0.46 50AL-C250● 2 1/2" 1.28 30AL-F200 2" 0.68 60AL-C300● 3" 2.20 15AL-F250 2 1/2" 0.96 30AL-C400● 4" 3.16 15AL-F300 3" 1.30 20AL-C500● 5" 3.88 4AL-F400 4" 2.32 25AL-C600● 6" 7.70 6AL-F500 5" 2.94 4AL-C800●* †8" 10.63 1AL-F600 6" 3.92 10† AL-C1000● 10" 16.67 1*AL-F800 8" 7.94 2HDAL-C801● 8" 12.58 1AL-F1000 10" 10.58 2● These couplers are supplied with locking feature . . . safety clips may be inserted to lock handles, preventing disconnection during product transfer.‡ Size 1/2" x 1/2" supplied with one forged brass handle.† Supplied with 4 locking handles, safety clips, pull rings and chains.* See page 6 for interchange information.See Material Specifications & Operating Pressure Charts on Pages 47 & 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA11105

Aluminum Quick-Acting <strong>Couplings</strong>Agriculture • Chemicals/Petroleum • Construction • Material HandlingAluminum Part DC Dust CapPartWeight StandardSizeNumberEach (lbs.) CartonAL-DC800● 8" 9.04 4* † † AL-DC1000● 10" 12.54 3AL-DC050‡ 1/ 2" X 1 / 2" 0.18 100AL-DC075● 3/4" 0.22 50AL-DC100● 1" 0.34 40AL-DC125● 1 1/4" 0.58 25AL-DC150● 1 1/2" 0.64 40AL-DC200● 2" 0.80 60AL-DC250● 2 1/2" 0.94 50AL-DC300● 3" 1.44 30AL-DC400● 4" 2.34 15AL-DC500● 5" 3.06 4AL-DC600● 6" 4.66 6Aluminum Part DP Dust PlugPartNumberWeightEach (lbs.)AL-DP050 1/ 2" X 1 / 2" 0.07 100AL-DP075 3/4" 0.08 50AL-DP100 1" 0.10 80AL-DP125 1 1/4" 0.18 50AL-DP150 1 1/2" 0.25 50AL-DP200 2" 0.38 60AL-DP250 2 1/2" 0.54 40AL-DP300 3" 0.74 50AL-DP400 4" 1.22 25AL-DP500 5" 1.46 4AL-DP600 6" 2.53 20AL-DP800 8" 4.04 6AL-DP1000 10" 5.36 4Note: Dust Caps & Dust Plugs are NOT DESIGNED FOR PRESSURE APPLICATIONS.● These couplers are supplied with locking feature . . . safety clips may be inserted to lock handles, preventing disconnection during product transfer.‡ Size 1/2" x 1/2" supplied with one forged brass handle.† Supplied with 4 locking handles, safety clips, pull rings and chains.* See interchange information below. Heavy Duty 8˝ <strong>Couplings</strong>*SizeStandardCartonAluminum Part A Male Adapter x Female NPTPartNumberDescriptionSizeWeightEach (lbs.)StandardCartonHDAL-A801 Heavy Duty 8" 12.10 2Aluminum Part C Female Coupler x Hose ShankPartNumberDescriptionSizeWeightEach (lbs.)StandardCartonHDAL-C801 Heavy Duty 8" 18.25 1Aluminum Part E Male Adapter x Hose ShankPartNumberDescriptionSizeWeightEach (lbs.)StandardCartonHDAL-E801 Heavy Duty 8" 11.75 2Compare <strong>Kuriyama</strong>'s heavy duty version for interchangeability withcurrent Ever-Tide, Andrews, and NECO couplings.Compare <strong>Kuriyama</strong>'s standard version with current PT and Campbell couplings.See Material Specifications & Operating Pressure Charts on Pages 47 & 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.6KCCA1110

EZ-Seal Leak Resistant <strong>Couplings</strong>Ideally suited for Layflat hoses• Indoor Watering • Agriculture • Water ConservationPart C Coupler x Hose ShankPartNumberSize(In.)Appox.WeightEach (lbs.)StandardCartonAL-CLF150 1 1/2 0.77 30AL-CLF200 2 0.98 40AL-CLF300 3 1.98 15AL-CLF400 4 2.87 15Part E Male Adapter x Hose ShankPartNumberSize(In.)Appox.WeightEach (lbs.)StandardCartonAL-ELF150 1 1/2 0.44 40AL-ELF200 2 0.64 50AL-ELF300 3 1.38 18AL-ELF400 4 2.51 20Note: To insure proper sealing attach band clamps directly over rubber seals.EZ-Seal Replacement Shank BandsPartNumberSize(In.)Appox.WeightEach (lbs.)StandardCartonNBR-LF150 1 1/2" 0.004 10NBR-LF200 2" 0.009 10NBR-LF300 3" 0.029 10NBR-LF400 4" 0.040 10See Material Specifications & Operating Pressure Charts on Pages 47 & 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA11107

SS316 Stainless Steel Quick-Acting <strong>Couplings</strong>Agriculture • Chemicals/PetroleumStainless Steel Part A Male Adapter x Female NPTPartNumberSizeWeightEach (lbs.)StandardCartonSS-A050 1/ 2" X 1 / 2" 0.20 50SS-A075 3/4" 0.26 25SS-A100 1" 0.34 25SS-A125 1 1/4" 0.62 36SS-A150 1 1/2" 0.80 25SS-A200 2" 1.12 20SS-A250 2 1/2" 1.76 12SS-A300 3" 2.16 8SS-A400 4" 2.88 6SS-A500 5" 4.30 4SS-A600 6" 6.00 2Stainless Steel Part E Male Adapter x Hose ShankPartNumberSizeWeightEach (lbs.)StandardCartonSS-E050 1/ 2" X 1 / 2" 0.25 50SS-E075 3/4" 0.36 25SS-E100 1" 0.60 25SS-E125 1 1/4" 0.95 25SS-E150 1 1/2" 1.22 25SS-E200 2" 1.98 20SS-E250 2 1/2" 2.64 12SS-E300 3" 3.90 8SS-E400 4" 6.38 6SS-E500 5" 9.10 4SS-E600 6" 13.49 2Stainless Steel Part B Female Coupler x Male NPTSS-B050‡ 1/ 2" X 1 / 2" 0.30 50SS-B075● 3/4" 0.42 25SS-B100● 1" 0.64 25SS-B125● 1 1/4" 1.32 20SS-B150● 1 1/2" 1.50 20SS-B200● 2" 1.92 20SS-B250● 2 1/2" 2.68 12SS-B300● 3" 3.20 8SS-B400● 4" 6.58 6SS-B500● 5" 6.80 4SS-B600● 6" 10.98 2Stainless Steel Part C Female Coupler x Hose ShankSS-C050‡ 1/ 2" X 1 / 2" 0.30 50SS-C075● 3/4" 0.46 25SS-C100● 1" 0.74 25SS-C125● 1 1/4" 1.41 20SS-C150● 1 1/2" 1.68 20SS-C200● 2" 2.30 20SS-C250● 2 1/2" 3.10 12SS-C300● 3" 4.12 8SS-C400● 4" 6.98 6SS-C500● 5" 10.32 4SS-C600● 6" 14.55 2Stainless Steel Part F Male Adapter x Male NPTSS-F050 1/ 2" X 1 / 2" 0.30 50SS-F075 3/4" 0.40 25SS-F100 1" 0.56 25SS-F125 1 1/4" 1.06 25SS-F150 1 1/2" 1.28 25SS-F200 2" 1.82 20SS-F250 2 1/2" 2.68 12SS-F300 3" 3.92 8SS-F400 4" 6.32 6SS-F500 5" 8.26 4SS-F600 6" 11.27 2Stainless Steel Part DC Dust CapSS-DC050‡ 1/ 2" X 1 / 2" 0.25 50SS-DC075● 3/4" 0.36 25SS-DC100● 1" 0.54 25SS-DC125● 1 1/4" 1.30 20SS-DC150● 1 1/2" 1.46 25SS-DC200● 2" 1.78 20SS-DC250● 2 1/2" 2.38 12SS-DC300● 3" 3.04 8SS-DC400● 4" 5.02 6SS-DC500● 5" 7.35 4SS-DC600● 6" 9.92 2Stainless Steel Part D Female Coupler x Female NPTSS-D050‡ 1/ 2" X 1 / 2" 0.40 50SS-D075● 3/4" 0.52 25SS-D100● 1" 0.74 25SS-D125● 1 1/4" 1.47 20SS-D150● 1 1/2" 1.52 25SS-D200● 2" 2.16 25SS-D250● 2 1/2" 3.12 12SS-D300● 3" 3.82 8SS-D400● 4" 5.14 6SS-D500● 5" 8.00 4SS-D600● 6" 10.06 2Stainless Steel Part DP Dust PlugSS-DP050 1/ 2" X 1 / 2" 0.15 50SS-DP075 3/4" 0.20 25SS-DP100 1" 0.28 25SS-DP125 1 1/4" 0.60 25SS-DP150 1 1/2" 0.72 25SS-DP200 2" 0.96 20SS-DP250 2 1/2" 1.47 12SS-DP300 3" 1.94 8SS-DP400 4" 3.36 6SS-DP600 6" 9.08 2Note: Dust Caps & Dust Plugs are NOT DESIGNED FOR PRESSURE APPLICATIONS.● These couplers are supplied with locking feature . . . safety clips may be inserted to lock handles, preventing disconnection during product transfer.‡ Size 1/2" x 1/2" supplied with one stainless steel handle.See Material Specifications & Operating Pressure Charts on Pages 47 & 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111013

K-Loc TM Auto Lock SS316 Quick-Acting <strong>Couplings</strong>Agriculture • Chemicals/Petroleumwith LTW (Lifetime Warranteed) investment-cast SS locking handlesK-Loc Auto Lock SS316Part B Quick-Acting CouplerPartNumberSizeWeightEach (lbs.)StandardCartonKLOC-SS-B150● 1 1 / 2" 1.57 20KLOC-SS-B200● 2" 2.09 16KLOC-SS-B300● 3" 3.63 4K-Loc Auto Lock SS316Part DC Dust CapPartNumberSizeWeightEach (lbs.)StandardCartonKLOC-SS-DC200● 2" 1.89 18KLOC-SS-DC300● 3" 3.33 8K-Loc Auto Lock SS316Part C Quick-Acting CouplerPartNumberSizeWeightEach (lbs.)StandardCartonKLOC-SS-C150● 1 1 / 2" 1.87 15KLOC-SS-C200● 2" 2.80 10KLOC-SS-C300● 3" 5.22 5K-Loc Auto Lock SSInvestment-Cast LTW Replacement Handles ‡ , 316SS Slot Pins, SS Safety Clips& SS Pull RingsPartNumberSizeK-LOCSSHA200 1 1 / 2" & 2"K-LOCSSHA300 3"K-Loc Auto Lock SS316Part D Quick-Acting CouplerPartNumberSizeWeightEach (lbs.)StandardCartonKLOC-SS-D150● 1 1 / 2" 1.74 20KLOC-SS-D200● 2" 2.26 16KLOC-SS-D300● 3" 3.85 4‡ Note: If a K-Loc Auto Lock handle breaks, it can be replaced with a standardLTW Investment-Cast SS handle to make the coupling functional. Although theK‐Loc Auto Lock locking feature would no longer be present, locking can still beaccomplished by inserting a safety clip through the holes provided.● These couplers are supplied with special K-Loc Auto Lock LTW locking handles.See Material Specifications & Operating Pressure Charts on Pages 47 & 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.14KCCA1110

Brass Quick-Acting <strong>Couplings</strong>Chemicals/Petroleum • ConstructionBrass Part A Male Adapter x Female NPTPartNumberSizeWeightEach (lbs.)BR-A050 1/ 2" X 1 / 2" 0.15 50BR-A075 3/4" 0.24 25BR-A100 1" 0.34 25BR-A125 1 1/4" 0.73 36BR-A150 1 1/2" 0.66 25BR-A200 2" 0.86 20BR-A250 2 1/2" 1.61 12BR-A300 3" 1.72 8BR-A400 4" 3.41 6BR-A500 5" 4.85 4BR-A600 6" 7.27 2Brass Part B Female Coupler x Male NPTStandardCartonBR-B050‡ 1/ 2" X 1 / 2" 0.36 50BR-B075● 3/4" 0.44 25BR-B100● 1" 0.66 25BR-B125● 1 1/4" 1.19 20BR-B150● 1 1/2" 1.21 20BR-B200● 2" 1.39 20BR-B250● 2 1/2" 1.87 12BR-B300● 3" 3.36 8BR-B400● 4" 4.19 6BR-B500● 5" 5.18 4BR-B600● 6" 8.15 2Brass Part C Female Coupler x Hose ShankBR-C050‡ 1/ 2" X 1 / 2" 0.35 50BR-C075● 3/4" 0.53 25BR-C100● 1" 0.81 25BR-C125● 1 1/4" 1.23 20BR-C150● 1 1/2" 1.32 20BR-C200● 2" 1.72 20BR-C250● 2 1/2" 2.42 12BR-C300● 3" 3.74 8BR-C400● 4" 5.51 6BR-C500● 5" 7.27 4BR-C600● 6" 13.77 2Brass Part D Female Coupler x Female NPTBR-D050‡ 1/ 2" X 1 / 2" 0.35 50BR-D075● 3/4" 0.51 25BR-D100● 1" 0.75 25BR-D125● 1 1/4" 1.12 20BR-D150● 1 1/2" 1.21 25BR-D200● 2" 1.43 25BR-D250● 2 1/2" 1.87 12BR-D300● 3" 3.13 8BR-D400● 4" 5.29 6BR-D500● 5" 5.62 4BR-D600● 6" 10.95 2Brass Part E Male Adapter x Hose ShankPartNumberSizeWeightEach (lbs.)StandardCartonBR-E050 1/ 2" X 1 / 2" 0.24 50BR-E075 3/4" 0.36 25BR-E100 1" 0.59 25BR-E125 1 1/4" 0.75 25BR-E150 1 1/2" 1.01 25BR-E200 2" 1.54 20BR-E250 2 1/2" 2.11 12BR-E300 3" 3.08 8BR-E400 4" 4.30 6BR-E500 5" 7.60 4BR-E600 6" 12.33 2Brass Part F Male Adapter x Male NPTBrass Part DC Dust CapBrass Part DP Dust PlugBR-F050 1/ 2" X 1 / 2" 0.22 50BR-F075 3/4" 0.33 25BR-F100 1" 0.53 25BR-F125 1 1/4" 0.66 25BR-F150 1 1/2" 0.88 25BR-F200 2" 1.08 20BR-F250 2 1/2" 1.85 12BR-F300 3" 2.42 8BR-F400 4" 3.74 6BR-F500 5" 4.63 4BR-F600 6" 9.03 2BR-DC075● 3/4" 0.42 50BR-DC100● 1" 0.66 25BR-DC125● 1 1/4" 0.95 20BR-DC150● 1 1/2" 1.04 25BR-DC200● 2" 1.32 20BR-DC250● 2 1/2" 2.05 12BR-DC300● 3" 2.20 8BR-DC400● 4" 3.96 6BR-DC500● 5" 4.74 4BR-DC600● 6" 8.59 2BR-DP075 3/4" 0.22 50BR-DP100 1" 0.33 25BR-DP125 1 1/4" 0.46 25BR-DP150 1 1/2" 0.53 25BR-DP200 2" 0.99 20BR-DP250 2 1/2" 1.20 12BR-DP300 3" 1.65 8BR-DP400 4" 2.42 6BR-DP500 5" 3.74 4BR-DP600 6" 4.74 2Note: Dust Caps & Dust Plugs are NOT DESIGNED FOR PRESSURE APPLICATIONS.● These couplers are supplied with locking feature . . . safety clips may be inserted to lock handles, preventing disconnection during product transfer.‡ Size 1/2" x 1/2" supplied with one forged brass handle.See Material Specifications & Operating Pressure Charts on Pages 47 & 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111015

Reducing Coupler/Adapters, Spool Adapters, FlangeAdapter & Coupler, Coupler X CouplerChemicals/PetroleumAluminum Reducing Coupler x Hose ShankPartNumberSizeWeightEach (lbs.)Aluminum Reducing Coupler/Adapter — Part D x Awith Forged Brass HandlesRDA-A2030 2" X 3" 1.64 12RDA-A3020 3" X 2" 2.37 6RDA-A3040 3" X 4" 2.60 6RDA-A4020 4" X 2" 2.70 6RDA-A4030 4" X 3" 2.96 6RDA-A6040 6" X 4" 6.66 2Brass Reducing Coupler/Adapter — Part D x AStandardCartonAL-C4030 4" X 3" 2.94 6with Forged Brass HandlesRDA-B2030 2" X 3" 2.86 6RDA-B3020 3" X 2" 6.12 6RDA-B4020 4" X 2" 7.07 6RDA-B4030 4" X 3" 9.42 6Stainless Steel (SS316) Reducing Coupler/Adapter –Part D x A with LTW (Lifetime Warranteed) Investment-CastSS Locking HandlesRDA-SS3020 3" X 2" 4.08 6RDA-SS4030 4" X 3" 6.41 4RDA-SS6040 6" X 4" 12.10 2Aluminum Spool AdaptersPartNumberBrass Spool AdaptersSizeWeightEach (lbs.)SA-A150 1 1 / 2" X 1 1 / 2" 0.43 50SA-A200 2" X 2" 0.68 40SA-A2030 2" X 3" 0.97 12SA-A300 3" X 3" 1.10 12SA-A3040 3" X 4" 1.78 8SA-A400 4" X 4" 1.91 6Stainless Steel (SS316) Spool AdaptersStandardCartonSA-B150 1 1 / 2" X 1 1 / 2" 1.35 50SA-B200 2" X 2" 2.11 40SA-B250 2 1 / 2" X 2 1 / 2" 3.55 30SA-B300 3" X 3" 3.69 20SA-B400 4" X 4" 5.97 6SA-SS150 1 1 / 2" X 1 1 / 2" 1.76 18SA-SS1520 1 1 / 2" X 2" 2.10 20SA-SS200 2" X 2" 2.48 20SA-SS2030 2" X 3" 3.14 10SA-SS300 3" X 3" 4.61 10SA-SS3040 3" X 4" 5.28 6SA-SS400 4" X 4" 7.28 6Aluminum Coupler x 150# ASA Flange DrillingAluminum Adapter x 150# ASA Flange DrillingFL-AL-A300 3" 3.86 4FL-AL-A400 4" 5.86 3FL-AL-A600 6" 9.92 2Aluminum DD Coupler x Couplerwith Forged Brass Handles and Carbon Steel Safety ClipsDD-AL200 2" X 2" 1.43 12DD-AL300 3" X 3" 2.40 6DD-AL400 4" X 4" 3.90 5FL-AL-D300 3" 5.07 3FL-AL-D400 4" 7.94 2FL-AL-D600 6" 12.89 1Stainless Steel (SS316) DD Coupler x Couplerwith LTW (Lifetime Warranted) Investment-Cast SS LockingHandles and SS Safety ClipsDD-SS150 1 1 / 2" X 1 1 / 2" 2.10 20DD-SS200 2" X 2" 2.89 12DD-SS300 3" X 3" 5.11 6DD-SS400 4" X 4" 6.66 5See Material Specifications & Operating Pressure Charts on Pages 47 & 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.16KCCA1110

Polypropylene Quick-Acting <strong>Couplings</strong> (continued)Agriculture • ConstructionPolypropylene 90° Male Adapter x Male NPTPartNumberSizeWeightEach (lbs.)Polypropylene Combination Hose Nipples —PPN Series / NPT ThreadStandardCartonPP150F90 1 1 / 2" 0.27 24PP200F90 2" 0.41 24PPN050 1/ 2" 0.03 400PPN075 3/ 4" 0.06 200PPN100 1" 0.07 100PPN125 1 1 / 4" 0.11 80PPN150 1 1 / 2" 0.13 60PPN200 2" 0.22 40PPN300 3" 0.55 12● These couplers are supplied with locking feature . . . safety clips may beinserted to lock handles, preventing disconnection during product transfer.‡ All 4" couplers are supplied with THREE locking handles to provide additionalstability and prevent wobbling.■ These couplers are supplied with 2 sintered stainless steel handles.Polypropylene Part DC Dust CapPartNumberSizeWeightEach (lbs.)StandardCartonPPDC050■ 1/ 2" 0.16 100PPDC075●■ 3/ 4" 0.17 50PPDC100● 1" 0.24 40PPDC125● 1 1 / 4" 0.42 25PPDC150● 1 1 / 2" 0.47 40PPDC200● 2" 0.50 60PPDC300● 3" 1.06 30PPDC400●‡ 4" 1.11 15Polypropylene Part DP Dust PlugPPDP050 1/ 2" 0.02 200PPDP075 3/ 4" 0.03 50PPDP100 1" 0.04 80PPDP125 1 1 / 4" 0.06 50PPDP150 1 1 / 2" 0.10 50PPDP200 2" 0.15 60PPDP300 3" 0.36 50PPDP400 4" 0.50 25Note: Dust Caps & Dust Plugs are NOT DESIGNED FOR PRESSURE APPLICATIONS.See Material Specifications & Operating Pressure Charts on Pages 47 & 48Polypropylene Ball Valves & HandlesFull Port • Stainless Steel Bolts and Nuts • Teflon Seals, Viton ® O-Ring Stem Seals4-Bolt Valve Design6-Bolt Valve DesignPartNumberFemaleThread SizePSIWeightEach (lbs.)StandardCartonPartNumberFemaleThread SizePSIWeightEach (lbs.)StandardCartonPPBV050 1/2" 150 0.88 24PPBV075 3/4" 150 0.85 24PPBV100 1" 150 1.16 24PPBV125 1 1/4" 150 1.65 24PPBV150 1 1/2" 150 1.67 24PPBV200 2" 150 3.71 8PPBV300 3" 100 6.60 6PPBV400 4" 75 9.90 2Viton ® is a registered trademark of DuPont Performance Elastomers.Polypropylene Ball Valve HandlesPartNumberSizeWeightEach (lbs.)StandardCartonHA POLY100 1/2” - 1” 0.06 60HA POLY150 1 1/4” - 1 1/2” 0.14 40HA POLY200 2” - 4” 0.27 20BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111019

Replacement Gaskets For Quick Acting <strong>Couplings</strong>EPDM GasketsEPDM100 1" .010 10EPDM125 1 1 / 4" .016 10EPDM150 1 1 / 2" .018 10EPDM200 2" .022 10EPDM250 2 1 / 2" .034 10EPDM300 3" .042 10EPDM400 4" .066 10Temperature Rating: -60ºF to 300ºFViton ® GasketsPartNumberSizeWeightEach (lbs.)StandardPackage†Viton® is a registered trademark of DuPont Performance Elastomers.VITON050 1/2" 0.007 10VITON075 3/4" 0.008 10VITON100 1" 0.010 10VITON125 1 1/4" 0.016 10VITON150 1 1/2" 0.018 10VITON200 2" 0.022 10VITON250 2 1/2" 0.034 10VITON300 3" 0.042 10VITON400 4" 0.066 10Temperature Rating: -20ºF to 400ºFBuna-N GasketsPartNumberSizeBUNA075 3/ 4" .008 10BUNA100 1" .010 10BUNA125 1 1 / 4" .016 10BUNA150 1 1 / 2" .018 10BUNA200 2" .022 10BUNA250 2 1 / 2" .034 10BUNA300 3" .042 10BUNA400 4" .066 10BUNA500 5" .094 10BUNA600 6" .116 10BUNA800 8" .220 10BUNA801 8" 0.240 10BUNA1000 10" 0.390 10Temperature Rating: -40ºF to 250ºFWhite Neoprene (FDA) GasketsWeightEach (lbs.)StandardPackage†WN100 1" 0.010 10WN200 2" 0.022 10WN300 3" 0.042 10WN400 4" 0.066 10WN500 5" 0.094 10WN600 6" 0.116 10Temperature Rating: -45ºF to 250ºF†Note: Sold in full standard packages onlyReplacement Handles & Safety ClipsForged Brass Replacement Handles – with StainlessSteel Slot Pins, SS Pull Rings & CS Safety ClipsPartNumberSizeHA BRASS075 1/ 2" – 3 / 4"HA BRASS100 1"HA BRASS200 1 1 / 4" – 2 1 / 2"HA BRASS300 3" – 5"HA BRASS600 6" – 8"Safety Clips — 304 Stainless Steel For Use On AllTypes of Quick-Acting Hose <strong>Couplings</strong>Investment Cast 304 SS LTW* Replacement Handleswith SS Slot Pins, SS Pull Rings & SS Safety ClipsPartNumber*Lifetime Warranty on handles only.SizeHA ST-STL075 1/ 2" – 3 / 4"HA ST-STL100 1"HA ST-STL200 1 1 / 4" – 2 1 / 2"HA ST-STL300 3" – 5"HA ST-STL600 6" – 8"PartNumberSizeWeightEach (lbs.)StandardPkg†SCSS-200 3/ 4" – 5" 0.25 10SCSS-600 6" – 8" 0.40 10See Material Specifications & Operating Pressure Charts on Pages 47 & 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.20KCCA1110

Universal Air Hose <strong>Couplings</strong> - PlatedConstructionPlated 2-Lug Universal Air Hose<strong>Couplings</strong> — Crimp FerrulePartNumberHoseODPlated 2-Lug Universal Air Hose <strong>Couplings</strong> —Hose EndPartNumberSizeWeightEach (lbs.)WeightEach (lbs.)StandardCartonFHE-50 54/64" - 1 2/64" 0.50 20FHE-75 1 4/64" - 1 22/64" 0.60 20FHE-100 1 18/64" - 1 34/64" 0.66 20FHE-101 1 30/64" - 1 46/64" 0.66 20StandardCarton‡HE-38 3/8" 0.44 25‡HE-50 1/2" 0.48 25‡HE-75 3/4" 0.56 25‡HE-100 1" 0.64 25Plated 2-Lug Universal Air Hose <strong>Couplings</strong> —Male EndPartNumberPlated 2-Bolt ClampPlated 3-Way ConnectorPartNumberSizeWeightEach (lbs.)WeightEach (lbs.)StandardCartonME-25 1/4" 0.36 25ME-38 3/8" 0.40 25ME-50 1/2" 0.44 25ME-75 3/4" 0.48 25ME-100 1" 0.60 25HC-50 1"–1 1 /8" 0.32 25HC-75 1 1 /8"–1 5 /16" 0.56 25HC-100 1 17 /32"–1 21 /32" 0.72 25StandardCartonTWC 2.08 12‡ Supplied with carbon steel safety clip and lanyard at NO CHARGEPlated 4-Lug Universal Air Hose <strong>Couplings</strong> —Hose End‡HE-125 1 1/4" 1.70 10‡HE-150 1 1/2" 1.80 10‡HE-200 2" 2.00 10Plated Blank EndPartNumberWeightEach (lbs.)StandardCartonBE 0.52 25‡ Supplied with carbon steel safety clip and lanyard at NO CHARGEPlated 2-Lug Universal Air Hose <strong>Couplings</strong> —Female EndFE-25 1/4" 0.32 25FE-38 3/8" 0.33 25FE-50 1/2" 0.44 25FE-75 3/4" 0.48 25FE-100 1" 0.52 25Plated 4-Lug Universal Air Hose <strong>Couplings</strong> —Female EndFE-125 1 1/4" 0.90 10FE-150 1 1/2" 1.00 10FE-200 2" 1.20 10Universal Carbon Steel Safety Clips and Lanyards —For use with all Universal Air Hose and Sandblast <strong>Couplings</strong>PartNumberHoseID SizeWeightEach (lbs.)StandardCartonUSCL — 0.025 10Rubber Air Hose Replacement GasketPartNumberHoseID SizeWeightEach (lbs.)StandardCartonAHG-75 1/2" – 1" 2-Lug 0.20 10AHG-100 1 1 /4" – 2" 4-Lug 0.20 10Temperature Range: -20° F. to 150° F.Warning: Not to be used for steam serviceWARNING: Not to be used for steam service.NOTE: For safety purposes, use of lanyard and safety clip (supplied with hose ends) is recommended withall Universal Air Hose <strong>Couplings</strong>.See Operating Pressure and Temperature Chart on Page 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111021

Sand Blast Hose <strong>Couplings</strong>ConstructionQuick Disconnect Ends(Supplied with PhillipsHead Screws)External Nozzle Holders(Supplied with PhillipsHead Screws)Aluminum Sand Blast Hose <strong>Couplings</strong> —Quick Disconnect EndsPartNumberBrass Sand Blast Hose <strong>Couplings</strong> —Quick Disconnect EndsPartNumberQ-BR1 3/4" 1 1 /2" 1.06 6Q-BR2 1" 1 7 /8" 1.12 6Q-BR3 1 1 /4" 2 5 /32" 1.94 6Q-BR4 1 1 /2" 2 3 /8" 2.64 6Q-BR5 ‡ 1 1 /2" 2 3 /8" 3.50 6Plated Iron Sand Blast Hose <strong>Couplings</strong> —Quick Disconnect EndsPartNumberQ-PI1 3/4" 1 1 /2" 0.98 10Q-PI2 1" 1 7 /8" 1.02 10Q-PI3 1 1 /4" 2 5 /32" 1.84 10Q-PI4 1 1 /2" 2 3 /8" 2.38 10Natural Rubber Replacement Gasketsfor Sand Blast Hose <strong>Couplings</strong>PartNumberHoseSizeHoseSizeHoseSizeHoseODHoseODHoseODWeightEach (lbs.)WeightEach (lbs.)WeightEach (lbs.)WeightEach (lbs.)StandardCarton*Q-AL050 1/2" 1.06" 0.15 6Q-AL1 3/4" 1 1 /2" 0.36 6Q-AL2 1" 1 7 /8" 0.36 6Q-AL3 1 1 /4" 2 5 /32" 0.66 6Q-AL4 1 1 /2" 2 3 /8" 0.88 6Q-AL5 ‡ 1 1 /2" 2 3 /8" 1.10 6To be used on 1.06" OD Hose only.StandardCarton*StandardCarton*StandardPackage*SBG 0.24 10SRG-2 ‡ 0.63 10‡ Note: QAL5, QBR5, SB-AL3, and SBBR3 are large ID full-flow fittingsfor 1 1 /2" ID hose and are not interchangeable with standardfittings. Full-flow fittings require SRG-2 gaskets.Aluminum Sand Blast Hose <strong>Couplings</strong> —External Nozzle Holders with Female NPS ThreadPartNumberHoseSizeHoseODNPS FemaleThread SizeWeightEach (lbs.)Std.*Ctn.NH-AL050 1/2" 1.06" 3/4" 0.15 6NH-AL1 3/4" 1 1 /2" 1 1 /4" 0.30 6NH-AL2 1" 1 7 /8" 1 1 /4" 0.36 6NH-AL3 1 1 /4" 2 5 /32" 1 1 /4" 0.52 6NH-AL4 1 1 /2" 2 3 /8" 1 1 /4" 0.98 6To be used on 1.06" OD Hose only.Brass Sand Blast Hose <strong>Couplings</strong> —External Nozzle Holders with Female NPS ThreadPartNumberHoseSizeHoseODNPS FemaleThread SizeNH-BR1 3/4" 1 1 /2" 1 1 /4" 0.94 6NH-BR2 1" 1 7 /8" 1 1 /4" 1.02 6NH-BR3 1 1 /4" 2 5 /32" 1 1 /4" 1.58 6NH-BR4 1 1 /2" 2 3 /8" 1 1 /4" 2.96 6Aluminum Quick DisconnectFemale Threaded Adapters — NPTPartNumberHoseSizeNPT FemaleThread SizeWeightEach (lbs.)WeightEach (lbs.)Std.*Ctn.Std.*Ctn.SB-AL1 1 1/4" 1 1/4" 0.34 6SB-AL2 1 1/2" 1 1/2" 0.28 6SB-AL3 ‡ 1 1/2" 1 1/2" 1.05 6Brass Quick DisconnectFemale Threaded Adapters — NPTPartNumberHoseSizeSB-BR1 1 1/4" 1 1/4" 1.02 6SB-BR2 1 1/2" 1 1/2" 0.84 6SB-BR3 ‡ 1 1/2" 1 1/2" 3.05 6Universal Carbon Steel Safety Clips and Lanyards —For use with all Universal Air Hose and Sandblast <strong>Couplings</strong>PartNumberNPT FemaleThread SizeWeightEach (lbs.)WeightEach (lbs.)Std.*Ctn.Std.*Pkg.USCL 0.025 10*All couplings, clamps, gaskets, safety clips and lanyards sold in full standard packages only.See Operating Pressure & Temperature Chart on Page 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.22KCCA1110

Quick Disconnect <strong>Couplings</strong> and PlugsIndustrial InterchangeQuick Disconnect <strong>Couplings</strong> and Plugs by <strong>Kuriyama</strong> are brass, semi-automatic and rated to 300 PSI.Coupler with Male ThreadPartNumberBodySizeThreadSizeWeightEach (lbs.)StandardPackage*QDAC-4MC 1/ 4" 1/ 4" 0.23 10QDAC-6MC 1/ 4" 3/ 8" 0.23 10Plug with Male ThreadPartNumberBodySizeThreadSizeWeightEach (lbs.)StandardPackage*QDAP-4MP 1/ 4" 1/ 4" 0.05 10QDAP-6MP 1/ 4" 3/ 8" 0.05 10Coupler with Female ThreadPartNumberBodySizeThreadSizeWeightEach (lbs.)StandardPackage*QDAC-4FC 1/ 4" 1/ 4" 0.23 10QDAC-6FC 1/ 4" 3/ 8" 0.23 10Plug with Female ThreadPartNumberBodySizeThreadSizeWeightEach (lbs.)StandardPackage*QDAP-4FP 1/ 4" 1/ 4" 0.05 10QDAP-6FP 1/ 4" 3/ 8" 0.05 10Coupler with Hose BarbPartNumberBodySizeBarbSizeWeightEach (lbs.)StandardPackage*QDAC-4HC 1/ 4" 1/ 4" 0.23 10QDAC-6HC 1/ 4" 3/ 8" 0.23 10Plug with Hose BarbPartNumberBodySizeBarbSizeWeightEach (lbs.)StandardPackage*QDAP-4HP 1/ 4" 1/ 4" 0.05 10QDAP-6HP 1/ 4" 3/ 8" 0.05 10*All Quick Disconnect <strong>Couplings</strong> and Plugs are sold in full standard packages only.Ground Joints<strong>Couplings</strong> and Clamps - Zinc PlatedHose Stem with Wing Nut and Female SpudHose Stem OnlyPartNumberSizeWeightEach (lbs.)StandardCartonPartNumberSizeWeightEach (lbs.)StandardCartonGJ-050 1/ 2" 0.75 50GJ-075 3/ 4" 1.86 25GJ-100 1" 1.81 30GJ-125 1 1 / 4" 3.73 15GJ-150 1 1 / 2" 3.68 15GJ-200 2" 5.69 10GJ-250 2 1 / 2" 12.59 4GJ-300 3" 15.85 4GJ-400 4” 28.46 2GJS-050 1/ 2" 0.18 200GJS-075 3/ 4" 0.55 100GJS-100 1" 0.81 100GJS-125 1 1 / 4" 1.17 32GJS-150 1 1 / 2" 1.30 35GJS-200 2" 1.72 25GJS-250 2 1 / 2" 3.70 10GJS-300 3" 4.83 8GJS-400 4” 8.95 4See Operating Pressure & Temperature Chart on Page 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111023

Ground Joints (continued)<strong>Couplings</strong> and Clamps - Zinc PlatedWing NutNPT ThreadWing NutThreadPartNumberSizeWeightEach (lbs.)StandardCartonGJN-050 1/ 2" 0.31 200GJN-075 3/ 4" 0.71 60GJN-100 1" 0.71 60GJN-125 1 1 / 4" 1.52 40GJN-150 1 1 / 2" 1.52 40GJN-200 2" 2.54 24GJN-250 2 1 / 2" 4.65 10GJN-300 3" 5.51 10GJN-400 4” 10.63 4Female Spud with Copper SealingNPT ThreadWing NutThreadGJF-050 1/ 2" 0.29 200GJF-075 3/ 4" 0.64 100GJF-100 1" 0.57 100GJF-125 1 1 / 4" 1.21 40GJF-150 1 1 / 2" 1.04 40GJF-200 2" 1.39 32GJF-250 2 1 / 2" 4.23 12GJF-300 3" 5.51 10GJF-400 4” 8.88 5Male Spud with Copper SealingWing NutThreadMale Pipe Stem (NPT)NPT ThreadGMS-050 1/ 2" 0.29 100GMS-075 3/ 4" 0.75 60GMS-100 1" 0.79 50GMS-125 1 1 / 4" 1.43 30GMS-150 1 1 / 2" 1.70 30GMS-200 2" 2.23 30Double Spud with Copper SealingWing NutThreadGDS-050 1/ 2" 0.40 100GDS-075 3/ 4" 1.32 60GDS-100 1" 1.32 60GDS-125 1 1 / 4" 1.41 30GDS-150 1 1 / 2" 1.41 30GDS-200 2" 1.92 24GJM-050 1/ 2" 0.17 250GJM-075 3/ 4" 0.33 250GJM-100 1" 0.55 100GJM-125 1 1 / 4" 1.28 32GJM-150 1 1 / 2" 1.79 25GJM-200 2" 2.65 20GJM-250 2 1 / 2" 4.83 8GJM-300 3" 6.26 6GJM-400 4” 11.40 3Whipcheck – Safety CableSTYLE WC for hose-to-hose servicePartNumberWC-1 1/2" - 1 1 /4" 1/8" 0.24 100WC-2 1 1 /2" - 3" 1/4" 1.15 50Whipcheck – Safety CableSTYLE WS for hose-to-tool serviceWeightEach (lbs.)BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.HoseID2 Bolt Type Hose Clamps4 Bolt Type Hose ClampsSizeStandardCartonWS-1 1/2" - 1 1 /4" 1/8" 0.17 100WS-2 1 1 /2" - 3" 1/ 4 " 0.95 50PartNumber6 Bolt Type Hose ClampsSee Operating Pressure & Temperature Chart on Page 48SizeWeightEach (lbs.)TorqueStd.CartonBC2-05013/ 16" – 15 / 16" 0.31 6 100BC2-050A15/ 16" – 1 1 / 16" 0.44 12 100BC2-050B 1 1 / 16" – 1 3 / 16" 0.48 12 100BC2-075 1 5 / 32" – 1 9 / 32" 0.73 21 60BC2-075A 1 3 / 16" – 1 5 / 16" 0.79 21 60BC2-075B 1 5 / 16" – 1 1 / 2" 0.88 21 60BC2-075C 1 1 / 2" – 1 11 / 16" 1.15 21 40BC4-100 1 17 / 32" – 1 23 / 32" 1.50 21 24BC4-100A 1 13 / 32" – 1 9 / 16" 1.54 21 24BC4-100B 1 11 / 16" – 1 27 / 32" 1.68 21 24BC4-100C 1 7 / 8" – 2 1 / 16" 1.90 21 20BC4-125 2 1 / 16" – 2 1 / 4" 2.36 40 20BC4-150 2" – 2 7 / 32" 2.40 40 20BC4-150A 2 3 / 32" – 2 9 / 32" 2.56 40 20BC4-150B 2 1 / 4" – 2 7 / 16" 2.78 40 20BC4-150C 2 15 / 32" – 2 23 / 32" 2.67 40 20BC4-200 2 11 / 32" – 2 17 / 32" 3.04 60 20BC4-200A 2 1 / 2" – 2 25 / 32" 2.84 60 20BC4-200B 2 3 / 4" – 3 1 / 16" 3.99 60 16BC4-200C 3 3 / 32" – 3 7 / 16" 3.97 60 14BC4-250 3 1 / 2" – 3 15 / 16" 6.86 150 5BC4-300 3 1 / 2" – 3 15 / 16" 7.45 150 5BC4-300A 3 13 / 16" – 4 1 / 16" 7.89 150 5BC4-300B 4 1 / 16" – 4 7 / 16" 10.19 200 4BC4-300C 4 1 / 4" – 4 13 / 16" 10.30 200 4BC6-300A 4 1 / 4" – 4 13 / 16" 12.32 150 4BC6-400A 4 7 / 8" – 5 5 / 16" 20.30 200 2BC6-400B 5 1 / 8" – 6 3 / 16" 21.45 200 2Torque Rating in Ft. lbs. Do Not Lubricate nuts and bolts.Lubricant use may affect torque rating.24KCCA1110

Pin Lug Hose Shank <strong>Couplings</strong>Agriculture • ConstructionPin Lug Hose Shank <strong>Couplings</strong> — Full SetsAluminum Shank with Brass Swivel Nut (NPSMThreads)PartNumberSizeWeightEach (lbs.)Std.CartonAB150 1 1/2" 0.56 75AB200 2" 0.88 40AB250 2 1/2" 1.34 18AB300 3" 2.70 12AB400 4" 4.42 10AB600 6" 8.30 4Pin Lug Hose Shank <strong>Couplings</strong> — Female EndsAluminum Shank with Brass Swivel NutABF150 1 1/2" 0.38 150ABF200 2" 0.62 80ABF250 2 1/2" 0.94 36ABF300 3" 1.66 24ABF400 4" 2.72 20ABF600 6" 5.26 8Fire Hydrant Pin Lug Hose <strong>Couplings</strong> — Full Sets ‡Aluminum Shank with Brass Swivel Nut – Pin Lugson Both Male and Female Ends (NST Threads)PartNumberSizeWeightEach (lbs.)Std.CartonFHNST150 1 1/2" 0.43 40FHNST250 2 1/2" 1.04 12Fire Hydrant Pin Lug Hose <strong>Couplings</strong> — FemaleEnds Aluminum Shank with Brass Swivel NutFHNST-F150 1 1/2" 0.29 150FHNST-F250 2 1/2" 0.70 36Replacement Rubber Washersfor Fire Hydrant Pin Lug Hose <strong>Couplings</strong> ONLY*FHW150 1 1/2" 0.008 10FHW250 2 1/2" 0.017 10Pin Lug Hose Shank <strong>Couplings</strong> — Male EndsAluminum ShankABM150 1 1/2" 0.18 150ABM200 2" 0.26 80ABM250 2 1/2" 0.40 36ABM300 3" 1.04 24ABM400 4" 1.70 20ABM600 6" 3.04 8Replacement Rubber Washersfor Pin Lug Hose Shank <strong>Couplings</strong> ONLY*HW150 1 1/2" 0.008 25HW200 2" 0.012 25HW250 2 1/2" 0.017 25HW300 3" 0.031 25HW400 4" 0.050 25HW600 6" 0.094 10*Note: Replacement washers sold in standard package quantitiesonly.Pin Lug Hose Shank <strong>Couplings</strong> — Full SetsBrass Shank with Brass Swivel Nut (NPSM Threads)Brass Pin Lug Hose Shank <strong>Couplings</strong>Agriculture • ConstructionPartNumberSize(In.)WeightEach (lbs.)StandardCartonBB150 1 1/2" 1.17 35BB200 2" 1.98 30BB300 3" 5.00 12BB400 4" 9.38 6See Operating Pressure & Temperature Chart on Page 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111025

EZ-Seal Leak Resistant <strong>Couplings</strong>Ideally suited for Layflat hoses • Indoor Watering • Agriculture • Water ConservationPin Lug Hose Shank<strong>Couplings</strong> - Female EndsPin Lug Hose Shank<strong>Couplings</strong> - Male EndsPartNumberSize(In.)WeightEach (lbs.)StandardCartonPartNumberSize(In.)WeightEach (lbs.)StandardCartonABF-LF150 1 1/2 0.37 150ABF-LF200 2 0.58 80ABF-LF300 3 1.16 24ABF-LF400 4 2.01 20Aluminum Shank with Brass Swivel Nut with NPSM ThreadsAluminum Shank NPSM ThreadsABM-LF150 1 1/2 0.22 150ABM-LF200 2 0.40 80ABM-LF300 3 1.04 24ABM-LF400 4 1.48 20EZ-Seal ReplacementShank BandsNBR-LF150 1 1/2" 0.004 10NBR-LF200 2" 0.009 10NBR-LF300 3" 0.029 10NBR-LF400 4" 0.040 10Note: To insure proper sealing attach band clamps directly over rubber seals.“Heavy Duty” Forged Brass FittingsAgriculture • Construction“Heavy Duty” Forged BrassFitting SetsPartNumberSizeThreadTypeShankLengthWeightEach (lbs.)MasterCartonQty.BRGHT050 1/2" GHT 1.18" 0.25 180BRGHT062 5/8" GHT 1.18" 0.25 180BRGHT075 3/4" GHT 1.18" 0.25 180BRNPS100 1" NPS 1.46" 0.49 120“Heavy Duty” Forged BrassFitting Female EndsPartNumberSizeThreadTypeShankLengthWeightEach (lbs.)MasterCartonQty.BRGHT-FEM050 1/2" GHT 1.18" 0.12 360BRGHT-FEM062 5/8" GHT 1.18" 0.12 360BRGHT-FEM075 3/4" GHT 1.18" 0.12 360BRNPS-FEM100 1" NPS 1.46" 0.25 240MendersAgriculture • ConstructionSteel Hose Menders (Zinc Plated)PartNumberSizeWeightEach (lbs.)StandardCartonSPHM050 1/2" 0.10 100SPHM062 5/8" 0.10 100SPHM075 3/4" 0.20 100SPHM100 1" 0.30 50SPHM125 1 1 / 4" 0.50 50SPHM150 1 1 / 2" 0.50 40SPHM200 2" 0.80 35SPHM250 2 1 / 2" 1.70 20SPHM300 3" 2.40 15SPHM400 4" 2.90 9SPHM600 6" 13.20 4SPHM800 8" 20.90 2See Operating Pressure & Temperature Chart on Page 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.26KCCA1110

Hex Combination Hose Nipples —(Plain Steel) NPT ThreadPartNumberSizeWeightEach (lbs.)Steel Hex Combination Hose NipplesAgriculture • ConstructionStandardCartonHEX-STN050 1/2" 0.14 25HEX-STN075 3/4" 0.22 25HEX-STN100 1" 0.32 50HEX-STN125 1 1 /4" 0.56 20Hex Combination Hose Nipples —(Plated Steel) NPT ThreadPartNumberSizeWeightEach (lbs.)StandardCartonHEX-SPN050 1/2" 0.14 25HEX-SPN075 3/4" 0.22 25HEX-SPN100 1" 0.32 50HEX-SPN125 1 1 /4" 0.56 20Steel Combination Hose NipplesAgriculture • ConstructionCombination Hose Nipples —(Plain Steel) NPT ThreadPartNumberSizeWeightEach (lbs.)StandardCartonSTN050 1/2" 0.14 25STN075 3/4" 0.22 25STN100 1" 0.32 50STN125 1 1 /4" 0.56 20STN150 1 1 /2" 0.72 10STN200 2" 1.10 40STN250 2 1 /2" 1.74 20STN300 3" 2.18 12STN400 4" 3.22 8STN500 5" 4.12 4STN600 6" 12.24 4Combination Hose Nipples —(Plated Steel) NPT ThreadPartNumberSizeWeightEach (lbs.)StandardCartonSPN050 1/2" 0.14 25SPN075 3/4" 0.20 25SPN100 1" 0.32 50SPN125 1 1 /4" 0.56 20SPN150 1 1 /2" 0.72 10SPN200 2" 1.10 40SPN250 2 1 /2" 1.74 20SPN300 3" 2.18 12SPN400 4" 3.22 8SPN600 6" 12.24 4SPN800 8" 16.44 2SPN1000 10" 21.78 1SPN1200 12" 33.18 1Stainless Steel Combination Hose NipplesAgriculture • ConstructionCombination Hose Nipples — SSNSeries (304 Stainless) NPT ThreadPartNumberSizeWeightEach (lbs.)StandardCartonSSN304-050 1/2” 0.18 25SSN304-075 3/4” 0.26 25SSN304-100 1” 0.35 50SSN304-125 1 1/4” 0.55 20SSN304-150 1 1/2” 0.66 10SSN304-200 2” 1.16 40SSN304-250 2 1/2” 1.31 20SSN304-300 3” 2.20 12SSN304-400 4” 3.31 8SSN304-500 5” 8.82 4SSN304-600 6” 11.02 4Combination Hose Nipples — SSNSeries (316 Stainless) NPT ThreadPartNumberSizeWeightEach (lbs.)StandardCartonSSN050 1/2” 0.18 25SSN075 3/4” 0.26 25SSN100 1” 0.35 50SSN125 1 1/4” 0.55 20SSN150 1 1/2” 0.66 10SSN200 2” 1.16 40SSN250 2 1/2” 1.31 20SSN300 3” 2.20 12SSN400 4” 3.31 8SSN500 5” 8.82 4SSN600 6” 11.02 4See Operating Pressure & Temperature Chart on Page 48BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111027

Strainers and SkimmersAgriculture • ConstructionPlated Steel Strainers & Skimmers with standard straight pipe threads (NPSM)Long Round Hole Steel StrainerPartNumberSizeWeightEach (lbs.)StandardCartonLHS150 1 1 /2" 0.75 30LHS200 2" 0.94 25LHS300 3" 2.00 16Top Hole Steel Strainer/SkimmerPartNumberSizeWeightEach (lbs.)StandardCartonTHS150 1 1 /2" 1.64 25THS200 2" 2.00 20THS300 3" 2.68 15Round Hole Steel StrainerPartNumberSizeWeightEach (lbs.)StandardCartonRHS150 1 1 /2" 1.36 32RHS200 2" 1.78 18RHS250 2 1 /2" 2.02 18RHS300 3" 3.08 18RHS400 4" 2.90 18RHS600 6" 6.04 6RHS800 8" 7.34 4Steel Bottom Hole SkimmerPartNumberSizeWeightEach (lbs.)StandardCartonBHS150 1 1 /2" 1.64 20BHS200 2" 2.00 20BHS300 3" 2.68 15Square Hole Steel StrainerPartNumberSizeWeightEach (lbs.)StandardCartonSHS150 1 1 /2" 1.12 32SHS200 2" 1.74 18SHS300 3" 2.50 18SHS400 4" 2.52 18SHS600 6" 6.32 6Polypropylene Strainerwith Standard Straight Pipe Threads (NPSM)PartNumberSizeWeightEach (lbs.)StandardCartonPPS150 1 1 /2" 0.25 12PPS200 2" 0.30 18PPS300 3" 0.65 12Hose and Tubing CutterKuri-Cutter Hose & Tubing CutterPartNumberWeightEach (lbs.)Kuri-Cutter 0.27BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.28KCCA1110

IRRI-LOC ® Galvanized <strong>Couplings</strong>Agriculture • Irrigation • ConstructionFemale Shank with EPDM GasketMale Shank OnlyLocking LeverPartNumberPartNumberSizeIL-A200 2” 0.84 16IL-A300 3” 1.32 16IL-A400 4” 3.56 4IL-A600 6” 5.90 4IL-A800 8” 11.55 1SizeWeightEach (lbs.)WeightEach (lbs.)StandardCartonStandardCartonIL-B200 2” 0.86 16IL-B300 3” 1.32 16IL-B400 4” 3.74 4IL-B600 6” 5.57 4IL-B800 8” 10.45 1PartNumberNew & Improved“CAM-BARB” Design!New & Improved“CAM-BARB” Design!SizeWeightEach (lbs.)StandardCartonIL-C200 2” 1.03 16IL-C300 3” 2.42 12IL-C400 4” 4.07 6IL-C600 6” 8.51 4IL-C800 8” 9.15 1New & Improved“CAM-BARB” Design• Greater Fitting Retention• Ease of AssemblyMale End with Locking Lever and Male NPT ThreadPartNumberEPDM Replacement GasketPartNumberSizeSizeIL-J200 2” 0.04 40IL-J300 3” 0.13 40IL-J400 4” 0.22 30IL-J600 6” 0.53 10IL-J800 8” 0.66 10Temperature Rating: -40ºF to 180ºFWeightEach (lbs.)WeightEach (lbs.)StandardCartonIL-H200 2” 1.96 9IL-H300 3” 3.92 6IL-H400 4” 7.50 4IL-H600 6” 13.95 2IL-H800 8” 19.60 1StandardCartonFemale End with EPDM Gasket and Male NPTThreadPartNumberSizeWeightEach (lbs.)StandardCartonIL-F200 2” 0.90 16IL-F300 3” 1.61 16IL-F400 4” 3.39 4IL-F600 6” 5.90 4IL-F800 8” 11.55 1Safety ClipPartNumberSizeWeightEach (lbs.)StandardCartonIL-K200 2” 0.03 100IL-K300 3” 0.03 100IL-K400 4” 0.06 60IL-K600 6” 0.08 60IL-K800 8” 0.08 20• Improved shank design for ease of assembly and greater fitting retention.• EPDM gaskets are included as standard.• Each locking lever coupling is provided with holes for use with safety clips. Safety clips should be used at all times to preventaccidental separation of parts while in service.• Ideal for use in suction applications in the agricultural, irrigation and construction industries. <strong>Couplings</strong> are not recommended for use inchemical or hazardous material applications.BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111029

Kuri-Clamp Center Punch ClampsAgriculture • Chemicals/Petroleum • Construction • Material HandlingFeatures & Advantages:• Doubled Wrapped for Secure Holding Ability• Compatible with Most Pneumatic Equipmentor Hand Operated Tools• Available in Both Carbon Steel &201 Stainless SteelCarbon Steel201 Stainless SteelKuri-Clamp Center Punch Clamp ToolPart Number Description Each (lbs.) Standard CartonCPT300 Center Punch Tool 3.00 1CPA032 Replacement Adapter for 3/8" Wide CP Clamps 0.14 1* The center punch tool is for both 3/8” and 5/8” wide center punch clamps.The CPA032 Adapter is provided at no charge with the CPT300 tool; the CPA032 Adapter may also be purchased separately.BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.30KCCA1110

Kuri-Clamp Center Punch ClampsAgriculture • Chemicals/Petroleum • Construction • Material Handlingnominal SpecificationsGalvanized Carbon SteelPart No.SizePieces Per BoxWeight Per Box (lbs.)Standard BoxBAnd Width - 3/8”CPCS03 13/16” 100 3.60 1CPCS31 1 3/8” 100 4.60 1BAnd Width - 5/8”CPCS04 1” 100 8.30 1CPCS05 1 1/4” 100 8.70 1CPCS06 1 1/2” 100 9.70 1CPCS07 1 3/4” 100 10.60 1CPCS08 2’ 100 11.50 1CPCS09 2 1/4” 100 12.60 1CPCS10 2 1/2” 50 6.80 1CPCS11 2 3/4” 50 7.30 1CPCS12 3” 50 7.70 1CPCS14 3 1/2” 50 8.70 1CPCS16 4” 25 4.90 1CPCS18 4 1/2” 25 5.50 1CPCS20 5” 25 5.90 1CPCS24 6” 25 6.80 1CPCS26 6 1/2” 25 7.10 1CPCS28 7” 25 7.40 1CPCS32 8” 25 8.20 1nominal SpecificationsPart No.SizePieces Per BoxWeight Per Box (lbs.)Standard BoxType 201 Stainless SteelBAnd Width - 3/8”CPSS03 13/16” 100 3.60 1CPSS31 1 3/8” 100 4.60 1BAnd Width - 5/8”CPSS04 1” 100 8.30 1CPSS05 1 1/4” 100 8.70 1CPSS06 1 1/2” 100 9.70 1CPSS07 1 3/4” 100 10.60 1CPSS08 2’ 100 11.50 1CPSS09 2 1/4” 100 12.60 1CPSS10 2 1/2” 50 6.80 1CPSS11 2 3/4” 50 7.30 1CPSS12 3” 50 7.70 1CPSS14 3 1/2” 50 8.70 1CPSS16 4” 25 4.90 1CPSS18 4 1/2” 25 5.50 1CPSS20 5” 25 5.90 1CPSS24 6” 25 6.80 1CPSS26 6 1/2” 25 7.10 1CPSS28 7” 25 7.40 1CPSS32 8” 25 8.20 1BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111031

ClampsAgriculture • ConstructionHeavy Duty T-Bolt Clamps304 Stainless Steel Band,Bolt and NutPartNumberSize RangeWeightEach (lbs.)StandardCartonTBC-SS019 21/32” - 3/4” 0.029 500TBC-SS022 25/32” - 7/8” 0.030 500TBC-SS025 29/32” - 1” 0.031 500TBC-SS028 1 1/32” - 1 3/32” 0.031 500TBC-SS031 1 5/32” - 1 15/32” 0.052 500TBC-SS035 1 1/4” - 1 3/8” 0.052 500TBC-SS039 1 3/8” - 1 9/16” 0.053 500TBC-SS043 1 5/8” - 1 13/16” 0.055 500TBC-SS047 1 3/4” - 1 15/16” 0.090 200TBC-SS051 1 7/8” - 2 1/16” 0.095 200TBC-SS055 2 1/8” - 2 5/16” 0.098 200TBC-SS059 2 1/4” - 2 7/16” 0.100 200TBC-SS063 2 3/8” - 2 9/16” 0.103 200TBC-SS067 2 17/32” - 2 13/16” 0.105 200TBC-SS073 2 21/32” - 2 15/16” 0.150 100TBC-SS079 2 29/32” - 3 3/16” 0.160 100TBC-SS085 3 1/32” - 3 5/16” 0.160 100TBC-SS091 3 9/32” - 3 9/16” 0.165 100TBC-SS097 3 17/32” - 3 13/16” 0.180 100TBC-SS103 3 25/32” - 4 1/16” 0.180 100TBC-SS112 4 1/32” - 4 5/16” 0.190 100TBC-SS121 4 17/32” - 4 13/16” 0.195 100TBC-SS130 4 25/32” - 5 1/16” 0.200 100TBC-SS139 5 9/32” - 5 9/16” 0.292 60TBC-SS148 5 17/32” - 5 13/16” 0.308 60TBC-SS161 5 7/8” - 6 11/32” 0.319 80TBC-SS174 6 17/32” - 6 13/16” 0.328 80TBC-SS187 6 7/8” - 7 3/8” 0.340 60TBC-SS200 7 13/32” - 7 7/8” 0.357 60TBC-SS213 7 29/32” - 8 3/8” 0.367 60TBC-SS226 8 21/32” - 8 15/16” 0.383 60TBC-SS239 8 15/16” - 9 13/32” 0.400 60TBC-SS252 9 7/16” - 9 29/32” 0.417 60Heavy Duty T-Bolt Clamps304 Stainless Steel Band withCarbon Steel Bolt and NutPartNumberSize RangeWeightEach (lbs.)StandardCartonTBC-SSC019 21/32” - 3/4” 0.029 500TBC-SSC022 25/32” - 7/8” 0.030 500TBC-SSC025 29/32” - 1” 0.031 500TBC-SSC028 1 1/32” - 1 3/32” 0.031 500TBC-SSC031 1 5/32” - 1 15/32” 0.052 500TBC-SSC035 1 1/4” - 1 3/8” 0.052 500TBC-SSC039 1 3/8” - 1 9/16” 0.053 500TBC-SSC043 1 5/8” - 1 13/16” 0.055 500TBC-SSC047 1 3/4” - 1 15/16” 0.090 200TBC-SSC051 1 7/8” - 2 1/16” 0.095 200TBC-SSC055 2 1/8” - 2 5/16” 0.098 200TBC-SSC059 2 1/4” - 2 7/16” 0.100 200TBC-SSC063 2 3/8” - 2 9/16” 0.103 200TBC-SSC067 2 17/32” - 2 13/16” 0.105 200TBC-SSC073 2 21/32” - 2 15/16” 0.150 100TBC-SSC079 2 29/32” - 3 3/16” 0.160 100TBC-SSC085 3 1/32” - 3 5/16” 0.160 100TBC-SSC091 3 9/32” - 3 9/16” 0.165 100TBC-SSC097 3 17/32” - 3 13/16” 0.180 100TBC-SSC103 3 25/32” - 4 1/16” 0.180 100TBC-SSC112 4 1/32” - 4 5/16” 0.190 100TBC-SSC121 4 17/32” - 4 13/16” 0.195 100TBC-SSC130 4 25/32” - 5 1/16” 0.200 100TBC-SSC139 5 9/32” - 5 9/16” 0.292 60TBC-SSC148 5 17/32” - 5 13/16” 0.308 60TBC-SSC161 5 7/8” - 6 11/32” 0.319 80TBC-SSC174 6 17/32” - 6 13/16” 0.328 80TBC-SSC187 6 7/8” - 7 3/8” 0.340 60TBC-SSC200 7 13/32” - 7 7/8” 0.357 60TBC-SSC213 7 29/32” - 8 3/8” 0.367 60TBC-SSC226 8 21/32” - 8 15/16” 0.383 60TBC-SSC239 8 15/16” - 9 13/32” 0.400 60TBC-SSC252 9 7/16” - 9 29/32” 0.417 60BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.32KCCA1110

ClampsConstruction • Material HandlingTigerClamp Zinc Plated Carbon SteelSpiral Double Bolt Clamps(For Counterclockwise Spiral)Specially designed to fit Tigerflex ® PVC suctionhose. Also works well on rubber suction hosePartNumberSizeWeightEach (lbs.)StandardCartonSDBC-1.5 1 1 / 2" 0.18 100SDBC-2 2" 0.36 100SDBC-2.25 2 1 / 4" 0.40 100SDBC-2.5 2 1 / 2" 0.48 100SDBC-3 3" 0.66 70SDBC-3.5 3 1 / 2" 0.70 70SDBC-4 4" 1.02 40SDBC-5 5" 1.76 30SDBC-6 6" 2.00 20SDBC-8 8" 2.76 10SDBC-10 10" 3.46 10SDBC-12 12" 4.14 10TigerClamp Zinc Plated Carbon SteelSpiral Double Bolt Clamps(For Clockwise Spiral Hoses)Designed to Fit Tigerflex Tiger-TR1 HosesPartNumberSizeWeightEach (lbs.)StandardCartonSDBCR-2 2 0.36 100SDBCR-3 3 0.66 70SDBCR-4 4 1.02 40SDBCR-5 5 1.76 30SDBCR-6 6 2.00 20Kuri-KrimpPlated SteelCrimp SleevesPartNumberHose IDSizeSleeve IDWeightEach (lbs.)StandardCartonCRS-CS10108 1" 1.50 0.19 200CRS-CS10109 1" 1.56 0.20 200CRS-CS15200 1 1/2" 2.00 0.25 128CRS-CS15202 1 1/2" 2.12 0.26 128CRS-CS20209 2" 2.56 0.37 80CRS-CS20210 2" 2.62 0.40 80CRS-CS20211 2" 2.68 0.40 80CRS-CS25302 2 1/2" 3.12 0.52 60CRS-CS25304 2 1/2" 3.25 0.54 60CRS-CS30310 3" 3.62 1.19 40CRS-CS30312 3" 3.75 1.21 40CRS-CS30313 3" 3.81 1.23 40CRS-CS30400 3" 4.00 1.30 40CRS-CS40411 4" 4.68 1.61 30CRS-CS40412 4" 4.75 1.63 30CRS-CS40413 4" 4.81 1.65 30CRS-CS40500 4" 5.00 1.72 30Double Bolt Zinc PlatedDuctile Iron Hose ClampsPartNumberSizeWeightEach (lbs.)StandardCartonDB76 2 3 / 8" – 3 1 / 64" 0.73 40 10DB94 3 1 / 32" – 3 11 / 16" 1.30 40 10DB400 3 1 / 2" – 4" 1.54 40 10DB463 4 1 / 16" – 4 7 / 16" 1.79 40 10DB525 4 3 / 16" – 5" 2.14 60 10DB550 5" – 5 1 / 2" 2.27 60 10DB600 5 1 / 2" – 6 1 / 16" 2.65 60 10DB675 6 1 / 8" – 6 7 / 8" 2.98 60 10DB769 6 15 / 16" – 7 5 / 8" 3.81 60 10DB818 7 11 / 16" – 8 3 / 16" 5.11 125 10DB875 8 1 / 4" – 8 7 / 8" 5.64 125 10DB988 8 15 / 16" – 9 7 / 8" 6.15 125 10DB1125 9 15 / 16" – 11 3 / 8" 9.48 125 4DB1275 11 3 / 16" – 12 1 / 2" 9.61 125 4DB1360 12 3 / 16" – 14" 15.43 200 4Kuri-Krimp 304Stainless SteelCrimp SleevesPartNumberHose IDSizeSleeve IDTorqueWeightEach (lbs.)StandardCartonCRS-SS10108 1" 1.50 0.20 200CRS-SS10109 1" 1.56 0.21 200CRS-SS15200 1 1/2" 2.00 0.27 128CRS-SS15202 1 1/2" 2.12 0.29 128CRS-SS20209 2" 2.56 0.40 80CRS-SS20210 2" 2.62 0.43 80CRS-SS20211 2" 2.68 0.43 80CRS-SS25302 2 1/2" 3.12 0.56 60CRS-SS25304 2 1/2" 3.25 0.58 60CRS-SS30310 3" 3.62 1.29 40CRS-SS30312 3" 3.75 1.31 40CRS-SS30313 3" 3.81 1.33 40CRS-SS30400 3" 4.00 1.40 40CRS-SS40411 4" 4.68 1.74 30CRS-SS40412 4" 4.75 1.76 30CRS-SS40413 4" 4.81 1.78 30CRS-SS40500 4" 5.00 1.86 30BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111033

Forged “Plate-Style” FlangesChemicals/Petroleum • Construction • Material Handling150# Carbon Steel Forged150# Carbon Steel Forged Plate-Style FlangesNom.SizePartNumber“A”O.D.“T”Thickness“B”BoreNo. of BoltHolesDia. of BoltHoles‘C”CircleWeightEach (lbs.)1/2" CSPF0050 3 1/2" 1/2" .77" 4 5/8" 2 3/8" 1.123/4" CSPF0075 3 7/8" 1/2" 1.10" 4 5/8" 2 3/4" 1.361" CSPF0100 4 1/4" 1/2" 1.36" 4 5/8" 3 1/8" 1.581 1/4" CSPF0125 4 5/8" 1/2" 1.70" 4 5/8" 3 1/2" 1.931 1/2" CSPF0150 5" 5/8" 1.95" 4 5/8" 3 7/8" 2.702" CSPF0200 6" 5/8" 2.44" 4 3/4" 4 3/4" 4.102 1/2" CSPF0250 7" 5/8" 2.94" 4 3/4" 5 1/2" 5.353" CSPF0300 7 1/2" 5/8" 3.57" 4 3/4" 6" 5.804" CSPF0400 9" 5/8" 4.57" 8 3/4" 7 1/2" 8.005" CSPF0500 10" 3/4" 5.66" 8 7/8" 8 1/2" 10.376" CSPF0600 11" 3/4" 6.72" 8 7/8" 9 1/2" 11.768" CSPF0800 13 1/2" 1" 8.72" 8 7/8" 11 3/4" 22.4810" CSPF1000 16" 1" 10.88" 12 1" 14 1/4" 26.8312" CSPF1200 19" 1" 12.88" 12 1" 17" 42.3014" CSPF1400 21" 1" 14.14" 12 1 1/8" 18 3/4" 52.5016" CSPF1600 23 1/2" 1 1/4" 16.16" 16 1 1/8" 21 1/4" 64.0018" CSPF1800 25 1/8" 1 1/4" 18.15" 16 1 1/4" 23" 72.00BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.34KCCA1110

Forged “Plate-Style” FlangesChemicals/Petroleum • Construction • Material Handling150# Stainless Steel Forged150# Stainless Steel Forged Plate-Style FlangesType 304Type 316Nom.“A” “T” “B” No. of Dia. of ‘C” WeightSizePartPartO.D. Thickness Bore Bolts Bolts Circle Each (lbs.)NumberNumber3/4" SSPF3040075 SSPF3160075 3 7/8" 1/2" 1.10" 4 5/8" 2 3/4" 1.361" SSPF3040100 SSPF3160100 4 1/4" 1/2" 1.36" 4 5/8" 3 1/8" 1.661 1/4" SSPF3040125 SSPF3160125 4 5/8" 1/2" 1.70" 4 5/8" 3 1/2" 2.001 1/2" SSPF3040150 SSPF3160150 5" 1/2" 1.95" 4 5/8" 3 7/8" 2.242" SSPF3040200 SSPF3160200 6" 1/2" 2.44" 4 3/4" 4 3/4" 3.062 1/2" SSPF3040250 SSPF3160250 7" 1/2" 2.94" 4 3/4" 5 1/2" 4.363" SSPF3040300 SSPF3160300 7 1/2" 1/2" 3.57" 4 3/4" 6" 4.724" SSPF3040400 SSPF3160400 9" 1/2" 4.57" 8 3/4" 7 1/2" 6.365" SSPF3040500 SSPF3160500 10" 1/2" 5.66" 8 7/8" 8 1/2" 7.086" SSPF3040600 SSPF3160600 11" 1/2" 6.72" 8 7/8" 9 1/2" 7.648" SSPF3040800 SSPF3160800 13 1/2" 1/2" 8.72" 8 7/8" 11 3/4" 11.4410" SSPF3041000 SSPF3161000 16" 1/2" 10.88" 12 1" 14 1/4" 13.3612" SSPF3041200 SSPF3161200 19" 1/2" 12.88" 12 1" 17" 21.0014" SSPF3041400 SSPF3161400 21" 1/2" 14.14" 12 1 1/8" 18 3/4" 27.8316" SSPF3041600 SSPF3161600 23 1/2" 1/2" 16.16" 16 1 1/8" 21 1/4" 30.00BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111035

Forged Threaded FlangesChemicals/Petroleum • Construction • Material Handling150# Carbon Steel Forged ANSI B16.5 & ASTM A-105150# Carbon Steel Forged Threaded FlangesNom.SizePartNumber“A”O.D.“T”Thickness“B”BoreNo. of BoltHolesDia. of BoltHoles‘C”CircleWeightEach (lbs.)1/2" CSRFTHD1500050 3 1/2" 5/8" 0.88" 4 5/8" 2 3/8" 1.103/4" CSRFTHD1500075 3 7/8" 5/8" 1.09" 4 5/8" 2 3/4" 1.981" CSRFTHD1500100 4 1/4" 3/4" 1.36" 4 5/8" 3 1/8" 2.181 1/4" CSRFTHD1500125 4 5/8" 7/8" 1.70" 4 5/8" 3 1/2" 3.091 1/2" CSRFTHD1500150 5" 7/8" 1.95" 4 5/8" 3 7/8" 3.602" CSRFTHD1500200 6" 1" 2.44" 4 3/4" 4 3/4" 5.072 1/2" CSRFTHD1500250 7" 1 1/8" 2.94" 4 3/4" 5 1/2" 7.053" CSRFTHD1500300 7 1/2" 1 1/4" 3.57" 4 3/4" 6" 7.944" CSRFTHD1500400 9" 1 3/8" 4.57" 8 3/4" 7 1/2" 13.015" CSRFTHD1500500 10" 1 3/8" 5.66" 8 7/8" 8 1/2" 14.996" CSRFTHD1500600 11" 1 1/2" 6.72" 8 7/8" 9 1/2" 18.748" CSRFTHD1500800 13 1/2" 1 3/4" 8.72" 8 7/8" 11 3/4" 29.9810" CSRFTHD1501000 16" 2" 10.88" 12 1" 14 1/4" 42.9912" CSRFTHD1501200 19" 2 1/8" 12.88" 12 1" 17" 63.93BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.36KCCA1110

Forged Raised Face Slip-On FlangesChemicals/Petroleum • Construction • Material Handling150# Carbon Steel Forged ANSI B16.5 & ASTM A-105150# Carbon Steel Forged Raised Face Slip-On FlangesNom.SizePartNumber“A”O.D.“T”Thickness“B”BoreNo. of BoltHolesDia. of BoltHoles‘C”CircleWeightEach (lbs.)1/2" CSRF1500050 3 1/2" 5/8" 0.88" 4 5/8" 2 3/8" 1.103/4" CSRF1500075 3 7/8" 5/8" 1.09" 4 5/8" 2 3/4" 1.981" CSRF1500100 4 1/4" 3/4" 1.36" 4 5/8" 3 1/8" 2.181 1/4" CSRF1500125 4 5/8" 7/8" 1.70" 4 5/8" 3 1/2" 3.091 1/2" CSRF1500150 5" 7/8" 1.95" 4 5/8" 3 7/8" 3.602" CSRF1500200 6" 1" 2.44" 4 3/4" 4 3/4" 5.072 1/2" CSRF1500250 7" 1 1/8" 2.94" 4 3/4" 5 1/2" 7.053" CSRF1500300 7 1/2" 1 1/4" 3.57" 4 3/4" 6" 7.944" CSRF1500400 9" 1 3/8" 4.57" 8 3/4" 7 1/2" 13.015" CSRF1500500 10" 1 3/8" 5.66" 8 7/8" 8 1/2" 14.996" CSRF1500600 11" 1 1/2" 6.72" 8 7/8" 9 1/2" 18.748" CSRF1500800 13 1/2" 1 3/4" 8.72" 8 7/8" 11 3/4" 29.9810" CSRF1501000 16" 2" 10.88" 12 1" 14 1/4" 42.9912" CSRF1501200 19" 2 1/8" 12.88" 12 1" 17" 63.9314" CSRF1501400 21" 2 1/4" 14.14" 12 1 1/8" 18 3/4" 90.39BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111037

Forged Raised Face Slip-On FlangesChemicals/Petroleum • Construction • Material Handling150# Stainless Steel Forged ANSI B16.5 & ASTM A-105150# Stainless Steel Forged Raised Face Slip-On FlangesNom.SizePartNumber“A”O.D.“T”Thickness“B”BoreNo. of BoltHolesDia. of BoltHoles‘C”CircleWeightEach (lbs.)1/2" SSRF3041500050 3 1/2" 5/8" 0.88" 4 5/8" 2 3/8" 1.101" SSRF3041500100 4 1/4" 3/4" 1.36" 4 5/8" 3 1/8" 2.181 1/4" SSRF3041500125 4 5/8" 7/8" 1.70" 4 5/8" 3 1/2" 3.091 1/2" SSRF3041500150 5" 7/8" 1.95" 4 5/8" 3 7/8" 3.602" SSRF3041500200 6" 1" 2.44" 4 3/4" 4 3/4" 5.072 1/2" SSRF3041500250 7" 1 1/8" 2.94" 4 3/4" 5 1/2" 7.053" SSRF3041500300 7 1/2" 1 1/4" 3.57" 4 3/4" 6" 7.944" SSRF3041500400 9" 1 3/8" 4.57" 8 3/4" 7 1/2" 13.015" SSRF3041500500 10" 1 3/8" 5.66" 8 7/8" 8 1/2" 14.996" SSRF3041500600 11" 1 1/2" 6.72" 8 7/8" 9 1/2" 18.748" SSRF3041500800 13 1/2" 1 3/4" 8.72" 8 7/8" 11 3/4" 29.9810" SSRF3041501000 16" 2" 10.88" 12 1" 14 1/4" 42.9912" SSRF3041501200 19" 2 1/8" 12.88" 12 1" 17" 63.93BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.38KCCA1110

Forged Raised Face Slip-On FlangesChemicals/Petroleum • Construction • Material Handling300# Carbon Steel Forged ANSI B16.5 & ASTM A-105300# Carbon Steel Forged Raised Face Slip-On FlangesNom.SizePartNumber“A”O.D.“T”Thickness“B”BoreNo. of BoltHolesDia. of BoltHoles‘C”CircleWeightEach (lbs.)1/2" CSRF3000050 3 3/4" 7/8" 0.88" 4 5/8" 2 5/8" 1.923/4" CSRF3000075 4 5/8" 1" 1.09" 4 3/4" 3 1/4" 2.531" CSRF3000100 4 7/8" 1 1/16" 1.36" 4 3/4" 3 1/2" 3.091 1/4" CSRF3000125 5 1/4" 1 1/16" 1.70" 4 3/4" 3 7/8" 3.561 1/2" CSRF3000150 6 1/8" 1 3/16" 1.95" 4 7/8" 4 1/2" 5.012" CSRF3000200 6 1/2" 1 5/16" 2.44" 8 3/4" 5" 7.052 1/2" CSRF3000250 7 1/2" 1 1/2" 2.94" 8 7/8" 5 7/8" 9.923" CSRF3000300 8 1/4" 1 11/16" 3.57" 8 7/8" 6 5/8" 13.014" CSRF3000400 10" 1 7/8" 4.57" 8 7/8" 7 7/8" 22.055" CSRF3000500 11" 2" 5.66" 8 7/8" 9 1/4" 28.006" CSRF3000600 12 1/2" 1 1/16" 6.72" 12 7/8" 10 5/8" 39.028" CSRF3000800 15" 2 7/16" 8.72" 12 1" 13" 57.9810" CSRF3001000 17 1/2" 2 5/8" 10.88" 16 1 1/8" 15 1/4" 80.9112" CSRF3001200 20 1/2" 2 7/8" 12.88" 16 1 1/4" 17 3/4" 115.08BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111039

Why Rubber Expansion Joints?There are a number of reasons why rubber expansion jointscan provide the ideal solution to your piping and plumbingproblems:● Minimal face-to-face dimensions — Rubber expansionjoints require considerably less space than typicalexpansion bends or loops and frequently have a lowerpressure drop. This can translate into savings oninstallation costs, as well as improved performance.● Light weight — Rubber expansion joints are relativelylight in weight. This makes installation easier and lesscostly.● Low movement forces required — The naturalflexibility of rubber expansion joints allows almostunlimited flexing and recovery, as well as requiring lessforce to move. This helps prevent damage to costlyequipment and expensive down time.● Reduced fatigue factor — The elastomers used inrubber expansion joints are not subject to fatiguebreakdown or embrittle ment. And they prevent electrolyticaction.● Reduced heat loss — Rubber expansion joints reduceheat losses and give longer maintenance-free service.● Corrosion- and erosion-resistance — The superiorcorrosion-resistant characteristics of rubber expansionjoints permit the safe handling of a wide variety ofmaterials within the rated pressures and temperaturesshown.Typical ApplicationsAir Conditioning, Heating & Ventilation SystemsCommercial & Institutional Buildings HospitalsSchoolsMotelsApartmentsHotelsStoresAboard Ships & BoatsCentral & Ancillary Power Generating StationsCommunitiesBuildingsFactoriesAboard Ships & BoatsSewage Disposal & Water Treatment PlantsIrrigation & Fire Fighting StationsProcess PipingPulp & PaperChemicalPrimary MetalPetroleum RefiningRubber Expansion Joint MovementExpansion joints are designed to absorb different movements concurrentlyAxial Compression Axial Elongation Angular DeflectionBending of the CenterlineTorsional MovementRotation about the centerline (twist)Transverse DeflectionPerpendicular to centerlineVibrationBECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.40KCCA1110

Flanged Rubber Expansion JointsChemicals/Petroleum • ConstructionHTSRF SeriesSingle Sphere Flanged Rubber Expansion JointsConstruction — Nylon fabric-reinforcedneoprene body with hardened spring steelwire reinforcement and forged carbon steelflanges.Features —● Excellent ability to absorb vibration andsound.● Allows for four-way movement.● Withstands high pressure.● Easy installation, using floating flanges.● Excellent for use with moderate chemicalsand acids, most oils, fats and grease andmany solvents. Not for use with oxidizingacids, esters and ketones.HTSRF SeriesSingle Sphere Flanged Rubber Expansion JointPart No.DiameterIn.mmAllowable Movement“L”In. Axial Axial Transverse AngularCompression Elongation Deflection DeflectionOperating ConditionMax. Max. Vacuum WeightPressure Temp. Rating EachPSIG ° F. HG In. (lbs.)HTSRF 12X6 1 1/4” 32 6” 1/2” 3/8” 1/2” 15° 225 220 16 5.0HTSRF 15X6 1 1/2” 40 6” 1/2” 3/8” 1/2” 15° 225 220 16 6.1HTSRF 20X6 2” 50 6” 1/2” 3/8” 1/2” 15° 225 220 16 8.9HTSRF 25X6 2 1/2” 65 6” 1/2” 3/8” 1/2” 15° 225 220 16 12.3HTSRF 30X6 3” 80 6” 1/2” 3/8” 1/2” 15° 225 220 16 14.0HTSRF 40X6 4” 100 6” 5/8” 3/8” 1/2” 15° 225 220 16 18.3HTSRF 50X6 5” 125 6” 5/8” 3/8” 1/2” 15° 225 220 16 22.8HTSRF 60X6 6” 150 6” 5/8” 3/8” 1/2” 15° 225 220 16 26.8HTSRF 80X6 8” 200 6” 5/8” 3/8” 1/2” 15° 225 220 16 40.6HTSRF 100X8 10” 250 8” 3/4” 1/2” 3/4” 15° 225 220 16 56.6HTSRF 120X8 12” 300 8” 3/4” 1/2” 3/4” 15° 225 220 16 83.0HTSRF 140X8 14” 350 8” 3/4” 1/2” 3/4” 15° 140 220 16 115.0HTSRF 160X8 16” 400 8” 3/4” 1/2” 3/4” 15° 140 220 16 165.0HTSRF 180X8 18” 450 8” 3/4” 1/2” 3/4” 15° 125 220 16 168.0HTSRF 200X8 20” 500 8” 3/4” 1/2” 3/4” 15° 125 220 16 170.0BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111041

Flanged Rubber Expansion JointsChemicals/Petroleum • ConstructionHTDRF SeriesDouble Sphere Flanged Rubber Expansion JointsConstruction — Nylon fabric-reinforcedneoprene body with hardened springsteel wire reinforcement and forgedcarbon steel flanges.Features —● Excellent ability to absorb vibration andsound.● Allows for four-way movement.● Withstands high pressure.● Easy installation, using floating flanges.● Excellent for use with moderatechemicals and acids, most oils, fatsand grease and many solvents. Not foruse with oxidizing acids, esters andketones.HTDRF SeriesDouble Sphere Flanged Rubber Expansion JointPart No.DiameterIn.mmAllowable Movement“L”In. Axial Axial Transverse AngularCompression Elongation Deflection DeflectionNote: Retention rings are supplied with all Double Sphere Flanged Expansion Joints.Operating ConditionMax. Max. Vacuum WeightPressure Temp. Rating EachPSIG ° F. HG In. (lbs.)HTDRF 12X7 1 1/4” 32 7” 2” 1 1/4” 1 1/2” 40° 150 220 16 5.3HTDRF 15X7 1 1/2” 40 7” 2” 1 1/4” 1 1/2” 40° 150 220 16 6.8HTDRF 20X7 2” 50 7” 2” 1 1/4” 1 1/2” 40° 150 220 16 9.0HTDRF 25X7 2 1/2” 65 7” 2” 1 1/4” 1 1/2” 40° 150 220 16 13.3HTDRF 30X7 3” 80 7” 2” 1 1/4” 1 1/2” 40° 150 220 16 14.3HTDRF 40X9 4” 100 9” 2 1/4” 1 1/2” 1 3/4” 35° 150 220 16 20.3HTDRF 50X9 5” 125 9” 2 1/4” 1 1/2” 1 3/4” 35° 150 220 16 24.5HTDRF 60X9 6” 150 9” 2 1/4” 1 1/2” 1 3/4” 35° 150 220 16 29.5HTDRF 80X13 8” 200 13” 2 1/2” 1 1/2” 1 3/4” 30° 150 220 16 43.8HTDRF 100X13 10” 250 13” 2 1/2” 1 1/2” 1 3/4” 30° 150 220 16 64.1HTDRF 120X13 12” 300 13” 2 1/2” 1 1/2” 1 3/4” 30° 150 220 16 95.0BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.42KCCA1110

Part No.Threaded Union Rubber Expansion JointsChemicals/Petroleum • ConstructionHTDRU Series Threaded Union Rubber Expansion JointHTDRU Series Threaded Union Rubber Expansion JointDiameterIn.mmConstruction — Nylon fabric-reinforced neoprenebody with cast ductile iron ground pipe unions.Features —• Superb vibration absorption.• Effective for large eccentricity thermal andbending angles.• Low-cost installation and operation.• Excellent for use with moderate chemicalsand acids, most oils, fats and grease andmany solvents. Not for use with oxidizingacids, esters and ketones.Allowable Movement“L”In. Axial Axial Transverse AngularCompression Elongation Deflection DeflectionOperating ConditionMax. Max. Vacuum WeightPressure Temp. Rating EachPSIG ° F. HG In. (lbs.)HTDRU0075 3/4” 20 8” 7/8” 1/4” 7/8” 45° 150 240 16 1.8HTDRU0100 1” 25 8” 7/8” 1/4” 7/8” 45° 150 240 16 2.8HTDRU0125 1 1/4” 32 8” 7/8” 1/4” 7/8” 45° 150 240 16 3.5HTDRU0150 1 1/2” 40 8” 7/8” 1/4” 7/8” 45° 150 240 16 4.0HTDRU0200 2” 50 8” 7/8” 1/4” 7/8” 45° 150 240 16 5.0Elastomer Physical Properties & Chemical ResistanceCommon NameMaterial Neoprene Natural Rubber BUTYL BUNA-N/Nitrile Hypalon EPDMDesignation Chloroprene Polyisoprene, Isobutene- Nitrile- Chloro-Sulfonyl- Ethylene-Propylene-Synthetic Isoprene Butadiene Polyethylene Diene-TerpolymerANSI/ASTM CR IR IIR NBR CSM EPDMD1418-17ASTM D-2000 bC bF bASAE J-200 bE AA AA bK CE CACHDAOzone VG X E F O OWeather E F VG F E ESunlight VG X VG X O OOxidation VG G E G E EHeat G F VG G G ECold G VG G FG G VGFlame G X X X G XTear G VG G FG FG GAbrasion VG E G G G VGImpermeability G F E G G GDynamic F F F VG F VGRebound-Hot VG E VG G G ERebound-Cold G E X G F EComp. Set F G FG VG F GTensile Strength G E G VG F VGDielectric Strength VG E VG X VG OElectrical Insulation FG VG VG PF FG EWater Absorption G VG VG G G ERadiation VG E G VG VG OSwelling in Oil G X X VG G XAcid, Dilute E FG E G E EAcid, Concentrated G FG G G G GAliphatic Hydrocarbons FG X X E FG XAromatic Hydrocarbons F X X G F XOxygenated Hydrocarbons PF G G X PF ELacquers X X FG F X FGOil & Gasoline G X X VG G XAlkali, Dilute G ND G G G EAlkali, Concentrated X ND G X G EAnimal & Vegetable Oil G ND VG VG G VGChemical FG FG E FG E EWater G VG VG G VG VGNote: This chart is only intended for use as a general guide. Specific elastomer compounds produced by various manufacturers may have different properties.Where chemical-resistance and mechanical characteristics are important, the product should be tested using the exact chemical formulation and under the exactenvironmental conditions the product will normally encounter in service.Key to Ratings: O – Outstanding E – Excellent VG – Very Good G – GoodFG – Fair-to-Good F – Fair PF – Poor-to-Fair X – Poor ND – No DataBECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111043

Chemical Resistance GuideRatings: E = Excellent; G = Good; F = Fair; A = Acceptable; X = Not Recommended; – = Contact FactoryCAUTION: This data has been compiled from generally availablesources and should not be relied upon without consulting themanufacturer regarding specific applications and coupling materials.All Ratings are based on 70° F. Chemical compatibility varies greatlywith temperature. For applications at temperatures other than 70° F,contact Factory for recommendations.Chemical Resistance of a material does not necessarily indicate thesuitability of a fitting for a given application due to such variablesas hose construction, gasket material, and the type and method ofattaching clamps.SPECIAL CAUTION SHOULD BE TAKEN WHEN HANDLINGHAZARDOUS MATERIALS.ChemicalAluminumBrass304 Stainless Steel316 Stainless SteelNylonAcetate Solvents (Crude) E X E E A XAcetate Solvents (Pure) E E E E A XAcetic Acid (80%) F X E E X XAcetic Acid (50%) G X G E X XAcetic Acid (20%) G X G E X XAcetic Acid (10%) G X E E X XAcetic Anhydride G X G G X XAcetone E G E E A XAcetyIene E X E E X XAlcohol, Amyl G G G G A AAlcohol, Benzyl G G E E X AAlcohol, Butyl E G E E A AAlcohol, Diacetone E E G G X AAlcohol, Ethyl E G G G X AAlcohol, Hexyl – – – – A –Alcohol, Isobutyl – – – – A –Alcohol, Isopropyl G G G G A AAlcohol, Methyl (Methanol) G G G G A AAlcohol, Octyl – – – – A –Alcohol, Propyl G G E E X AAluminum Chloride (Aqu.) X X X X A AAluminum Fluoride (Sat.) G – X G X AAluminum Nitrate (Sat.) F X G G A AAluminum PotassiumSulfate (Alum) G G X G X AAluminum Sulfate (Sat.) X X – G A AAmmonia Anhydrous E X G E A XAmmonia Gas X X E E A XAmmonia Nitrate – – – – X –Ammonium Biflouride – X – – X AAmmonium Carbonate (Sat.) G X G G A AAmmonium Casenate – – – – A –Ammonium Chloride (Sat.) X X X X A AAmmonium Hydroxide (Sat.) G X G G A AAmmonum Nitrate G X – – A AAmmonium Phosphate(10-40%) X X E G A AAmmonium Sulfate (10-40%) X X X G A AAniline – X E E X XArsenic Acid X X G G X AAsphalt – – – G X XBarium Carbonate (Sat.) X G G G A ABarium Chloride (Sat.) – G X – A ABarium Hydroxide (Sat.) X G G G A ABarium Sulfate G G G G A APolypropyleneChemicalAluminumBrass304 Stainless Steel316 Stainless SteelNylonBarium Sulfide X X G G A ABeer E G E E A ABenzaldehyde G G G G X XBenzene, Benzol E G G G A XBenzine – – – – A XBenzoic Acid G G G G X XBlack Liquor X X G G X ABlEach (lbs.) (12.5% Active Chlorine) X – – X X ABorax X G E E X ABoric Acid E X – – X ABrine Acid – G – – X ABromic Acid X X – – X ABromine Liquid G – X X X XButadiene, Butylene G G G G X XButane G G G G X XButyl Acetate E G G G A XButvric Acid G G G G A ACalcium Bisulfate X – X G X ACalcium Bisulfide – – – G A ACalcium Bisulfite X X – G X ACalcium Carbonate X G E G A ACalcium Chloride (Sat.) – G – – A ACalcium Hydroxide (Sat.) X G G G A ACalcium Hypochlorite (Sat.) X X X G X ACarbon Bisulfide E X G G A XCarbon Dioxide (Dry) E E G G A ACarbon Dioxide (Wet) E X G G X ACarbon Disulfide E X G G A XCarbon Monoxide E E E E A ACarbon Tetrachloride X – E – A XCarbonic Acid E G G G X ACastor Oil G G G G X ACaustic Potash X – – G A ACellosolves G G G G X AChlorine (Liquid) – – – F X XChloroform – – – – X XChlorosulfonic Acid – X X X X XClorox (BlEach (lbs.), 5.5% CL) X – – G X –Chromic Acid (50%) G X F – X XCitric Acid F X – – X ACoke Oven Gas G F G G X XCopper Chloride X X X X A ACopper Cyanide X X G G X –Copper Sulfate X X – G A ACrysylic Acid (Conc.) G G G G X XPolypropyleneBECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.44KCCA1110

Chemical Resistance GuideRatings: E = Excellent; G = Good; F = Fair; A = Acceptable; X = Not Recommended; – = Contact FactoryChemical ChemicalAluminumBrass304 Stainless Steel316 Stainless SteelNylonCyclohexane G G G G A XDetergents G G E G A ADextrose G – – – A ADiesel Fuels E E E E A XDiethylamine G – G G X ADisodium Phosphate – – – E A AEthers G G E E A XEthyl Acetate – – G G A XEthyl Chloride – – – E A XEthylene Chloride – – – – A XEthylene Dichloride – G G G A XEthylene Glycol E G G G A XEthylene Oxide E X G G X XFatty Acids E F – E A AFerric Chloride X X X X X AFerric Hydroxide – – E E A –Ferric Nitrate (10-50%) X X G G X AFerric Sulfate X X – – X AFerrous Chloride (Sat.) X X X X X AFerrous Sulfate G G G – X AFluboric Acid X – – – X AFormaldehyde (50%) – G E E X AFormic Acid (Anhyd.) E X – – X AFreon 11 G G G G A XFreon 12 G G G G A XFreon 22 G G G G A XFruit Juices G G G G A AFuel Oil G G G G A XFurfural G G G G A XGasoline, Refined G G G G A XGasoline, Sour X G G G A XGelatin G G G G A AGlucose G G G G A AGlue G G – G – AGlycerine E E E E A AGlycols G G G G A AGreen Liquor – – – – – AHeptane G G G G A XHexane G G E E A XHydrobromic Acid (50%) X X X X X AHvdrobromic Acid (20%) X X X X X AHvdrochloric Acid (20%) X X X X X AHydrochloric Acid (38%) X X X X X AHydrocyanic Acid G X G G X AHydrofluosilicic Acid (10-50%) X G X G X –Hydrogen Peroxide (50%) – X – – X AHydrogen Sulfide (Aqueous) – – X G X AHydrogen Chloride (Dry Gas) X G – – X AHydrogen Gas E E E E X AHypochlorous Acid X X X X X XIodine E X X X X AIsopropyl Ether – G E G A XJet Fuel (JP4, JPS) G E G G X XKerosene G G G G X XPolypropyleneKetones G G G G A XLactic Acid (25%) F G – – A ALactic Acid (80%) G G – – A ALard Oil G – G G A ALead Acetate X X G G X ALead Chloride X – G G X –Lead Sulfate X – G G X –Lime Sulphur X X G G X ALinoleic Acid G X G G X ALinseed Oil G G G G A ALubricants (Oil) G E G G A XMagnesium Carbonate G – G G X AMagnesium Chloride X X – – X AMagnesium Hydroxide G G E E X AMaanesium Nitrate G G G G X AMagnesium Oxide – – – – X –Magnesium Sulfate G – G G X AMaleic Acid – G – G X AMercuric Chloride X X X – X AMercuric Cyanide X X G G X AMercury X X E E A AMethane E E E E A XMethanol G G G G A AMethyl Bromide X – G G X XMethyl EthyI Ketone G G G G A XMethyl Isobutyl Ketone G G G G A XMethyl Methacrylate G – G G X AMethylene Chloride – G – – A XMilk E X E E A AMineral Oil G E E G A AMuriatic Acid X – X X X ANapthalene G G E E A ANaptha G G G G A XNickel Chloride X X – – X ANickel Sulfate X X G G X ANitric Acid (100%) E X G – X XNitric Acid (50%) X X G – X XNitric Acid (30%) X X E – X XNitrobenzene E G G G A AOil, Castor G G G G A AOil, Coconut G – G G A AOil, Corn G G – G A AOil, Cotton Seed G G G G A AOil, Fuel G G G G A XOil, Linseed G G G G A AOil, Mineral G E E G A AOil, Silicon G E G G A AOil, Vegetable G G E E A XOleic-Acid G F – E A XOleum G X G G X XOxalic Acid (Sat.) G – X X X AOxygen G G G G X XPalmitic Acid (Sat.) G F G G X AParaffin G G G G A ABECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.AluminumBrass304 Stainless Steel316 Stainless SteelNylonPolypropyleneKCCA111045

Chemical Resistance GuideRatings: E = Excellent; G = Good; F = Fair; A = Acceptable; X = Not Recommended; – = Contact FactoryChemicalAluminumBrass304 Stainless Steel316 Stainless SteelNylonPerchloroethylene G G – – X XPetrolatum G – G G A –Phenol (Carbolic Acid) E E – E X XPhosphoric Acid (25-50%) X X – – X APhosphoric Acid (50-85%) X X – – X APhotographic Solutions – – E E X XPhthalic Anhydride – G E E X XPicric Acid E X G G X –Plating Solution, Brass – – – G X APlating Solution,Cadmium Plating – – – G X APlating Solution,Chrome (40%) X G G G X APlating Solution,Copper (Cyanide) – – – – X APlating Solution, Gold – – – E X APlating Solution, Iron – – – – X APlating Solution, Lead – – E E X APlating Solution, Nickel – – E E X APlating Solution, Silver – – E E X APlating Solution, Tin – – – F X APlating Solution, Zinc – – – – X APotassium Acetate X X – – A APotassium Bicarbonate (30%) X G E E A APotassium Carbonate (50%) X G E E A APotassium Chlorate (30%) G X G E X APotassium Chloride (30%) X X – – A APotassium Chromate (30%) G G G G X APotassium CyanideSolution (30%) X X G G X APotassium Dichromate (30%) E G E I X APotassium Hydroxide (90%) X X X – X APotassium Nitrate (80%) E G G G X APotassium Permanganate (20%) G G G G X APotassium Sulfate (10%) E G E E A APropane E E G G X XPropylene Gylcol G G G G A APropylene Oxide (90%) – – E E X XPyridine G G G G A XPyrogallic Acid G G G G X XSilver Nitrate X X G E X ASoap Solutions G G G G A ASodium Acetate E G G G A ASodium Bicarbonate (20%) G G E E A ASodium Bisulfate X – – – A ASodium Bisulfite X G – – A ASodium Borate G G G G A ASodium Perborate (10%) G X G G X ASodium Carbonate X G – G A ASodium Chlorate (50%) G G G G X ASodium Cyanide X X – – A ASodium Dichromate G X G G X ASodium Hydroxide (70%) X X G G X ASodium Hydroxide (50%) X X E – X APolypropyleneChemicalSodium Hydroxide (30%) X G E E X ASodium Chloride (30%) X G – – X ASodium Hypochlorite X X – – X ASodium Metaphosphate X X G G X XSodium Nitrate (40%) E G E E A ASodium Perborate (10%) G X G G X ASodium Peroxide (10%) G X G G X ASodium Silicate E G G G A ASodium Sulfate – G – E A ASodium Sulfide (50%) X X – G X ASodium Thiosulphate G X G G A AStannic Chloride X X X X X AStannous Chloride X X X – X XSteam – – – – X –Stearic Acid G F G E A AStoddard’s Solvent G G G G X ASugar Liquors (Cane) E G G G A ASugar Liquors (Beet) E G E E A ASulfate Liquors G X – G X ASulfite Liquors X X G G X XSulfur Chloride X – – – X XSulfur Dioxide (Dry) G G – G X ASulfur Trioxide G G – G X XSulfuric Acid (up to 10%) X G X X X ASulfuric Acid (100%) X X – – X XSulfurous Acid G G X – X ATannic Acid X – G G X ATanning Liquors E – E E X ATartaric Acid – – E E A ATitanium Tetrachloride X X – G X XToluene E E E E A XTetrahydrofuran X – E G A XTomato Juice G – G G X ATrichloroethylene E – – – A XTriethanolamine G X G G A XTriethylamine – – G G A XTrisodium Phosphate (10%) X G E E A ATurpentine G X E E X XUrea (50%) G – G G A AUrine – – E E X AVinegar G X G G X AWater Acid (Mine) X X – – X AWater (Distilled) X G G G A AWater (Sea) G G G G A AWhiskey X G E E X AWhite Liquor (Pulp) G – G G X AWine X G E E X AXylene G G G G A XZinc Chloride X X X G A AZinc Nitrate – – G G X AZinc Sulfate (50%) X G E E X ABECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.AluminumBrass304 Stainless Steel316 Stainless SteelNylonPolypropylene46KCCA1110

Aluminum Quick-Acting <strong>Couplings</strong> from pages 5, 6, 7, 8, 9, 10 and 11Material SpecificationsBodyHandlesSlot PinsPull RingsGasketsSafety ClipsAluminumAluminum alloy, specially designedfor high tensile strength, lightnessand rigidity.ForgedBrassZinc-platedCarbon SteelZinc-platedCarbon SteelAll sizes except 5" and 8" are made to comply with MIL Spec A-A-59326 for interchangeability.Sizes 5" & 8" comply with ASTM Specifications for interchangeability.1/2" X 1/2" are not specified under MIL Specs.Brass Quick-Acting <strong>Couplings</strong> from page 15 and 16Buna-NZinc-platedCarbon Steel† All 8" couplers supplied with 4locking handles, safety clips, pullrings and chains at NO CHARGE.BodyHandlesSlot PinsPull RingsGasketsSafety ClipsBrassBrass alloy, specially designed forhigh tensile strength and rigidity.ForgedBrassType 304StainlessSteelType 304StainlessSteelBuna-NZinc-platedCarbon SteelAll sizes except 5" are made to comply with MIL Spec A-A-59326 for interchangeability.5" size complies with ASTM F1122 Specifications for interchangeability.1/2" X 1/2" are not specified under MIL Specs.Glass Reinforced Nylon Quick-Acting <strong>Couplings</strong> from page 17BodyHandlesSlot PinsPull RingsGasketsSafety ClipsGlass ReinforcedNylonFiberglass-reinforced Nylon, for hightensile strength, light weight andrigidityType 304LTWStainlessSteelType 304StainlessSteelType 304StainlessSteelEPDMType 304StainlessSteelAll sizes are made to comply with MIL Spec A-A-59326 for interchangeability.Polypropylene Quick-Acting <strong>Couplings</strong> from pages 18 and 19BodyHandlesSlot PinsPull RingsGasketsSafety ClipsPolypropylenePolypropylene is glass-filled foradded strength and durabilityType 304InvestmentCastStainlessSteelType 304StainlessSteelType 304StainlessSteelEPDMType 304StainlessSteelAll sizes are made to comply with MIL Spec A-A-59326 for interchangeability.1/2" X 1/2" are not specified under MIL Specs.SS304 Stainless Steel Quick-Acting <strong>Couplings</strong> from page 12BodyHandlesSlot PinsPull RingsGasketsSafety ClipsStainless SteelStainless Steel Type 304 (ASTMA351 Grade CF-8). Every melt is analyzedfor chemical composition. A ChemicalTest Certificate showing the generalcomposition is available upon request.Type 304StainlessSteelType 304StainlessSteelType 304StainlessSteelBuna-NType 304StainlessSteelAll sizes except 5" and 8" are made to comply with MIL Spec A-A-59326 for material and interchangeability.Sizes 5" & 8" comply with ASTM Specifications for material and interchangeability.1/2" X 1/2" are not specified under MIL Specs.SS 316 Stainless Steel Quick-Acting <strong>Couplings</strong> from pages 13, 14 and 16BodyHandlesSlot PinsPull RingsGasketsSafety ClipsStainless SteelStainless Steel Type 316 (ASTMA351 Grade CF-8M). Every meltis analyzed for chemical composition. AChemical Test Certificate showing the generalcomposition is available upon request.Type 304StainlessSteelType 304StainlessSteelType 304StainlessSteelBuna-NType 304StainlessSteelAll sizes except 5" and 8" are made to comply with MIL Spec A-A-59326 for material and interchangeability.Sizes 5" & 8" comply with ASTM Specifications for material and interchangeability.1/2" X 1/2" are not specified under MIL Specs.BECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.KCCA111047

Operating Pressures & TemperaturesPartAluminum Quick-Acting <strong>Couplings</strong>from pages 5, 6, 7, 8, 9, 10 and 11Maximum PSI Rating1/2” - 4”: 150 PSI5” - 6”: 75 PSI8”: 50 PSIMaximum TemperatureAmbientPartBrass Quick-Acting <strong>Couplings</strong>from pages 15 and 16PartCombination Nipplesfrom page 27PartGlass Reinforced Nylon <strong>Couplings</strong>from page 17PartGround Jointsfrom pages 23 and 24PartIrri-Loc ® <strong>Couplings</strong>from page 29PartPin Lugsfrom page 25 and 26PartPolypropylene Quick-Acting <strong>Couplings</strong>from pages 18 and 19PartQuick Disconnect <strong>Couplings</strong> &Plugs from page 23PartSandblast <strong>Couplings</strong> from page 22Maximum PSI Rating1/2” - 4”: 150 PSI5” - 6”: 75 PSIMaximum PSI Rating1/2” - 1 1/2”: 125 PSI2” - 6”: 75 PSIMaximum PSI Rating1”: 175 PSI1/2” - 2”: 150 PSI3”: 125 PSI4”: 75 PSIMaximum PSI RatingSteam - 250 PSIAsphalt & Hot Tar - 200 PSIAir - 600 PSIMaximum PSI Rating2” - 3”: 250 PSI4” - 8”: 150 PSIMaximum PSI Rating1/2” - 2”: 75 PSI2 1/2” - 4”: 50 PSI5” - 6”: 25 PSIMaximum PSI Rating1/2” - 2”: 100 PSI @ 0ºF125 PSI @70ºF,70 PSI @ 150ºF3” - 4”: 75 PSI @ 70ºFMaximum PSI Rating300 PSIMaximum PSI Rating110 PSIMaximum TemperatureAmbientMaximum TemperatureAmbientMaximum TemperatureAmbientMaximum Temperature450ºFMaximum TemperatureAmbientMaximum TemperatureAmbientMaximum Temperature1/2” - 2”: 100 PSI @ 0ºF125 PSI @70ºF70 PSI @ 150ºF3” - 4”: 75 PSI @ 70ºFMaximum Temperature240ºFMaximum TemperatureAmbientPartSS304 Stainless SteelQuick-Acting <strong>Couplings</strong> frompage 12PartSS316 Stainless Steel Quick-Acting<strong>Couplings</strong> from pages 13, 14, and 16PartUniversal <strong>Couplings</strong> from page 21Maximum PSI Rating1/2” - 2”: 250 PSI4”: 150 PSI5” - 6”: 75 PSIMaximum PSI Rating1/2” - 2”: 250 PSI2 1/4” - 4”: 150 PSI5” - 6”: 75 PSIMaximum PSI Rating150 PSIMaximum TemperatureAmbientMaximum TemperatureAmbientMaximum Temperature70ºFBECAUSE WE CONTINUALLY EXAMINE WAYS TO IMPROVE OUR PRODUCTS, WE RESERVE THE RIGHT TO ALTER SPECIFICATIONS WITHOUT PRIOR NOTICE.48KCCA1110